Hypochlorous Acid Applications in Cannabis Cultivation

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl in Cannabis: Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising solution in various agricultural applications, including cannabis cultivation. This naturally occurring compound, known for its potent antimicrobial properties, has been utilized in water treatment, food safety, and healthcare for decades. The cannabis industry, facing challenges in pest management and microbial contamination, has recently turned its attention to HOCl as a potential game-changer in cultivation practices.

The evolution of HOCl technology in agriculture has been marked by significant advancements in production methods and application techniques. Initially, HOCl was primarily produced through electrolysis of salt water, a process that has been refined over time to yield more stable and effective solutions. The development of on-site generation systems has further revolutionized its use, allowing growers to produce HOCl as needed, ensuring freshness and potency.

In the context of cannabis cultivation, the objectives of HOCl research are multifaceted. Primarily, researchers aim to establish HOCl as a safe and effective alternative to traditional chemical pesticides and fungicides. This goal aligns with the growing demand for organic and sustainable cultivation practices in the cannabis industry. Additionally, studies seek to optimize HOCl concentrations and application methods specifically for cannabis plants, considering their unique physiological characteristics and growth requirements.

Another critical objective is to investigate HOCl's potential in mitigating common cannabis cultivation challenges, such as powdery mildew, botrytis, and other pathogenic infections. Researchers are exploring its efficacy in both preventive and curative applications, aiming to develop comprehensive protocols for disease management in cannabis grow operations.

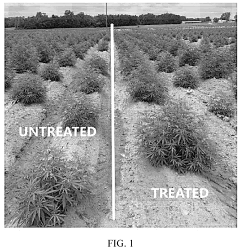

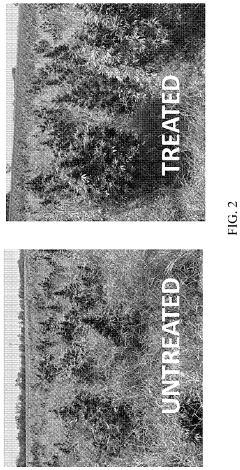

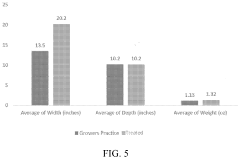

Furthermore, the research aims to assess the impact of HOCl on cannabis plant health, yield, and cannabinoid profiles. This includes studying its effects on root development, nutrient uptake, and overall plant vigor. Understanding these interactions is crucial for integrating HOCl into existing cultivation practices without compromising product quality or potency.

As the cannabis industry continues to evolve and face stricter regulations, another key objective of HOCl research is to evaluate its potential in meeting stringent microbial testing standards. This includes investigating its efficacy in reducing total yeast and mold counts, as well as its ability to eliminate specific pathogens of concern in cannabis products.

The technological trajectory of HOCl in cannabis cultivation is expected to focus on developing more sophisticated delivery systems, such as automated fogging and irrigation solutions. These advancements aim to optimize application efficiency and ensure uniform coverage, addressing the unique challenges posed by dense cannabis canopies and varying grow environments.

The evolution of HOCl technology in agriculture has been marked by significant advancements in production methods and application techniques. Initially, HOCl was primarily produced through electrolysis of salt water, a process that has been refined over time to yield more stable and effective solutions. The development of on-site generation systems has further revolutionized its use, allowing growers to produce HOCl as needed, ensuring freshness and potency.

In the context of cannabis cultivation, the objectives of HOCl research are multifaceted. Primarily, researchers aim to establish HOCl as a safe and effective alternative to traditional chemical pesticides and fungicides. This goal aligns with the growing demand for organic and sustainable cultivation practices in the cannabis industry. Additionally, studies seek to optimize HOCl concentrations and application methods specifically for cannabis plants, considering their unique physiological characteristics and growth requirements.

Another critical objective is to investigate HOCl's potential in mitigating common cannabis cultivation challenges, such as powdery mildew, botrytis, and other pathogenic infections. Researchers are exploring its efficacy in both preventive and curative applications, aiming to develop comprehensive protocols for disease management in cannabis grow operations.

Furthermore, the research aims to assess the impact of HOCl on cannabis plant health, yield, and cannabinoid profiles. This includes studying its effects on root development, nutrient uptake, and overall plant vigor. Understanding these interactions is crucial for integrating HOCl into existing cultivation practices without compromising product quality or potency.

As the cannabis industry continues to evolve and face stricter regulations, another key objective of HOCl research is to evaluate its potential in meeting stringent microbial testing standards. This includes investigating its efficacy in reducing total yeast and mold counts, as well as its ability to eliminate specific pathogens of concern in cannabis products.

The technological trajectory of HOCl in cannabis cultivation is expected to focus on developing more sophisticated delivery systems, such as automated fogging and irrigation solutions. These advancements aim to optimize application efficiency and ensure uniform coverage, addressing the unique challenges posed by dense cannabis canopies and varying grow environments.

Market Analysis: Cannabis Cultivation Demand

The cannabis cultivation market has experienced significant growth in recent years, driven by increasing legalization and acceptance of cannabis for both medical and recreational use. This expanding market has created a substantial demand for innovative cultivation techniques and technologies, including the potential application of hypochlorous acid in cannabis production.

The global cannabis cultivation market size was valued at USD 180.5 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 21.4% from 2022 to 2030. This growth is primarily attributed to the rising adoption of cannabis for medical purposes and the increasing number of countries legalizing its use for various applications.

North America dominates the cannabis cultivation market, with the United States and Canada being the major contributors. The U.S. market alone is expected to reach USD 40.0 billion by 2030, driven by the legalization of cannabis in multiple states for both medical and recreational use. Europe is also emerging as a significant market, with countries like Germany, the Netherlands, and the United Kingdom showing increased interest in cannabis cultivation.

The demand for cannabis cultivation is further fueled by the growing recognition of its potential therapeutic benefits. Medical cannabis is being used to treat various conditions, including chronic pain, epilepsy, and anxiety disorders. This has led to an increased focus on developing high-quality, consistent cannabis products, creating opportunities for advanced cultivation techniques.

As the cannabis industry matures, there is a growing emphasis on sustainable and efficient cultivation practices. Cultivators are seeking methods to improve crop yield, enhance product quality, and reduce the environmental impact of their operations. This trend has sparked interest in innovative solutions, such as the potential use of hypochlorous acid in cannabis cultivation.

The application of hypochlorous acid in cannabis cultivation aligns with the industry's focus on developing clean, safe, and effective growing methods. Hypochlorous acid, known for its antimicrobial properties, could potentially address several challenges faced by cannabis cultivators, including pest control, disease prevention, and overall plant health management.

Furthermore, the increasing regulatory scrutiny on cannabis cultivation practices has created a demand for solutions that can help growers meet stringent quality and safety standards. Hypochlorous acid, being a naturally occurring compound with a strong safety profile, could potentially offer a compliant solution for cultivators looking to optimize their operations while adhering to regulatory requirements.

In conclusion, the rapidly expanding cannabis cultivation market presents a significant opportunity for innovative technologies and practices. The potential application of hypochlorous acid in this sector aligns with the industry's needs for sustainable, efficient, and compliant cultivation methods. As the market continues to evolve, the demand for such solutions is expected to grow, making research into hypochlorous acid applications in cannabis cultivation a timely and relevant endeavor.

The global cannabis cultivation market size was valued at USD 180.5 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 21.4% from 2022 to 2030. This growth is primarily attributed to the rising adoption of cannabis for medical purposes and the increasing number of countries legalizing its use for various applications.

North America dominates the cannabis cultivation market, with the United States and Canada being the major contributors. The U.S. market alone is expected to reach USD 40.0 billion by 2030, driven by the legalization of cannabis in multiple states for both medical and recreational use. Europe is also emerging as a significant market, with countries like Germany, the Netherlands, and the United Kingdom showing increased interest in cannabis cultivation.

The demand for cannabis cultivation is further fueled by the growing recognition of its potential therapeutic benefits. Medical cannabis is being used to treat various conditions, including chronic pain, epilepsy, and anxiety disorders. This has led to an increased focus on developing high-quality, consistent cannabis products, creating opportunities for advanced cultivation techniques.

As the cannabis industry matures, there is a growing emphasis on sustainable and efficient cultivation practices. Cultivators are seeking methods to improve crop yield, enhance product quality, and reduce the environmental impact of their operations. This trend has sparked interest in innovative solutions, such as the potential use of hypochlorous acid in cannabis cultivation.

The application of hypochlorous acid in cannabis cultivation aligns with the industry's focus on developing clean, safe, and effective growing methods. Hypochlorous acid, known for its antimicrobial properties, could potentially address several challenges faced by cannabis cultivators, including pest control, disease prevention, and overall plant health management.

Furthermore, the increasing regulatory scrutiny on cannabis cultivation practices has created a demand for solutions that can help growers meet stringent quality and safety standards. Hypochlorous acid, being a naturally occurring compound with a strong safety profile, could potentially offer a compliant solution for cultivators looking to optimize their operations while adhering to regulatory requirements.

In conclusion, the rapidly expanding cannabis cultivation market presents a significant opportunity for innovative technologies and practices. The potential application of hypochlorous acid in this sector aligns with the industry's needs for sustainable, efficient, and compliant cultivation methods. As the market continues to evolve, the demand for such solutions is expected to grow, making research into hypochlorous acid applications in cannabis cultivation a timely and relevant endeavor.

HOCl Technology: Current State and Challenges

Hypochlorous acid (HOCl) technology has gained significant attention in cannabis cultivation due to its potential as a powerful yet safe disinfectant. The current state of HOCl technology in this field is characterized by a growing body of research and practical applications, but also faces several challenges that need to be addressed for wider adoption.

One of the primary advantages of HOCl in cannabis cultivation is its effectiveness against a broad spectrum of pathogens, including bacteria, fungi, and viruses. This makes it an attractive option for maintaining a clean growing environment and preventing crop losses due to infections. HOCl solutions are typically generated on-site through electrolysis of salt water, which provides a cost-effective and sustainable approach to disinfection.

However, the stability of HOCl solutions remains a significant challenge. The active chlorine content in HOCl can degrade over time, especially when exposed to light or organic matter. This necessitates frequent production and careful storage practices, which can be labor-intensive and may limit its application in large-scale operations.

Another challenge lies in the standardization of HOCl production and application methods. The efficacy of HOCl solutions can vary depending on factors such as pH, concentration, and contact time. Developing consistent protocols for different cultivation scenarios is crucial for ensuring reliable results across various cannabis growing operations.

The regulatory landscape surrounding HOCl use in cannabis cultivation is also evolving. While HOCl is generally recognized as safe (GRAS) by the FDA for food contact applications, its specific use in cannabis production may require additional approvals or certifications in some jurisdictions. This regulatory uncertainty can pose challenges for growers looking to implement HOCl technology.

Research into the long-term effects of HOCl on cannabis plants and their chemical profiles is ongoing. While initial studies suggest that HOCl does not negatively impact plant growth or cannabinoid production, more comprehensive studies are needed to fully understand its effects on terpene profiles and overall plant health across different cannabis strains and growth stages.

The integration of HOCl technology with existing cultivation systems presents both opportunities and challenges. Automated HOCl generation and distribution systems are being developed to streamline the disinfection process, but these need to be carefully designed to ensure compatibility with various growing setups and to prevent any potential negative interactions with nutrients or other cultivation inputs.

As the cannabis industry continues to grow and face increasing quality control demands, the development of HOCl technology tailored specifically for cannabis cultivation is likely to accelerate. Overcoming the current challenges will require collaborative efforts between researchers, equipment manufacturers, and cannabis growers to optimize HOCl applications and establish best practices for its use in this unique agricultural sector.

One of the primary advantages of HOCl in cannabis cultivation is its effectiveness against a broad spectrum of pathogens, including bacteria, fungi, and viruses. This makes it an attractive option for maintaining a clean growing environment and preventing crop losses due to infections. HOCl solutions are typically generated on-site through electrolysis of salt water, which provides a cost-effective and sustainable approach to disinfection.

However, the stability of HOCl solutions remains a significant challenge. The active chlorine content in HOCl can degrade over time, especially when exposed to light or organic matter. This necessitates frequent production and careful storage practices, which can be labor-intensive and may limit its application in large-scale operations.

Another challenge lies in the standardization of HOCl production and application methods. The efficacy of HOCl solutions can vary depending on factors such as pH, concentration, and contact time. Developing consistent protocols for different cultivation scenarios is crucial for ensuring reliable results across various cannabis growing operations.

The regulatory landscape surrounding HOCl use in cannabis cultivation is also evolving. While HOCl is generally recognized as safe (GRAS) by the FDA for food contact applications, its specific use in cannabis production may require additional approvals or certifications in some jurisdictions. This regulatory uncertainty can pose challenges for growers looking to implement HOCl technology.

Research into the long-term effects of HOCl on cannabis plants and their chemical profiles is ongoing. While initial studies suggest that HOCl does not negatively impact plant growth or cannabinoid production, more comprehensive studies are needed to fully understand its effects on terpene profiles and overall plant health across different cannabis strains and growth stages.

The integration of HOCl technology with existing cultivation systems presents both opportunities and challenges. Automated HOCl generation and distribution systems are being developed to streamline the disinfection process, but these need to be carefully designed to ensure compatibility with various growing setups and to prevent any potential negative interactions with nutrients or other cultivation inputs.

As the cannabis industry continues to grow and face increasing quality control demands, the development of HOCl technology tailored specifically for cannabis cultivation is likely to accelerate. Overcoming the current challenges will require collaborative efforts between researchers, equipment manufacturers, and cannabis growers to optimize HOCl applications and establish best practices for its use in this unique agricultural sector.

Existing HOCl Applications in Cannabis Cultivation

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization techniques for hypochlorous acid solutions: Researchers have developed various stabilization techniques to prolong the shelf life and maintain the efficacy of hypochlorous acid solutions. These methods may involve pH adjustment, addition of stabilizing agents, or specialized packaging to prevent degradation and ensure consistent performance over time.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid has found applications in medical treatments and therapies, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental remediation and industrial processes due to its strong oxidizing properties. Applications include water treatment, air purification, and surface decontamination in various industries, offering an eco-friendly alternative to harsher chemicals.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization and formulation of hypochlorous acid solutions

Techniques for stabilizing hypochlorous acid solutions are crucial for maintaining their efficacy over time. This includes pH adjustment, addition of stabilizing agents, and specialized packaging to prevent degradation. Formulation strategies aim to enhance shelf life and preserve the active properties of hypochlorous acid.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid finds applications in various medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to promote healing while providing antimicrobial protection makes it valuable in clinical settings and for personal healthcare products.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in environmental remediation, industrial cleaning, and agricultural practices. Its eco-friendly nature and effectiveness in removing contaminants make it suitable for applications ranging from water treatment to surface disinfection in various industries.Expand Specific Solutions

Key Players in HOCl and Cannabis Sectors

The research on hypochlorous acid applications in cannabis cultivation is in its early stages, with the market still developing. The industry is characterized by a mix of established players and emerging startups exploring this niche. Companies like WIAB WATER INNOVATION AB and Industrie De Nora SpA are leveraging their expertise in water treatment and electrochemistry to develop solutions for cannabis cultivation. The technology's maturity is evolving, with research institutions such as the Institute of Hemp Research, CAAS, and universities like Bristol and Valencia contributing to advancements. As the cannabis industry grows, the potential market for hypochlorous acid applications is expected to expand, attracting more players and driving innovation in this field.

Industrie De Nora SpA

Technical Solution: Industrie De Nora, a global leader in electrochemistry and water treatment solutions, has applied its expertise to develop HOCl generation systems suitable for cannabis cultivation. Their technology allows for the on-site production of stable and effective HOCl solutions, which can be integrated into existing irrigation and fertigation systems. De Nora's systems are designed to provide precise control over HOCl concentration, ensuring optimal dosage for pathogen control without risking phytotoxicity. The company has conducted field trials in collaboration with cannabis cultivators, demonstrating the efficacy of their HOCl solutions in reducing biofilm formation in hydroponic systems and controlling foliar diseases in greenhouse environments[9][10].

Strengths: Advanced electrochemical technology for HOCl generation; Scalable solutions for large-scale cannabis operations. Weaknesses: High initial cost for implementation; May require specialized training for operation and maintenance.

Institute of Hemp Research, Chinese Academy of Agricultural Sciences

Technical Solution: The Institute of Hemp Research has conducted extensive studies on the application of Hypochlorous Acid in cannabis cultivation, focusing on its potential to mitigate fungal diseases and improve overall plant health. Their research has explored the optimal concentrations and application methods of HOCl for different stages of cannabis growth. The institute has developed protocols for using HOCl in seed sterilization, which has shown to improve germination rates and seedling vigor. Additionally, they have investigated the effects of HOCl foliar sprays on cannabinoid and terpene profiles, finding that when used correctly, HOCl treatments do not negatively impact the plant's chemical composition[5][6].

Strengths: Comprehensive research on HOCl applications in cannabis; Evidence-based protocols for various growth stages. Weaknesses: Research may be more theoretical than practical; Potential limitations in commercialization of findings.

Innovative HOCl Technologies for Cannabis

A method of production of phytocannabinoids for use in medical treatments

PatentPendingUS20240081209A1

Innovation

- Cultured Cannabis sativa plant cells are grown through tissue culture, with controlled light exposure to regulate phytocannabinoid content, allowing for consistent and controllable production of phytocannabinoids, such as THC, without genetic variation.

Microbe-Based Products for Enhancing Growth and Phytocannabinoid Content of Cannabis

PatentPendingUS20220369647A1

Innovation

- Microbe-based soil treatment compositions comprising non-pathogenic fungal and bacterial strains, such as Trichoderma spp. and Bacillus spp., are used to enhance nutrient and moisture retention, promote root health, and increase phytocannabinoid content in hemp plants, even in compromised conditions, through improved rhizosphere properties and synergistic microbial interactions.

Regulatory Framework for HOCl Use in Cannabis

The regulatory framework for hypochlorous acid (HOCl) use in cannabis cultivation is a complex and evolving landscape. As cannabis legalization continues to spread across various jurisdictions, the need for clear guidelines on the use of agricultural inputs, including HOCl, has become increasingly important.

At the federal level in the United States, cannabis remains classified as a Schedule I controlled substance, which has historically limited research and regulatory development. However, individual states have taken the lead in establishing regulatory frameworks for cannabis cultivation, including the use of pesticides and other agricultural inputs.

Many states have adopted a "whitelist" approach, specifying which products are allowed for use in cannabis cultivation. HOCl, being a relatively new entrant in this space, is not universally included in these lists. Some states, recognizing its potential benefits and low toxicity profile, have begun to explicitly allow its use, while others maintain more restrictive policies.

The Environmental Protection Agency (EPA) plays a crucial role in regulating pesticides and antimicrobial agents in the United States. While the EPA has not specifically approved HOCl for use on cannabis due to federal restrictions, it has recognized HOCl as a safe and effective sanitizer in other agricultural applications. This recognition may pave the way for future acceptance in cannabis cultivation as federal regulations evolve.

In Canada, where cannabis is federally legal, the regulatory framework is more unified. Health Canada oversees the regulation of cannabis production, including the use of pest control products. HOCl is currently not listed among the approved pesticides for cannabis, but ongoing research and regulatory reviews may lead to changes in its status.

The European Union, with its varied approach to cannabis legalization, presents a fragmented regulatory landscape. Countries like the Netherlands and Germany, which have more progressive cannabis policies, are at the forefront of developing regulations for cultivation practices, including the use of inputs like HOCl.

Internationally, the United Nations Office on Drugs and Crime (UNODC) and the World Health Organization (WHO) provide guidelines that influence global cannabis policies. While these organizations have not specifically addressed HOCl use in cannabis cultivation, their recommendations on good agricultural practices and food safety standards may indirectly impact future regulations.

As the cannabis industry matures and scientific evidence accumulates, it is likely that regulatory frameworks will continue to evolve. The trend towards organic and sustainable cultivation practices may favor the adoption of HOCl as a safer alternative to traditional chemical pesticides. However, this will require ongoing dialogue between industry stakeholders, researchers, and regulatory bodies to establish clear guidelines and standards for its use in cannabis cultivation.

At the federal level in the United States, cannabis remains classified as a Schedule I controlled substance, which has historically limited research and regulatory development. However, individual states have taken the lead in establishing regulatory frameworks for cannabis cultivation, including the use of pesticides and other agricultural inputs.

Many states have adopted a "whitelist" approach, specifying which products are allowed for use in cannabis cultivation. HOCl, being a relatively new entrant in this space, is not universally included in these lists. Some states, recognizing its potential benefits and low toxicity profile, have begun to explicitly allow its use, while others maintain more restrictive policies.

The Environmental Protection Agency (EPA) plays a crucial role in regulating pesticides and antimicrobial agents in the United States. While the EPA has not specifically approved HOCl for use on cannabis due to federal restrictions, it has recognized HOCl as a safe and effective sanitizer in other agricultural applications. This recognition may pave the way for future acceptance in cannabis cultivation as federal regulations evolve.

In Canada, where cannabis is federally legal, the regulatory framework is more unified. Health Canada oversees the regulation of cannabis production, including the use of pest control products. HOCl is currently not listed among the approved pesticides for cannabis, but ongoing research and regulatory reviews may lead to changes in its status.

The European Union, with its varied approach to cannabis legalization, presents a fragmented regulatory landscape. Countries like the Netherlands and Germany, which have more progressive cannabis policies, are at the forefront of developing regulations for cultivation practices, including the use of inputs like HOCl.

Internationally, the United Nations Office on Drugs and Crime (UNODC) and the World Health Organization (WHO) provide guidelines that influence global cannabis policies. While these organizations have not specifically addressed HOCl use in cannabis cultivation, their recommendations on good agricultural practices and food safety standards may indirectly impact future regulations.

As the cannabis industry matures and scientific evidence accumulates, it is likely that regulatory frameworks will continue to evolve. The trend towards organic and sustainable cultivation practices may favor the adoption of HOCl as a safer alternative to traditional chemical pesticides. However, this will require ongoing dialogue between industry stakeholders, researchers, and regulatory bodies to establish clear guidelines and standards for its use in cannabis cultivation.

Environmental Impact of HOCl in Cannabis Farming

The use of hypochlorous acid (HOCl) in cannabis cultivation has significant environmental implications that warrant careful consideration. As a powerful sanitizing agent, HOCl offers several benefits in terms of pest and disease control, but its impact on the surrounding ecosystem must be thoroughly evaluated.

One of the primary environmental advantages of HOCl in cannabis farming is its potential to reduce the reliance on traditional pesticides and fungicides. Many conventional agricultural chemicals can persist in the environment, leading to soil and water contamination. In contrast, HOCl breaks down rapidly into harmless components, primarily water and salt, minimizing long-term environmental accumulation.

However, the production and application of HOCl require energy and resources, which contribute to the overall environmental footprint of cannabis cultivation. The electrolysis process used to generate HOCl consumes electricity, and the transportation and storage of the solution may involve plastic containers, raising concerns about energy use and plastic waste.

The impact of HOCl on soil microbiology is another crucial aspect to consider. While HOCl effectively eliminates harmful pathogens, it may also affect beneficial microorganisms in the soil ecosystem. This could potentially alter soil health and fertility over time, necessitating careful management and monitoring of application rates and frequencies.

Water usage is a critical environmental factor in cannabis cultivation, and HOCl may offer some advantages in this regard. Its effectiveness as a sanitizer could allow for more efficient water recycling in hydroponic systems, potentially reducing overall water consumption. However, the discharge of HOCl-treated water into the environment must be carefully managed to prevent any adverse effects on aquatic ecosystems.

The use of HOCl in cannabis farming may also impact air quality. While HOCl itself is not a significant air pollutant, its production and application may involve the release of chlorine gas, which can be harmful if not properly controlled. Proper ventilation and safety measures are essential to mitigate any potential air quality issues.

In terms of biodiversity, the adoption of HOCl as a primary sanitizing agent could have mixed effects. On one hand, it may reduce the need for more harmful pesticides, potentially benefiting local insect and animal populations. On the other hand, its broad-spectrum antimicrobial action could impact non-target organisms if not applied judiciously.

As the cannabis industry continues to grow, the cumulative environmental impact of HOCl use across multiple cultivation sites becomes increasingly important. Large-scale adoption of this technology could lead to significant changes in local ecosystems, necessitating comprehensive environmental monitoring and adaptive management strategies.

One of the primary environmental advantages of HOCl in cannabis farming is its potential to reduce the reliance on traditional pesticides and fungicides. Many conventional agricultural chemicals can persist in the environment, leading to soil and water contamination. In contrast, HOCl breaks down rapidly into harmless components, primarily water and salt, minimizing long-term environmental accumulation.

However, the production and application of HOCl require energy and resources, which contribute to the overall environmental footprint of cannabis cultivation. The electrolysis process used to generate HOCl consumes electricity, and the transportation and storage of the solution may involve plastic containers, raising concerns about energy use and plastic waste.

The impact of HOCl on soil microbiology is another crucial aspect to consider. While HOCl effectively eliminates harmful pathogens, it may also affect beneficial microorganisms in the soil ecosystem. This could potentially alter soil health and fertility over time, necessitating careful management and monitoring of application rates and frequencies.

Water usage is a critical environmental factor in cannabis cultivation, and HOCl may offer some advantages in this regard. Its effectiveness as a sanitizer could allow for more efficient water recycling in hydroponic systems, potentially reducing overall water consumption. However, the discharge of HOCl-treated water into the environment must be carefully managed to prevent any adverse effects on aquatic ecosystems.

The use of HOCl in cannabis farming may also impact air quality. While HOCl itself is not a significant air pollutant, its production and application may involve the release of chlorine gas, which can be harmful if not properly controlled. Proper ventilation and safety measures are essential to mitigate any potential air quality issues.

In terms of biodiversity, the adoption of HOCl as a primary sanitizing agent could have mixed effects. On one hand, it may reduce the need for more harmful pesticides, potentially benefiting local insect and animal populations. On the other hand, its broad-spectrum antimicrobial action could impact non-target organisms if not applied judiciously.

As the cannabis industry continues to grow, the cumulative environmental impact of HOCl use across multiple cultivation sites becomes increasingly important. Large-scale adoption of this technology could lead to significant changes in local ecosystems, necessitating comprehensive environmental monitoring and adaptive management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!