How Vacuum Pumps Influence Automated Liquid Handling Systems

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Technology Evolution and Objectives

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. From early mechanical pumps to modern sophisticated designs, the progression has been driven by the need for improved efficiency, reliability, and precision in various applications. In the context of automated liquid handling systems, vacuum pumps play a crucial role in enabling accurate and consistent fluid manipulation.

The primary objective of vacuum pump technology in automated liquid handling systems is to create controlled negative pressure for precise aspiration and dispensing of liquids. This technology aims to enhance the accuracy, speed, and reproducibility of liquid handling operations across various industries, including life sciences, pharmaceuticals, and clinical diagnostics.

Over time, vacuum pump technology has evolved from simple mechanical designs to more advanced electromagnetic and piezoelectric systems. These advancements have led to significant improvements in pump performance, miniaturization, and integration capabilities. The trend towards smaller, more efficient pumps has been particularly beneficial for automated liquid handling systems, allowing for more compact and versatile instruments.

Another key objective in the evolution of vacuum pump technology for liquid handling applications is the reduction of pulsation and noise. Smooth, consistent vacuum generation is essential for maintaining the accuracy and reliability of liquid handling operations. This has led to the development of innovative pump designs and control mechanisms that minimize fluctuations in vacuum pressure.

The integration of smart features and digital control systems represents a recent trend in vacuum pump technology. These advancements allow for precise regulation of vacuum levels, real-time monitoring of pump performance, and seamless integration with automated liquid handling workflows. The ability to adjust vacuum parameters dynamically based on specific liquid properties or experimental conditions has greatly expanded the capabilities of automated systems.

Environmental considerations have also shaped the evolution of vacuum pump technology. There is a growing emphasis on developing energy-efficient pumps that consume less power and generate less heat. Additionally, the use of oil-free pump designs has become increasingly important in applications where contamination must be minimized, such as in pharmaceutical and biotech research.

Looking ahead, the objectives for vacuum pump technology in automated liquid handling systems include further miniaturization, increased energy efficiency, and enhanced integration with artificial intelligence and machine learning algorithms. These developments aim to enable more sophisticated and adaptive liquid handling processes, capable of handling a wider range of sample types and volumes with even greater precision and reliability.

The primary objective of vacuum pump technology in automated liquid handling systems is to create controlled negative pressure for precise aspiration and dispensing of liquids. This technology aims to enhance the accuracy, speed, and reproducibility of liquid handling operations across various industries, including life sciences, pharmaceuticals, and clinical diagnostics.

Over time, vacuum pump technology has evolved from simple mechanical designs to more advanced electromagnetic and piezoelectric systems. These advancements have led to significant improvements in pump performance, miniaturization, and integration capabilities. The trend towards smaller, more efficient pumps has been particularly beneficial for automated liquid handling systems, allowing for more compact and versatile instruments.

Another key objective in the evolution of vacuum pump technology for liquid handling applications is the reduction of pulsation and noise. Smooth, consistent vacuum generation is essential for maintaining the accuracy and reliability of liquid handling operations. This has led to the development of innovative pump designs and control mechanisms that minimize fluctuations in vacuum pressure.

The integration of smart features and digital control systems represents a recent trend in vacuum pump technology. These advancements allow for precise regulation of vacuum levels, real-time monitoring of pump performance, and seamless integration with automated liquid handling workflows. The ability to adjust vacuum parameters dynamically based on specific liquid properties or experimental conditions has greatly expanded the capabilities of automated systems.

Environmental considerations have also shaped the evolution of vacuum pump technology. There is a growing emphasis on developing energy-efficient pumps that consume less power and generate less heat. Additionally, the use of oil-free pump designs has become increasingly important in applications where contamination must be minimized, such as in pharmaceutical and biotech research.

Looking ahead, the objectives for vacuum pump technology in automated liquid handling systems include further miniaturization, increased energy efficiency, and enhanced integration with artificial intelligence and machine learning algorithms. These developments aim to enable more sophisticated and adaptive liquid handling processes, capable of handling a wider range of sample types and volumes with even greater precision and reliability.

Market Demand Analysis for Automated Liquid Handling

The market demand for automated liquid handling systems has been experiencing significant growth, driven by the increasing need for high-throughput screening, precision, and efficiency in various industries. The pharmaceutical and biotechnology sectors are at the forefront of this demand, as they require accurate and reproducible liquid handling for drug discovery, genomics, and proteomics research. Clinical diagnostics laboratories also contribute substantially to the market growth, with the rising prevalence of chronic diseases and the need for rapid, high-volume testing.

The global automated liquid handling market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is fueled by technological advancements in robotics, microfluidics, and artificial intelligence, which are enhancing the capabilities and reliability of these systems. The integration of vacuum pumps into automated liquid handling systems has become a crucial factor in meeting the market's demands for improved precision and reduced contamination risks.

In recent years, there has been a notable shift towards miniaturization and increased throughput in liquid handling processes. This trend has led to a growing demand for systems that can handle smaller volumes with greater accuracy, where vacuum pump technology plays a vital role. The ability of vacuum pumps to precisely control pressure and flow rates has become essential in applications such as microplate filling, reagent dispensing, and sample preparation.

The COVID-19 pandemic has further accelerated the adoption of automated liquid handling systems, particularly in diagnostic laboratories and vaccine development facilities. This surge in demand has highlighted the importance of reliable and efficient liquid handling technologies, including those incorporating advanced vacuum pump systems. The market has seen an increased focus on systems that can handle a wide range of viscosities and volumes, from nanoliters to milliliters, with minimal cross-contamination.

Environmental concerns and sustainability initiatives are also shaping market demand. There is a growing preference for energy-efficient automated liquid handling systems that minimize waste and reduce the use of disposable plastics. Vacuum pump technologies that offer lower power consumption and longer operational lifespans are gaining traction in this context, aligning with the broader industry trend towards green laboratory practices.

As the market continues to evolve, there is an increasing demand for integrated solutions that combine liquid handling with other laboratory processes. This integration often relies on sophisticated vacuum systems to ensure seamless operation across different modules. The ability of vacuum pumps to maintain consistent performance under varying conditions is becoming a key differentiator in the competitive landscape of automated liquid handling systems.

The global automated liquid handling market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is fueled by technological advancements in robotics, microfluidics, and artificial intelligence, which are enhancing the capabilities and reliability of these systems. The integration of vacuum pumps into automated liquid handling systems has become a crucial factor in meeting the market's demands for improved precision and reduced contamination risks.

In recent years, there has been a notable shift towards miniaturization and increased throughput in liquid handling processes. This trend has led to a growing demand for systems that can handle smaller volumes with greater accuracy, where vacuum pump technology plays a vital role. The ability of vacuum pumps to precisely control pressure and flow rates has become essential in applications such as microplate filling, reagent dispensing, and sample preparation.

The COVID-19 pandemic has further accelerated the adoption of automated liquid handling systems, particularly in diagnostic laboratories and vaccine development facilities. This surge in demand has highlighted the importance of reliable and efficient liquid handling technologies, including those incorporating advanced vacuum pump systems. The market has seen an increased focus on systems that can handle a wide range of viscosities and volumes, from nanoliters to milliliters, with minimal cross-contamination.

Environmental concerns and sustainability initiatives are also shaping market demand. There is a growing preference for energy-efficient automated liquid handling systems that minimize waste and reduce the use of disposable plastics. Vacuum pump technologies that offer lower power consumption and longer operational lifespans are gaining traction in this context, aligning with the broader industry trend towards green laboratory practices.

As the market continues to evolve, there is an increasing demand for integrated solutions that combine liquid handling with other laboratory processes. This integration often relies on sophisticated vacuum systems to ensure seamless operation across different modules. The ability of vacuum pumps to maintain consistent performance under varying conditions is becoming a key differentiator in the competitive landscape of automated liquid handling systems.

Current Challenges in Vacuum Pump Integration

The integration of vacuum pumps into automated liquid handling systems presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the precise control of vacuum pressure. Automated liquid handling systems require extremely accurate and consistent vacuum levels to ensure reliable and reproducible results. However, maintaining such precision across different liquid types, volumes, and environmental conditions remains a complex task.

Another challenge lies in the miniaturization of vacuum pump components. As automated liquid handling systems become more compact and portable, there is a growing demand for smaller, lighter vacuum pumps that can deliver the same performance as their larger counterparts. This miniaturization process often leads to trade-offs between size, power consumption, and vacuum efficiency, creating a delicate balance that engineers must navigate.

Noise and vibration reduction is yet another hurdle in vacuum pump integration. The operation of vacuum pumps can introduce unwanted vibrations and noise into the liquid handling system, potentially affecting the accuracy of liquid dispensing and the overall performance of sensitive laboratory equipment. Developing quieter, low-vibration vacuum pumps without compromising on performance is an ongoing challenge in the field.

Energy efficiency and heat management also pose significant challenges. Vacuum pumps consume considerable energy and generate heat during operation, which can affect the temperature-sensitive processes in liquid handling systems. Improving the energy efficiency of vacuum pumps while effectively managing heat dissipation is crucial for the long-term reliability and sustainability of automated liquid handling systems.

Furthermore, the integration of smart features and connectivity into vacuum pumps presents both opportunities and challenges. While the ability to monitor and control vacuum pumps remotely can enhance system performance and maintenance, it also introduces complexities in terms of software integration, data security, and system compatibility.

Lastly, the need for chemical resistance and contamination prevention in vacuum pumps used in liquid handling systems cannot be overstated. Many laboratory applications involve corrosive or volatile substances that can potentially damage pump components or contaminate samples. Developing vacuum pumps with robust materials and effective sealing mechanisms to withstand a wide range of chemicals while maintaining performance is an ongoing challenge in the industry.

Another challenge lies in the miniaturization of vacuum pump components. As automated liquid handling systems become more compact and portable, there is a growing demand for smaller, lighter vacuum pumps that can deliver the same performance as their larger counterparts. This miniaturization process often leads to trade-offs between size, power consumption, and vacuum efficiency, creating a delicate balance that engineers must navigate.

Noise and vibration reduction is yet another hurdle in vacuum pump integration. The operation of vacuum pumps can introduce unwanted vibrations and noise into the liquid handling system, potentially affecting the accuracy of liquid dispensing and the overall performance of sensitive laboratory equipment. Developing quieter, low-vibration vacuum pumps without compromising on performance is an ongoing challenge in the field.

Energy efficiency and heat management also pose significant challenges. Vacuum pumps consume considerable energy and generate heat during operation, which can affect the temperature-sensitive processes in liquid handling systems. Improving the energy efficiency of vacuum pumps while effectively managing heat dissipation is crucial for the long-term reliability and sustainability of automated liquid handling systems.

Furthermore, the integration of smart features and connectivity into vacuum pumps presents both opportunities and challenges. While the ability to monitor and control vacuum pumps remotely can enhance system performance and maintenance, it also introduces complexities in terms of software integration, data security, and system compatibility.

Lastly, the need for chemical resistance and contamination prevention in vacuum pumps used in liquid handling systems cannot be overstated. Many laboratory applications involve corrosive or volatile substances that can potentially damage pump components or contaminate samples. Developing vacuum pumps with robust materials and effective sealing mechanisms to withstand a wide range of chemicals while maintaining performance is an ongoing challenge in the industry.

Existing Vacuum Pump Solutions for Liquid Handling

01 Vacuum pump design and efficiency

Improvements in vacuum pump design focus on enhancing efficiency and performance. This includes optimizing internal components, reducing friction, and implementing advanced sealing technologies. These advancements result in better vacuum generation, increased reliability, and reduced energy consumption.- Vacuum pump design and efficiency: Innovations in vacuum pump design focus on improving efficiency and performance. This includes optimizing internal components, reducing friction, and enhancing sealing mechanisms. Advanced designs aim to achieve higher vacuum levels while minimizing energy consumption and maintenance requirements.

- Application in semiconductor manufacturing: Vacuum pumps play a crucial role in semiconductor manufacturing processes. They are used for creating controlled environments, removing contaminants, and facilitating thin film deposition. Specialized pump designs cater to the unique requirements of semiconductor fabrication, ensuring high purity and precision in chip production.

- Vacuum pump control systems: Advanced control systems enhance the operation of vacuum pumps. These systems incorporate sensors, feedback mechanisms, and intelligent algorithms to optimize pump performance. They enable precise pressure regulation, automatic adjustment to varying load conditions, and improved energy efficiency in industrial applications.

- Vacuum pump noise reduction: Efforts to reduce noise levels in vacuum pump operation focus on innovative designs and materials. This includes the use of sound-absorbing enclosures, vibration isolation techniques, and optimized fluid flow paths. Quieter pump operation is particularly important in laboratory and medical settings.

- Vacuum pumps in automotive applications: Vacuum pumps are increasingly utilized in automotive systems, particularly in brake boosters and emission control systems. Developments in this area focus on compact designs, durability under varying conditions, and integration with electronic control systems to enhance vehicle performance and safety.

02 Application in semiconductor manufacturing

Vacuum pumps play a crucial role in semiconductor manufacturing processes. They are used for creating clean, controlled environments necessary for wafer processing, thin film deposition, and etching. The influence of vacuum pumps in this field extends to improving yield, reducing contamination, and enabling the production of more advanced semiconductor devices.Expand Specific Solutions03 Vacuum pump control systems

Advanced control systems for vacuum pumps enhance their performance and adaptability. These systems incorporate sensors, feedback mechanisms, and intelligent algorithms to optimize pump operation based on specific process requirements. This results in improved vacuum stability, energy efficiency, and the ability to handle varying load conditions.Expand Specific Solutions04 Vacuum pumps in automotive applications

Vacuum pumps have significant influence in automotive systems, particularly in brake boosters and engine management. They contribute to improved vehicle safety, enhanced engine performance, and reduced emissions. Advancements in this area focus on developing more compact, efficient, and durable vacuum pumps for automotive use.Expand Specific Solutions05 Environmental impact and sustainability

The influence of vacuum pumps extends to environmental considerations and sustainability efforts. This includes developing pumps with reduced noise levels, lower power consumption, and minimal oil usage or oil-free operation. These advancements contribute to cleaner manufacturing processes, reduced carbon footprint, and improved workplace environments.Expand Specific Solutions

Key Players in Automated Liquid Handling Industry

The vacuum pump market for automated liquid handling systems is in a growth phase, driven by increasing demand in pharmaceutical and biotechnology industries. The market size is expanding, with key players like Edwards Ltd., Cytiva Sweden AB, and Hamilton Bonaduz AG competing for market share. Technological advancements are pushing the industry towards more efficient and precise pumps, with companies like Gardner Denver Nash Machinery Ltd. and Ateliers Busch SA focusing on innovative solutions. The technology's maturity varies, with established firms like Johnson & Johnson and Air Products & Chemicals, Inc. investing in R&D to maintain their competitive edge, while newer entrants are emerging with specialized offerings for niche applications.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for automated liquid handling systems. Their innovative dry pumps, such as the nXDS scroll pump series, offer oil-free operation and low vibration, crucial for precise liquid handling[1]. These pumps utilize intelligent control systems to maintain consistent vacuum levels, ensuring accurate aspiration and dispensing of liquids. Edwards' pumps also incorporate adaptive pressure control algorithms that adjust pump speed based on the system's requirements, optimizing energy efficiency and reducing wear[2]. The company has further enhanced their pumps with advanced materials and coatings to improve chemical resistance and longevity in diverse laboratory environments[3].

Strengths: Oil-free operation reduces contamination risks; intelligent control systems ensure precise vacuum levels; energy-efficient operation. Weaknesses: Higher initial cost compared to traditional pumps; may require specialized maintenance.

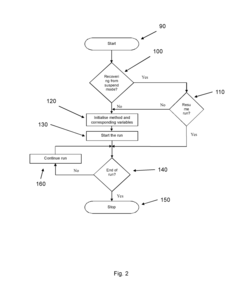

Cytiva Sweden AB

Technical Solution: Cytiva Sweden AB has integrated sophisticated vacuum pump technology into their automated liquid handling systems, particularly in their Biacore™ and Äkta™ product lines. Their systems utilize high-precision vacuum pumps that enable accurate sample aspiration and dispensing in protein interaction analysis and chromatography applications[1]. Cytiva's pumps incorporate advanced flow path designs that minimize dead volumes and reduce sample loss, crucial for working with valuable biological samples[2]. The company has developed intelligent vacuum control algorithms that adapt to changes in environmental conditions and sample properties, ensuring consistent performance across different experimental setups[3]. Additionally, Cytiva's pumps feature self-diagnostic capabilities that monitor performance and alert users to potential issues, enhancing system reliability and reducing downtime[4].

Strengths: Optimized for biological sample handling; minimal dead volumes reduce sample loss; intelligent adaptive control for consistent performance. Weaknesses: Specialized design may limit flexibility for non-standard applications; potentially higher cost due to advanced features tailored for life sciences.

Core Innovations in Vacuum Pump Technology

Automated liquid handling apparatus comprising an optimised waste collection container

PatentWO2025083049A1

Innovation

- The automated liquid handling device incorporates a waste collection container with a tub body and a container lid that covers the absorption volume, reducing the risk of splashes and contamination. The device also features a control system and a lifting device for efficient handling and disposal of waste liquids.

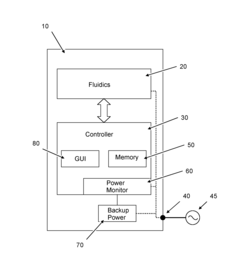

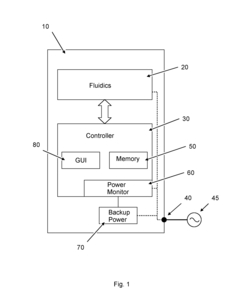

Automated fluid handling system

PatentActiveUS20160223574A1

Innovation

- An automated fluid handling system with a controller that monitors power sources, utilizes a backup power source to suspend operations during power shortages, saves process status information, and verifies the safety of resuming processes upon power restoration, allowing for automatic or user-confirmed resumption based on predefined settings.

Precision and Accuracy Considerations

Precision and accuracy are paramount considerations in automated liquid handling systems, and vacuum pumps play a crucial role in achieving these objectives. The influence of vacuum pumps on the precision and accuracy of liquid handling operations is multifaceted and requires careful analysis.

Vacuum pumps contribute significantly to the aspiration and dispensing processes in automated liquid handling systems. The consistency and stability of the vacuum pressure generated by these pumps directly impact the volume accuracy of liquid transfers. Fluctuations in vacuum pressure can lead to inconsistent aspiration volumes, resulting in errors that propagate through subsequent steps of an assay or experiment.

The speed and control of liquid aspiration are also heavily influenced by vacuum pump performance. High-quality vacuum pumps with precise pressure control mechanisms allow for finer adjustments in aspiration rates, enabling more accurate handling of small volumes and viscous liquids. This level of control is particularly critical when working with valuable or limited samples, where even minor inaccuracies can have significant consequences.

Furthermore, the vacuum pump's ability to maintain consistent performance over time affects the long-term reliability of liquid handling operations. Pumps that exhibit drift or degradation in vacuum pressure generation can lead to gradual shifts in accuracy, potentially compromising experimental results or manufacturing quality over extended periods.

The integration of vacuum pumps with liquid level detection systems is another crucial aspect of precision and accuracy. Advanced systems utilize vacuum-based liquid level sensing to detect the exact position of the liquid surface, allowing for more precise aspiration and reducing the risk of cross-contamination or incomplete sample transfer.

Temperature fluctuations induced by vacuum pump operation can also impact liquid handling accuracy. Heat generated by pumps can cause thermal expansion of liquids, leading to volume changes that may affect precision, especially when working with temperature-sensitive reagents or in applications requiring strict temperature control.

To address these challenges, modern automated liquid handling systems often incorporate feedback mechanisms that continuously monitor and adjust vacuum pressure. These systems can compensate for variations in environmental conditions or changes in liquid properties, maintaining consistent performance across different operating conditions.

The choice of vacuum pump technology also plays a role in precision and accuracy considerations. Diaphragm pumps, for instance, offer pulsation-free operation, which can be advantageous for applications requiring smooth and consistent liquid flow. On the other hand, rotary vane pumps may provide higher vacuum levels suitable for handling volatile liquids or working with challenging sample types.

In conclusion, the influence of vacuum pumps on the precision and accuracy of automated liquid handling systems is a critical factor that demands careful consideration in system design and operation. Optimizing vacuum pump performance and integration is essential for achieving the high levels of reliability and reproducibility required in modern laboratory and industrial applications.

Vacuum pumps contribute significantly to the aspiration and dispensing processes in automated liquid handling systems. The consistency and stability of the vacuum pressure generated by these pumps directly impact the volume accuracy of liquid transfers. Fluctuations in vacuum pressure can lead to inconsistent aspiration volumes, resulting in errors that propagate through subsequent steps of an assay or experiment.

The speed and control of liquid aspiration are also heavily influenced by vacuum pump performance. High-quality vacuum pumps with precise pressure control mechanisms allow for finer adjustments in aspiration rates, enabling more accurate handling of small volumes and viscous liquids. This level of control is particularly critical when working with valuable or limited samples, where even minor inaccuracies can have significant consequences.

Furthermore, the vacuum pump's ability to maintain consistent performance over time affects the long-term reliability of liquid handling operations. Pumps that exhibit drift or degradation in vacuum pressure generation can lead to gradual shifts in accuracy, potentially compromising experimental results or manufacturing quality over extended periods.

The integration of vacuum pumps with liquid level detection systems is another crucial aspect of precision and accuracy. Advanced systems utilize vacuum-based liquid level sensing to detect the exact position of the liquid surface, allowing for more precise aspiration and reducing the risk of cross-contamination or incomplete sample transfer.

Temperature fluctuations induced by vacuum pump operation can also impact liquid handling accuracy. Heat generated by pumps can cause thermal expansion of liquids, leading to volume changes that may affect precision, especially when working with temperature-sensitive reagents or in applications requiring strict temperature control.

To address these challenges, modern automated liquid handling systems often incorporate feedback mechanisms that continuously monitor and adjust vacuum pressure. These systems can compensate for variations in environmental conditions or changes in liquid properties, maintaining consistent performance across different operating conditions.

The choice of vacuum pump technology also plays a role in precision and accuracy considerations. Diaphragm pumps, for instance, offer pulsation-free operation, which can be advantageous for applications requiring smooth and consistent liquid flow. On the other hand, rotary vane pumps may provide higher vacuum levels suitable for handling volatile liquids or working with challenging sample types.

In conclusion, the influence of vacuum pumps on the precision and accuracy of automated liquid handling systems is a critical factor that demands careful consideration in system design and operation. Optimizing vacuum pump performance and integration is essential for achieving the high levels of reliability and reproducibility required in modern laboratory and industrial applications.

Environmental Impact and Energy Efficiency

Vacuum pumps play a crucial role in automated liquid handling systems, and their environmental impact and energy efficiency are important considerations in the design and operation of these systems. The use of vacuum pumps in liquid handling contributes significantly to the overall energy consumption of laboratory automation equipment. As such, there is a growing focus on improving the energy efficiency of these pumps to reduce their environmental footprint.

Modern vacuum pumps used in automated liquid handling systems have undergone substantial improvements in energy efficiency. Manufacturers have implemented various technologies to optimize pump performance while minimizing power consumption. These advancements include the use of variable speed drives, which allow pumps to adjust their operation based on the specific requirements of each liquid handling task. This dynamic adjustment helps reduce unnecessary energy expenditure during periods of low demand.

Additionally, the integration of smart control systems has further enhanced the energy efficiency of vacuum pumps in liquid handling applications. These systems can monitor and regulate pump operation in real-time, ensuring optimal performance while minimizing energy waste. Some advanced systems even incorporate predictive maintenance algorithms, which can detect potential issues before they lead to increased energy consumption or system failures.

The environmental impact of vacuum pumps in automated liquid handling systems extends beyond energy consumption. The choice of pump technology can also affect the system's overall ecological footprint. For instance, oil-free vacuum pumps have gained popularity due to their reduced environmental impact compared to traditional oil-sealed pumps. These oil-free pumps eliminate the need for regular oil changes and disposal, thereby reducing waste generation and the potential for contamination.

Furthermore, the noise pollution associated with vacuum pump operation has been addressed in recent pump designs. Quieter pumps not only improve the laboratory working environment but also contribute to reduced overall environmental impact. This is particularly important in facilities where multiple automated liquid handling systems are in operation simultaneously.

Water consumption is another environmental factor to consider in vacuum pump systems. Some liquid handling applications may utilize water-ring vacuum pumps, which can consume significant amounts of water. However, there is a trend towards adopting more water-efficient technologies or implementing closed-loop water recycling systems to minimize water usage and waste.

As sustainability becomes an increasingly important factor in laboratory operations, manufacturers of automated liquid handling systems are placing greater emphasis on the life cycle assessment of their equipment, including vacuum pumps. This holistic approach considers the environmental impact from production and operation to disposal and recycling. Consequently, there is a growing market for vacuum pumps designed with recyclable materials and modular construction, facilitating easier maintenance and end-of-life recycling.

Modern vacuum pumps used in automated liquid handling systems have undergone substantial improvements in energy efficiency. Manufacturers have implemented various technologies to optimize pump performance while minimizing power consumption. These advancements include the use of variable speed drives, which allow pumps to adjust their operation based on the specific requirements of each liquid handling task. This dynamic adjustment helps reduce unnecessary energy expenditure during periods of low demand.

Additionally, the integration of smart control systems has further enhanced the energy efficiency of vacuum pumps in liquid handling applications. These systems can monitor and regulate pump operation in real-time, ensuring optimal performance while minimizing energy waste. Some advanced systems even incorporate predictive maintenance algorithms, which can detect potential issues before they lead to increased energy consumption or system failures.

The environmental impact of vacuum pumps in automated liquid handling systems extends beyond energy consumption. The choice of pump technology can also affect the system's overall ecological footprint. For instance, oil-free vacuum pumps have gained popularity due to their reduced environmental impact compared to traditional oil-sealed pumps. These oil-free pumps eliminate the need for regular oil changes and disposal, thereby reducing waste generation and the potential for contamination.

Furthermore, the noise pollution associated with vacuum pump operation has been addressed in recent pump designs. Quieter pumps not only improve the laboratory working environment but also contribute to reduced overall environmental impact. This is particularly important in facilities where multiple automated liquid handling systems are in operation simultaneously.

Water consumption is another environmental factor to consider in vacuum pump systems. Some liquid handling applications may utilize water-ring vacuum pumps, which can consume significant amounts of water. However, there is a trend towards adopting more water-efficient technologies or implementing closed-loop water recycling systems to minimize water usage and waste.

As sustainability becomes an increasingly important factor in laboratory operations, manufacturers of automated liquid handling systems are placing greater emphasis on the life cycle assessment of their equipment, including vacuum pumps. This holistic approach considers the environmental impact from production and operation to disposal and recycling. Consequently, there is a growing market for vacuum pumps designed with recyclable materials and modular construction, facilitating easier maintenance and end-of-life recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!