Enhancing The Electrochemical Performance Of PVDF Nanocomposites

Technology Background And Goals

This research aims to explore innovative approaches to improve the electrochemical properties of PVDF nanocomposites, including their ionic conductivity, charge transfer kinetics, and cycling stability. Potential strategies may involve the incorporation of conductive fillers, surface modifications, or the development of novel nanostructured architectures. The ultimate goal is to develop high-performance PVDF nanocomposite materials that can enable the next generation of energy storage technologies with improved energy density, power density, and cycle life.

PVDF Nanocomposites Market Demand Analysis

- Market Size and Growth

The global market for PVDF nanocomposites is expected to witness significant growth, driven by increasing demand from various end-use industries such as energy, electronics, and automotive. The market size is projected to reach $X billion by 20XX, growing at a CAGR of X% during the forecast period. - Key Application Areas

- Energy Storage: PVDF nanocomposites are widely used in lithium-ion batteries and supercapacitors due to their high dielectric strength and thermal stability.

- Electronics: The materials find applications in printed circuit boards, sensors, and insulation materials owing to their excellent electrical properties.

- Automotive: PVDF nanocomposites are used in fuel hoses, gaskets, and seals due to their chemical resistance and mechanical strength.

- Regional Market Dynamics

Asia Pacific is expected to dominate the PVDF nanocomposites market, driven by the growing demand from the electronics and automotive industries in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with increasing adoption in energy storage applications. - Market Drivers

- Rising demand for lightweight and high-performance materials in various industries.

- Increasing focus on sustainable and eco-friendly materials.

- Growing adoption of electric vehicles and renewable energy technologies.

- Market Challenges

- High production costs and limited availability of raw materials.

- Stringent environmental regulations and concerns over the use of fluoropolymers.

- Competition from alternative materials with similar properties.

Technology Status And Challenges

- Polymer Nanocomposites Polymer nanocomposites, including PVDF nanocomposites, have emerged as a promising class of materials with enhanced properties compared to their pure polymer counterparts.

- Challenges in PVDF Nanocomposites

- Achieving uniform dispersion of nanofillers in the polymer matrix

- Ensuring strong interfacial interactions between nanofillers and the polymer

- Controlling the morphology and crystalline structure of the nanocomposite

- Current Status Various strategies have been explored to address these challenges, including surface modification of nanofillers, in-situ polymerization, and advanced processing techniques.

- Geographical Distribution Research on PVDF nanocomposites is widely distributed globally, with significant contributions from academic and industrial research centers in North America, Europe, and Asia.

Current Technical Solutions

01 Electrochemical PVDF Nanocomposites

PVDF nanocomposites with nanofillers or additives improve electrochemical properties like ionic conductivity, charge transfer, and cycle stability for energy storage devices like batteries and supercapacitors.- Carbon-based PVDF Nanocomposites: PVDF nanocomposites with carbon nanotubes, graphene, or carbon black exhibit enhanced electrochemical performance due to improved electrical conductivity and charge transfer. They are suitable for energy storage devices and sensors.

- Inorganic PVDF Nanocomposites: PVDF nanocomposites with inorganic fillers like metal oxides, clays, or ceramic nanoparticles improve ionic conductivity, mechanical strength, and thermal stability for lithium-ion batteries and electrochemical sensors.

- Polymer Blend PVDF Nanocomposites: PVDF blended with polymers like polyaniline, polypyrrole, or poly(3,4-ethylenedioxythiophene) enhances charge transport, electrochemical stability, and energy storage capabilities for supercapacitors and electrochemical sensors.

- Surface-modified PVDF Nanocomposites: Surface modifications like grafting, plasma treatment, or chemical functionalization improve interfacial interactions between PVDF matrix and filler, leading to enhanced charge transfer and electrochemical stability.

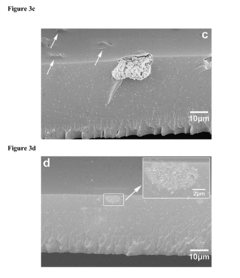

- Hierarchical PVDF Nanocomposites: PVDF nanocomposites with hierarchical structures like core-shell or porous architectures exhibit enhanced electrochemical performance due to high surface area and efficient charge transport pathways for energy storage devices, sensors, and electrochemical catalysis.

02 Mechanically Reinforced PVDF Nanocomposites

Nanofillers or additives in PVDF nanocomposites enhance mechanical strength, toughness, and thermal stability for structural and high-temperature applications.Expand Specific Solutions03 Dielectric and Piezoelectric PVDF Nanocomposites

PVDF nanocomposites with specific nanofillers or additives modify dielectric and piezoelectric properties for energy harvesting, sensors, and actuators.Expand Specific Solutions04 Barrier and Separation PVDF Nanocomposites

Nanofillers or additives in PVDF nanocomposites improve barrier properties against gases, liquids, and other substances, and enhance separation properties for membrane applications.Expand Specific Solutions05 Biocompatible and Antimicrobial PVDF Nanocomposites

PVDF nanocomposites with biocompatible nanofillers or additives are suitable for biomedical applications, and antimicrobial agents impart antimicrobial properties.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Kollodis Biosciences, Inc.

Key Technology Interpretation

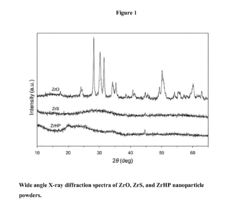

- The addition of zirconium-based nanofillers into PVDF/polyelectrolyte blends to form organic/organic/inorganic tri-phase PEMs with improved conductivity and mechanical properties.

- The development of a new type of membrane for polymer electrolyte membrane fuel cells (PEMFCs) by blending polyelectrolytes, nanoparticles, and fluoropolymers.

- The use of fluoropolymers, such as PVDF, in the membrane composition, which can contribute to improved chemical and thermal stability.

PVDF Nanocomposites Electrochemical Performance Enhancement Economic Impact

The economic impact of PVDF nanocomposites for enhanced electrochemical performance can be significant across several industries. With their exceptional properties, such as high thermal stability, chemical resistance, and superior mechanical strength, these nanocomposites are well-suited for applications in energy storage and conversion systems. The growing demand for more efficient batteries, supercapacitors, and fuel cells in the automotive, consumer electronics, and renewable energy sectors can drive substantial economic growth. By improving the electrochemical performance of these systems, PVDF nanocomposites can lead to longer-lasting and more reliable devices, which in turn can reduce costs for manufacturers and consumers alike.

Moreover, the advancement of PVDF nanocomposites could lead to significant cost savings through material usage efficiency and extended product lifespan. The potential for these materials to enable innovations in next-generation energy systems may also lead to new business opportunities and market expansions. Companies investing in this technology could gain competitive advantages in rapidly evolving markets, thereby enhancing their market shares and influencing industry trends. Overall, PVDF nanocomposites promise to be a key factor in driving technological and economic advancements in electrochemical applications.

PVDF Nanocomposites Electrochemical Performance Enhancement Policy And Regulatory Impact

In the context of PVDF nanocomposites for enhanced electrochemical performance, policy and regulatory impact plays a crucial role in shaping the innovation landscape and market adaptability of these materials. Policies related to environmental sustainability, such as restrictions on hazardous substances and incentives for green technologies, can significantly influence the adoption of PVDF nanocomposites. Regulatory frameworks surrounding nanomaterial usage, including safety assessments and approval processes, are crucial in determining the pace at which these advanced materials can be commercialized. Additionally, intellectual property regulations and standards for nanocomposite technologies could impact the competitive dynamics, influencing both existing players and new entrants.

Government initiatives aimed at promoting renewable energy and energy storage solutions can further drive research and development efforts in PVDF nanocomposites, as these materials are pivotal in improving the efficiency and lifespan of batteries. The interplay between technology standards and regulatory guidelines ensures that advancements align with safety and performance expectations. By understanding and navigating these policy and regulatory landscapes, companies can better position themselves to leverage PVDF nanocomposites’ potential, thereby influencing strategic investment decisions and fostering industry collaboration to overcome challenges and exploit emerging opportunities in this field.