Hypochlorous Acid: Integration into Next-Gen Antiseptic Products

AUG 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Tech Evolution

The evolution of Hypochlorous Acid (HOCl) technology in antiseptic products has been marked by significant advancements over the past few decades. Initially discovered in the early 19th century, HOCl's potential as a powerful yet safe disinfectant remained largely untapped until recent years. The technology's progression can be traced through several key stages, each contributing to its current status as a promising component in next-generation antiseptic products.

In the 1970s and 1980s, researchers began to explore HOCl's natural occurrence in the human immune system, where it is produced by white blood cells to fight infections. This discovery sparked renewed interest in its potential applications. However, the unstable nature of HOCl solutions posed significant challenges for practical use, limiting its commercial viability.

The 1990s saw a breakthrough in HOCl production methods. Electrochemical activation (ECA) technology emerged as a reliable means to generate stable HOCl solutions. This development marked a turning point, enabling the creation of HOCl-based products with longer shelf lives and consistent efficacy. During this period, early adopters in the medical field began incorporating HOCl solutions into wound care protocols.

The early 2000s witnessed a surge in research focused on optimizing HOCl formulations. Scientists worked on enhancing stability, developing pH-balanced solutions, and improving production efficiency. This era also saw the first wave of commercial HOCl products entering the market, primarily in healthcare and industrial cleaning applications.

From 2010 onwards, HOCl technology experienced rapid advancement. Improved understanding of its mechanism of action led to more targeted applications. The development of novel delivery systems, such as mists and gels, expanded HOCl's potential uses. Additionally, advancements in packaging technology addressed previous stability issues, significantly extending product shelf life.

Recent years have seen a convergence of HOCl technology with other emerging fields. Integration with nanotechnology has led to the development of HOCl-infused materials with sustained antimicrobial properties. The rise of smart devices has also influenced HOCl technology, with the introduction of automated dispensing systems and IoT-enabled monitoring of HOCl levels in various applications.

Looking ahead, the evolution of HOCl technology is poised to continue its upward trajectory. Current research is focusing on enhancing its efficacy against a broader spectrum of pathogens, including antibiotic-resistant strains. There is also growing interest in combining HOCl with other natural antimicrobial agents to create synergistic formulations. As environmental concerns gain prominence, efforts are underway to develop more sustainable production methods and eco-friendly packaging solutions for HOCl products.

In the 1970s and 1980s, researchers began to explore HOCl's natural occurrence in the human immune system, where it is produced by white blood cells to fight infections. This discovery sparked renewed interest in its potential applications. However, the unstable nature of HOCl solutions posed significant challenges for practical use, limiting its commercial viability.

The 1990s saw a breakthrough in HOCl production methods. Electrochemical activation (ECA) technology emerged as a reliable means to generate stable HOCl solutions. This development marked a turning point, enabling the creation of HOCl-based products with longer shelf lives and consistent efficacy. During this period, early adopters in the medical field began incorporating HOCl solutions into wound care protocols.

The early 2000s witnessed a surge in research focused on optimizing HOCl formulations. Scientists worked on enhancing stability, developing pH-balanced solutions, and improving production efficiency. This era also saw the first wave of commercial HOCl products entering the market, primarily in healthcare and industrial cleaning applications.

From 2010 onwards, HOCl technology experienced rapid advancement. Improved understanding of its mechanism of action led to more targeted applications. The development of novel delivery systems, such as mists and gels, expanded HOCl's potential uses. Additionally, advancements in packaging technology addressed previous stability issues, significantly extending product shelf life.

Recent years have seen a convergence of HOCl technology with other emerging fields. Integration with nanotechnology has led to the development of HOCl-infused materials with sustained antimicrobial properties. The rise of smart devices has also influenced HOCl technology, with the introduction of automated dispensing systems and IoT-enabled monitoring of HOCl levels in various applications.

Looking ahead, the evolution of HOCl technology is poised to continue its upward trajectory. Current research is focusing on enhancing its efficacy against a broader spectrum of pathogens, including antibiotic-resistant strains. There is also growing interest in combining HOCl with other natural antimicrobial agents to create synergistic formulations. As environmental concerns gain prominence, efforts are underway to develop more sustainable production methods and eco-friendly packaging solutions for HOCl products.

Market Demand Analysis

The market demand for next-generation antiseptic products incorporating Hypochlorous Acid (HOCl) has been steadily increasing, driven by growing awareness of its effectiveness and safety profile. Healthcare facilities, including hospitals, clinics, and long-term care centers, are showing particular interest in HOCl-based solutions due to their broad-spectrum antimicrobial properties and low toxicity.

The global antiseptics market, which includes HOCl products, is experiencing significant growth. This expansion is fueled by the rising incidence of healthcare-associated infections, increasing surgical procedures, and a growing emphasis on infection prevention and control measures. The COVID-19 pandemic has further accelerated the demand for effective antiseptic solutions, with HOCl gaining attention for its potential in surface disinfection and hand sanitization.

Consumer markets are also showing increased interest in HOCl-based products for personal care and household use. The trend towards natural and eco-friendly disinfectants has positioned HOCl favorably, as it is perceived as a safer alternative to traditional chemical-based antiseptics. This shift in consumer preferences is opening up new opportunities for HOCl integration into everyday products such as wound care solutions, oral care products, and household cleaners.

The food and beverage industry represents another significant market for HOCl-based antiseptics. With stringent food safety regulations and the need for effective, non-toxic sanitizers, HOCl solutions are gaining traction in food processing facilities, restaurants, and agricultural settings. The ability of HOCl to effectively eliminate pathogens without leaving harmful residues aligns well with the industry's requirements.

Geographically, North America and Europe currently lead in the adoption of HOCl-based antiseptic products, primarily due to advanced healthcare infrastructure and stringent infection control standards. However, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in demand, driven by improving healthcare facilities, increasing disposable income, and growing awareness of hygiene practices.

The market potential for HOCl in next-generation antiseptic products is substantial, with opportunities spanning various sectors. As research continues to validate its efficacy and safety, and as manufacturing processes become more cost-effective, the integration of HOCl into a wider range of antiseptic products is likely to accelerate. This trend is expected to reshape the antiseptics market, potentially disrupting traditional product categories and creating new niches for innovative HOCl-based solutions.

The global antiseptics market, which includes HOCl products, is experiencing significant growth. This expansion is fueled by the rising incidence of healthcare-associated infections, increasing surgical procedures, and a growing emphasis on infection prevention and control measures. The COVID-19 pandemic has further accelerated the demand for effective antiseptic solutions, with HOCl gaining attention for its potential in surface disinfection and hand sanitization.

Consumer markets are also showing increased interest in HOCl-based products for personal care and household use. The trend towards natural and eco-friendly disinfectants has positioned HOCl favorably, as it is perceived as a safer alternative to traditional chemical-based antiseptics. This shift in consumer preferences is opening up new opportunities for HOCl integration into everyday products such as wound care solutions, oral care products, and household cleaners.

The food and beverage industry represents another significant market for HOCl-based antiseptics. With stringent food safety regulations and the need for effective, non-toxic sanitizers, HOCl solutions are gaining traction in food processing facilities, restaurants, and agricultural settings. The ability of HOCl to effectively eliminate pathogens without leaving harmful residues aligns well with the industry's requirements.

Geographically, North America and Europe currently lead in the adoption of HOCl-based antiseptic products, primarily due to advanced healthcare infrastructure and stringent infection control standards. However, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in demand, driven by improving healthcare facilities, increasing disposable income, and growing awareness of hygiene practices.

The market potential for HOCl in next-generation antiseptic products is substantial, with opportunities spanning various sectors. As research continues to validate its efficacy and safety, and as manufacturing processes become more cost-effective, the integration of HOCl into a wider range of antiseptic products is likely to accelerate. This trend is expected to reshape the antiseptics market, potentially disrupting traditional product categories and creating new niches for innovative HOCl-based solutions.

Current Challenges

The integration of hypochlorous acid (HOCl) into next-generation antiseptic products faces several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the stability of HOCl solutions. While HOCl is a potent antimicrobial agent, it is inherently unstable and can degrade rapidly, especially when exposed to light, heat, or organic matter. This instability poses difficulties in formulation, packaging, and shelf-life of products, requiring innovative approaches to maintain its efficacy over time.

Another challenge lies in the production and scalability of HOCl solutions. Current methods of generating HOCl often involve electrolysis of salt water, which can be energy-intensive and may not be easily scalable for large-scale industrial production. Additionally, ensuring consistent concentration and purity of HOCl across batches remains a technical hurdle that needs to be overcome for reliable product manufacturing.

The pH sensitivity of HOCl presents another significant challenge. The antimicrobial efficacy of HOCl is highest within a narrow pH range, typically between 3.5 and 6.5. Maintaining this optimal pH in various product formulations and ensuring it remains stable during storage and use is crucial for product effectiveness. This requirement complicates the formulation process and may limit the types of ingredients that can be combined with HOCl in antiseptic products.

Regulatory hurdles also pose challenges for the integration of HOCl into next-generation antiseptic products. While HOCl has been recognized for its safety and efficacy, obtaining regulatory approvals for new formulations and applications can be a complex and time-consuming process. This is particularly true for medical-grade antiseptic products, which are subject to stringent regulatory requirements.

The perception and education of both healthcare professionals and consumers regarding HOCl present another challenge. Despite its effectiveness, HOCl is still relatively unknown compared to traditional antiseptic agents like alcohol or chlorhexidine. Overcoming this knowledge gap and building trust in HOCl-based products requires significant educational and marketing efforts.

Lastly, the development of appropriate delivery systems for HOCl-based antiseptic products presents technical challenges. Given the reactive nature of HOCl, designing packaging and application methods that preserve its stability and ensure effective delivery to the target site is crucial. This may involve developing novel spray systems, impregnated materials, or other innovative delivery mechanisms that maintain the integrity of HOCl until the point of use.

Another challenge lies in the production and scalability of HOCl solutions. Current methods of generating HOCl often involve electrolysis of salt water, which can be energy-intensive and may not be easily scalable for large-scale industrial production. Additionally, ensuring consistent concentration and purity of HOCl across batches remains a technical hurdle that needs to be overcome for reliable product manufacturing.

The pH sensitivity of HOCl presents another significant challenge. The antimicrobial efficacy of HOCl is highest within a narrow pH range, typically between 3.5 and 6.5. Maintaining this optimal pH in various product formulations and ensuring it remains stable during storage and use is crucial for product effectiveness. This requirement complicates the formulation process and may limit the types of ingredients that can be combined with HOCl in antiseptic products.

Regulatory hurdles also pose challenges for the integration of HOCl into next-generation antiseptic products. While HOCl has been recognized for its safety and efficacy, obtaining regulatory approvals for new formulations and applications can be a complex and time-consuming process. This is particularly true for medical-grade antiseptic products, which are subject to stringent regulatory requirements.

The perception and education of both healthcare professionals and consumers regarding HOCl present another challenge. Despite its effectiveness, HOCl is still relatively unknown compared to traditional antiseptic agents like alcohol or chlorhexidine. Overcoming this knowledge gap and building trust in HOCl-based products requires significant educational and marketing efforts.

Lastly, the development of appropriate delivery systems for HOCl-based antiseptic products presents technical challenges. Given the reactive nature of HOCl, designing packaging and application methods that preserve its stability and ensure effective delivery to the target site is crucial. This may involve developing novel spray systems, impregnated materials, or other innovative delivery mechanisms that maintain the integrity of HOCl until the point of use.

Existing HOCL Solutions

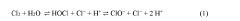

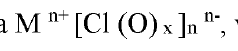

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization techniques for hypochlorous acid solutions: To enhance the shelf life and maintain the efficacy of hypochlorous acid solutions, various stabilization techniques are employed. These may include pH adjustment, addition of stabilizing agents, and specialized packaging to prevent degradation and maintain the active chlorine content over time.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in medical and therapeutic settings, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental remediation and industrial processes, such as water treatment, air purification, and surface decontamination. Its eco-friendly nature and broad-spectrum antimicrobial properties make it suitable for various environmental and industrial applications.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization techniques for hypochlorous acid solutions

Stabilization of hypochlorous acid solutions is crucial for maintaining their efficacy over time. Various techniques are employed, such as pH adjustment, addition of stabilizing agents, and specialized packaging methods, to extend the shelf life and preserve the antimicrobial properties of hypochlorous acid products.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid finds applications in medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in environmental and industrial settings for purposes such as water treatment, surface disinfection, and odor control. Its eco-friendly nature and broad-spectrum antimicrobial activity make it suitable for various large-scale applications.Expand Specific Solutions

Key Industry Players

The integration of Hypochlorous Acid into next-generation antiseptic products represents a competitive landscape in the early growth stage. The market is expanding due to increasing demand for effective, safe disinfectants, particularly in healthcare and consumer sectors. While the technology is not entirely new, its application in advanced antiseptic products is gaining traction. Companies like Bactiguard AB, Integrated Healing Technologies LLC, and Annihilare Medical Systems, Inc. are at the forefront, developing innovative applications. Established players such as Kao Corp. and Industrie De Nora SpA are also entering this space, leveraging their research capabilities and market presence. The technology's maturity is advancing, with ongoing research at institutions like Jilin University and South China Agricultural University contributing to its development.

Applied Chemicals Ltd.

Technical Solution: Applied Chemicals has developed a novel stabilization process for HOCl, enabling the production of highly stable and effective HOCl solutions. Their proprietary technology involves a carefully controlled pH adjustment and the addition of specific stabilizing agents to extend the shelf life of HOCl without compromising its antimicrobial efficacy[13]. The company's stabilized HOCl products maintain their potency for up to 18 months, significantly longer than traditional HOCl solutions[14]. Applied Chemicals' HOCl formulations are available in various concentrations, ranging from 50 to 500 ppm, suitable for applications in healthcare, food processing, and water treatment[15].

Strengths: Extended shelf life of HOCl solutions; Maintained antimicrobial efficacy over time; Suitable for various industrial applications. Weaknesses: May involve higher production costs due to stabilization process; Potential limitations in extremely high concentration applications.

Bactiguard AB

Technical Solution: Bactiguard has developed a unique coating technology that incorporates HOCl into medical devices to prevent healthcare-associated infections. Their proprietary coating, consisting of noble metals including gold, silver, and palladium, creates a galvanic effect that generates small amounts of HOCl on the device surface[10]. This continuous production of HOCl provides long-lasting antimicrobial protection without the need for additional chemicals or antibiotics[11]. Bactiguard's technology has been successfully applied to various medical devices, including urinary catheters, endotracheal tubes, and central venous catheters, demonstrating significant reductions in infection rates[12].

Strengths: Long-lasting antimicrobial effect; Reduced risk of antibiotic resistance; Applicable to various medical devices. Weaknesses: Limited to specific medical device applications; May require regulatory approval for each new application.

Core HOCL Innovations

Compositions and methods to disinfect, treat and prevent microbial infections

PatentWO2022008972A1

Innovation

- Development of compositions comprising oxidized chlorine precursors combined with acetic acid or its salts, which are stabilized and activated on-site using a multi-compartment device, forming hypochlorous acid-based solutions for broad-spectrum antimicrobial and antiviral effects, suitable for inhalation and surface disinfection.

Multi-chamber hypochlorous acid dispenser

PatentActiveUS20230399228A1

Innovation

- A multi-chambered container system that separates and stabilizes the components for producing hypochlorous acid, using one-way valves and buffering agents to maintain a stable pH range, allowing for on-site preparation and long-term storage by controlling pH, ion concentration, and air exposure, thereby preventing degradation.

Regulatory Framework

The regulatory framework surrounding the integration of hypochlorous acid (HOCl) into next-generation antiseptic products is complex and multifaceted, involving various governmental agencies and international bodies. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating antiseptic products, including those containing HOCl. The FDA categorizes these products based on their intended use, with over-the-counter (OTC) antiseptics falling under different monographs depending on their application.

For healthcare antiseptics, the FDA has established stringent requirements for safety and efficacy data. Manufacturers must demonstrate that their HOCl-based products meet these standards through extensive clinical trials and laboratory studies. The FDA's 2017 final rule on OTC healthcare antiseptics has further tightened regulations, requiring additional data for active ingredients to maintain their generally recognized as safe and effective (GRASE) status.

In the European Union, the regulatory landscape is governed by the Biocidal Products Regulation (BPR). HOCl products intended for use as disinfectants or antiseptics must comply with the BPR, which mandates a thorough assessment of their safety and efficacy. The European Chemicals Agency (ECHA) oversees the evaluation process, ensuring that only products meeting strict criteria enter the market.

Globally, the World Health Organization (WHO) provides guidelines on hand hygiene in healthcare settings, which influence the development and use of antiseptic products. While not directly regulating HOCl, these guidelines shape the standards that new antiseptic formulations must meet to be considered effective in clinical environments.

Environmental regulations also play a crucial role in the development of HOCl-based antiseptics. In many jurisdictions, manufacturers must consider the environmental impact of their products, including biodegradability and potential effects on aquatic ecosystems. The Environmental Protection Agency (EPA) in the US and similar agencies in other countries set standards for the environmental safety of chemical products.

As HOCl gains prominence in next-generation antiseptic products, regulatory bodies are likely to evolve their frameworks to address specific concerns related to its use. This may include updated guidelines on concentration levels, stability requirements, and packaging specifications to ensure product integrity and safety throughout its shelf life.

For healthcare antiseptics, the FDA has established stringent requirements for safety and efficacy data. Manufacturers must demonstrate that their HOCl-based products meet these standards through extensive clinical trials and laboratory studies. The FDA's 2017 final rule on OTC healthcare antiseptics has further tightened regulations, requiring additional data for active ingredients to maintain their generally recognized as safe and effective (GRASE) status.

In the European Union, the regulatory landscape is governed by the Biocidal Products Regulation (BPR). HOCl products intended for use as disinfectants or antiseptics must comply with the BPR, which mandates a thorough assessment of their safety and efficacy. The European Chemicals Agency (ECHA) oversees the evaluation process, ensuring that only products meeting strict criteria enter the market.

Globally, the World Health Organization (WHO) provides guidelines on hand hygiene in healthcare settings, which influence the development and use of antiseptic products. While not directly regulating HOCl, these guidelines shape the standards that new antiseptic formulations must meet to be considered effective in clinical environments.

Environmental regulations also play a crucial role in the development of HOCl-based antiseptics. In many jurisdictions, manufacturers must consider the environmental impact of their products, including biodegradability and potential effects on aquatic ecosystems. The Environmental Protection Agency (EPA) in the US and similar agencies in other countries set standards for the environmental safety of chemical products.

As HOCl gains prominence in next-generation antiseptic products, regulatory bodies are likely to evolve their frameworks to address specific concerns related to its use. This may include updated guidelines on concentration levels, stability requirements, and packaging specifications to ensure product integrity and safety throughout its shelf life.

Environmental Impact

The integration of hypochlorous acid (HOCl) into next-generation antiseptic products presents a promising avenue for environmentally friendly disinfection solutions. HOCl is a naturally occurring compound produced by the human immune system, making it inherently biocompatible and less harmful to the environment compared to traditional chemical disinfectants.

One of the primary environmental benefits of HOCl-based products is their rapid biodegradability. Unlike many conventional antiseptics that persist in the environment, HOCl quickly breaks down into harmless components: water and salt. This characteristic significantly reduces the potential for long-term environmental contamination and minimizes the risk of contributing to antimicrobial resistance in ecosystems.

The production process of HOCl also offers environmental advantages. It can be generated on-site through the electrolysis of salt water, reducing the need for transportation and storage of hazardous chemicals. This not only decreases the carbon footprint associated with product distribution but also minimizes the risk of chemical spills during transport.

Furthermore, HOCl-based antiseptics typically require lower concentrations to achieve effective disinfection compared to traditional chemical alternatives. This results in reduced chemical usage and less residual discharge into wastewater systems, thereby lessening the burden on water treatment facilities and aquatic ecosystems.

The non-toxic nature of HOCl at recommended concentrations means that its use in healthcare settings, public spaces, and households does not contribute to indoor air pollution or pose risks to non-target organisms. This is particularly important in sensitive environments such as hospitals, schools, and food processing facilities, where the balance between effective sanitation and environmental safety is crucial.

However, it is important to consider the environmental impact of the materials used in packaging and delivery systems for HOCl-based products. Sustainable packaging solutions and refillable systems could further enhance the overall environmental profile of these next-generation antiseptics.

As the demand for eco-friendly disinfection solutions grows, the adoption of HOCl-based products could lead to a significant reduction in the use of more environmentally harmful antiseptics. This shift has the potential to positively impact water quality, reduce chemical pollution, and support broader sustainability goals across various industries and applications.

One of the primary environmental benefits of HOCl-based products is their rapid biodegradability. Unlike many conventional antiseptics that persist in the environment, HOCl quickly breaks down into harmless components: water and salt. This characteristic significantly reduces the potential for long-term environmental contamination and minimizes the risk of contributing to antimicrobial resistance in ecosystems.

The production process of HOCl also offers environmental advantages. It can be generated on-site through the electrolysis of salt water, reducing the need for transportation and storage of hazardous chemicals. This not only decreases the carbon footprint associated with product distribution but also minimizes the risk of chemical spills during transport.

Furthermore, HOCl-based antiseptics typically require lower concentrations to achieve effective disinfection compared to traditional chemical alternatives. This results in reduced chemical usage and less residual discharge into wastewater systems, thereby lessening the burden on water treatment facilities and aquatic ecosystems.

The non-toxic nature of HOCl at recommended concentrations means that its use in healthcare settings, public spaces, and households does not contribute to indoor air pollution or pose risks to non-target organisms. This is particularly important in sensitive environments such as hospitals, schools, and food processing facilities, where the balance between effective sanitation and environmental safety is crucial.

However, it is important to consider the environmental impact of the materials used in packaging and delivery systems for HOCl-based products. Sustainable packaging solutions and refillable systems could further enhance the overall environmental profile of these next-generation antiseptics.

As the demand for eco-friendly disinfection solutions grows, the adoption of HOCl-based products could lead to a significant reduction in the use of more environmentally harmful antiseptics. This shift has the potential to positively impact water quality, reduce chemical pollution, and support broader sustainability goals across various industries and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!