Research on PVDF Nanofiber Membranes For Water Treatment

Technology Background And Goals

This report provides a comprehensive overview of the development history, current status, and future trends of polyvinylidene fluoride (PVDF) nanofiber membrane technology for water treatment applications. This includes tracing the key milestones and technological advancements that have shaped the evolution of PVDF nanofiber membranes, as well as identifying the current challenges and bottlenecks hindering their widespread adoption.

Additionally, the report aims to shed light on the geographical distribution of research and development efforts in this field, highlighting the regions and institutions that have made significant contributions to the advancement of PVDF nanofiber membrane technology for water treatment.

Market Demand Analysis

- Growing Demand for Clean Water

The demand for clean water is increasing globally due to population growth, urbanization, and industrial development, driving the need for efficient water treatment technologies. - Membrane Filtration Market

The membrane filtration market for water treatment is expanding rapidly, driven by stringent regulations and the need for cost-effective and energy-efficient solutions. - Advantages of PVDF Nanofiber Membranes

PVDF nanofiber membranes offer advantages such as high porosity, large surface area, and improved mechanical and chemical stability, making them attractive for water treatment applications. - Emerging Applications

PVDF nanofiber membranes are finding applications in various water treatment processes, including desalination, wastewater treatment, and industrial effluent treatment. - Market Potential

The market potential for PVDF nanofiber membranes in water treatment is significant, driven by their superior performance and the growing demand for sustainable water treatment solutions.

Technology Status And Challenges

- Current Status

PVDF nanofiber membranes have gained significant attention for water treatment due to their high porosity, large surface area, and good chemical resistance. However, their widespread application is still limited by challenges such as membrane fouling and low mechanical strength. - Technological Challenges

Key challenges include:- Membrane fouling caused by organic matter, microorganisms, and inorganic scales

- Low mechanical strength and durability under high pressure or flow rates

- Difficulty in controlling pore size and distribution during fabrication

- Geographic Distribution

Research on PVDF nanofiber membranes is primarily concentrated in developed countries like the United States, China, and European nations. However, there is growing interest in developing regions due to the need for affordable water treatment solutions.

Current Technical Solutions

01 PVDF Nanofiber Membranes for Water Treatment

PVDF nanofiber membranes, with high porosity, large surface area, and good chemical resistance, effectively remove contaminants like heavy metals, organic pollutants, and microorganisms from water.- PVDF Nanofiber Membranes for Water Treatment: PVDF nanofiber membranes exhibit high porosity, large surface area, and good mechanical strength, making them effective for removing various contaminants from water. The nanofiber structure enhances filtration efficiency and selectivity.

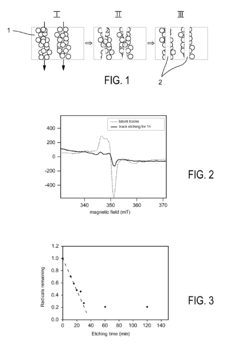

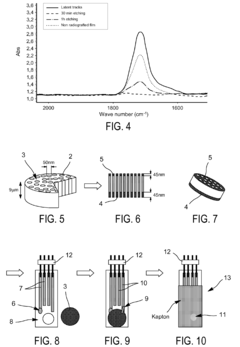

- Fabrication Methods: Various methods like electrospinning, phase inversion, and template-assisted techniques allow precise control over fiber diameter, porosity, and surface properties, enabling tailored performance for specific water treatment applications.

- Membrane Modifications: PVDF nanofiber membranes can be modified through surface functionalization, blending with other polymers or additives, and incorporating nanoparticles or functional groups to enhance hydrophilicity, fouling resistance, selectivity, and overall performance.

- Water Treatment Applications: PVDF nanofiber membranes are explored for desalination, wastewater treatment, removal of heavy metals, dyes, and organic pollutants, owing to their high surface area and tunable pore size for efficient separation and purification.

- Hybrid and Composite Membranes: Incorporating materials like carbon nanotubes, metal-organic frameworks, or inorganic nanoparticles into PVDF nanofiber membranes creates hybrid and composite membranes, combining advantages of different materials for improved performance, selectivity, and durability in water treatment.

02 Fabrication Methods

Electrospinning, phase inversion, and melt-blowing are employed to fabricate PVDF nanofiber membranes, allowing precise control over fiber diameter, porosity, and surface properties for enhanced water treatment performance.Expand Specific Solutions03 Membrane Modifications

Surface grafting, blending with other polymers, or incorporating functional additives modify PVDF nanofiber membranes, improving hydrophilicity, fouling resistance, and selectivity for specific contaminants, enhancing water treatment performance.Expand Specific Solutions04 Membrane Modules and Systems

PVDF nanofiber membranes are integrated into membrane modules and systems like microfiltration, ultrafiltration, and membrane bioreactors, designed for efficient contaminant removal, minimizing fouling, and maximizing water recovery.Expand Specific Solutions05 Performance Evaluation and Characterization

Permeability tests, rejection studies, fouling analysis, and long-term stability assessments evaluate the water treatment performance of PVDF nanofiber membranes, optimizing their design and operating conditions for specific applications.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

EMD Millipore Corp.

Key Technology Interpretation

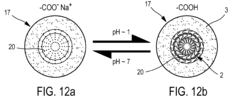

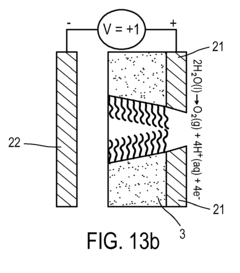

- 1. A novel arrangement for controlling the diameter of nanopores realized inside nanoporous polymeric membranes, specifically PVDF membranes.

- 2. The use of at least two electrodes to apply an electric field across the nanoporous membrane, enabling control over the nanopore diameter by adjusting the electric field strength.

- 3. Functionalization of the nanopores with a polyelectrolyte, which can interact with the applied electric field and facilitate the modulation of the nanopore diameter.