Hypochlorous Acid's Role in Emerging Pharmaceutical Applications

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl in Pharma: Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising compound in the pharmaceutical industry, with its potential applications spanning various therapeutic areas. This naturally occurring molecule, produced by the human immune system, has garnered significant attention due to its potent antimicrobial properties and low toxicity profile. The evolution of HOCl in pharmaceutical applications can be traced back to its initial use as a disinfectant and wound care agent.

Over the past decade, researchers and pharmaceutical companies have been exploring the broader potential of HOCl beyond its traditional applications. The growing interest in HOCl stems from its unique chemical properties, which allow it to effectively combat pathogens while remaining gentle on human tissues. This dual characteristic has opened up new avenues for its use in various pharmaceutical formulations and delivery systems.

The technological progression in HOCl production and stabilization has been a key driver in its pharmaceutical adoption. Early challenges in maintaining the stability of HOCl solutions have been largely overcome through advanced manufacturing processes and formulation techniques. These advancements have paved the way for the development of HOCl-based products with extended shelf life and improved efficacy.

Current research objectives in the field of HOCl pharmaceuticals are multifaceted. One primary goal is to expand the therapeutic applications of HOCl beyond topical treatments. Investigators are exploring its potential in respiratory therapies, ophthalmic solutions, and even systemic applications. Another key objective is to enhance the delivery mechanisms of HOCl to improve its bioavailability and targeted action within the body.

The pharmaceutical industry is also focusing on understanding the molecular mechanisms by which HOCl exerts its therapeutic effects. This includes investigating its role in modulating inflammation, promoting wound healing, and interacting with various cellular pathways. Such insights are crucial for developing novel HOCl-based drugs and optimizing existing formulations.

As the field progresses, there is a growing emphasis on combining HOCl with other active pharmaceutical ingredients to create synergistic effects. This approach aims to develop more effective and versatile treatment options for a range of medical conditions. Additionally, researchers are exploring the potential of HOCl in addressing antibiotic resistance, a critical global health concern.

The overarching goal of HOCl research in pharmaceuticals is to harness its natural antimicrobial and healing properties to create safer, more effective treatments. As the technology evolves, the industry anticipates a new generation of HOCl-based pharmaceuticals that could revolutionize approaches to infection control, wound management, and beyond.

Over the past decade, researchers and pharmaceutical companies have been exploring the broader potential of HOCl beyond its traditional applications. The growing interest in HOCl stems from its unique chemical properties, which allow it to effectively combat pathogens while remaining gentle on human tissues. This dual characteristic has opened up new avenues for its use in various pharmaceutical formulations and delivery systems.

The technological progression in HOCl production and stabilization has been a key driver in its pharmaceutical adoption. Early challenges in maintaining the stability of HOCl solutions have been largely overcome through advanced manufacturing processes and formulation techniques. These advancements have paved the way for the development of HOCl-based products with extended shelf life and improved efficacy.

Current research objectives in the field of HOCl pharmaceuticals are multifaceted. One primary goal is to expand the therapeutic applications of HOCl beyond topical treatments. Investigators are exploring its potential in respiratory therapies, ophthalmic solutions, and even systemic applications. Another key objective is to enhance the delivery mechanisms of HOCl to improve its bioavailability and targeted action within the body.

The pharmaceutical industry is also focusing on understanding the molecular mechanisms by which HOCl exerts its therapeutic effects. This includes investigating its role in modulating inflammation, promoting wound healing, and interacting with various cellular pathways. Such insights are crucial for developing novel HOCl-based drugs and optimizing existing formulations.

As the field progresses, there is a growing emphasis on combining HOCl with other active pharmaceutical ingredients to create synergistic effects. This approach aims to develop more effective and versatile treatment options for a range of medical conditions. Additionally, researchers are exploring the potential of HOCl in addressing antibiotic resistance, a critical global health concern.

The overarching goal of HOCl research in pharmaceuticals is to harness its natural antimicrobial and healing properties to create safer, more effective treatments. As the technology evolves, the industry anticipates a new generation of HOCl-based pharmaceuticals that could revolutionize approaches to infection control, wound management, and beyond.

Market Demand Analysis for HOCl-Based Pharmaceuticals

The market demand for Hypochlorous Acid (HOCl) based pharmaceuticals has been steadily growing, driven by its unique properties and versatile applications in healthcare. HOCl, a naturally occurring molecule produced by the human immune system, has gained significant attention in the pharmaceutical industry due to its potent antimicrobial properties and low toxicity profile.

In recent years, there has been a notable increase in research and development activities focused on HOCl-based pharmaceutical products. This surge in interest is primarily attributed to the growing awareness of antibiotic resistance and the need for alternative antimicrobial agents. The global market for HOCl-based pharmaceuticals is expected to experience substantial growth in the coming years, with applications spanning wound care, oral care, eye care, and respiratory treatments.

The wound care segment represents a particularly promising market for HOCl-based products. With the rising incidence of chronic wounds, diabetic ulcers, and surgical site infections, there is a growing demand for effective and safe antimicrobial solutions. HOCl-based wound care products have demonstrated excellent efficacy in promoting wound healing and preventing infections, positioning them as valuable alternatives to traditional antiseptics and antibiotics.

In the oral care market, HOCl-based mouthwashes and dental rinses are gaining traction due to their ability to effectively combat oral pathogens without causing irritation or staining. The increasing prevalence of periodontal diseases and the growing emphasis on oral hygiene are driving the demand for these products.

The ophthalmic sector also presents significant opportunities for HOCl-based pharmaceuticals. With the rising incidence of eye infections and the need for preservative-free eye care solutions, HOCl-based eye drops and contact lens disinfectants are attracting considerable attention from both healthcare professionals and patients.

Furthermore, the ongoing COVID-19 pandemic has heightened interest in HOCl-based products for respiratory care and surface disinfection. The potential of HOCl in reducing viral load and its safety profile make it an attractive option for developing nasal sprays and inhalation solutions for respiratory infections.

Market analysts predict that the global HOCl-based pharmaceutical market will continue to expand at a robust rate in the coming years. This growth is supported by increasing investments in research and development, growing awareness among healthcare providers, and the shift towards natural and safe antimicrobial solutions. Additionally, the regulatory landscape is becoming more favorable for HOCl-based products, with several regulatory agencies recognizing their safety and efficacy.

In recent years, there has been a notable increase in research and development activities focused on HOCl-based pharmaceutical products. This surge in interest is primarily attributed to the growing awareness of antibiotic resistance and the need for alternative antimicrobial agents. The global market for HOCl-based pharmaceuticals is expected to experience substantial growth in the coming years, with applications spanning wound care, oral care, eye care, and respiratory treatments.

The wound care segment represents a particularly promising market for HOCl-based products. With the rising incidence of chronic wounds, diabetic ulcers, and surgical site infections, there is a growing demand for effective and safe antimicrobial solutions. HOCl-based wound care products have demonstrated excellent efficacy in promoting wound healing and preventing infections, positioning them as valuable alternatives to traditional antiseptics and antibiotics.

In the oral care market, HOCl-based mouthwashes and dental rinses are gaining traction due to their ability to effectively combat oral pathogens without causing irritation or staining. The increasing prevalence of periodontal diseases and the growing emphasis on oral hygiene are driving the demand for these products.

The ophthalmic sector also presents significant opportunities for HOCl-based pharmaceuticals. With the rising incidence of eye infections and the need for preservative-free eye care solutions, HOCl-based eye drops and contact lens disinfectants are attracting considerable attention from both healthcare professionals and patients.

Furthermore, the ongoing COVID-19 pandemic has heightened interest in HOCl-based products for respiratory care and surface disinfection. The potential of HOCl in reducing viral load and its safety profile make it an attractive option for developing nasal sprays and inhalation solutions for respiratory infections.

Market analysts predict that the global HOCl-based pharmaceutical market will continue to expand at a robust rate in the coming years. This growth is supported by increasing investments in research and development, growing awareness among healthcare providers, and the shift towards natural and safe antimicrobial solutions. Additionally, the regulatory landscape is becoming more favorable for HOCl-based products, with several regulatory agencies recognizing their safety and efficacy.

Current State and Challenges in HOCl Pharmaceutical Applications

Hypochlorous acid (HOCl) has gained significant attention in pharmaceutical applications due to its potent antimicrobial properties and biocompatibility. The current state of HOCl in pharmaceuticals is characterized by a growing body of research and an increasing number of clinical applications, particularly in wound care, dermatology, and oral health.

In wound care, HOCl has shown promising results in promoting healing and preventing infections. Several studies have demonstrated its efficacy in reducing bacterial load and accelerating wound closure. However, challenges remain in maintaining the stability of HOCl solutions over extended periods, which can limit shelf life and practical applications in clinical settings.

Dermatological applications of HOCl have expanded rapidly, with products targeting conditions such as acne, atopic dermatitis, and fungal infections. The non-irritating nature of HOCl at appropriate concentrations makes it an attractive option for sensitive skin conditions. Nevertheless, formulation challenges persist in creating stable, long-lasting products that maintain HOCl's efficacy throughout their shelf life.

In oral health, HOCl-based mouthwashes and dental rinses have emerged as alternatives to traditional chlorhexidine products. These formulations offer broad-spectrum antimicrobial activity without the side effects associated with long-term chlorhexidine use. However, taste and sensory acceptance by patients remain areas for improvement.

One of the primary challenges in HOCl pharmaceutical applications is the development of standardized production methods that ensure consistent quality and concentration. The reactive nature of HOCl necessitates careful handling and packaging to prevent degradation and maintain efficacy. Researchers are actively exploring stabilization techniques and novel delivery systems to address these issues.

Regulatory considerations pose another significant challenge. As HOCl straddles the line between a pharmaceutical ingredient and a medical device, navigating regulatory pathways can be complex. Manufacturers must work closely with regulatory bodies to establish appropriate classification and approval processes for HOCl-based products.

The scalability of HOCl production for pharmaceutical use presents both opportunities and challenges. While electrochemical generation methods offer on-site production capabilities, ensuring consistent quality and concentration at scale requires sophisticated monitoring and control systems. Additionally, the cost-effectiveness of large-scale HOCl production compared to traditional antimicrobial agents is an ongoing area of investigation.

Despite these challenges, the pharmaceutical industry continues to invest in HOCl research and development. Emerging applications in respiratory care, particularly in light of recent global health challenges, highlight the potential for HOCl in addressing unmet medical needs. As technology advances and our understanding of HOCl's mechanisms of action deepens, new opportunities for innovative pharmaceutical applications are likely to emerge.

In wound care, HOCl has shown promising results in promoting healing and preventing infections. Several studies have demonstrated its efficacy in reducing bacterial load and accelerating wound closure. However, challenges remain in maintaining the stability of HOCl solutions over extended periods, which can limit shelf life and practical applications in clinical settings.

Dermatological applications of HOCl have expanded rapidly, with products targeting conditions such as acne, atopic dermatitis, and fungal infections. The non-irritating nature of HOCl at appropriate concentrations makes it an attractive option for sensitive skin conditions. Nevertheless, formulation challenges persist in creating stable, long-lasting products that maintain HOCl's efficacy throughout their shelf life.

In oral health, HOCl-based mouthwashes and dental rinses have emerged as alternatives to traditional chlorhexidine products. These formulations offer broad-spectrum antimicrobial activity without the side effects associated with long-term chlorhexidine use. However, taste and sensory acceptance by patients remain areas for improvement.

One of the primary challenges in HOCl pharmaceutical applications is the development of standardized production methods that ensure consistent quality and concentration. The reactive nature of HOCl necessitates careful handling and packaging to prevent degradation and maintain efficacy. Researchers are actively exploring stabilization techniques and novel delivery systems to address these issues.

Regulatory considerations pose another significant challenge. As HOCl straddles the line between a pharmaceutical ingredient and a medical device, navigating regulatory pathways can be complex. Manufacturers must work closely with regulatory bodies to establish appropriate classification and approval processes for HOCl-based products.

The scalability of HOCl production for pharmaceutical use presents both opportunities and challenges. While electrochemical generation methods offer on-site production capabilities, ensuring consistent quality and concentration at scale requires sophisticated monitoring and control systems. Additionally, the cost-effectiveness of large-scale HOCl production compared to traditional antimicrobial agents is an ongoing area of investigation.

Despite these challenges, the pharmaceutical industry continues to invest in HOCl research and development. Emerging applications in respiratory care, particularly in light of recent global health challenges, highlight the potential for HOCl in addressing unmet medical needs. As technology advances and our understanding of HOCl's mechanisms of action deepens, new opportunities for innovative pharmaceutical applications are likely to emerge.

Existing HOCl Pharmaceutical Formulations and Delivery Methods

01 Production methods of hypochlorous acid

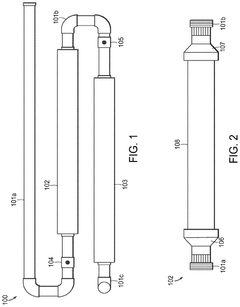

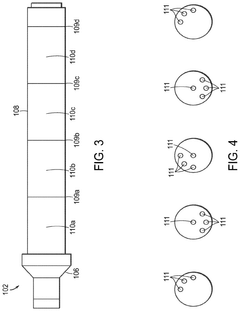

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and the use of specialized equipment for on-site generation. These methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization techniques for hypochlorous acid solutions: Stabilization of hypochlorous acid solutions is crucial for maintaining their efficacy over time. Various techniques are employed, such as pH adjustment, addition of stabilizing agents, and specialized packaging methods, to extend the shelf life and preserve the antimicrobial properties of hypochlorous acid products.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental and industrial settings for purposes such as water treatment, air purification, and surface disinfection. Its eco-friendly nature and broad-spectrum antimicrobial activity make it a preferred choice for various large-scale applications.

02 Applications in disinfection and sterilization

Hypochlorous acid is widely used as a powerful disinfectant and sterilizing agent. It is effective against a broad spectrum of pathogens, including bacteria, viruses, and fungi. Applications include water treatment, surface disinfection, and medical sterilization, with its efficacy and safety making it suitable for various environments.Expand Specific Solutions03 Formulations and stability enhancement

Research focuses on developing stable formulations of hypochlorous acid to extend its shelf life and maintain its effectiveness. This includes the use of specific additives, pH adjustments, and packaging innovations to prevent degradation and ensure consistent potency over time.Expand Specific Solutions04 Medical and therapeutic applications

Hypochlorous acid is being explored for various medical and therapeutic uses due to its antimicrobial properties and low toxicity. Applications include wound care, eye care, respiratory treatments, and dermatological therapies. Research is ongoing to develop new medical products and treatments utilizing hypochlorous acid.Expand Specific Solutions05 Environmental and industrial uses

Hypochlorous acid finds applications in environmental remediation and industrial processes. It is used in water treatment, air purification, and as a cleaning agent in various industries. Its eco-friendly nature and effectiveness make it a preferred choice for sustainable cleaning and disinfection solutions in industrial settings.Expand Specific Solutions

Key Players in HOCl Pharmaceutical Development

The competitive landscape for Hypochlorous Acid in emerging pharmaceutical applications is evolving rapidly. The industry is in a growth phase, with increasing market size driven by rising awareness of its antimicrobial properties and potential medical uses. The technology is maturing, but still offers significant room for innovation. Key players like Annihilare Medical Systems, Industrie De Nora, and Realm Therapeutics are advancing research and development in this field. Academic institutions such as Hunan University of Science & Technology and Qilu University of Technology are also contributing to technological advancements. The market is characterized by a mix of established companies and emerging startups, indicating a dynamic and competitive environment with potential for further growth and technological breakthroughs.

ANNIHILARE MEDICAL SYSTEMS, INC.

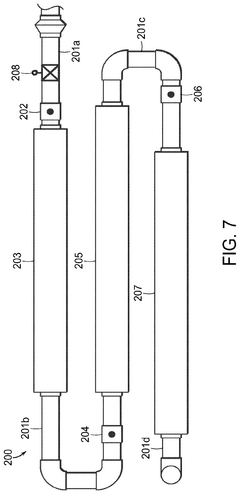

Technical Solution: Annihilare Medical Systems has developed an advanced HOCl generation system for on-site production of hypochlorous acid solutions. Their technology utilizes a patented electrolysis process that creates a highly pure and stable HOCl solution with a neutral pH[4]. The company's focus is on providing HOCl solutions for healthcare facilities, emphasizing infection control and wound care applications. Annihilare's system produces HOCl at concentrations ranging from 200-500 ppm, which has been shown to be effective against a wide range of pathogens, including antibiotic-resistant bacteria[5]. Their approach includes a proprietary monitoring system that ensures consistent HOCl production and quality control, addressing the stability issues often associated with HOCl solutions[6].

Strengths: On-site generation capability, consistent quality control, effective against antibiotic-resistant pathogens. Weaknesses: Requires specialized equipment for production, may have higher initial costs compared to pre-packaged solutions.

Integrated Healing Technologies LLC

Technical Solution: Integrated Healing Technologies has developed a proprietary HOCl formulation specifically targeted at advanced wound care applications. Their technology focuses on creating a stable, pH-balanced HOCl solution that promotes wound healing while providing effective antimicrobial action[10]. The company's approach involves a unique manufacturing process that ensures the purity and consistency of their HOCl products. Their formulation has been shown to effectively reduce biofilm formation in chronic wounds, a significant challenge in wound care management[11]. Integrated Healing Technologies' HOCl solutions are designed to be compatible with various wound dressings and delivery systems, enhancing their versatility in clinical settings[12].

Strengths: Specialized focus on wound care applications, effective against biofilms, compatibility with existing wound care products. Weaknesses: Limited scope beyond wound care, potential challenges in expanding to other pharmaceutical applications.

Core Innovations in HOCl Synthesis and Stabilization

Composition of hypochlorous acid and its applications

PatentWO2003028741A1

Innovation

- A composition of hypochlorous acid with a specific concentration of available chlorine, produced through a process involving aqueous solutions and chlorine gas, offering rapid disinfection and bactericidal action while being non-toxic and biodegradable.

Compositions of hypochlorous acid and methods of manufacture thereof

PatentActiveUS12115185B2

Innovation

- An air-free mixing method producing stable HOCl by combining a compound that generates protons (H+) with one that generates hypochlorite anions (OCl-) in water, without using chlorine gas or electrolysis, maintaining a controlled pH and using buffering agents to stabilize the product.

Regulatory Framework for HOCl-Based Pharmaceuticals

The regulatory framework for Hypochlorous Acid (HOCl)-based pharmaceuticals is a complex and evolving landscape that requires careful navigation by manufacturers and healthcare providers. As HOCl gains recognition for its potential in various pharmaceutical applications, regulatory bodies worldwide are adapting their guidelines to ensure the safety and efficacy of these products.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing HOCl-based pharmaceuticals. The FDA categorizes HOCl products based on their intended use, concentration, and manufacturing process. For instance, HOCl solutions used as topical antiseptics may be regulated as over-the-counter (OTC) drugs, while those intended for more advanced medical applications might require approval through the New Drug Application (NDA) process.

The European Medicines Agency (EMA) has also established guidelines for HOCl-based products within the European Union. These regulations often focus on the quality control of manufacturing processes, stability testing, and the demonstration of consistent HOCl concentrations in the final product. Manufacturers must adhere to Good Manufacturing Practice (GMP) standards and provide comprehensive documentation on their production methods.

In Asia, countries like Japan and South Korea have implemented their own regulatory frameworks for HOCl pharmaceuticals. The Japanese Pharmaceuticals and Medical Devices Agency (PMDA) has specific requirements for the registration and approval of HOCl-based products, particularly those used in wound care and disinfection.

One of the key challenges in regulating HOCl-based pharmaceuticals is the variability in production methods and resulting product characteristics. Regulatory bodies are increasingly requiring manufacturers to demonstrate the stability and consistency of their HOCl solutions, including pH levels, redox potential, and free available chlorine content.

Safety assessments for HOCl pharmaceuticals often focus on potential skin irritation, systemic toxicity, and environmental impact. Long-term stability studies are typically required to ensure that the product maintains its efficacy and safety profile throughout its shelf life.

As the pharmaceutical applications of HOCl continue to expand, regulatory frameworks are likely to evolve. There is a growing emphasis on harmonizing international standards to facilitate global market access for HOCl-based products. This may lead to more streamlined approval processes and consistent quality standards across different regions.

Manufacturers and researchers working with HOCl in pharmaceutical applications must stay informed about these regulatory developments and engage proactively with regulatory bodies. Early consultation and adherence to current good manufacturing practices (cGMP) are essential for successful product development and market approval in this emerging field.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing HOCl-based pharmaceuticals. The FDA categorizes HOCl products based on their intended use, concentration, and manufacturing process. For instance, HOCl solutions used as topical antiseptics may be regulated as over-the-counter (OTC) drugs, while those intended for more advanced medical applications might require approval through the New Drug Application (NDA) process.

The European Medicines Agency (EMA) has also established guidelines for HOCl-based products within the European Union. These regulations often focus on the quality control of manufacturing processes, stability testing, and the demonstration of consistent HOCl concentrations in the final product. Manufacturers must adhere to Good Manufacturing Practice (GMP) standards and provide comprehensive documentation on their production methods.

In Asia, countries like Japan and South Korea have implemented their own regulatory frameworks for HOCl pharmaceuticals. The Japanese Pharmaceuticals and Medical Devices Agency (PMDA) has specific requirements for the registration and approval of HOCl-based products, particularly those used in wound care and disinfection.

One of the key challenges in regulating HOCl-based pharmaceuticals is the variability in production methods and resulting product characteristics. Regulatory bodies are increasingly requiring manufacturers to demonstrate the stability and consistency of their HOCl solutions, including pH levels, redox potential, and free available chlorine content.

Safety assessments for HOCl pharmaceuticals often focus on potential skin irritation, systemic toxicity, and environmental impact. Long-term stability studies are typically required to ensure that the product maintains its efficacy and safety profile throughout its shelf life.

As the pharmaceutical applications of HOCl continue to expand, regulatory frameworks are likely to evolve. There is a growing emphasis on harmonizing international standards to facilitate global market access for HOCl-based products. This may lead to more streamlined approval processes and consistent quality standards across different regions.

Manufacturers and researchers working with HOCl in pharmaceutical applications must stay informed about these regulatory developments and engage proactively with regulatory bodies. Early consultation and adherence to current good manufacturing practices (cGMP) are essential for successful product development and market approval in this emerging field.

Environmental Impact of HOCl Production and Use

The production and use of hypochlorous acid (HOCl) in pharmaceutical applications have significant environmental implications that warrant careful consideration. The primary method of HOCl production involves the electrolysis of salt water, which requires electricity and salt as key inputs. While this process is relatively simple and can be performed on-site, it does consume energy and resources.

The energy consumption associated with HOCl production varies depending on the scale and efficiency of the electrolysis system. Large-scale industrial production tends to be more energy-efficient, but even small-scale on-site generation systems have become increasingly optimized. The environmental impact of this energy use depends largely on the local energy mix, with renewable energy sources significantly reducing the carbon footprint of HOCl production.

Salt consumption in HOCl production is another environmental factor to consider. While salt is an abundant resource, its extraction and transportation can have ecological consequences. However, the quantities required for HOCl production are relatively small compared to other industrial uses of salt.

One of the most significant environmental benefits of HOCl is its rapid degradation into harmless byproducts. Unlike many traditional disinfectants and pharmaceutical compounds, HOCl breaks down into water, oxygen, and sodium chloride, leaving no harmful residues in the environment. This characteristic makes HOCl an environmentally friendly alternative to more persistent chemicals.

In pharmaceutical applications, the use of HOCl can lead to reduced environmental contamination from drug residues. Many conventional pharmaceuticals persist in wastewater and can have detrimental effects on aquatic ecosystems. HOCl's ability to break down quickly minimizes this risk, potentially reducing the pharmaceutical industry's environmental footprint.

The production of HOCl also generates hydrogen gas as a byproduct. While this can be seen as a waste product, there is growing interest in capturing and utilizing this hydrogen for clean energy applications, further improving the overall environmental profile of HOCl production.

When considering the lifecycle environmental impact, HOCl compares favorably to many alternative disinfectants and pharmaceutical compounds. Its production requires fewer toxic chemicals and generates less hazardous waste. Additionally, the on-site generation capability of HOCl can reduce transportation-related emissions associated with the distribution of pre-made disinfectants.

However, it is important to note that improper disposal or overuse of HOCl solutions can lead to localized environmental issues, such as soil or water salinity increases. Proper training and protocols for HOCl use and disposal are essential to mitigate these potential negative impacts.

The energy consumption associated with HOCl production varies depending on the scale and efficiency of the electrolysis system. Large-scale industrial production tends to be more energy-efficient, but even small-scale on-site generation systems have become increasingly optimized. The environmental impact of this energy use depends largely on the local energy mix, with renewable energy sources significantly reducing the carbon footprint of HOCl production.

Salt consumption in HOCl production is another environmental factor to consider. While salt is an abundant resource, its extraction and transportation can have ecological consequences. However, the quantities required for HOCl production are relatively small compared to other industrial uses of salt.

One of the most significant environmental benefits of HOCl is its rapid degradation into harmless byproducts. Unlike many traditional disinfectants and pharmaceutical compounds, HOCl breaks down into water, oxygen, and sodium chloride, leaving no harmful residues in the environment. This characteristic makes HOCl an environmentally friendly alternative to more persistent chemicals.

In pharmaceutical applications, the use of HOCl can lead to reduced environmental contamination from drug residues. Many conventional pharmaceuticals persist in wastewater and can have detrimental effects on aquatic ecosystems. HOCl's ability to break down quickly minimizes this risk, potentially reducing the pharmaceutical industry's environmental footprint.

The production of HOCl also generates hydrogen gas as a byproduct. While this can be seen as a waste product, there is growing interest in capturing and utilizing this hydrogen for clean energy applications, further improving the overall environmental profile of HOCl production.

When considering the lifecycle environmental impact, HOCl compares favorably to many alternative disinfectants and pharmaceutical compounds. Its production requires fewer toxic chemicals and generates less hazardous waste. Additionally, the on-site generation capability of HOCl can reduce transportation-related emissions associated with the distribution of pre-made disinfectants.

However, it is important to note that improper disposal or overuse of HOCl solutions can lead to localized environmental issues, such as soil or water salinity increases. Proper training and protocols for HOCl use and disposal are essential to mitigate these potential negative impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!