Cellulose Acetate as a Replacement for Petrochemical Polymers

Cellulose Acetate Background and Objectives

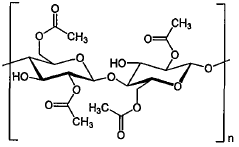

Cellulose acetate, a versatile biopolymer derived from natural cellulose, has emerged as a promising alternative to petrochemical-based polymers. The development of this material can be traced back to the early 20th century when it was first synthesized as a more stable form of cellulose nitrate. Over the years, cellulose acetate has evolved from its initial applications in photographic films and fibers to a wide range of uses in various industries.

The growing concern over environmental sustainability and the depletion of fossil resources has led to increased interest in bio-based materials. Cellulose acetate, being derived from renewable sources, aligns well with the global shift towards more sustainable and eco-friendly alternatives to traditional petrochemical polymers. Its biodegradability and potential for recycling further enhance its appeal as a green material.

The technical evolution of cellulose acetate has focused on improving its properties and expanding its applicability. Researchers have made significant strides in enhancing its thermal stability, mechanical strength, and processability. These advancements have opened up new possibilities for cellulose acetate in fields such as packaging, textiles, and biomedical applications.

One of the primary objectives in cellulose acetate research is to optimize its production process. This involves developing more efficient and environmentally friendly methods for cellulose extraction and acetylation. Additionally, there is a strong focus on tailoring the degree of substitution and molecular weight distribution to achieve desired material properties for specific applications.

Another key goal is to expand the functional versatility of cellulose acetate. This includes modifying its surface properties, improving its compatibility with other materials for composite formation, and enhancing its barrier properties for packaging applications. Researchers are also exploring ways to incorporate additional functionalities, such as antimicrobial or flame-retardant properties, to broaden its potential uses.

The development of cellulose acetate as a replacement for petrochemical polymers faces several technical challenges. These include improving its moisture resistance, enhancing its thermal and mechanical properties to match those of conventional plastics, and developing cost-effective production methods that can compete with well-established petrochemical polymer manufacturing processes.

As research in this field progresses, the ultimate aim is to position cellulose acetate as a viable, sustainable alternative to petrochemical polymers across a wide range of applications. This involves not only technical advancements but also addressing economic and scalability considerations to facilitate its widespread adoption in various industries.

Market Demand for Sustainable Polymers

The global market for sustainable polymers has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. Cellulose acetate, as a biodegradable and renewable alternative to petrochemical-based polymers, is well-positioned to capitalize on this growing demand for eco-friendly materials.

Consumer awareness of environmental issues has led to a shift in preferences towards sustainable products, creating a strong market pull for bio-based polymers like cellulose acetate. Industries such as packaging, textiles, and consumer goods are actively seeking alternatives to traditional plastics, presenting substantial opportunities for cellulose acetate adoption.

The packaging industry, in particular, shows promising potential for cellulose acetate applications. With the increasing focus on reducing single-use plastics, cellulose acetate's biodegradability and versatility make it an attractive option for food packaging, disposable cutlery, and other short-lived products. The textile industry is another key market, where cellulose acetate fibers can replace synthetic fibers in clothing and home textiles, appealing to environmentally conscious consumers.

Regulatory initiatives worldwide are also driving the demand for sustainable polymers. Many countries have implemented or are considering bans on single-use plastics, creating a regulatory landscape that favors alternatives like cellulose acetate. This regulatory push is expected to accelerate market growth and adoption of sustainable polymers across various industries.

The automotive and construction sectors are emerging as potential growth areas for cellulose acetate. As these industries seek to reduce their carbon footprint and improve sustainability, cellulose acetate's properties make it suitable for applications in interior components, insulation, and building materials.

Market analysts project robust growth for the sustainable polymers market in the coming years. The global bio-based polymer market is expected to expand significantly, with cellulose acetate playing a crucial role in this growth. However, challenges such as production costs and performance limitations compared to traditional polymers need to be addressed to fully realize the market potential.

In conclusion, the market demand for sustainable polymers like cellulose acetate is strong and growing. Driven by consumer preferences, regulatory pressures, and industry initiatives, cellulose acetate has the potential to capture a significant share of the polymer market across multiple sectors. As research and development efforts continue to improve its properties and reduce production costs, cellulose acetate is poised to become a key player in the transition towards a more sustainable materials economy.

Current State and Challenges of Cellulose Acetate

Cellulose acetate has gained significant attention as a potential replacement for petrochemical polymers due to its biodegradability and renewable source. Currently, the production and application of cellulose acetate are well-established in various industries, including textiles, packaging, and personal care products. The global cellulose acetate market is experiencing steady growth, driven by increasing environmental concerns and stringent regulations on plastic usage.

Despite its promising attributes, cellulose acetate faces several challenges in its widespread adoption as a petrochemical polymer substitute. One of the primary obstacles is the higher production cost compared to conventional plastics. The complex manufacturing process, involving the acetylation of cellulose and subsequent hydrolysis, contributes to increased expenses. This cost differential makes it difficult for cellulose acetate to compete with cheaper petrochemical alternatives in price-sensitive markets.

Another significant challenge is the limited mechanical properties of cellulose acetate compared to some petrochemical polymers. While suitable for many applications, it may not meet the performance requirements for certain high-stress or high-temperature uses. This limitation restricts its potential to replace petrochemical polymers in some specialized industries, such as automotive or aerospace.

The biodegradability of cellulose acetate, while generally considered an advantage, also presents challenges in terms of product stability and shelf life. Manufacturers must carefully balance the material's biodegradability with its durability to ensure that products maintain their integrity throughout their intended lifespan. This balance is particularly crucial in packaging applications where long-term storage may be required.

Water sensitivity is another issue facing cellulose acetate. The material can absorb moisture from the environment, leading to dimensional changes and potential degradation of mechanical properties. This characteristic limits its use in applications where water resistance is essential, necessitating additional treatments or coatings to improve its performance in humid conditions.

From a processing standpoint, cellulose acetate requires specific equipment and expertise, which may not be readily available in existing plastic manufacturing facilities. This necessitates significant investment in new machinery and training, posing a barrier to entry for some manufacturers looking to transition from petrochemical polymers.

Lastly, while cellulose acetate is derived from renewable sources, concerns exist regarding the sustainability of its raw material supply. The increasing demand for cellulose-based products could potentially lead to competition with food crops for agricultural land, raising ethical and environmental questions that need to be addressed as the industry scales up.

Existing Cellulose Acetate Applications

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications, such as textiles, filters, and packaging materials. The properties of these fibers can be tailored through modifications in the production process or by blending with other materials to suit specific end-use requirements.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology focus on improving properties such as permeability, selectivity, and durability. These developments are particularly relevant for applications in separation processes, including water treatment and gas separation.

- Biodegradable cellulose acetate materials: Research into biodegradable cellulose acetate materials addresses environmental concerns by developing formulations and processing methods that enhance the material's biodegradability while maintaining desired functional properties for various applications.

- Cellulose acetate composites and blends: Innovations in cellulose acetate composites and blends involve combining cellulose acetate with other materials to create products with enhanced properties. These developments aim to expand the range of applications for cellulose acetate-based materials in industries such as packaging, construction, and automotive.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in diverse applications, such as textiles, filters, and packaging materials. The properties of these fibers can be tailored through modifications in the production process or by incorporating additives to enhance performance characteristics.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology focus on improving properties such as permeability, selectivity, and durability. These developments are particularly relevant for applications in separation processes, water treatment, and gas purification.Expand Specific Solutions04 Cellulose acetate composites and blends

Research on cellulose acetate composites and blends explores the combination of cellulose acetate with other materials to create products with enhanced properties. This includes the development of biodegradable composites and materials with improved mechanical or thermal characteristics.Expand Specific Solutions05 Cellulose acetate modification and functionalization

Techniques for modifying and functionalizing cellulose acetate are investigated to impart specific properties or functionalities. This includes chemical modifications, surface treatments, and the incorporation of reactive groups to expand the material's potential applications.Expand Specific Solutions

Key Players in Cellulose Acetate Industry

The research on cellulose acetate as a replacement for petrochemical polymers is in a growth phase, with increasing market potential due to environmental concerns and sustainability trends. The global cellulose acetate market is projected to expand significantly, driven by demand in various industries. Technologically, cellulose acetate is relatively mature, but ongoing research focuses on improving its properties and production processes. Companies like Eastman Chemical Co., Daicel Corp., and Celanese Acetate LLC are leading players, with significant contributions from research institutions such as the Chinese Academy of Sciences and universities like Virginia Tech. The involvement of major petrochemical companies like China Petroleum & Chemical Corp. indicates a shift towards more sustainable alternatives in the polymer industry.

Daicel Corp.

Eastman Chemical Co.

Core Innovations in Cellulose Acetate Research

- A cellulose acetate with a total degree of acetyl substitution not greater than 2.7, a specific ratio of acetyl substitution at different positions, and a sulfate component content of 20-400 ppm, along with additives like magnesium oxide and triacetin, enhances biodegradability in seawater.

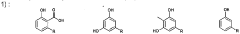

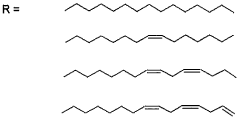

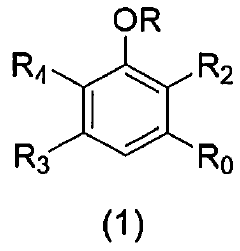

- Derivatives from Cashew Nut Shell Oil (CNSL), specifically compounds with ester and epoxy functions, are used as plasticizing agents for cellulose acetate to create biodegradable and compatible plastic materials, addressing the need for sustainable and environmentally friendly thermoplastic solutions.

Environmental Impact Assessment

The environmental impact assessment of cellulose acetate as a replacement for petrochemical polymers reveals significant potential benefits in reducing the carbon footprint and overall environmental burden associated with plastic production and disposal. Cellulose acetate, derived from renewable sources such as wood pulp or cotton linters, offers a more sustainable alternative to traditional petroleum-based plastics.

One of the primary environmental advantages of cellulose acetate is its biodegradability. Unlike conventional plastics that persist in the environment for hundreds of years, cellulose acetate can decompose within months to a few years under proper conditions. This characteristic significantly reduces the long-term accumulation of plastic waste in landfills and oceans, mitigating the detrimental effects on ecosystems and wildlife.

The production process of cellulose acetate also demonstrates lower environmental impact compared to petrochemical polymers. The raw materials used are renewable and abundant, reducing the reliance on finite fossil fuel resources. Additionally, the manufacturing of cellulose acetate typically requires less energy and produces fewer greenhouse gas emissions than the production of petroleum-based plastics, contributing to a reduction in overall carbon emissions.

Water pollution is another area where cellulose acetate shows promise. As it breaks down, it does not release harmful microplastics into aquatic environments, a significant issue associated with conventional plastics. This property helps preserve water quality and protects marine life from the detrimental effects of plastic pollution.

However, it is important to note that the environmental benefits of cellulose acetate are not without challenges. The cultivation and harvesting of raw materials for cellulose acetate production, such as trees or cotton, can have land-use implications and potential impacts on biodiversity if not managed sustainably. Furthermore, the use of chemical solvents in the production process requires careful handling and disposal to prevent environmental contamination.

The end-of-life management of cellulose acetate products also warrants consideration. While biodegradable, these materials may require specific conditions to decompose efficiently. Proper waste management infrastructure and consumer education are necessary to ensure that cellulose acetate products are disposed of correctly to maximize their environmental benefits.

In conclusion, the environmental impact assessment of cellulose acetate as a replacement for petrochemical polymers indicates a promising shift towards more sustainable materials. Its biodegradability, renewable sourcing, and reduced carbon footprint offer significant advantages over traditional plastics. However, ongoing research and development are crucial to address remaining challenges and optimize the environmental performance of cellulose acetate throughout its lifecycle.

Regulatory Framework for Biopolymers

The regulatory framework for biopolymers, including cellulose acetate, is evolving rapidly as governments and international organizations recognize the potential of these materials to replace petrochemical polymers. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating biopolymers under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new biopolymers, ensuring their safety and environmental impact are thoroughly assessed before market entry.

The European Union has implemented a comprehensive regulatory framework for biopolymers through its Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH mandates that companies register biopolymers with the European Chemicals Agency (ECHA) and provide detailed information on their properties, potential risks, and safe use. Additionally, the EU's Circular Economy Action Plan promotes the use of bio-based, biodegradable, and compostable plastics, further supporting the adoption of cellulose acetate and other biopolymers.

In Japan, the Ministry of Economy, Trade, and Industry (METI) has established guidelines for biodegradable plastics, including cellulose acetate. These guidelines set standards for biodegradability, compostability, and environmental safety, encouraging the development and use of sustainable alternatives to petrochemical polymers.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for biopolymers. These standards provide a framework for testing and certifying the biodegradability, compostability, and overall environmental performance of materials like cellulose acetate. For example, ISO 17088 and ASTM D6400 set specifications for compostable plastics, while ISO 14851 and ASTM D5338 provide methods for determining aerobic biodegradability of plastic materials in an aqueous medium.

The regulatory landscape also includes incentives and support mechanisms for biopolymer development and adoption. Many countries have implemented tax incentives, research grants, and other financial support programs to encourage the transition from petrochemical polymers to more sustainable alternatives. For instance, the U.S. Department of Agriculture's BioPreferred Program promotes the purchase and use of bio-based products, including those made from cellulose acetate, through federal procurement preferences and voluntary labeling initiatives.

As the urgency to address plastic pollution and reduce dependence on fossil fuels grows, regulatory frameworks are likely to become more stringent and supportive of biopolymers. This evolving regulatory environment presents both challenges and opportunities for cellulose acetate as a replacement for petrochemical polymers, necessitating ongoing research and development to ensure compliance and maximize market potential.