How to Improve The Hydrophilicity Of PVDF (Polyvinylidene Fluoride)?

Technology Background And Goals

Several approaches have been explored to address this challenge, including surface modification techniques like plasma treatment, chemical grafting, and blending with hydrophilic polymers. However, these methods often face limitations in terms of long-term stability, scalability, and cost-effectiveness. Consequently, there is a need for innovative solutions that can provide a more robust and sustainable enhancement of PVDF's hydrophilicity.

Market Demand Analysis

- Market Size and Growth

PVDF membranes have a significant market demand in water treatment, biopharmaceuticals, and chemical processing industries. The global PVDF membrane market is projected to grow at a CAGR of around 6% from 2022 to 2030, driven by increasing water scarcity and stringent environmental regulations. - Applications and Demand Drivers

The hydrophilic nature of PVDF membranes makes them suitable for various applications, including:- Water purification and desalination

- Biopharmaceutical filtration and separation

- Chemical processing and solvent recovery

- Food and beverage processing

- Regional Market Dynamics

The Asia-Pacific region is expected to dominate the PVDF membrane market due to rapid industrialization and increasing water treatment needs. North America and Europe also have significant demand due to stringent environmental regulations and the presence of established pharmaceutical and chemical industries. - Competitive Landscape

The PVDF membrane market is highly competitive, with major players including Arkema, Solvay, Toray Industries, and Merck KGaA. These companies focus on product innovation, capacity expansion, and strategic partnerships to maintain their market position.

Technology Status And Challenges

- Hydrophobicity of PVDF PVDF is inherently hydrophobic due to its non-polar chemical structure, limiting its applications in areas requiring hydrophilicity.

- Challenges in Improving Hydrophilicity

- Modifying the surface chemistry without compromising bulk properties

- Ensuring long-term stability of the hydrophilic surface

- Developing cost-effective and scalable methods

- Current Status Various techniques have been explored, including surface grafting, plasma treatment, and blending with hydrophilic polymers, but with limited success or practical challenges.

Current Technical Solutions

01 Surface Modification

Various techniques have been developed to modify the PVDF membrane surface, increasing hydrophilicity through chemical treatments, plasma treatments, and grafting of hydrophilic polymers or functional groups. The increased hydrophilicity improves wettability, fouling resistance, and separation performance.- Surface Modification: Various techniques are employed to modify the surface of PVDF membranes, enhancing their hydrophilicity. These include plasma treatment, chemical grafting, blending with hydrophilic polymers, and coating with hydrophilic materials. The improved hydrophilicity enhances wettability, fouling resistance, and separation performance.

- Hydrophilic Additives: Hydrophilic additives like inorganic nanoparticles, hydrophilic polymers, or surfactants are incorporated into the PVDF membrane matrix during fabrication. These additives improve hydrophilicity, leading to enhanced water permeability and antifouling properties.

- Water Treatment Applications: Hydrophilic PVDF membranes find applications in water treatment processes such as microfiltration, ultrafiltration, and membrane bioreactors. The improved hydrophilicity reduces fouling and enhances contaminant separation from water.

- Biomedical Applications: Hydrophilic PVDF membranes are used in biomedical applications like hemodialysis, protein separation, and tissue engineering scaffolds. The improved hydrophilicity enhances biocompatibility, cell adhesion, and protein adsorption properties.

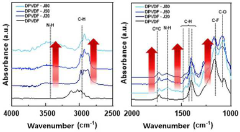

- Characterization and Evaluation: Various techniques are employed to characterize and evaluate the hydrophilicity of modified PVDF membranes, including contact angle measurements, surface energy analysis, water permeability tests, and fouling resistance studies. These evaluations optimize performance and understand hydrophilic modification effects.

02 Hydrophilic Additives

Hydrophilic additives like inorganic nanoparticles or hydrophilic polymers can be incorporated into the PVDF membrane matrix during fabrication, enhancing hydrophilicity, water permeability, and antifouling properties.Expand Specific Solutions03 Hydrophilic Coatings

Hydrophilic coatings such as polyvinyl alcohol (PVA) or zwitterionic polymers can be applied to the PVDF membrane surface, improving hydrophilicity, antifouling properties, and separation performance, particularly in aqueous environments.Expand Specific Solutions04 Hydrophilic Porous Structure

The porous structure of PVDF membranes can be engineered to enhance hydrophilicity through techniques like electrospinning, phase inversion, or incorporating hydrophilic additives during fabrication. The resulting porous structure improves water permeability and fouling resistance.Expand Specific Solutions05 Surface Modification with Functional Groups

The PVDF membrane surface can be modified to introduce hydrophilic functional groups like hydroxyl, carboxyl, or amine groups through chemical treatments, plasma treatments, or grafting reactions. The modified surface enhances hydrophilicity, fouling resistance, and separation performance.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Toray Chemical Korea, Inc.

Key Technology Interpretation

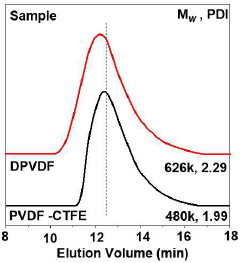

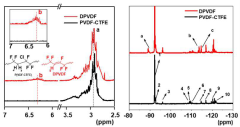

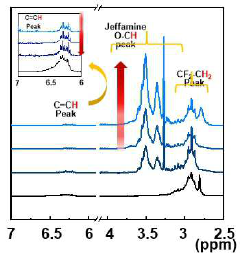

- Introducing hydrophilic groups to the hydrophobic PVDF-based polymer to impart hydrophilicity while maintaining the physical properties of conventional fluorine-based polymers.

- Providing a simple and efficient method for synthesizing the modified PVDF-based copolymer with improved hydrophilicity.

- Enabling the use of the modified PVDF-based copolymer in various applications due to its hydrophilicity and retained physical properties of fluorine-based polymers.

PVDF Hydrophilicity Improvement Economic Analysis

Analyzing the economic impact of improving the hydrophilicity of polyvinylidene fluoride (PVDF) reveals several potential benefits and market opportunities. Enhancing the hydrophilic properties of PVDF could broaden its application across diverse sectors, such as water treatment, filtration, and biotechnology, leading to increased demand. The development of more hydrophilic PVDF membranes can offer industries cost savings by improving efficiency and performance in filtration processes, which in turn could reduce operational costs and increase profitability for companies adopting these technologies.

Moreover, these improvements could accelerate innovation, creating opportunities for new product development and value-added services, further driving economic growth in sectors that rely heavily on filtration technologies. The transformative potential of more hydrophilic PVDF also suggests a disruptive impact on the competitive landscape, potentially redefining industry standards and market leaders. Companies investing in this technology may gain significant competitive advantages, while those slow to adapt might face reduced market shares.

In terms of geographical impact, regions with strong industrial bases in filtration and water treatment, often in developed economies, could initially see the most pronounced economic benefits. However, as the technology becomes more accessible, emerging markets could also capitalize on these advancements, fostering economic development and improving public and environmental health standards.

PVDF Hydrophilicity Improvement Policy And Regulatory Impact

When considering the enhancement of the hydrophilicity of PVDF (Polyvinylidene Fluoride), policy and regulatory impacts play a significant role, particularly in the context of environmental standards and materials safety requirements. Regulatory frameworks often drive innovation by enforcing more stringent environmental guidelines, pushing companies to explore new material modifications to meet these standards. For instance, regulations on per- and polyfluoroalkyl substances (PFAS) necessitate the development of PVDF alternatives with reduced environmental impact. Furthermore, policies promoting sustainable and green chemistry influence the modification processes applied to PVDF, encouraging the use of non-toxic, eco-friendly hydrophilicity enhancers.

Additionally, intellectual property laws may also impact technological advancements in this area by protecting innovative methods for improving PVDF's hydrophilicity, incentivizing research and development efforts with the promise of competitive advantage and potential market exclusivity. Compliance with international standards, such as those set by the European Union's REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation, forms another critical aspect, as it limits certain chemicals in manufacturing processes. Thus, adapting PVDF to make it more hydrophilic must align with evolving legal requirements and sustainability criteria, shaping both the direction of research and the applicability of emerging solutions in various industrial contexts.