Nichrome Innovations for Battery Thermal Management

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome in Battery Thermal Management: Background and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has emerged as a pivotal material in the realm of battery thermal management. The evolution of this technology can be traced back to the early 20th century when nichrome was first developed for its high electrical resistance and heat-generating properties. Over the decades, its application has expanded significantly, finding its way into various industries, including the rapidly growing field of battery technology.

The progression of battery technology, particularly in electric vehicles and renewable energy storage systems, has brought thermal management to the forefront of research and development. As batteries become more powerful and energy-dense, the need for efficient heat dissipation and temperature control has become increasingly critical. This is where nichrome's unique properties have found a new purpose, offering innovative solutions to the complex challenges of battery thermal management.

The primary objective of incorporating nichrome in battery thermal management is to achieve precise temperature control within battery systems. This involves maintaining optimal operating temperatures to enhance battery performance, extend lifespan, and ensure safety. By leveraging nichrome's controllable heat generation capabilities, researchers and engineers aim to develop more efficient and responsive thermal management systems that can adapt to varying environmental conditions and battery usage patterns.

Another key goal is to improve the overall energy efficiency of battery systems. Traditional thermal management solutions often rely on external cooling systems that can be energy-intensive and bulky. Nichrome-based solutions offer the potential for more integrated and energy-efficient thermal management, potentially reducing the parasitic energy losses associated with battery temperature control.

Safety is a paramount concern in battery technology, and nichrome innovations aim to address this by providing more reliable and precise temperature regulation. This is particularly crucial in preventing thermal runaway events, which can lead to catastrophic battery failures. The ability to quickly and uniformly distribute heat or absorb excess thermal energy could significantly enhance the safety profile of high-capacity battery systems.

As the demand for electric vehicles and renewable energy storage continues to grow, the development of advanced battery thermal management systems becomes increasingly important. Nichrome innovations in this field are expected to play a crucial role in enabling the next generation of high-performance, safe, and long-lasting battery technologies. The ongoing research and development in this area seek to push the boundaries of what is possible in energy storage and utilization, potentially revolutionizing multiple industries and contributing to a more sustainable energy future.

The progression of battery technology, particularly in electric vehicles and renewable energy storage systems, has brought thermal management to the forefront of research and development. As batteries become more powerful and energy-dense, the need for efficient heat dissipation and temperature control has become increasingly critical. This is where nichrome's unique properties have found a new purpose, offering innovative solutions to the complex challenges of battery thermal management.

The primary objective of incorporating nichrome in battery thermal management is to achieve precise temperature control within battery systems. This involves maintaining optimal operating temperatures to enhance battery performance, extend lifespan, and ensure safety. By leveraging nichrome's controllable heat generation capabilities, researchers and engineers aim to develop more efficient and responsive thermal management systems that can adapt to varying environmental conditions and battery usage patterns.

Another key goal is to improve the overall energy efficiency of battery systems. Traditional thermal management solutions often rely on external cooling systems that can be energy-intensive and bulky. Nichrome-based solutions offer the potential for more integrated and energy-efficient thermal management, potentially reducing the parasitic energy losses associated with battery temperature control.

Safety is a paramount concern in battery technology, and nichrome innovations aim to address this by providing more reliable and precise temperature regulation. This is particularly crucial in preventing thermal runaway events, which can lead to catastrophic battery failures. The ability to quickly and uniformly distribute heat or absorb excess thermal energy could significantly enhance the safety profile of high-capacity battery systems.

As the demand for electric vehicles and renewable energy storage continues to grow, the development of advanced battery thermal management systems becomes increasingly important. Nichrome innovations in this field are expected to play a crucial role in enabling the next generation of high-performance, safe, and long-lasting battery technologies. The ongoing research and development in this area seek to push the boundaries of what is possible in energy storage and utilization, potentially revolutionizing multiple industries and contributing to a more sustainable energy future.

Market Analysis for Advanced Battery Thermal Solutions

The market for advanced battery thermal management solutions is experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry and the increasing demand for high-performance energy storage systems. As battery technology continues to evolve, the need for efficient thermal management solutions becomes paramount to ensure optimal performance, safety, and longevity of battery systems.

The global market for battery thermal management systems is projected to grow substantially over the next decade. This growth is primarily attributed to the rising adoption of electric vehicles, stringent regulations on vehicle emissions, and the push for sustainable energy solutions. The automotive sector remains the largest consumer of advanced battery thermal management systems, with electric and hybrid vehicles leading the demand.

In addition to the automotive industry, other sectors such as consumer electronics, renewable energy storage, and aerospace are also contributing to the market expansion. The increasing use of lithium-ion batteries in these applications necessitates sophisticated thermal management solutions to prevent overheating and ensure efficient operation.

Key market drivers include the need for improved battery performance, extended battery life, and enhanced safety features. As battery energy densities continue to increase, the challenge of managing heat generation becomes more critical. This has led to a growing demand for innovative thermal management solutions that can effectively dissipate heat and maintain optimal operating temperatures.

The market landscape is characterized by intense competition among established players and new entrants. Major automotive manufacturers and battery suppliers are investing heavily in research and development to gain a competitive edge. Collaborations between automotive OEMs, battery manufacturers, and thermal management solution providers are becoming more common, fostering innovation and accelerating market growth.

Geographically, Asia-Pacific dominates the market, with China leading in both production and consumption of battery thermal management systems. This is largely due to the country's robust EV market and supportive government policies. North America and Europe follow closely, driven by increasing EV adoption and stringent environmental regulations.

Emerging trends in the market include the development of advanced materials for thermal management, such as phase change materials and nanocomposites. These materials offer improved thermal conductivity and heat dissipation properties. Additionally, there is a growing focus on intelligent thermal management systems that utilize sensors and advanced algorithms to optimize battery performance in real-time.

The global market for battery thermal management systems is projected to grow substantially over the next decade. This growth is primarily attributed to the rising adoption of electric vehicles, stringent regulations on vehicle emissions, and the push for sustainable energy solutions. The automotive sector remains the largest consumer of advanced battery thermal management systems, with electric and hybrid vehicles leading the demand.

In addition to the automotive industry, other sectors such as consumer electronics, renewable energy storage, and aerospace are also contributing to the market expansion. The increasing use of lithium-ion batteries in these applications necessitates sophisticated thermal management solutions to prevent overheating and ensure efficient operation.

Key market drivers include the need for improved battery performance, extended battery life, and enhanced safety features. As battery energy densities continue to increase, the challenge of managing heat generation becomes more critical. This has led to a growing demand for innovative thermal management solutions that can effectively dissipate heat and maintain optimal operating temperatures.

The market landscape is characterized by intense competition among established players and new entrants. Major automotive manufacturers and battery suppliers are investing heavily in research and development to gain a competitive edge. Collaborations between automotive OEMs, battery manufacturers, and thermal management solution providers are becoming more common, fostering innovation and accelerating market growth.

Geographically, Asia-Pacific dominates the market, with China leading in both production and consumption of battery thermal management systems. This is largely due to the country's robust EV market and supportive government policies. North America and Europe follow closely, driven by increasing EV adoption and stringent environmental regulations.

Emerging trends in the market include the development of advanced materials for thermal management, such as phase change materials and nanocomposites. These materials offer improved thermal conductivity and heat dissipation properties. Additionally, there is a growing focus on intelligent thermal management systems that utilize sensors and advanced algorithms to optimize battery performance in real-time.

Current Challenges in Nichrome-based Thermal Management

Despite the widespread adoption of nichrome in battery thermal management systems, several challenges persist in optimizing its performance and efficiency. One of the primary issues is the non-uniform heating distribution across the battery pack. Nichrome wire-based heating elements often create localized hot spots, leading to temperature gradients within the battery cells. This uneven heating can result in reduced battery life and potentially compromise safety.

Another significant challenge is the power consumption of nichrome-based heating systems. As batteries in electric vehicles (EVs) become larger to increase range, the energy required for thermal management also increases. This power draw can negatively impact the overall efficiency and range of EVs, especially in cold weather conditions where heating is most needed.

The durability and longevity of nichrome heating elements in harsh automotive environments pose additional concerns. Repeated thermal cycling, exposure to vibrations, and potential chemical interactions with battery components can lead to degradation of the nichrome wire over time. This degradation may result in reduced heating efficiency or even failure of the thermal management system.

Control and responsiveness of nichrome-based systems present another set of challenges. The thermal inertia of nichrome wire can lead to slower response times in adjusting battery temperature, particularly when rapid heating or cooling is required. This lag in temperature control can impact battery performance and charging speeds, especially in fast-charging scenarios.

Integration complexity is a further hurdle in nichrome-based thermal management. Designing an effective and compact heating system that can be seamlessly incorporated into various battery pack geometries while ensuring uniform heat distribution remains a significant engineering challenge. This complexity often leads to increased manufacturing costs and potential reliability issues.

Lastly, the environmental impact and recyclability of nichrome-based systems are growing concerns. As the automotive industry shifts towards more sustainable practices, the end-of-life disposal and recycling of nichrome heating elements integrated into battery packs become important considerations. Developing eco-friendly alternatives or improving the recyclability of nichrome-based systems is crucial for long-term sustainability.

Addressing these challenges requires innovative approaches in material science, thermal engineering, and system design. Researchers and engineers are exploring advanced control algorithms, novel materials with better thermal properties, and hybrid heating solutions to overcome the limitations of current nichrome-based thermal management systems in batteries.

Another significant challenge is the power consumption of nichrome-based heating systems. As batteries in electric vehicles (EVs) become larger to increase range, the energy required for thermal management also increases. This power draw can negatively impact the overall efficiency and range of EVs, especially in cold weather conditions where heating is most needed.

The durability and longevity of nichrome heating elements in harsh automotive environments pose additional concerns. Repeated thermal cycling, exposure to vibrations, and potential chemical interactions with battery components can lead to degradation of the nichrome wire over time. This degradation may result in reduced heating efficiency or even failure of the thermal management system.

Control and responsiveness of nichrome-based systems present another set of challenges. The thermal inertia of nichrome wire can lead to slower response times in adjusting battery temperature, particularly when rapid heating or cooling is required. This lag in temperature control can impact battery performance and charging speeds, especially in fast-charging scenarios.

Integration complexity is a further hurdle in nichrome-based thermal management. Designing an effective and compact heating system that can be seamlessly incorporated into various battery pack geometries while ensuring uniform heat distribution remains a significant engineering challenge. This complexity often leads to increased manufacturing costs and potential reliability issues.

Lastly, the environmental impact and recyclability of nichrome-based systems are growing concerns. As the automotive industry shifts towards more sustainable practices, the end-of-life disposal and recycling of nichrome heating elements integrated into battery packs become important considerations. Developing eco-friendly alternatives or improving the recyclability of nichrome-based systems is crucial for long-term sustainability.

Addressing these challenges requires innovative approaches in material science, thermal engineering, and system design. Researchers and engineers are exploring advanced control algorithms, novel materials with better thermal properties, and hybrid heating solutions to overcome the limitations of current nichrome-based thermal management systems in batteries.

Existing Nichrome Solutions for Battery Thermal Control

01 Nichrome heating elements in electronic devices

Nichrome is used as a heating element in various electronic devices due to its high electrical resistance and heat-generating properties. These elements are designed to manage thermal output efficiently, providing controlled heating for applications such as vaporizers, e-cigarettes, and other portable electronic devices.- Nichrome heating elements in electronic devices: Nichrome is used as a heating element in various electronic devices due to its high resistance and heat-generating properties. These elements are designed to manage thermal output efficiently, providing controlled heating for applications such as vaporizers, e-cigarettes, and other portable electronic devices.

- Thermal management systems for batteries: Nichrome-based heating elements are integrated into thermal management systems for batteries, particularly in electric vehicles. These systems help maintain optimal battery temperature, improving performance and longevity. The heating elements can be precisely controlled to provide uniform heat distribution across battery packs.

- Nichrome in semiconductor manufacturing: Nichrome is utilized in semiconductor manufacturing processes for thermal management. It is employed in heating elements for wafer processing, annealing, and other temperature-sensitive operations. The precise control of nichrome heating elements allows for accurate temperature regulation in semiconductor fabrication equipment.

- Nichrome-based temperature sensors: Nichrome alloys are used in the development of temperature sensors due to their stable resistance-temperature characteristics. These sensors are employed in various thermal management applications, providing accurate temperature readings for feedback control systems in industrial and consumer electronics.

- Thermal management in aerospace applications: Nichrome is employed in thermal management systems for aerospace applications. It is used in heating elements for de-icing systems, cabin temperature control, and other critical thermal regulation functions in aircraft and spacecraft. The reliability and performance of nichrome under extreme conditions make it suitable for these demanding applications.

02 Thermal management systems for batteries

Nichrome-based heating elements are incorporated into thermal management systems for batteries, particularly in electric vehicles. These systems help maintain optimal battery temperature, improving performance and longevity. The heating elements can be precisely controlled to provide uniform heat distribution across battery packs.Expand Specific Solutions03 Temperature control in semiconductor manufacturing

Nichrome is utilized in temperature control systems for semiconductor manufacturing processes. The material's properties allow for precise temperature regulation in various stages of chip production, including wafer processing and thermal annealing. This contributes to improved yield and quality in semiconductor fabrication.Expand Specific Solutions04 Nichrome-based sensors for thermal monitoring

Nichrome is employed in the development of thermal sensors for monitoring and controlling temperature in various applications. These sensors leverage the material's temperature-dependent resistance to provide accurate temperature readings and feedback for thermal management systems in industrial and consumer electronics.Expand Specific Solutions05 Energy-efficient heating solutions

Nichrome is used in the design of energy-efficient heating solutions for appliances and industrial equipment. The material's properties allow for rapid heat generation with minimal energy input, making it suitable for applications where quick temperature changes and precise control are required, such as in advanced cooking appliances or industrial processes.Expand Specific Solutions

Key Players in Nichrome and Battery Thermal Management

The competitive landscape for nichrome innovations in battery thermal management is evolving rapidly, reflecting the industry's early growth stage. The market is expanding due to increasing demand for efficient thermal management in electric vehicles and energy storage systems. While the technology is still maturing, several key players are emerging. Companies like Caterpillar, GM Global Technology Operations, and Boeing are leveraging their extensive R&D capabilities to develop advanced nichrome-based solutions. Specialized firms such as SGL Carbon and Schneider Electric are focusing on niche applications, while academic institutions like South China University of Technology and Tianjin University are contributing to fundamental research. The involvement of diverse players indicates a highly competitive and innovation-driven market with significant growth potential.

GM Global Technology Operations LLC

Technical Solution: GM has developed a novel nichrome-based battery thermal management system that focuses on rapid warm-up and maintaining optimal operating temperatures. Their technology employs a multi-layer approach, with nichrome heating elements strategically placed between battery cells and integrated into the battery pack structure[7]. This design allows for targeted heating of specific areas within the battery, optimizing energy use and reducing warm-up times. GM's system also incorporates a smart control unit that uses machine learning algorithms to predict heating needs based on driving patterns, weather conditions, and battery state of charge[8]. Additionally, the nichrome elements are designed with a variable resistance profile, allowing for more precise temperature control and reduced energy consumption during steady-state operation[9].

Strengths: Targeted heating capabilities, intelligent predictive control, energy-efficient operation. Weaknesses: Increased manufacturing complexity, potential for higher costs in mass production.

Gentherm, Inc.

Technical Solution: Gentherm has developed advanced nichrome-based heating solutions for battery thermal management. Their technology utilizes thin-film nichrome elements integrated directly into battery modules, providing precise and efficient heating. The system employs a closed-loop control algorithm that adjusts heating based on real-time temperature sensors, ensuring optimal battery performance across various operating conditions[1]. Gentherm's solution also incorporates a proprietary coating on the nichrome elements, enhancing durability and thermal conductivity while reducing electrical resistance[2]. This innovation allows for faster warm-up times and more uniform heat distribution, crucial for extending battery life and maintaining performance in cold climates[3].

Strengths: Precise temperature control, energy-efficient heating, improved battery performance in cold conditions. Weaknesses: Potentially higher initial cost, complexity in integration with existing battery designs.

Innovative Nichrome Applications in Battery Systems

Battery thermal management system

PatentInactiveEP4060793A3

Innovation

- Self-regulating heating system using a special polymer material containing carbon particles for automatic temperature control of battery modules.

- Direct placement of the heating system inside the battery module for maximum heat control and efficiency.

- Lightweight and efficient design that minimizes heat loss and overall system weight.

Battery with temperature control

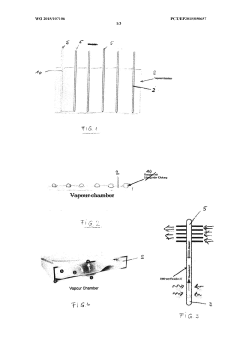

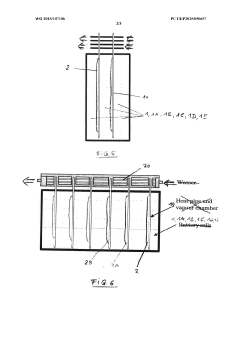

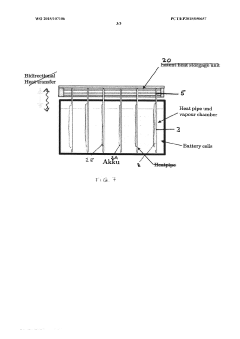

PatentWO2015107106A1

Innovation

- A battery arrangement featuring a vapor chamber in direct contact with battery cells and heat pipes connected to a heat exchanger, utilizing latent heat accumulators and phase change materials to rapidly absorb and dissipate heat, ensuring efficient temperature control and preventing overheating.

Environmental Impact of Nichrome in Battery Systems

The environmental impact of nichrome in battery thermal management systems is a crucial consideration as the demand for electric vehicles and energy storage solutions continues to grow. Nichrome, an alloy of nickel and chromium, offers excellent thermal properties but also raises concerns about its ecological footprint throughout its lifecycle.

The production of nichrome involves mining and processing nickel and chromium, which can lead to significant environmental disturbances. Open-pit mining for these metals often results in habitat destruction, soil erosion, and water pollution. The refining process is energy-intensive, contributing to greenhouse gas emissions and air pollution. However, the long lifespan and recyclability of nichrome partially offset these initial environmental costs.

In battery thermal management applications, nichrome's durability and resistance to corrosion contribute to extended system lifespans, reducing the frequency of replacements and associated waste. This longevity helps mitigate the environmental impact of manufacturing and disposal processes. Additionally, the efficient heat distribution provided by nichrome can improve overall battery performance and lifespan, potentially reducing the need for battery replacements and the associated environmental burden.

The use of nichrome in battery systems also presents challenges in terms of end-of-life management. While the alloy is recyclable, the complex nature of battery thermal management systems can make separation and recovery of nichrome components difficult. Improper disposal of these systems can lead to soil and water contamination, as nickel and chromium compounds can be toxic to ecosystems.

Efforts to minimize the environmental impact of nichrome in battery systems include developing more efficient recycling techniques, exploring alternative materials with similar thermal properties but lower environmental footprints, and optimizing nichrome usage to reduce the overall amount required in thermal management systems. Some researchers are investigating bio-based or nano-engineered materials as potential substitutes for nichrome, aiming to maintain thermal performance while reducing environmental impact.

The regulatory landscape surrounding the use of nichrome and other potentially hazardous materials in battery systems is evolving. Stricter regulations on material sourcing, manufacturing processes, and end-of-life management are being implemented in various regions, driving innovation in more sustainable thermal management solutions. This regulatory pressure, combined with growing consumer awareness of environmental issues, is likely to shape the future development and application of nichrome in battery thermal management systems.

The production of nichrome involves mining and processing nickel and chromium, which can lead to significant environmental disturbances. Open-pit mining for these metals often results in habitat destruction, soil erosion, and water pollution. The refining process is energy-intensive, contributing to greenhouse gas emissions and air pollution. However, the long lifespan and recyclability of nichrome partially offset these initial environmental costs.

In battery thermal management applications, nichrome's durability and resistance to corrosion contribute to extended system lifespans, reducing the frequency of replacements and associated waste. This longevity helps mitigate the environmental impact of manufacturing and disposal processes. Additionally, the efficient heat distribution provided by nichrome can improve overall battery performance and lifespan, potentially reducing the need for battery replacements and the associated environmental burden.

The use of nichrome in battery systems also presents challenges in terms of end-of-life management. While the alloy is recyclable, the complex nature of battery thermal management systems can make separation and recovery of nichrome components difficult. Improper disposal of these systems can lead to soil and water contamination, as nickel and chromium compounds can be toxic to ecosystems.

Efforts to minimize the environmental impact of nichrome in battery systems include developing more efficient recycling techniques, exploring alternative materials with similar thermal properties but lower environmental footprints, and optimizing nichrome usage to reduce the overall amount required in thermal management systems. Some researchers are investigating bio-based or nano-engineered materials as potential substitutes for nichrome, aiming to maintain thermal performance while reducing environmental impact.

The regulatory landscape surrounding the use of nichrome and other potentially hazardous materials in battery systems is evolving. Stricter regulations on material sourcing, manufacturing processes, and end-of-life management are being implemented in various regions, driving innovation in more sustainable thermal management solutions. This regulatory pressure, combined with growing consumer awareness of environmental issues, is likely to shape the future development and application of nichrome in battery thermal management systems.

Safety Regulations for Battery Thermal Management Technologies

Safety regulations for battery thermal management technologies have become increasingly stringent as the adoption of electric vehicles and energy storage systems continues to grow. These regulations aim to ensure the safe operation of batteries under various conditions, including extreme temperatures, charging and discharging cycles, and potential impact scenarios.

The primary focus of safety regulations in this field is to prevent thermal runaway, a catastrophic event where the battery's temperature rises uncontrollably, potentially leading to fire or explosion. To address this concern, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's Battery Directive have established comprehensive guidelines for battery thermal management systems.

These regulations typically require manufacturers to implement robust thermal management solutions that can effectively dissipate heat and maintain optimal operating temperatures. This includes the use of advanced cooling systems, such as liquid cooling or phase-change materials, as well as sophisticated temperature monitoring and control mechanisms.

Additionally, safety standards often mandate the incorporation of thermal insulation and fire-resistant materials in battery pack designs to contain potential thermal events and prevent their spread to adjacent cells or modules. The regulations also emphasize the importance of fail-safe mechanisms that can quickly isolate affected battery components in case of a thermal incident.

Furthermore, safety regulations extend to the testing and certification processes for battery thermal management systems. Manufacturers are required to conduct extensive thermal abuse tests, including nail penetration, crush tests, and overcharging simulations, to demonstrate the resilience of their thermal management solutions under extreme conditions.

The evolving nature of battery technology has led to ongoing updates in safety regulations. For instance, recent amendments have addressed the specific challenges posed by high-energy-density batteries, such as those using nickel-rich cathodes or solid-state electrolytes. These updates often include more stringent temperature control requirements and enhanced fire suppression capabilities.

Compliance with these safety regulations is crucial for manufacturers, as it not only ensures the safety of end-users but also plays a significant role in product liability and market acceptance. As such, companies investing in nichrome innovations for battery thermal management must carefully consider these regulatory requirements throughout their research and development process to ensure their solutions meet or exceed the established safety standards.

The primary focus of safety regulations in this field is to prevent thermal runaway, a catastrophic event where the battery's temperature rises uncontrollably, potentially leading to fire or explosion. To address this concern, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's Battery Directive have established comprehensive guidelines for battery thermal management systems.

These regulations typically require manufacturers to implement robust thermal management solutions that can effectively dissipate heat and maintain optimal operating temperatures. This includes the use of advanced cooling systems, such as liquid cooling or phase-change materials, as well as sophisticated temperature monitoring and control mechanisms.

Additionally, safety standards often mandate the incorporation of thermal insulation and fire-resistant materials in battery pack designs to contain potential thermal events and prevent their spread to adjacent cells or modules. The regulations also emphasize the importance of fail-safe mechanisms that can quickly isolate affected battery components in case of a thermal incident.

Furthermore, safety regulations extend to the testing and certification processes for battery thermal management systems. Manufacturers are required to conduct extensive thermal abuse tests, including nail penetration, crush tests, and overcharging simulations, to demonstrate the resilience of their thermal management solutions under extreme conditions.

The evolving nature of battery technology has led to ongoing updates in safety regulations. For instance, recent amendments have addressed the specific challenges posed by high-energy-density batteries, such as those using nickel-rich cathodes or solid-state electrolytes. These updates often include more stringent temperature control requirements and enhanced fire suppression capabilities.

Compliance with these safety regulations is crucial for manufacturers, as it not only ensures the safety of end-users but also plays a significant role in product liability and market acceptance. As such, companies investing in nichrome innovations for battery thermal management must carefully consider these regulatory requirements throughout their research and development process to ensure their solutions meet or exceed the established safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!