Hypochlorous Acid R&D: Overcoming Formulation Challenges

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCI Background & Objectives

Hypochlorous acid (HOCl) has emerged as a powerful and versatile disinfectant with a rich history dating back to its discovery in the early 19th century. This naturally occurring compound, produced by the human immune system to fight infections, has gained significant attention in recent years due to its broad-spectrum antimicrobial properties and environmental friendliness.

The evolution of HOCl technology has been marked by continuous advancements in production methods, stability enhancement, and application techniques. Initially used primarily in industrial settings, HOCl has gradually found its way into healthcare, food safety, and consumer products. The growing demand for safe and effective disinfectants, particularly in the wake of global health crises, has further accelerated research and development efforts in this field.

Despite its numerous advantages, HOCl formulation faces several challenges that have hindered its widespread adoption. The primary obstacle lies in maintaining the stability of HOCl solutions over extended periods. The compound's reactive nature, while beneficial for its disinfecting properties, also leads to rapid degradation when exposed to light, heat, or organic matter. This instability has limited shelf life and necessitated on-site generation or frequent replenishment of HOCl solutions.

Another significant challenge is achieving consistent production of HOCl at specific concentrations and pH levels. The efficacy and safety of HOCl are highly dependent on these parameters, making precise control crucial for various applications. Additionally, the presence of contaminants or byproducts in HOCl solutions can affect their performance and safety profile, necessitating rigorous purification processes.

The objectives of current HOCl research and development efforts are multifaceted. Foremost among these is the development of stabilized HOCl formulations that maintain their potency over extended periods without compromising efficacy or safety. This involves exploring novel stabilizing agents, optimizing storage conditions, and investigating packaging solutions that minimize degradation.

Another key goal is to enhance the scalability and cost-effectiveness of HOCl production. This includes improving electrolysis techniques, developing more efficient reactors, and optimizing raw material utilization. Researchers are also focusing on creating versatile HOCl formulations that can be easily adapted for various applications, from medical-grade disinfectants to household cleaning products.

Furthermore, there is a growing emphasis on understanding the mechanisms of HOCl's antimicrobial action at a molecular level. This knowledge is crucial for optimizing its effectiveness against a wide range of pathogens, including antibiotic-resistant strains. It also aids in developing targeted formulations for specific use cases, such as wound care or food preservation.

The evolution of HOCl technology has been marked by continuous advancements in production methods, stability enhancement, and application techniques. Initially used primarily in industrial settings, HOCl has gradually found its way into healthcare, food safety, and consumer products. The growing demand for safe and effective disinfectants, particularly in the wake of global health crises, has further accelerated research and development efforts in this field.

Despite its numerous advantages, HOCl formulation faces several challenges that have hindered its widespread adoption. The primary obstacle lies in maintaining the stability of HOCl solutions over extended periods. The compound's reactive nature, while beneficial for its disinfecting properties, also leads to rapid degradation when exposed to light, heat, or organic matter. This instability has limited shelf life and necessitated on-site generation or frequent replenishment of HOCl solutions.

Another significant challenge is achieving consistent production of HOCl at specific concentrations and pH levels. The efficacy and safety of HOCl are highly dependent on these parameters, making precise control crucial for various applications. Additionally, the presence of contaminants or byproducts in HOCl solutions can affect their performance and safety profile, necessitating rigorous purification processes.

The objectives of current HOCl research and development efforts are multifaceted. Foremost among these is the development of stabilized HOCl formulations that maintain their potency over extended periods without compromising efficacy or safety. This involves exploring novel stabilizing agents, optimizing storage conditions, and investigating packaging solutions that minimize degradation.

Another key goal is to enhance the scalability and cost-effectiveness of HOCl production. This includes improving electrolysis techniques, developing more efficient reactors, and optimizing raw material utilization. Researchers are also focusing on creating versatile HOCl formulations that can be easily adapted for various applications, from medical-grade disinfectants to household cleaning products.

Furthermore, there is a growing emphasis on understanding the mechanisms of HOCl's antimicrobial action at a molecular level. This knowledge is crucial for optimizing its effectiveness against a wide range of pathogens, including antibiotic-resistant strains. It also aids in developing targeted formulations for specific use cases, such as wound care or food preservation.

Market Analysis for HOCI Products

The global market for Hypochlorous Acid (HOCl) products has experienced significant growth in recent years, driven by increasing awareness of its effectiveness as a disinfectant and sanitizer. The COVID-19 pandemic has further accelerated this trend, with heightened focus on hygiene and infection control across various sectors.

In the healthcare industry, HOCl products have gained traction for wound care, sterilization, and general disinfection purposes. Hospitals, clinics, and long-term care facilities are adopting HOCl solutions as an alternative to traditional chemical disinfectants due to their non-toxic nature and broad-spectrum antimicrobial properties.

The food and beverage sector represents another key market for HOCl products. Food processing plants, restaurants, and packaging facilities are increasingly utilizing HOCl for sanitization of surfaces, equipment, and produce. The ability of HOCl to effectively eliminate pathogens without leaving harmful residues aligns well with food safety regulations and consumer preferences for clean-label products.

Water treatment applications have also emerged as a growing market segment for HOCl. Municipal water systems, swimming pools, and industrial water treatment facilities are exploring HOCl as an eco-friendly alternative to chlorine-based disinfectants. The reduced environmental impact and lower risk of harmful by-product formation make HOCl an attractive option in this sector.

The personal care and cosmetics industry has shown interest in HOCl formulations for skincare products, mouthwashes, and hand sanitizers. The gentle yet effective nature of HOCl appeals to consumers seeking natural and non-irritating antimicrobial solutions.

Geographically, North America and Europe currently lead the HOCl product market, with established regulatory frameworks and high adoption rates across various industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, rising healthcare expenditure, and growing awareness of hygiene practices.

Despite the positive market outlook, challenges remain in the widespread adoption of HOCl products. These include the need for improved stability in formulations, scalability of production processes, and education of end-users about the benefits and proper application of HOCl solutions. Overcoming these hurdles will be crucial for realizing the full market potential of HOCl products across diverse industries and geographical regions.

In the healthcare industry, HOCl products have gained traction for wound care, sterilization, and general disinfection purposes. Hospitals, clinics, and long-term care facilities are adopting HOCl solutions as an alternative to traditional chemical disinfectants due to their non-toxic nature and broad-spectrum antimicrobial properties.

The food and beverage sector represents another key market for HOCl products. Food processing plants, restaurants, and packaging facilities are increasingly utilizing HOCl for sanitization of surfaces, equipment, and produce. The ability of HOCl to effectively eliminate pathogens without leaving harmful residues aligns well with food safety regulations and consumer preferences for clean-label products.

Water treatment applications have also emerged as a growing market segment for HOCl. Municipal water systems, swimming pools, and industrial water treatment facilities are exploring HOCl as an eco-friendly alternative to chlorine-based disinfectants. The reduced environmental impact and lower risk of harmful by-product formation make HOCl an attractive option in this sector.

The personal care and cosmetics industry has shown interest in HOCl formulations for skincare products, mouthwashes, and hand sanitizers. The gentle yet effective nature of HOCl appeals to consumers seeking natural and non-irritating antimicrobial solutions.

Geographically, North America and Europe currently lead the HOCl product market, with established regulatory frameworks and high adoption rates across various industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, rising healthcare expenditure, and growing awareness of hygiene practices.

Despite the positive market outlook, challenges remain in the widespread adoption of HOCl products. These include the need for improved stability in formulations, scalability of production processes, and education of end-users about the benefits and proper application of HOCl solutions. Overcoming these hurdles will be crucial for realizing the full market potential of HOCl products across diverse industries and geographical regions.

HOCI Formulation Challenges

Hypochlorous acid (HOCl) formulation presents several significant challenges that researchers and manufacturers must overcome to develop stable and effective products. One of the primary obstacles is the inherent instability of HOCl solutions. The compound tends to decompose rapidly, especially when exposed to light, heat, or certain impurities. This instability not only reduces the shelf life of HOCl products but also compromises their efficacy over time.

Another major challenge lies in maintaining the optimal pH range for HOCl solutions. The effectiveness of HOCl is highly dependent on pH, with maximum antimicrobial activity occurring between pH 3.5 and 5.5. However, maintaining this narrow pH range during formulation and storage can be difficult, as even slight deviations can significantly impact the solution's stability and efficacy.

The concentration of HOCl in the formulation also poses a challenge. Higher concentrations may offer increased antimicrobial potency, but they can also lead to faster decomposition and reduced stability. Conversely, lower concentrations may improve stability but potentially sacrifice efficacy. Striking the right balance between concentration, stability, and effectiveness is a critical aspect of HOCl formulation.

Packaging and storage considerations further complicate the formulation process. HOCl solutions are sensitive to light and can react with certain packaging materials, potentially leading to degradation or contamination. Developing appropriate packaging that protects the solution from light exposure and prevents interactions with container materials is essential for maintaining product integrity.

The presence of impurities in the formulation can also significantly impact HOCl stability. Trace amounts of metals, organic compounds, or other contaminants can catalyze the decomposition of HOCl, reducing its shelf life and effectiveness. Ensuring high purity of raw materials and implementing stringent quality control measures throughout the manufacturing process are crucial steps in addressing this challenge.

Compatibility with other ingredients in multi-component formulations presents another hurdle. HOCl may react with or be inactivated by certain additives commonly used in personal care or medical products, such as preservatives, fragrances, or thickening agents. Developing formulations that incorporate HOCl while maintaining its stability and efficacy in the presence of other ingredients requires careful selection and testing of compatible components.

Another major challenge lies in maintaining the optimal pH range for HOCl solutions. The effectiveness of HOCl is highly dependent on pH, with maximum antimicrobial activity occurring between pH 3.5 and 5.5. However, maintaining this narrow pH range during formulation and storage can be difficult, as even slight deviations can significantly impact the solution's stability and efficacy.

The concentration of HOCl in the formulation also poses a challenge. Higher concentrations may offer increased antimicrobial potency, but they can also lead to faster decomposition and reduced stability. Conversely, lower concentrations may improve stability but potentially sacrifice efficacy. Striking the right balance between concentration, stability, and effectiveness is a critical aspect of HOCl formulation.

Packaging and storage considerations further complicate the formulation process. HOCl solutions are sensitive to light and can react with certain packaging materials, potentially leading to degradation or contamination. Developing appropriate packaging that protects the solution from light exposure and prevents interactions with container materials is essential for maintaining product integrity.

The presence of impurities in the formulation can also significantly impact HOCl stability. Trace amounts of metals, organic compounds, or other contaminants can catalyze the decomposition of HOCl, reducing its shelf life and effectiveness. Ensuring high purity of raw materials and implementing stringent quality control measures throughout the manufacturing process are crucial steps in addressing this challenge.

Compatibility with other ingredients in multi-component formulations presents another hurdle. HOCl may react with or be inactivated by certain additives commonly used in personal care or medical products, such as preservatives, fragrances, or thickening agents. Developing formulations that incorporate HOCl while maintaining its stability and efficacy in the presence of other ingredients requires careful selection and testing of compatible components.

Current HOCI Formulation Approaches

01 Stabilization of hypochlorous acid

Various methods are employed to stabilize hypochlorous acid in formulations, including pH adjustment, addition of buffer systems, and use of specific stabilizing agents. These techniques help maintain the efficacy and shelf-life of hypochlorous acid-containing products.- Stabilization of hypochlorous acid solutions: Various methods are employed to stabilize hypochlorous acid solutions, preventing rapid degradation and maintaining efficacy. These may include pH adjustment, addition of stabilizing agents, or use of specific packaging materials to protect the solution from light and air exposure.

- Formulation for medical and disinfection applications: Hypochlorous acid formulations are developed for medical uses such as wound care, eye treatments, and as broad-spectrum disinfectants. These formulations often include specific concentrations of hypochlorous acid and may be combined with other ingredients to enhance their effectiveness or application properties.

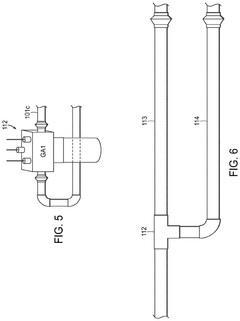

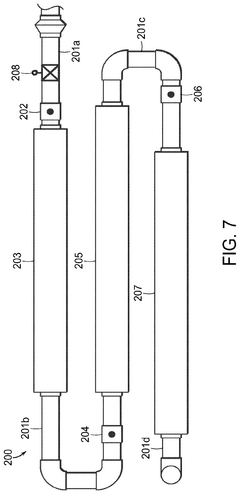

- Production methods for hypochlorous acid: Various techniques are used to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and methods to generate it in-situ. The focus is on developing efficient and cost-effective production processes that yield high-purity hypochlorous acid.

- Combination with other active ingredients: Hypochlorous acid is often combined with other active ingredients to create synergistic formulations. These may include other antimicrobial agents, surfactants, or compounds that enhance its stability or effectiveness. The goal is to develop multi-functional products with improved performance.

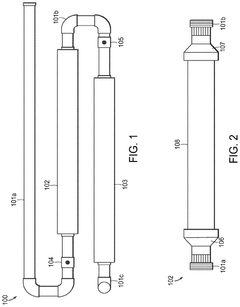

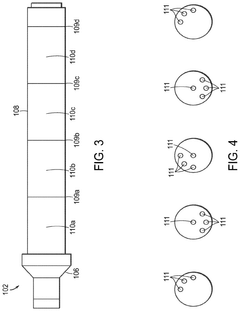

- Packaging and delivery systems: Innovative packaging and delivery systems are developed to maintain the stability and efficacy of hypochlorous acid formulations. These may include specialized containers, spray mechanisms, or devices that generate hypochlorous acid on-demand. The focus is on preserving the active ingredient and ensuring convenient application.

02 Hypochlorous acid production methods

Different approaches for producing hypochlorous acid are explored, such as electrolysis of saline solutions, chemical reactions involving chlorine and water, and novel synthesis techniques. These methods aim to improve the purity and yield of hypochlorous acid for various applications.Expand Specific Solutions03 Formulation for medical and disinfection applications

Hypochlorous acid is formulated for use in medical treatments and disinfection products. These formulations often include specific concentrations of hypochlorous acid, along with other ingredients to enhance its antimicrobial properties and suitability for various applications.Expand Specific Solutions04 Combination with other active ingredients

Hypochlorous acid is combined with other active ingredients to create synergistic effects or enhance specific properties. These combinations may include other antimicrobial agents, surfactants, or compounds that improve the overall efficacy of the formulation.Expand Specific Solutions05 Delivery systems and packaging

Innovative delivery systems and packaging solutions are developed for hypochlorous acid formulations. These may include specialized containers, spray mechanisms, or other dispensing methods designed to maintain the stability and effectiveness of the hypochlorous acid solution during storage and use.Expand Specific Solutions

Key HOCI Industry Players

The hypochlorous acid R&D market is in a growth phase, driven by increasing demand for safe and effective disinfectants. The global market size is expanding, with applications in healthcare, water treatment, and consumer products. Technologically, the field is advancing rapidly, with companies like WIAB WATER INNOVATION AB and Industrie De Nora SpA leading in formulation innovations. Established players such as Schlumberger and Kaneka Corp. are leveraging their expertise to overcome stability and production challenges. Emerging companies like Aquaox, Inc. and Reoxcyn LLC are focusing on niche applications, while research institutions like The Walker Cancer Research Institute contribute to fundamental advancements in the field.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrochemical cell technology for on-site generation of hypochlorous acid (HOCl). Their system utilizes a membrane-free electrolytic cell design that allows for the efficient production of HOCl from salt and water. The process involves passing an electric current through a brine solution, resulting in the formation of HOCl without the need for additional chemicals[1]. The company has also implemented precise control mechanisms to maintain optimal pH levels and chlorine concentrations, ensuring consistent product quality[2]. Additionally, De Nora has integrated IoT capabilities into their systems, enabling remote monitoring and automated adjustments to production parameters[3].

Strengths: Efficient on-site generation, reduced chemical handling, and precise control over product quality. Weaknesses: Requires consistent electricity supply and may have higher initial capital costs compared to traditional chlorine-based disinfection methods.

Aquaox, Inc.

Technical Solution: Aquaox, Inc. has pioneered a proprietary electrochemical activation (ECA) technology for producing stable hypochlorous acid solutions. Their approach utilizes a specialized electrolytic cell with unique electrode materials and a carefully controlled electrolysis process. The Aquaox system can generate HOCl solutions with concentrations ranging from 10 to 1000 ppm, maintaining stability for extended periods[4]. A key innovation is their use of a diaphragm-less cell design, which simplifies maintenance and reduces production costs[5]. The company has also developed a patented method for enhancing the antimicrobial efficacy of their HOCl solutions by optimizing the ratio of hypochlorous acid to hypochlorite ions[6].

Strengths: Production of stable HOCl solutions with extended shelf life, scalable concentration ranges, and enhanced antimicrobial efficacy. Weaknesses: May require specialized training for operation and maintenance of ECA systems.

Innovative HOCI Stabilization Techniques

Compositions of hypochlorous acid and methods of manufacture thereof

PatentActiveUS12115185B2

Innovation

- An air-free mixing method producing stable HOCl by combining a compound that generates protons (H+) with one that generates hypochlorite anions (OCl-) in water, without using chlorine gas or electrolysis, maintaining a controlled pH and using buffering agents to stabilize the product.

HYPOCHLOROUS ACID PRODUCTION METHOD

PatentUndeterminedCR20230148A

Innovation

- Production of stable hypochlorous acid solution using calcium hypochlorite and sodium carbonate, followed by acidification with an organic acid.

- Achieving a slightly acidic pH (4-6) and high Oxidation Reduction Potential (>900 mV) for enhanced stability and efficacy.

- Development of a chlorine gas-free HOCl composition with a minimum concentration of 150 ppm and extended shelf life (12-18 months).

Regulatory Framework for HOCI

The regulatory framework for Hypochlorous Acid (HOCl) is complex and varies across different regions and applications. In the United States, the Environmental Protection Agency (EPA) regulates HOCl as a pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). The EPA has approved HOCl for use as a disinfectant and sanitizer in various settings, including food contact surfaces, medical facilities, and water treatment.

The Food and Drug Administration (FDA) also plays a role in regulating HOCl, particularly for its use in medical devices and over-the-counter (OTC) products. The FDA has classified HOCl solutions as Class II medical devices when used for wound care and management. This classification requires manufacturers to submit a 510(k) premarket notification before marketing their products.

In the European Union, HOCl falls under the Biocidal Products Regulation (BPR). The European Chemicals Agency (ECHA) oversees the implementation of this regulation, which aims to ensure that biocidal products are safe for human health and the environment. HOCl is listed as an active substance in the BPR, and products containing it must undergo a thorough assessment before being authorized for use in the EU market.

The regulatory landscape for HOCl in Asia varies by country. In Japan, the Ministry of Health, Labour and Welfare regulates HOCl as a food additive and disinfectant. The Japanese government has approved its use in food processing and as a sanitizer in various industries. In China, the National Medical Products Administration (NMPA) oversees the regulation of HOCl-based products, particularly for medical and cosmetic applications.

Globally, the World Health Organization (WHO) recognizes HOCl as an effective disinfectant and has included it in its list of essential medicines for basic health care systems. This recognition has influenced many countries to adopt favorable regulatory policies for HOCl-based products.

As research and development in HOCl formulations continue to advance, regulatory bodies are adapting their frameworks to accommodate new applications and ensure product safety. For instance, the increasing use of HOCl in agriculture has prompted regulatory agencies to develop specific guidelines for its application in crop protection and post-harvest treatments.

Manufacturers and researchers working on HOCl formulations must navigate these diverse regulatory landscapes to ensure compliance and market access. This often involves conducting extensive safety studies, efficacy tests, and stability assessments to meet the requirements of different regulatory agencies. The challenge lies in developing formulations that not only overcome technical hurdles but also align with the evolving regulatory standards across various regions and applications.

The Food and Drug Administration (FDA) also plays a role in regulating HOCl, particularly for its use in medical devices and over-the-counter (OTC) products. The FDA has classified HOCl solutions as Class II medical devices when used for wound care and management. This classification requires manufacturers to submit a 510(k) premarket notification before marketing their products.

In the European Union, HOCl falls under the Biocidal Products Regulation (BPR). The European Chemicals Agency (ECHA) oversees the implementation of this regulation, which aims to ensure that biocidal products are safe for human health and the environment. HOCl is listed as an active substance in the BPR, and products containing it must undergo a thorough assessment before being authorized for use in the EU market.

The regulatory landscape for HOCl in Asia varies by country. In Japan, the Ministry of Health, Labour and Welfare regulates HOCl as a food additive and disinfectant. The Japanese government has approved its use in food processing and as a sanitizer in various industries. In China, the National Medical Products Administration (NMPA) oversees the regulation of HOCl-based products, particularly for medical and cosmetic applications.

Globally, the World Health Organization (WHO) recognizes HOCl as an effective disinfectant and has included it in its list of essential medicines for basic health care systems. This recognition has influenced many countries to adopt favorable regulatory policies for HOCl-based products.

As research and development in HOCl formulations continue to advance, regulatory bodies are adapting their frameworks to accommodate new applications and ensure product safety. For instance, the increasing use of HOCl in agriculture has prompted regulatory agencies to develop specific guidelines for its application in crop protection and post-harvest treatments.

Manufacturers and researchers working on HOCl formulations must navigate these diverse regulatory landscapes to ensure compliance and market access. This often involves conducting extensive safety studies, efficacy tests, and stability assessments to meet the requirements of different regulatory agencies. The challenge lies in developing formulations that not only overcome technical hurdles but also align with the evolving regulatory standards across various regions and applications.

Environmental Impact of HOCI Production

The production of hypochlorous acid (HOCl) has significant environmental implications that must be carefully considered in the research and development process. The primary environmental concerns associated with HOCl production stem from the raw materials used, energy consumption, and potential byproducts or waste generated during manufacturing.

One of the key environmental impacts of HOCl production is related to the use of chlorine as a raw material. Chlorine production typically involves energy-intensive electrolysis processes, which can contribute to greenhouse gas emissions if the energy source is not renewable. Additionally, the transportation and handling of chlorine pose potential risks of accidental releases, which can have severe environmental consequences.

Water usage is another critical factor in HOCl production. The process requires substantial amounts of water, both as a reactant and for cooling purposes. In regions facing water scarcity, this high water demand can strain local resources and ecosystems. Implementing water recycling and conservation measures in the production process is essential to mitigate this impact.

The generation of byproducts during HOCl production, such as sodium hydroxide and hydrogen gas, also presents environmental challenges. While these byproducts have industrial applications, their proper handling and disposal are crucial to prevent environmental contamination. Developing efficient methods to capture and utilize these byproducts can significantly reduce the overall environmental footprint of HOCl production.

Energy efficiency in the production process is a key area for environmental improvement. Optimizing reaction conditions, implementing heat recovery systems, and utilizing energy-efficient equipment can substantially reduce the carbon footprint associated with HOCl manufacturing. Furthermore, transitioning to renewable energy sources for production facilities can dramatically decrease the environmental impact.

The packaging and distribution of HOCl products also contribute to the overall environmental impact. Developing eco-friendly packaging solutions and optimizing transportation logistics can help reduce waste and emissions associated with product delivery. Additionally, promoting the use of concentrated HOCl formulations can decrease packaging material requirements and transportation-related emissions.

As research and development efforts focus on overcoming formulation challenges, it is crucial to integrate environmental considerations into the process. This includes exploring alternative raw materials, developing more efficient production methods, and investigating ways to minimize waste and emissions throughout the product lifecycle. By addressing these environmental aspects, researchers can contribute to the development of more sustainable HOCl production processes and formulations.

One of the key environmental impacts of HOCl production is related to the use of chlorine as a raw material. Chlorine production typically involves energy-intensive electrolysis processes, which can contribute to greenhouse gas emissions if the energy source is not renewable. Additionally, the transportation and handling of chlorine pose potential risks of accidental releases, which can have severe environmental consequences.

Water usage is another critical factor in HOCl production. The process requires substantial amounts of water, both as a reactant and for cooling purposes. In regions facing water scarcity, this high water demand can strain local resources and ecosystems. Implementing water recycling and conservation measures in the production process is essential to mitigate this impact.

The generation of byproducts during HOCl production, such as sodium hydroxide and hydrogen gas, also presents environmental challenges. While these byproducts have industrial applications, their proper handling and disposal are crucial to prevent environmental contamination. Developing efficient methods to capture and utilize these byproducts can significantly reduce the overall environmental footprint of HOCl production.

Energy efficiency in the production process is a key area for environmental improvement. Optimizing reaction conditions, implementing heat recovery systems, and utilizing energy-efficient equipment can substantially reduce the carbon footprint associated with HOCl manufacturing. Furthermore, transitioning to renewable energy sources for production facilities can dramatically decrease the environmental impact.

The packaging and distribution of HOCl products also contribute to the overall environmental impact. Developing eco-friendly packaging solutions and optimizing transportation logistics can help reduce waste and emissions associated with product delivery. Additionally, promoting the use of concentrated HOCl formulations can decrease packaging material requirements and transportation-related emissions.

As research and development efforts focus on overcoming formulation challenges, it is crucial to integrate environmental considerations into the process. This includes exploring alternative raw materials, developing more efficient production methods, and investigating ways to minimize waste and emissions throughout the product lifecycle. By addressing these environmental aspects, researchers can contribute to the development of more sustainable HOCl production processes and formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!