How to Sustain Hypochlorous Acid Quality in Long-Term Storage?

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Stability Challenges and Objectives

Hypochlorous acid (HOCl) has gained significant attention in recent years due to its potent antimicrobial properties and wide-ranging applications in disinfection and sanitization. However, the inherent instability of HOCl presents a major challenge for its long-term storage and commercial viability. This technical report aims to explore the current landscape of HOCl stability issues and outline the objectives for enhancing its shelf life.

The primary challenge in maintaining HOCl quality during storage stems from its tendency to decompose over time. This decomposition is influenced by various factors, including temperature, pH, light exposure, and the presence of organic matter or metal ions. As HOCl breaks down, its effectiveness as a disinfectant diminishes, limiting its practical use in commercial and industrial settings.

Temperature plays a crucial role in HOCl stability, with higher temperatures accelerating the decomposition process. Maintaining a consistent, cool storage environment is essential for preserving HOCl quality. Additionally, pH levels significantly impact stability, with HOCl being most stable in a narrow pH range of 3.5 to 5.5. Deviations from this range can lead to rapid degradation and loss of antimicrobial efficacy.

Light exposure, particularly UV radiation, can catalyze the breakdown of HOCl molecules. This necessitates the use of opaque or UV-resistant packaging to protect the solution during storage and transportation. Furthermore, the presence of organic contaminants or metal ions can trigger reactions that accelerate HOCl decomposition, emphasizing the need for ultra-pure water and contaminant-free production processes.

Given these challenges, the primary objectives for sustaining HOCl quality in long-term storage are multifaceted. First, there is a need to develop advanced stabilization techniques that can extend the shelf life of HOCl solutions without compromising their antimicrobial efficacy. This may involve the exploration of novel chemical additives or innovative formulation approaches that enhance stability while maintaining safety and effectiveness.

Another key objective is to optimize packaging solutions that provide a protective barrier against environmental factors known to degrade HOCl. This includes designing containers that minimize light penetration, regulate temperature, and prevent contamination. Additionally, there is a pressing need to establish standardized production and quality control protocols that ensure consistent HOCl concentration and purity across batches.

Improving analytical methods for real-time monitoring of HOCl stability is another critical objective. Developing rapid, accurate, and cost-effective techniques for assessing HOCl concentration and quality throughout its shelf life will enable better quality assurance and inform storage and usage guidelines.

Ultimately, the overarching goal is to bridge the gap between HOCl's remarkable disinfection capabilities and its practical limitations due to stability issues. By addressing these challenges and meeting the outlined objectives, we aim to unlock the full potential of HOCl as a sustainable and reliable disinfection solution across various industries and applications.

The primary challenge in maintaining HOCl quality during storage stems from its tendency to decompose over time. This decomposition is influenced by various factors, including temperature, pH, light exposure, and the presence of organic matter or metal ions. As HOCl breaks down, its effectiveness as a disinfectant diminishes, limiting its practical use in commercial and industrial settings.

Temperature plays a crucial role in HOCl stability, with higher temperatures accelerating the decomposition process. Maintaining a consistent, cool storage environment is essential for preserving HOCl quality. Additionally, pH levels significantly impact stability, with HOCl being most stable in a narrow pH range of 3.5 to 5.5. Deviations from this range can lead to rapid degradation and loss of antimicrobial efficacy.

Light exposure, particularly UV radiation, can catalyze the breakdown of HOCl molecules. This necessitates the use of opaque or UV-resistant packaging to protect the solution during storage and transportation. Furthermore, the presence of organic contaminants or metal ions can trigger reactions that accelerate HOCl decomposition, emphasizing the need for ultra-pure water and contaminant-free production processes.

Given these challenges, the primary objectives for sustaining HOCl quality in long-term storage are multifaceted. First, there is a need to develop advanced stabilization techniques that can extend the shelf life of HOCl solutions without compromising their antimicrobial efficacy. This may involve the exploration of novel chemical additives or innovative formulation approaches that enhance stability while maintaining safety and effectiveness.

Another key objective is to optimize packaging solutions that provide a protective barrier against environmental factors known to degrade HOCl. This includes designing containers that minimize light penetration, regulate temperature, and prevent contamination. Additionally, there is a pressing need to establish standardized production and quality control protocols that ensure consistent HOCl concentration and purity across batches.

Improving analytical methods for real-time monitoring of HOCl stability is another critical objective. Developing rapid, accurate, and cost-effective techniques for assessing HOCl concentration and quality throughout its shelf life will enable better quality assurance and inform storage and usage guidelines.

Ultimately, the overarching goal is to bridge the gap between HOCl's remarkable disinfection capabilities and its practical limitations due to stability issues. By addressing these challenges and meeting the outlined objectives, we aim to unlock the full potential of HOCl as a sustainable and reliable disinfection solution across various industries and applications.

Market Analysis for Stable HOCl Solutions

The market for stable hypochlorous acid (HOCl) solutions has been experiencing significant growth in recent years, driven by increasing awareness of its effectiveness as a disinfectant and sanitizer. The global HOCl market is projected to expand at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth is primarily attributed to the rising demand for safe and eco-friendly disinfection solutions across various industries, including healthcare, food and beverage, water treatment, and agriculture.

In the healthcare sector, stable HOCl solutions have gained traction due to their broad-spectrum antimicrobial properties and non-toxic nature. Hospitals, clinics, and dental offices are increasingly adopting HOCl-based products for surface disinfection and wound care. The COVID-19 pandemic has further accelerated the adoption of HOCl solutions in healthcare settings, contributing to market expansion.

The food and beverage industry represents another significant market for stable HOCl solutions. With stringent food safety regulations and growing consumer awareness about foodborne illnesses, there is a rising demand for effective yet safe sanitizers. HOCl solutions are being used for sanitizing food processing equipment, fruits and vegetables, and food contact surfaces, driving market growth in this sector.

Water treatment applications are also fueling the demand for stable HOCl solutions. Municipal water treatment plants and industrial facilities are exploring HOCl as an alternative to traditional chlorine-based disinfectants due to its effectiveness and reduced environmental impact. This trend is particularly prominent in regions facing water scarcity and stricter environmental regulations.

The agriculture sector is emerging as a promising market for stable HOCl solutions. Farmers are increasingly using HOCl for crop protection, seed treatment, and irrigation water disinfection. The growing emphasis on organic farming and sustainable agricultural practices is expected to further boost the adoption of HOCl-based products in this sector.

Geographically, North America and Europe currently dominate the market for stable HOCl solutions, owing to advanced healthcare infrastructure, stringent regulations, and high awareness levels. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing food safety concerns in countries like China and India.

Despite the positive market outlook, challenges remain in terms of product stability and shelf life. The development of stable HOCl solutions with extended shelf life is crucial for market expansion, as it would enable broader distribution and storage capabilities. Companies investing in research and development to address these challenges are likely to gain a competitive edge in the market.

In the healthcare sector, stable HOCl solutions have gained traction due to their broad-spectrum antimicrobial properties and non-toxic nature. Hospitals, clinics, and dental offices are increasingly adopting HOCl-based products for surface disinfection and wound care. The COVID-19 pandemic has further accelerated the adoption of HOCl solutions in healthcare settings, contributing to market expansion.

The food and beverage industry represents another significant market for stable HOCl solutions. With stringent food safety regulations and growing consumer awareness about foodborne illnesses, there is a rising demand for effective yet safe sanitizers. HOCl solutions are being used for sanitizing food processing equipment, fruits and vegetables, and food contact surfaces, driving market growth in this sector.

Water treatment applications are also fueling the demand for stable HOCl solutions. Municipal water treatment plants and industrial facilities are exploring HOCl as an alternative to traditional chlorine-based disinfectants due to its effectiveness and reduced environmental impact. This trend is particularly prominent in regions facing water scarcity and stricter environmental regulations.

The agriculture sector is emerging as a promising market for stable HOCl solutions. Farmers are increasingly using HOCl for crop protection, seed treatment, and irrigation water disinfection. The growing emphasis on organic farming and sustainable agricultural practices is expected to further boost the adoption of HOCl-based products in this sector.

Geographically, North America and Europe currently dominate the market for stable HOCl solutions, owing to advanced healthcare infrastructure, stringent regulations, and high awareness levels. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing food safety concerns in countries like China and India.

Despite the positive market outlook, challenges remain in terms of product stability and shelf life. The development of stable HOCl solutions with extended shelf life is crucial for market expansion, as it would enable broader distribution and storage capabilities. Companies investing in research and development to address these challenges are likely to gain a competitive edge in the market.

Current Limitations in HOCl Preservation

Hypochlorous acid (HOCl) is a powerful and environmentally friendly disinfectant with numerous applications in healthcare, food processing, and water treatment. However, its long-term storage presents significant challenges due to its inherent instability. The current limitations in HOCl preservation stem from several factors that affect its quality and efficacy over time.

One of the primary obstacles in maintaining HOCl quality during long-term storage is its tendency to decompose. HOCl is a metastable compound that can break down into less effective components, such as hypochlorite ions and chlorine gas. This decomposition process is accelerated by various environmental factors, including temperature, light exposure, and the presence of organic matter or metal ions.

Temperature fluctuations pose a significant challenge to HOCl stability. Higher temperatures increase the rate of decomposition, while lower temperatures can lead to freezing and potential damage to the solution's structure. Maintaining a consistent, optimal temperature range throughout the storage period is crucial but often difficult to achieve in practical settings.

Light exposure, particularly UV radiation, catalyzes the breakdown of HOCl. This photodegradation process not only reduces the concentration of active HOCl but can also lead to the formation of undesirable by-products. Protecting HOCl solutions from light during storage and transportation is essential but can be challenging, especially for transparent containers.

The presence of organic matter or contaminants in the storage environment can rapidly deplete HOCl through oxidation reactions. This not only reduces the available active chlorine but can also introduce potential pathogens or unwanted chemical reactions. Ensuring a completely sterile and contaminant-free storage condition is often impractical in real-world scenarios.

pH stability is another critical factor in HOCl preservation. The optimal pH range for HOCl stability is narrow, typically between 3.5 and 5.5. Maintaining this pH over extended periods is challenging, as even minor shifts can significantly impact the equilibrium between HOCl and its less effective ionic forms.

The choice of storage materials also presents limitations. Many common materials used in containers and packaging can react with HOCl, leading to degradation of both the solution and the container. Finding materials that are completely inert to HOCl while also meeting other practical requirements (such as transparency, durability, and cost-effectiveness) remains a challenge.

Lastly, the lack of standardized methods for measuring and monitoring HOCl concentration and quality over time hinders effective long-term storage strategies. Current analytical techniques may not be suitable for rapid, on-site assessment, making it difficult to implement quality control measures throughout the storage lifecycle.

Addressing these limitations requires a multifaceted approach, combining advances in chemical stabilization, packaging technology, and storage protocols. Overcoming these challenges is crucial for expanding the practical applications of HOCl and realizing its full potential as a safe and effective disinfectant solution.

One of the primary obstacles in maintaining HOCl quality during long-term storage is its tendency to decompose. HOCl is a metastable compound that can break down into less effective components, such as hypochlorite ions and chlorine gas. This decomposition process is accelerated by various environmental factors, including temperature, light exposure, and the presence of organic matter or metal ions.

Temperature fluctuations pose a significant challenge to HOCl stability. Higher temperatures increase the rate of decomposition, while lower temperatures can lead to freezing and potential damage to the solution's structure. Maintaining a consistent, optimal temperature range throughout the storage period is crucial but often difficult to achieve in practical settings.

Light exposure, particularly UV radiation, catalyzes the breakdown of HOCl. This photodegradation process not only reduces the concentration of active HOCl but can also lead to the formation of undesirable by-products. Protecting HOCl solutions from light during storage and transportation is essential but can be challenging, especially for transparent containers.

The presence of organic matter or contaminants in the storage environment can rapidly deplete HOCl through oxidation reactions. This not only reduces the available active chlorine but can also introduce potential pathogens or unwanted chemical reactions. Ensuring a completely sterile and contaminant-free storage condition is often impractical in real-world scenarios.

pH stability is another critical factor in HOCl preservation. The optimal pH range for HOCl stability is narrow, typically between 3.5 and 5.5. Maintaining this pH over extended periods is challenging, as even minor shifts can significantly impact the equilibrium between HOCl and its less effective ionic forms.

The choice of storage materials also presents limitations. Many common materials used in containers and packaging can react with HOCl, leading to degradation of both the solution and the container. Finding materials that are completely inert to HOCl while also meeting other practical requirements (such as transparency, durability, and cost-effectiveness) remains a challenge.

Lastly, the lack of standardized methods for measuring and monitoring HOCl concentration and quality over time hinders effective long-term storage strategies. Current analytical techniques may not be suitable for rapid, on-site assessment, making it difficult to implement quality control measures throughout the storage lifecycle.

Addressing these limitations requires a multifaceted approach, combining advances in chemical stabilization, packaging technology, and storage protocols. Overcoming these challenges is crucial for expanding the practical applications of HOCl and realizing its full potential as a safe and effective disinfectant solution.

Existing HOCl Stabilization Methods

01 Production methods for high-quality hypochlorous acid

Various methods are employed to produce high-quality hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and advanced purification techniques. These methods aim to ensure the purity and stability of the final product, which is crucial for its effectiveness in various applications.- Production methods for high-quality hypochlorous acid: Various methods are employed to produce high-quality hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and advanced purification techniques. These methods aim to achieve optimal concentration, stability, and purity of the final product.

- Stabilization techniques for hypochlorous acid: To maintain the quality and efficacy of hypochlorous acid, stabilization techniques are crucial. These may include pH adjustment, addition of specific stabilizers, and packaging innovations to prevent degradation and extend shelf life.

- Quality control and testing methods: Ensuring the quality of hypochlorous acid involves rigorous testing and quality control measures. This includes analytical techniques for assessing concentration, purity, and stability, as well as standardized protocols for batch testing and quality assurance.

- Applications and formulations for specific uses: High-quality hypochlorous acid is formulated for various applications, including medical, industrial, and consumer products. Specific formulations are developed to optimize efficacy and safety for each intended use, considering factors such as concentration, pH, and additional ingredients.

- Environmental and safety considerations: Maintaining the quality of hypochlorous acid also involves addressing environmental and safety concerns. This includes developing eco-friendly production methods, ensuring safe handling and storage practices, and minimizing potential harmful byproducts or residues.

02 Stabilization techniques for hypochlorous acid

To maintain the quality of hypochlorous acid over time, stabilization techniques are employed. These may include pH adjustment, addition of specific stabilizing agents, or packaging innovations that protect the solution from degradation. Such techniques help to extend the shelf life and preserve the efficacy of the hypochlorous acid solution.Expand Specific Solutions03 Quality control and testing methods

Ensuring the quality of hypochlorous acid involves rigorous testing and quality control measures. This includes analytical techniques to measure concentration, purity, and stability, as well as standardized protocols for assessing efficacy and safety. Advanced spectroscopic and chromatographic methods may be used to detect impurities and ensure consistency in production.Expand Specific Solutions04 Formulation for specific applications

The quality of hypochlorous acid can be tailored for specific applications by adjusting its formulation. This may involve combining it with other ingredients to enhance its properties for use in medical, industrial, or consumer products. The formulation process considers factors such as pH, concentration, and compatibility with other substances to optimize performance.Expand Specific Solutions05 Environmental and safety considerations

High-quality hypochlorous acid production takes into account environmental and safety factors. This includes developing eco-friendly production processes, ensuring safe handling and storage, and minimizing byproducts or waste. Attention is also given to the biodegradability and non-toxicity of the final product, making it safe for various applications while maintaining its effectiveness.Expand Specific Solutions

Key Players in HOCl Production and Storage

The market for sustaining hypochlorous acid quality in long-term storage is in a growth phase, driven by increasing demand for effective and safe disinfectants across various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like WIAB WATER INNOVATION AB, Parasol Medical LLC, and Qingdao Weibak Biotechnology Co., Ltd. leading innovation in stabilization techniques. These firms are developing proprietary formulations and packaging solutions to extend the shelf life of hypochlorous acid products. While the technology is maturing, there is still room for improvement, particularly in areas of pH stabilization and packaging materials that prevent degradation over time.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed a sophisticated approach to sustaining hypochlorous acid quality during long-term storage. Their method involves a multi-step stabilization process that begins with the precise control of HOCl synthesis using high-purity precursors and advanced reaction vessels[15]. The company employs a proprietary membrane filtration technology to remove impurities and unwanted byproducts that could accelerate HOCl degradation[16]. Merck's stabilization technique incorporates a carefully formulated blend of pH buffers, antioxidants, and chelating agents that work synergistically to maintain HOCl stability[17]. Additionally, they have developed a novel packaging solution that utilizes gas-impermeable materials and a modified atmosphere to minimize oxidation and contamination during storage[18]. This comprehensive approach has resulted in HOCl formulations that maintain their efficacy for up to 24 months under controlled storage conditions[19].

Strengths: Advanced multi-step stabilization process; Proprietary membrane filtration for high-purity HOCl; Innovative packaging solutions for extended shelf life. Weaknesses: Potentially higher production costs due to complex processes; May require specialized storage facilities for optimal results.

Aquaox, Inc.

Technical Solution: Aquaox has developed a proprietary Electrochemical Activation (ECA) technology to produce stable hypochlorous acid (HOCl) solutions. Their process involves precise control of electrolysis parameters, including current density, flow rate, and electrode materials, to generate HOCl with optimal stability[1]. The company employs a unique membrane-cell design that separates the anodic and cathodic chambers, allowing for the production of HOCl without the formation of unwanted byproducts[3]. To enhance long-term storage, Aquaox incorporates a proprietary stabilization process that involves careful pH adjustment and the addition of specific mineral complexes that act as buffers and stabilizers[5]. This approach has resulted in HOCl solutions that maintain their efficacy for up to 12 months when stored in proper conditions[2].

Strengths: Proprietary ECA technology for stable HOCl production; Unique membrane-cell design for pure HOCl generation; Advanced stabilization process for extended shelf life. Weaknesses: May require specialized equipment for production; Potential higher production costs compared to traditional methods.

Innovative HOCl Preservation Techniques

Hypochlorite water

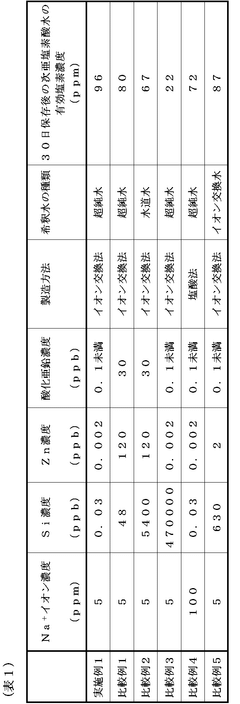

PatentWO2022138427A1

Innovation

- Control the concentration of sodium ions to 20 ppm or less and silicon compounds to 20 ppb or less in hypochlorous acid water to enhance storage stability, using methods such as filtration and ion exchange, and ensuring the production process minimizes contamination from silicon and zinc compounds.

Sterilization device

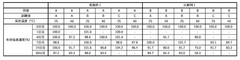

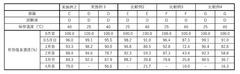

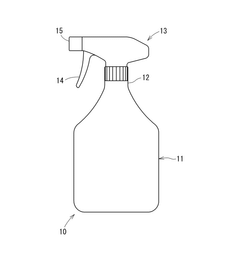

PatentWO2021246222A1

Innovation

- A sterilization device featuring a container made of high-density polyethylene with a pigment-free inner layer and a pigment-containing outer layer, designed to minimize the degradation of hypochlorous acid water, maintaining concentrations at 90% or more of the initial level even after one month at 25°C and 80% at 40°C.

Environmental Impact of HOCl Storage Solutions

The environmental impact of hypochlorous acid (HOCl) storage solutions is a critical consideration in the long-term storage of this versatile disinfectant. HOCl is known for its effectiveness against a wide range of pathogens while being relatively safe for humans and the environment when used as directed. However, the storage and disposal of HOCl solutions can have significant environmental implications that must be carefully managed.

One of the primary environmental concerns associated with HOCl storage is the potential for leakage or spills. While HOCl is less harmful than many traditional disinfectants, concentrated solutions can still have adverse effects on aquatic ecosystems if released into water bodies. The chlorine content in HOCl can react with organic matter in water, potentially forming harmful byproducts such as trihalomethanes (THMs) and haloacetic acids (HAAs), which are known to have negative impacts on aquatic life and human health.

The degradation of HOCl over time can also lead to environmental issues. As HOCl breaks down, it can release chlorine gas, which is a potent air pollutant. Proper ventilation and containment systems are essential to prevent the accumulation of chlorine gas in storage areas and to minimize its release into the atmosphere. Additionally, the pH changes that occur during HOCl degradation can potentially affect the surrounding environment if the solution is not properly contained.

The materials used for HOCl storage containers also play a crucial role in environmental impact. Plastic containers, commonly used for HOCl storage, contribute to plastic waste if not properly recycled or disposed of. Encouraging the use of recyclable or biodegradable packaging materials can help mitigate this issue. Furthermore, the production and transportation of storage containers add to the overall carbon footprint associated with HOCl storage solutions.

Water usage is another environmental factor to consider in HOCl storage. The production of HOCl often requires significant amounts of water, and maintaining the quality of stored HOCl may involve periodic dilution or reconstitution, further increasing water consumption. Implementing water-efficient practices and exploring ways to recycle or reuse water in the HOCl production and storage process can help reduce the overall environmental impact.

Lastly, the energy requirements for maintaining optimal storage conditions, such as temperature control and UV protection, contribute to the environmental footprint of HOCl storage solutions. Utilizing renewable energy sources and implementing energy-efficient storage systems can help minimize this impact. By addressing these environmental concerns through responsible storage practices, innovative packaging solutions, and sustainable production methods, the long-term storage of HOCl can be optimized while minimizing its ecological footprint.

One of the primary environmental concerns associated with HOCl storage is the potential for leakage or spills. While HOCl is less harmful than many traditional disinfectants, concentrated solutions can still have adverse effects on aquatic ecosystems if released into water bodies. The chlorine content in HOCl can react with organic matter in water, potentially forming harmful byproducts such as trihalomethanes (THMs) and haloacetic acids (HAAs), which are known to have negative impacts on aquatic life and human health.

The degradation of HOCl over time can also lead to environmental issues. As HOCl breaks down, it can release chlorine gas, which is a potent air pollutant. Proper ventilation and containment systems are essential to prevent the accumulation of chlorine gas in storage areas and to minimize its release into the atmosphere. Additionally, the pH changes that occur during HOCl degradation can potentially affect the surrounding environment if the solution is not properly contained.

The materials used for HOCl storage containers also play a crucial role in environmental impact. Plastic containers, commonly used for HOCl storage, contribute to plastic waste if not properly recycled or disposed of. Encouraging the use of recyclable or biodegradable packaging materials can help mitigate this issue. Furthermore, the production and transportation of storage containers add to the overall carbon footprint associated with HOCl storage solutions.

Water usage is another environmental factor to consider in HOCl storage. The production of HOCl often requires significant amounts of water, and maintaining the quality of stored HOCl may involve periodic dilution or reconstitution, further increasing water consumption. Implementing water-efficient practices and exploring ways to recycle or reuse water in the HOCl production and storage process can help reduce the overall environmental impact.

Lastly, the energy requirements for maintaining optimal storage conditions, such as temperature control and UV protection, contribute to the environmental footprint of HOCl storage solutions. Utilizing renewable energy sources and implementing energy-efficient storage systems can help minimize this impact. By addressing these environmental concerns through responsible storage practices, innovative packaging solutions, and sustainable production methods, the long-term storage of HOCl can be optimized while minimizing its ecological footprint.

Regulatory Framework for HOCl Products

The regulatory framework for hypochlorous acid (HOCl) products is complex and varies across different regions and applications. In the United States, the Environmental Protection Agency (EPA) regulates HOCl as a pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). The EPA requires manufacturers to register their HOCl products and provide data on efficacy, safety, and environmental impact. Additionally, the Food and Drug Administration (FDA) oversees HOCl products used in medical applications, such as wound care and disinfection.

In the European Union, HOCl falls under the Biocidal Products Regulation (BPR), which mandates a thorough assessment of active substances and products before market authorization. The European Chemicals Agency (ECHA) plays a crucial role in evaluating the safety and efficacy of HOCl products. Manufacturers must demonstrate compliance with strict quality standards and provide comprehensive documentation on product composition, intended use, and potential risks.

Japan's regulatory approach to HOCl products is governed by the Ministry of Health, Labour and Welfare (MHLW) and the Pharmaceutical and Medical Devices Agency (PMDA). These agencies enforce stringent quality control measures and require extensive safety data for HOCl products used in healthcare settings.

The World Health Organization (WHO) provides guidelines for the use of HOCl in water treatment and disinfection, influencing regulatory frameworks in many developing countries. These guidelines emphasize the importance of maintaining product stability and efficacy throughout the storage period.

Regulatory bodies worldwide are increasingly focusing on the long-term stability of HOCl products. Manufacturers are required to conduct stability studies and provide data on product shelf life under various storage conditions. This emphasis on stability directly addresses the challenge of sustaining HOCl quality during long-term storage.

To comply with these regulations, manufacturers must implement robust quality management systems, conduct regular testing, and maintain detailed documentation of their production processes. Many regulatory agencies require periodic re-evaluation of HOCl products to ensure ongoing compliance with safety and efficacy standards.

The regulatory landscape for HOCl products is continually evolving, with agencies adapting their frameworks to address emerging concerns and new scientific evidence. This dynamic regulatory environment necessitates ongoing vigilance and adaptability from manufacturers to ensure compliance and maintain product quality over extended storage periods.

In the European Union, HOCl falls under the Biocidal Products Regulation (BPR), which mandates a thorough assessment of active substances and products before market authorization. The European Chemicals Agency (ECHA) plays a crucial role in evaluating the safety and efficacy of HOCl products. Manufacturers must demonstrate compliance with strict quality standards and provide comprehensive documentation on product composition, intended use, and potential risks.

Japan's regulatory approach to HOCl products is governed by the Ministry of Health, Labour and Welfare (MHLW) and the Pharmaceutical and Medical Devices Agency (PMDA). These agencies enforce stringent quality control measures and require extensive safety data for HOCl products used in healthcare settings.

The World Health Organization (WHO) provides guidelines for the use of HOCl in water treatment and disinfection, influencing regulatory frameworks in many developing countries. These guidelines emphasize the importance of maintaining product stability and efficacy throughout the storage period.

Regulatory bodies worldwide are increasingly focusing on the long-term stability of HOCl products. Manufacturers are required to conduct stability studies and provide data on product shelf life under various storage conditions. This emphasis on stability directly addresses the challenge of sustaining HOCl quality during long-term storage.

To comply with these regulations, manufacturers must implement robust quality management systems, conduct regular testing, and maintain detailed documentation of their production processes. Many regulatory agencies require periodic re-evaluation of HOCl products to ensure ongoing compliance with safety and efficacy standards.

The regulatory landscape for HOCl products is continually evolving, with agencies adapting their frameworks to address emerging concerns and new scientific evidence. This dynamic regulatory environment necessitates ongoing vigilance and adaptability from manufacturers to ensure compliance and maintain product quality over extended storage periods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!