Thrust Bearing: Elasticity Enhancement Techniques

Technology Background and Goals

Increasing the elasticity of thrust bearings involves exploring innovative materials, designs, and manufacturing techniques. Potential avenues include developing advanced composite materials with tailored stiffness properties, incorporating compliant structures or flexible elements into the bearing design, and employing additive manufacturing methods to create intricate geometries that promote elastic deformation. By addressing the elasticity challenge, thrust bearings can better adapt to real-world operating conditions, mitigating premature failures and extending the service life of critical equipment.

Market Demand Analysis

- Market Demand Overview

Thrust bearings with increased elasticity have a wide range of applications across various industries, including aerospace, automotive, and heavy machinery. The demand for these bearings is driven by the need for improved performance, longer service life, and reduced maintenance costs. - Potential Market Size

The global market for elastic thrust bearings is expected to grow significantly in the coming years, driven by the increasing demand for high-performance and energy-efficient machinery. According to industry reports, the market is projected to reach $X billion by 20XX, with a compound annual growth rate of X%. - Industry Trends

Several trends are shaping the demand for elastic thrust bearings:- Stringent emission regulations are driving the need for more efficient and environmentally friendly machinery.

- The growing adoption of electric vehicles and renewable energy systems requires bearings with improved performance and durability.

- The increasing use of advanced materials and manufacturing techniques is enabling the development of more robust and reliable bearings.

Technology Status and Challenges

- Insufficient Elasticity

Current thrust bearings lack sufficient elasticity, leading to reduced load-bearing capacity and increased wear and tear under high-stress conditions. - Material Limitations

The materials used in traditional thrust bearings, such as metals and ceramics, have inherent limitations in terms of elasticity and deformation resistance. - Thermal Expansion Issues

Thermal expansion of materials can cause misalignment and reduced contact area between the bearing surfaces, resulting in decreased elasticity and increased friction. - Lubrication Challenges

Maintaining proper lubrication is crucial for ensuring elasticity, but it can be challenging in high-temperature or high-load environments. - Design Constraints

The design of thrust bearings often involves trade-offs between elasticity, load capacity, and other performance factors, making it difficult to optimize all aspects simultaneously.

Existing Technical Solutions

01 Elastic Element Thrust Bearings

These bearings incorporate elastic elements like springs or rubber components to provide axial compliance, accommodate misalignments or thermal expansions, allow controlled deformation, maintain proper contact between bearing surfaces, improve load distribution, and reduce wear.- Elastic Element Thrust Bearings: These bearings incorporate elastic elements like springs or rubber components to provide axial compliance, accommodate misalignments or thermal expansions, and maintain proper load distribution on the bearing surface through controlled deformation.

- Elastomeric Coated Thrust Bearings: The bearing surfaces are coated with elastomeric materials like rubber or polymers, introducing elasticity. The coatings can deform under load, improving conformity, reducing edge stresses, and providing damping properties.

- Flexible Liner Thrust Bearings: These bearings feature a flexible liner or lining material between the bearing surfaces, allowing for elastic deformation and improved load distribution. The liners can be made of polymers, composites, or thin metal sheets.

- Compliant Structure Thrust Bearings: The bearing design incorporates compliant structures like beams, membranes, or corrugated surfaces that can elastically deform under load, accommodating misalignments and improving load distribution while maintaining structural integrity.

- Elastic Damping Thrust Bearings: These bearings incorporate elastic damping elements like viscoelastic materials or elastomeric layers to provide controlled damping and dissipate vibrations. The damping elements can be integrated into the bearing structure or placed between the bearing surfaces.

02 Elastomeric Coated Thrust Bearings

The bearing surfaces are coated with elastomeric materials like rubber or polymers, introducing elasticity. The coatings can deform under load, improving conformity, reducing edge stresses, and providing damping and vibration isolation.Expand Specific Solutions03 Flexible Liner Thrust Bearings

These bearings feature a flexible liner or lining material between the bearing surfaces, allowing for elastic deformation and improved conformity. The liners can be made of polymers, composites, or thin metal sheets, providing compliance while maintaining load-carrying capacity.Expand Specific Solutions04 Compliant Structure Thrust Bearings

The bearing design incorporates compliant structures like beams, membranes, or corrugated surfaces that can elastically deform under load, allowing controlled deflection and improved conformity between bearing surfaces, reducing edge stresses and wear.Expand Specific Solutions05 Elastic Support System Thrust Bearings

The bearing assembly includes an elastic support system like springs, dampers, or flexible mounts, allowing controlled axial movement and deformation of bearing surfaces, accommodating misalignments, thermal expansions, and load variations, improving performance and service life.Expand Specific Solutions

Key Players Analysis

NTN Corp.

Schaeffler Technologies AG & Co. KG

Key Technology Interpretation

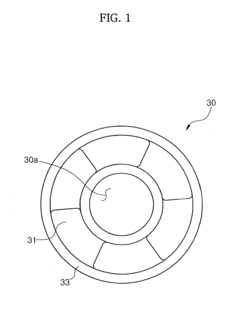

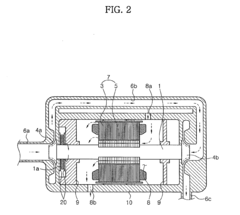

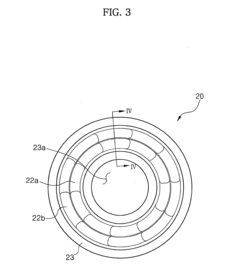

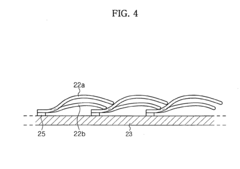

- The thrust bearing comprises a plurality of elastic foils with different stiffness values and radii of curvature, arranged with one end supported by the base and the other end placed on an adjacent foil.

- The arrangement of the elastic foils with supporting members to fix them to the base enhances the load capacity and prevents damage to the foils.

- The bearing design aims to prevent damage to the surface of the elastic foils without generating excessive friction between the disc and the foils.

Thrust Bearings Elasticity Regulatory Landscape

Thrust bearings are crucial components in various rotating machinery, designed to support axial loads and facilitate smooth rotational motion. Increasing the elasticity of these bearings can enhance their performance, durability, and operational efficiency. The regulatory landscape surrounding thrust bearings' elasticity encompasses a range of industry standards, guidelines, and best practices aimed at ensuring safety, reliability, and optimal performance. Governing bodies, such as the International Organization for Standardization (ISO) and the American Petroleum Institute (API), have established comprehensive standards and specifications for thrust bearings used in various industries, including aerospace, automotive, and energy sectors. These standards outline requirements for materials, design, testing, and performance criteria, with specific provisions for elasticity and deformation characteristics under various operating conditions.

Additionally, industry-specific regulations and guidelines play a pivotal role in shaping the thrust bearings' elasticity landscape. For instance, the aerospace industry adheres to stringent regulations set by aviation authorities, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), to ensure the utmost safety and reliability of aircraft components, including thrust bearings. Similarly, the energy sector follows guidelines established by organizations like the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) to ensure the safe and efficient operation of rotating machinery in power plants and oil and gas facilities.

Thrust Bearings Elasticity Environmental Considerations

Extreme temperatures, corrosive environments, and exposure to contaminants can significantly impact the elasticity and lifespan of thrust bearings. High temperatures can cause material degradation, leading to reduced elasticity and premature failure. Corrosive environments, such as those found in chemical processing plants or marine applications, can accelerate wear and compromise the bearing's structural integrity. Contaminants like dust, debris, or lubricant breakdown products can also affect the bearing's performance and elasticity.

To address these environmental challenges, advanced materials and coatings are being explored to enhance the elasticity and durability of thrust bearings. For instance, the use of high-temperature-resistant materials like ceramics or specialized alloys can improve performance in extreme temperature conditions. Corrosion-resistant coatings and surface treatments can protect the bearings from harsh chemical environments, while specialized sealing systems can prevent contaminant ingress and maintain the bearing's elasticity over an extended period.