Hydrogen Supply Strategies: Green Hydrogen And SMR–CCS For Hydrogenolysis

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Production Evolution and Objectives

Hydrogen production has undergone significant evolution since its industrial inception in the early 20th century. Initially dominated by coal gasification processes, the industry shifted towards steam methane reforming (SMR) in the mid-20th century due to the abundance and cost-effectiveness of natural gas. This conventional production method, while economically viable, generates substantial carbon emissions—approximately 9-12 kg CO2 per kg of hydrogen produced—contributing significantly to global greenhouse gas emissions.

The 21st century has witnessed a paradigm shift towards cleaner hydrogen production pathways, driven by increasing environmental concerns and climate change mitigation efforts. Green hydrogen, produced through water electrolysis powered by renewable energy sources, has emerged as a zero-emission alternative. Concurrently, blue hydrogen—produced via traditional SMR coupled with carbon capture and storage (CCS) technologies—offers a transitional solution that leverages existing infrastructure while reducing carbon footprint by 70-90%.

Recent technological breakthroughs in electrolysis, including proton exchange membrane (PEM), alkaline, and solid oxide electrolyzers, have dramatically improved efficiency and reduced capital costs. The International Energy Agency reports that electrolyzer costs have decreased by approximately 60% since 2010, with projections suggesting further reductions of 40-50% by 2030 as manufacturing scales up and technologies mature.

The primary objective of modern hydrogen production strategies is to achieve cost parity with conventional fossil-based methods while minimizing environmental impact. Current green hydrogen production costs range from $3-8 per kg, compared to $1-2 per kg for grey hydrogen (SMR without CCS). Industry roadmaps aim to reduce green hydrogen costs to below $2 per kg by 2030 through technological improvements, economies of scale, and increased renewable energy penetration.

For hydrogenolysis applications specifically, which require high-purity hydrogen for selective bond cleavage in chemical processing, the technical objectives focus on developing production methods that deliver consistent purity levels (>99.99%) while maintaining economic viability. The chemical industry increasingly recognizes that sustainable hydrogenolysis processes demand clean hydrogen sources to truly reduce lifecycle emissions.

Looking forward, the hydrogen production landscape aims to establish regional and global supply chains that can support industrial decarbonization efforts across multiple sectors. This includes developing distributed production capabilities near point-of-use facilities, creating hydrogen hubs that leverage existing natural gas infrastructure for blue hydrogen, and building integrated renewable energy systems for green hydrogen production at industrial scale.

The 21st century has witnessed a paradigm shift towards cleaner hydrogen production pathways, driven by increasing environmental concerns and climate change mitigation efforts. Green hydrogen, produced through water electrolysis powered by renewable energy sources, has emerged as a zero-emission alternative. Concurrently, blue hydrogen—produced via traditional SMR coupled with carbon capture and storage (CCS) technologies—offers a transitional solution that leverages existing infrastructure while reducing carbon footprint by 70-90%.

Recent technological breakthroughs in electrolysis, including proton exchange membrane (PEM), alkaline, and solid oxide electrolyzers, have dramatically improved efficiency and reduced capital costs. The International Energy Agency reports that electrolyzer costs have decreased by approximately 60% since 2010, with projections suggesting further reductions of 40-50% by 2030 as manufacturing scales up and technologies mature.

The primary objective of modern hydrogen production strategies is to achieve cost parity with conventional fossil-based methods while minimizing environmental impact. Current green hydrogen production costs range from $3-8 per kg, compared to $1-2 per kg for grey hydrogen (SMR without CCS). Industry roadmaps aim to reduce green hydrogen costs to below $2 per kg by 2030 through technological improvements, economies of scale, and increased renewable energy penetration.

For hydrogenolysis applications specifically, which require high-purity hydrogen for selective bond cleavage in chemical processing, the technical objectives focus on developing production methods that deliver consistent purity levels (>99.99%) while maintaining economic viability. The chemical industry increasingly recognizes that sustainable hydrogenolysis processes demand clean hydrogen sources to truly reduce lifecycle emissions.

Looking forward, the hydrogen production landscape aims to establish regional and global supply chains that can support industrial decarbonization efforts across multiple sectors. This includes developing distributed production capabilities near point-of-use facilities, creating hydrogen hubs that leverage existing natural gas infrastructure for blue hydrogen, and building integrated renewable energy systems for green hydrogen production at industrial scale.

Market Analysis for Hydrogen in Hydrogenolysis Applications

The global hydrogen market for hydrogenolysis applications is experiencing significant growth, driven by increasing demand for sustainable chemical processes and renewable fuels. Currently valued at approximately $150 billion, the market is projected to expand at a compound annual growth rate of 6.8% through 2030, with hydrogenolysis applications representing about 12% of total hydrogen consumption.

Hydrogenolysis, a chemical reaction involving the breaking of carbon-carbon or carbon-heteroatom bonds with hydrogen, is gaining prominence in various industrial sectors. The petroleum refining industry remains the largest consumer, utilizing hydrogen for hydrocracking and hydrodesulfurization processes. This sector accounts for roughly 45% of hydrogen demand in hydrogenolysis applications, with annual consumption exceeding 38 million metric tons.

The renewable chemicals sector presents the fastest-growing market segment, with 15.3% annual growth, as manufacturers increasingly adopt hydrogenolysis for converting biomass into valuable chemicals and fuels. This transition is particularly evident in the production of renewable diesel, where hydrogen-based processes have demonstrated superior yield and product quality compared to traditional methods.

Regionally, Asia-Pacific dominates the market with 42% share, led by China's aggressive expansion of hydrogen infrastructure. North America follows at 28%, with particular strength in petroleum refining applications. Europe represents 23% of the market but is growing rapidly due to stringent carbon reduction policies and substantial investments in green hydrogen production facilities.

The price dynamics within this market reveal significant variations based on hydrogen source. Conventional hydrogen derived from natural gas through Steam Methane Reforming (SMR) remains the most cost-competitive at $1.50-2.50/kg. However, green hydrogen produced via electrolysis currently ranges from $4.00-6.00/kg, presenting a substantial premium that impacts adoption rates in price-sensitive applications.

Customer segments demonstrate varying price elasticity. Large-scale petroleum refiners prioritize consistent supply and competitive pricing, while specialty chemical manufacturers show greater willingness to absorb premium costs for green hydrogen to meet sustainability targets and consumer demands. This segmentation is reshaping supplier strategies, with increasing focus on differentiated offerings based on carbon intensity and production method.

The market exhibits strong correlation with regulatory frameworks, particularly carbon pricing mechanisms. Regions with established carbon markets show accelerated transition toward low-carbon hydrogen solutions, with price premiums for green hydrogen decreasing as carbon costs increase. This relationship suggests that future market growth will be heavily influenced by evolving climate policies and carbon pricing structures.

Hydrogenolysis, a chemical reaction involving the breaking of carbon-carbon or carbon-heteroatom bonds with hydrogen, is gaining prominence in various industrial sectors. The petroleum refining industry remains the largest consumer, utilizing hydrogen for hydrocracking and hydrodesulfurization processes. This sector accounts for roughly 45% of hydrogen demand in hydrogenolysis applications, with annual consumption exceeding 38 million metric tons.

The renewable chemicals sector presents the fastest-growing market segment, with 15.3% annual growth, as manufacturers increasingly adopt hydrogenolysis for converting biomass into valuable chemicals and fuels. This transition is particularly evident in the production of renewable diesel, where hydrogen-based processes have demonstrated superior yield and product quality compared to traditional methods.

Regionally, Asia-Pacific dominates the market with 42% share, led by China's aggressive expansion of hydrogen infrastructure. North America follows at 28%, with particular strength in petroleum refining applications. Europe represents 23% of the market but is growing rapidly due to stringent carbon reduction policies and substantial investments in green hydrogen production facilities.

The price dynamics within this market reveal significant variations based on hydrogen source. Conventional hydrogen derived from natural gas through Steam Methane Reforming (SMR) remains the most cost-competitive at $1.50-2.50/kg. However, green hydrogen produced via electrolysis currently ranges from $4.00-6.00/kg, presenting a substantial premium that impacts adoption rates in price-sensitive applications.

Customer segments demonstrate varying price elasticity. Large-scale petroleum refiners prioritize consistent supply and competitive pricing, while specialty chemical manufacturers show greater willingness to absorb premium costs for green hydrogen to meet sustainability targets and consumer demands. This segmentation is reshaping supplier strategies, with increasing focus on differentiated offerings based on carbon intensity and production method.

The market exhibits strong correlation with regulatory frameworks, particularly carbon pricing mechanisms. Regions with established carbon markets show accelerated transition toward low-carbon hydrogen solutions, with price premiums for green hydrogen decreasing as carbon costs increase. This relationship suggests that future market growth will be heavily influenced by evolving climate policies and carbon pricing structures.

Current Hydrogen Supply Technologies and Barriers

The hydrogen production landscape is currently dominated by two main technologies: Steam Methane Reforming (SMR) and electrolysis. SMR accounts for approximately 76% of global hydrogen production, utilizing natural gas as feedstock in a process that generates significant carbon emissions—approximately 9-12 kg CO2 per kg H2 produced. While economically efficient at $1-2 per kg H2, this method faces increasing scrutiny due to its environmental impact.

Electrolysis, particularly when powered by renewable energy sources (green hydrogen), represents a cleaner alternative but currently accounts for less than 4% of global hydrogen production. The technology splits water molecules using electricity, producing hydrogen with minimal emissions when renewable power is utilized. However, production costs remain high at $3-7 per kg H2, primarily due to expensive electrolyzer systems and the intermittent nature of renewable energy sources.

SMR with Carbon Capture and Storage (SMR-CCS) has emerged as a transitional technology, capturing up to 90% of carbon emissions from traditional SMR processes. This "blue hydrogen" approach reduces environmental impact while maintaining relatively competitive costs of $1.5-3 per kg H2, though still higher than conventional SMR.

Significant barriers impede widespread adoption of cleaner hydrogen production technologies. For green hydrogen, high capital costs for electrolyzer systems represent a major obstacle, with current systems costing $500-1,000 per kW. Additionally, the technology faces efficiency challenges, with most commercial electrolyzers operating at 60-80% efficiency, resulting in substantial energy losses.

Infrastructure limitations present another critical barrier. The hydrogen economy lacks comprehensive distribution networks, storage facilities, and refueling stations. Current hydrogen storage options—including compression, liquefaction, and material-based storage—each present technical challenges regarding energy density, cost, and safety.

Regulatory frameworks remain underdeveloped in many regions, creating uncertainty for potential investors. The absence of standardized carbon pricing mechanisms further complicates economic comparisons between production methods, as the environmental costs of conventional SMR are not fully internalized in market prices.

For hydrogenolysis applications specifically, hydrogen purity requirements present additional challenges. While SMR typically produces hydrogen with 99.9% purity after purification, certain catalyst-sensitive hydrogenolysis processes may require ultra-high purity hydrogen (99.999+%), necessitating additional purification steps that increase production costs and complexity.

Electrolysis, particularly when powered by renewable energy sources (green hydrogen), represents a cleaner alternative but currently accounts for less than 4% of global hydrogen production. The technology splits water molecules using electricity, producing hydrogen with minimal emissions when renewable power is utilized. However, production costs remain high at $3-7 per kg H2, primarily due to expensive electrolyzer systems and the intermittent nature of renewable energy sources.

SMR with Carbon Capture and Storage (SMR-CCS) has emerged as a transitional technology, capturing up to 90% of carbon emissions from traditional SMR processes. This "blue hydrogen" approach reduces environmental impact while maintaining relatively competitive costs of $1.5-3 per kg H2, though still higher than conventional SMR.

Significant barriers impede widespread adoption of cleaner hydrogen production technologies. For green hydrogen, high capital costs for electrolyzer systems represent a major obstacle, with current systems costing $500-1,000 per kW. Additionally, the technology faces efficiency challenges, with most commercial electrolyzers operating at 60-80% efficiency, resulting in substantial energy losses.

Infrastructure limitations present another critical barrier. The hydrogen economy lacks comprehensive distribution networks, storage facilities, and refueling stations. Current hydrogen storage options—including compression, liquefaction, and material-based storage—each present technical challenges regarding energy density, cost, and safety.

Regulatory frameworks remain underdeveloped in many regions, creating uncertainty for potential investors. The absence of standardized carbon pricing mechanisms further complicates economic comparisons between production methods, as the environmental costs of conventional SMR are not fully internalized in market prices.

For hydrogenolysis applications specifically, hydrogen purity requirements present additional challenges. While SMR typically produces hydrogen with 99.9% purity after purification, certain catalyst-sensitive hydrogenolysis processes may require ultra-high purity hydrogen (99.999+%), necessitating additional purification steps that increase production costs and complexity.

Green Hydrogen vs SMR-CCS Technical Comparison

01 Green hydrogen production technologies

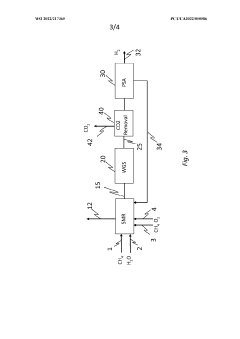

Green hydrogen production involves using renewable energy sources to power electrolysis processes that split water into hydrogen and oxygen. These technologies focus on sustainable hydrogen generation with minimal carbon footprint. Advanced electrolyzers, including PEM (Proton Exchange Membrane) and alkaline systems, are being developed to improve efficiency and reduce costs. Integration with renewable energy sources such as solar and wind power ensures the hydrogen produced is truly carbon-neutral.- Green hydrogen production technologies: Green hydrogen is produced through electrolysis powered by renewable energy sources such as solar, wind, or hydroelectric power. This method splits water molecules into hydrogen and oxygen without carbon emissions. Various electrolysis technologies are employed, including Proton Exchange Membrane (PEM), alkaline, and solid oxide electrolyzers. These systems can be scaled from small distributed units to large centralized facilities, offering flexibility in deployment based on renewable energy availability and hydrogen demand patterns.

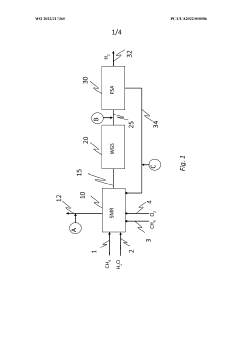

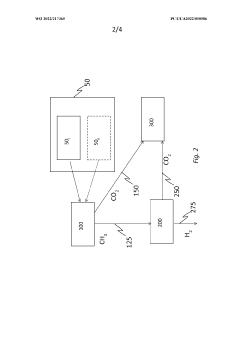

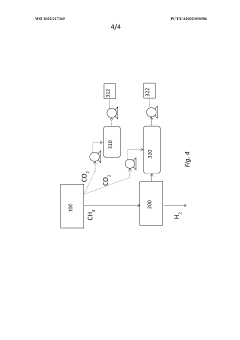

- SMR with Carbon Capture and Storage (CCS) systems: Steam Methane Reforming (SMR) with Carbon Capture and Storage involves capturing CO2 emissions from traditional hydrogen production processes. The technology uses natural gas as feedstock and implements various carbon capture methods including pre-combustion, post-combustion, and oxy-fuel combustion techniques. The captured carbon dioxide is then compressed, transported, and stored in geological formations such as depleted oil and gas fields or saline aquifers. This approach allows continued use of existing hydrogen production infrastructure while significantly reducing greenhouse gas emissions.

- Hydrogen storage and distribution infrastructure: Effective hydrogen supply strategies require robust storage and distribution systems. Technologies include compressed gas storage, liquid hydrogen storage at cryogenic temperatures, and chemical storage in the form of ammonia or liquid organic hydrogen carriers. Distribution methods encompass dedicated hydrogen pipelines, blending with natural gas in existing pipeline networks, and transportation via trucks, ships, or rail in various forms. The infrastructure development focuses on safety measures, material compatibility, and energy efficiency to minimize losses during storage and transport.

- Integrated hydrogen production and utilization systems: Integrated systems combine hydrogen production with immediate utilization applications to optimize efficiency and reduce transportation requirements. These systems include on-site hydrogen production for industrial processes, refueling stations with integrated electrolyzers, and combined heat, power, and hydrogen facilities. The integration allows for better energy management, reduced losses, and improved economics by sharing infrastructure and utilizing by-products. Some systems incorporate energy storage capabilities to balance intermittent renewable energy inputs and provide grid services while producing hydrogen.

- Economic and policy frameworks for hydrogen deployment: Successful hydrogen supply strategies depend on supportive economic models and policy frameworks. These include carbon pricing mechanisms, renewable energy incentives, production subsidies, and regulatory standards for hydrogen purity and carbon intensity. Investment strategies focus on risk mitigation through public-private partnerships, international collaboration for technology transfer, and development of hydrogen hubs that concentrate production, distribution, and consumption. Policy frameworks also address certification schemes for different hydrogen types (green, blue, etc.) and establish targets for hydrogen adoption in various sectors.

02 SMR-CCS (Steam Methane Reforming with Carbon Capture and Storage) systems

Steam Methane Reforming with Carbon Capture and Storage combines conventional hydrogen production methods with technologies to capture and sequester carbon emissions. These systems modify traditional natural gas reforming processes by incorporating carbon capture technologies that can trap up to 95% of CO2 emissions. The captured carbon is then compressed and transported for permanent geological storage, significantly reducing the carbon footprint of hydrogen production from fossil fuels while leveraging existing infrastructure.Expand Specific Solutions03 Hydrogen distribution and storage infrastructure

Effective hydrogen supply strategies require robust distribution and storage infrastructure. This includes pipeline networks specifically designed for hydrogen transport, compression and liquefaction technologies for efficient storage, and specialized materials resistant to hydrogen embrittlement. Advanced storage solutions such as liquid organic hydrogen carriers (LOHCs), metal hydrides, and underground cavern storage are being developed to address the challenges of hydrogen's low volumetric energy density and to enable large-scale deployment across various sectors.Expand Specific Solutions04 Integrated hydrogen production and utilization systems

Integrated systems combine hydrogen production, storage, and utilization in comprehensive solutions for various applications. These systems optimize energy efficiency by integrating hydrogen production with end-use applications such as fuel cells, industrial processes, or power generation. Smart control systems manage production rates based on demand and renewable energy availability, while heat recovery systems capture and utilize waste heat from production processes, improving overall system efficiency and economic viability.Expand Specific Solutions05 Hydrogen supply chain optimization and management

Optimization of hydrogen supply chains involves strategic planning of production facilities, distribution networks, and end-use applications to maximize efficiency and minimize costs. Advanced modeling tools analyze factors such as production capacity, transportation distances, storage requirements, and demand patterns to determine optimal supply chain configurations. Digital technologies including IoT sensors, blockchain for traceability, and AI-driven predictive analytics enable real-time monitoring and management of hydrogen supply chains, enhancing reliability and reducing operational costs.Expand Specific Solutions

Leading Companies in Hydrogen Production Ecosystem

The hydrogen supply landscape for hydrogenolysis is evolving rapidly, with the market transitioning from early development to commercial scaling. The global hydrogen market is projected to reach $200 billion by 2030, driven by decarbonization initiatives. Green hydrogen technology is advancing through innovations from Haldor Topsøe, Air Liquide, and Linde, while SMR-CCS (Steam Methane Reforming with Carbon Capture and Storage) is being commercialized by Air Products, Sinopec, and NuScale Power. The competitive landscape features established industrial gas companies expanding their hydrogen portfolios alongside specialized technology providers. The market is characterized by strategic partnerships between energy majors and technology developers to overcome scale and cost challenges, with both green hydrogen and SMR-CCS pathways progressing toward commercial viability for hydrogenolysis applications.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed advanced catalytic solutions specifically for hydrogenolysis processes using both green hydrogen and SMR-CCS (Steam Methane Reforming with Carbon Capture and Storage) pathways. Their TITAN series catalysts are designed to optimize hydrogen utilization efficiency in hydrogenolysis reactions, achieving up to 95% selectivity for target products while minimizing hydrogen consumption. For green hydrogen integration, they've engineered their HydroFlex™ technology that seamlessly connects electrolysis units with hydrogenolysis reactors, enabling direct utilization of fluctuating renewable electricity sources. On the SMR-CCS front, Topsøe's SynCOR Methane™ technology captures over 95% of CO2 emissions from hydrogen production while maintaining high energy efficiency. Their integrated approach includes proprietary heat recovery systems that reduce the overall energy penalty of carbon capture by approximately 15% compared to conventional amine-based systems[1][3].

Strengths: Industry-leading catalyst technology with exceptional selectivity and stability; integrated solutions that address both production and utilization sides of hydrogen; proven commercial-scale implementations. Weaknesses: Higher initial capital costs compared to unabated hydrogen pathways; technology optimization still required for smaller-scale applications; dependence on regional carbon storage infrastructure for SMR-CCS implementation.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has pioneered a comprehensive hydrogen supply strategy for hydrogenolysis applications through their dual-pathway approach. Their green hydrogen portfolio centers around PEM and alkaline electrolysis technologies scaled to industrial levels, with their flagship projects achieving electrolyzer efficiencies of 70-75% (LHV basis). For hydrogenolysis applications specifically, they've developed modular hydrogen supply units that can be integrated directly with processing facilities, reducing transportation losses and ensuring pressure-optimized delivery. Their SMR-CCS technology utilizes proprietary pressure swing adsorption systems achieving hydrogen purities exceeding 99.999%, critical for catalyst longevity in hydrogenolysis processes. Their ECLIPSE™ carbon capture technology can be retrofitted to existing SMR units, capturing up to 98% of CO2 emissions while maintaining hydrogen production costs within 15-20% of unabated hydrogen. Air Products has also developed specialized hydrogen storage and compression systems designed specifically for the pressure and purity requirements of hydrogenolysis reactions, with their HyPure™ system ensuring contaminant levels below 10 ppb[2][4].

Strengths: Extensive hydrogen infrastructure network providing reliable supply; advanced purification technologies ensuring catalyst-friendly hydrogen; demonstrated experience in large-scale hydrogen projects across both pathways. Weaknesses: Green hydrogen production capacity still limited compared to SMR-based production; geographic constraints on hydrogen delivery networks; higher costs for green hydrogen pathway compared to SMR-CCS in most regions.

Critical Patents in Hydrogen Production Technologies

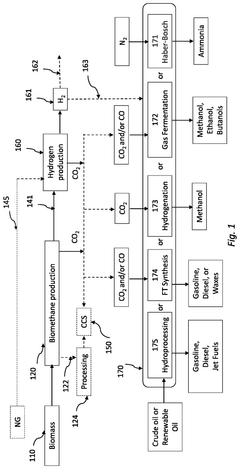

Process and system for producing low carbon intensity renewable hydrogen

PatentWO2022217365A1

Innovation

- A process that upgrades biogas to remove at least 50% of its CO2, transports the upgraded biogas to a hydrogen plant for methane reforming, and captures and stores CO2 from both the biogas upgrading and hydrogen production stages, optimizing CO2 capture at each stage to achieve negative carbon intensity for the produced hydrogen.

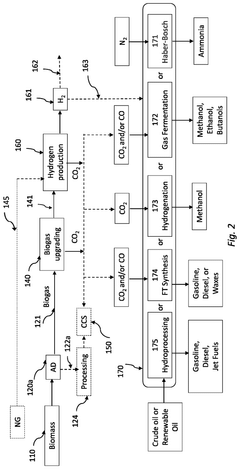

Hybrid-electric process and/or system for producing hydrogen

PatentPendingUS20250019235A1

Innovation

- A hybrid-electric process combining biomethane production from diverse biomass sources with low-carbon electricity for methane reforming and a three-tiered carbon capture and storage (CCS) approach, including CCS from biomethane, hydrogen production, and digestate processing, to enhance energy efficiency and reduce carbon intensity.

Economic Viability Assessment of Hydrogen Production Methods

The economic viability of hydrogen production methods represents a critical factor in determining the feasibility of hydrogen as a sustainable energy carrier for hydrogenolysis applications. Current analysis indicates that green hydrogen production costs range between $4-6/kg, while SMR with carbon capture and storage (SMR-CCS) typically costs $1.5-3/kg, creating a significant cost differential that impacts industrial adoption.

Capital expenditure requirements vary substantially between these production methods. Green hydrogen facilities require investments of approximately $900-1,500/kW of electrolyzer capacity, with additional costs for renewable energy infrastructure. Conversely, SMR-CCS facilities demand $600-1,000/kW of production capacity, but necessitate additional investment in carbon capture technology and sequestration infrastructure.

Operational expenses present another dimension of economic comparison. Green hydrogen production costs are dominated by electricity prices, with renewable electricity accounting for 60-70% of total production costs. Production efficiency becomes economically viable when electricity prices fall below $0.04/kWh. SMR-CCS operational costs are primarily influenced by natural gas prices, which historically have shown significant volatility, and additional expenses related to carbon management.

Scale economics significantly impact viability assessments. Green hydrogen currently benefits from modular deployment capabilities but faces challenges in achieving economies of scale. Industry projections suggest that costs could decrease by 40-60% by 2030 through technological improvements and manufacturing scale-up. SMR-CCS benefits from established economies of scale but faces diminishing returns on carbon capture efficiency beyond 90% capture rates.

Geographic factors substantially influence economic viability. Regions with abundant low-cost renewable energy resources (e.g., Australia, Chile, and parts of the Middle East) demonstrate more favorable economics for green hydrogen. Meanwhile, regions with established natural gas infrastructure and suitable geological formations for carbon storage present advantages for SMR-CCS implementation.

Policy incentives increasingly shape the economic landscape for hydrogen production. Carbon pricing mechanisms, production tax credits, and regulatory frameworks for carbon management significantly impact the comparative economics of these production pathways. The Inflation Reduction Act in the US, offering up to $3/kg for clean hydrogen production, has substantially altered regional economic calculations.

Capital expenditure requirements vary substantially between these production methods. Green hydrogen facilities require investments of approximately $900-1,500/kW of electrolyzer capacity, with additional costs for renewable energy infrastructure. Conversely, SMR-CCS facilities demand $600-1,000/kW of production capacity, but necessitate additional investment in carbon capture technology and sequestration infrastructure.

Operational expenses present another dimension of economic comparison. Green hydrogen production costs are dominated by electricity prices, with renewable electricity accounting for 60-70% of total production costs. Production efficiency becomes economically viable when electricity prices fall below $0.04/kWh. SMR-CCS operational costs are primarily influenced by natural gas prices, which historically have shown significant volatility, and additional expenses related to carbon management.

Scale economics significantly impact viability assessments. Green hydrogen currently benefits from modular deployment capabilities but faces challenges in achieving economies of scale. Industry projections suggest that costs could decrease by 40-60% by 2030 through technological improvements and manufacturing scale-up. SMR-CCS benefits from established economies of scale but faces diminishing returns on carbon capture efficiency beyond 90% capture rates.

Geographic factors substantially influence economic viability. Regions with abundant low-cost renewable energy resources (e.g., Australia, Chile, and parts of the Middle East) demonstrate more favorable economics for green hydrogen. Meanwhile, regions with established natural gas infrastructure and suitable geological formations for carbon storage present advantages for SMR-CCS implementation.

Policy incentives increasingly shape the economic landscape for hydrogen production. Carbon pricing mechanisms, production tax credits, and regulatory frameworks for carbon management significantly impact the comparative economics of these production pathways. The Inflation Reduction Act in the US, offering up to $3/kg for clean hydrogen production, has substantially altered regional economic calculations.

Environmental Impact and Carbon Footprint Analysis

The environmental impact assessment of hydrogen production methods reveals significant differences between green hydrogen and Steam Methane Reforming with Carbon Capture and Storage (SMR-CCS) for hydrogenolysis applications. Green hydrogen, produced through water electrolysis powered by renewable energy, demonstrates near-zero operational carbon emissions, with lifecycle emissions primarily stemming from manufacturing and installation of renewable energy infrastructure and electrolyzers.

In contrast, SMR-CCS technology, while more carbon-intensive than green hydrogen, offers substantial improvements over conventional SMR processes. Current SMR-CCS systems can capture 60-90% of carbon emissions, reducing the carbon footprint from approximately 9-12 kg CO2/kg H2 to 1-4 kg CO2/kg H2. However, this approach still contributes to greenhouse gas emissions through uncaptured CO2 and fugitive methane leaks throughout the natural gas supply chain.

Water consumption presents another critical environmental consideration. Green hydrogen production via electrolysis requires approximately 9 kg of water per kg of hydrogen produced. While this represents significant water usage, SMR-CCS processes consume approximately 4.5 kg of water per kg of hydrogen, though additional water is required for cooling systems in both production methods.

Land use impacts also differ substantially between the two approaches. Green hydrogen production chains require extensive land area for renewable energy generation—particularly for solar PV installations—whereas SMR-CCS facilities have a more concentrated footprint but require infrastructure for CO2 transportation and storage.

The environmental assessment must also consider the potential risks of carbon storage in SMR-CCS systems, including leakage risks and induced seismicity. These factors must be carefully managed through appropriate site selection and monitoring protocols to ensure long-term environmental safety.

When applied specifically to hydrogenolysis processes, which utilize hydrogen to break chemical bonds in various industrial applications, the environmental benefits of cleaner hydrogen production are amplified through the value chain. Hydrogenolysis using green hydrogen can potentially achieve near carbon-neutral operation for certain chemical transformations, while SMR-CCS-based hydrogen significantly reduces but does not eliminate the carbon footprint of these processes.

The comprehensive environmental analysis indicates that while green hydrogen represents the ideal long-term solution for truly sustainable hydrogenolysis applications, SMR-CCS offers a viable transitional technology that can deliver substantial carbon reductions compared to conventional hydrogen production methods while the renewable energy infrastructure continues to scale.

In contrast, SMR-CCS technology, while more carbon-intensive than green hydrogen, offers substantial improvements over conventional SMR processes. Current SMR-CCS systems can capture 60-90% of carbon emissions, reducing the carbon footprint from approximately 9-12 kg CO2/kg H2 to 1-4 kg CO2/kg H2. However, this approach still contributes to greenhouse gas emissions through uncaptured CO2 and fugitive methane leaks throughout the natural gas supply chain.

Water consumption presents another critical environmental consideration. Green hydrogen production via electrolysis requires approximately 9 kg of water per kg of hydrogen produced. While this represents significant water usage, SMR-CCS processes consume approximately 4.5 kg of water per kg of hydrogen, though additional water is required for cooling systems in both production methods.

Land use impacts also differ substantially between the two approaches. Green hydrogen production chains require extensive land area for renewable energy generation—particularly for solar PV installations—whereas SMR-CCS facilities have a more concentrated footprint but require infrastructure for CO2 transportation and storage.

The environmental assessment must also consider the potential risks of carbon storage in SMR-CCS systems, including leakage risks and induced seismicity. These factors must be carefully managed through appropriate site selection and monitoring protocols to ensure long-term environmental safety.

When applied specifically to hydrogenolysis processes, which utilize hydrogen to break chemical bonds in various industrial applications, the environmental benefits of cleaner hydrogen production are amplified through the value chain. Hydrogenolysis using green hydrogen can potentially achieve near carbon-neutral operation for certain chemical transformations, while SMR-CCS-based hydrogen significantly reduces but does not eliminate the carbon footprint of these processes.

The comprehensive environmental analysis indicates that while green hydrogen represents the ideal long-term solution for truly sustainable hydrogenolysis applications, SMR-CCS offers a viable transitional technology that can deliver substantial carbon reductions compared to conventional hydrogen production methods while the renewable energy infrastructure continues to scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!