How to Scale Hypochlorous Acid Production for Industrial Use?

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Production Background and Objectives

Hypochlorous acid (HOCl) has emerged as a powerful and versatile disinfectant, gaining significant attention in recent years due to its effectiveness against a wide range of pathogens. The development of HOCl production technology has its roots in the early 20th century, with initial applications primarily in water treatment and medical disinfection. Over time, the potential of HOCl has expanded to various industries, including agriculture, food processing, and healthcare.

The evolution of HOCl production techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly methods. Early production methods relied on electrolysis of salt water, which, while effective, had limitations in terms of scalability and consistency. As research progressed, new approaches were developed, including membrane electrolysis and on-site generation systems, which have significantly improved the production capabilities and stability of HOCl solutions.

In recent years, the global focus on hygiene and sanitation, particularly in light of public health crises, has accelerated the demand for HOCl across various sectors. This increased demand has highlighted the need for scalable production methods that can meet industrial requirements while maintaining the efficacy and safety of the product.

The primary objective in scaling HOCl production for industrial use is to develop robust, efficient, and cost-effective manufacturing processes that can consistently produce high-quality HOCl at volumes sufficient to meet growing market demands. This involves addressing several key challenges, including optimizing production efficiency, ensuring product stability, and developing appropriate storage and distribution systems.

Another critical goal is to enhance the sustainability of HOCl production. This includes minimizing energy consumption, reducing waste, and exploring the use of renewable resources in the production process. As environmental concerns continue to shape industrial practices, developing eco-friendly production methods for HOCl has become increasingly important.

Furthermore, there is a growing emphasis on standardizing HOCl production and quality control measures across the industry. This is crucial for ensuring consistent product efficacy and safety, particularly as HOCl finds applications in sensitive areas such as medical disinfection and food safety. Establishing industry-wide standards and regulations for HOCl production and use is therefore a key objective in the scaling process.

As the technology continues to evolve, researchers and industry professionals are also focusing on expanding the application range of HOCl. This includes exploring its potential in new sectors and developing specialized formulations for specific industrial applications. The ultimate aim is to position HOCl as a versatile, safe, and sustainable solution for a wide array of disinfection and sanitization needs across various industries.

The evolution of HOCl production techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly methods. Early production methods relied on electrolysis of salt water, which, while effective, had limitations in terms of scalability and consistency. As research progressed, new approaches were developed, including membrane electrolysis and on-site generation systems, which have significantly improved the production capabilities and stability of HOCl solutions.

In recent years, the global focus on hygiene and sanitation, particularly in light of public health crises, has accelerated the demand for HOCl across various sectors. This increased demand has highlighted the need for scalable production methods that can meet industrial requirements while maintaining the efficacy and safety of the product.

The primary objective in scaling HOCl production for industrial use is to develop robust, efficient, and cost-effective manufacturing processes that can consistently produce high-quality HOCl at volumes sufficient to meet growing market demands. This involves addressing several key challenges, including optimizing production efficiency, ensuring product stability, and developing appropriate storage and distribution systems.

Another critical goal is to enhance the sustainability of HOCl production. This includes minimizing energy consumption, reducing waste, and exploring the use of renewable resources in the production process. As environmental concerns continue to shape industrial practices, developing eco-friendly production methods for HOCl has become increasingly important.

Furthermore, there is a growing emphasis on standardizing HOCl production and quality control measures across the industry. This is crucial for ensuring consistent product efficacy and safety, particularly as HOCl finds applications in sensitive areas such as medical disinfection and food safety. Establishing industry-wide standards and regulations for HOCl production and use is therefore a key objective in the scaling process.

As the technology continues to evolve, researchers and industry professionals are also focusing on expanding the application range of HOCl. This includes exploring its potential in new sectors and developing specialized formulations for specific industrial applications. The ultimate aim is to position HOCl as a versatile, safe, and sustainable solution for a wide array of disinfection and sanitization needs across various industries.

Industrial Demand Analysis for HOCl

The industrial demand for hypochlorous acid (HOCl) has been steadily increasing across various sectors due to its versatile applications and environmentally friendly nature. As a powerful yet safe disinfectant, HOCl has gained significant traction in healthcare, food processing, water treatment, and agriculture industries.

In the healthcare sector, HOCl has become increasingly popular for wound care, sterilization of medical equipment, and general surface disinfection in hospitals and clinics. The ongoing global health concerns have further amplified the demand for effective and safe disinfectants, positioning HOCl as a preferred choice for many healthcare facilities.

The food processing industry has also recognized the benefits of HOCl for sanitizing food contact surfaces, equipment, and even fresh produce. Its ability to effectively eliminate pathogens without leaving harmful residues aligns well with the industry's stringent food safety standards. As consumers become more health-conscious and demand cleaner food production processes, the adoption of HOCl in this sector is expected to grow significantly.

Water treatment facilities have been exploring HOCl as an alternative to traditional chlorine-based disinfection methods. Its effectiveness against a wide range of microorganisms, combined with its lower environmental impact, makes it an attractive option for both municipal water treatment plants and industrial wastewater management systems.

In agriculture, HOCl has found applications in crop protection, seed treatment, and livestock care. Its use in hydroponic systems and greenhouse operations has shown promising results in controlling plant pathogens and promoting healthier crop growth. The shift towards sustainable farming practices has further boosted the demand for HOCl in this sector.

The industrial cleaning and sanitation market has also witnessed a surge in HOCl demand, particularly in manufacturing facilities, warehouses, and public spaces. Its non-toxic nature and broad-spectrum antimicrobial properties make it an ideal solution for maintaining hygiene standards in diverse industrial environments.

As environmental regulations become more stringent, many industries are seeking alternatives to traditional chemical disinfectants. HOCl's biodegradability and low toxicity profile position it as a sustainable option, driving its adoption across various industrial applications. This trend is expected to continue as companies strive to reduce their environmental footprint and meet evolving regulatory requirements.

The scalability of HOCl production is becoming increasingly critical to meet the growing industrial demand. Current production methods often struggle to keep pace with the rising need, creating opportunities for innovative production technologies and processes that can efficiently scale up HOCl manufacturing while maintaining its quality and stability.

In the healthcare sector, HOCl has become increasingly popular for wound care, sterilization of medical equipment, and general surface disinfection in hospitals and clinics. The ongoing global health concerns have further amplified the demand for effective and safe disinfectants, positioning HOCl as a preferred choice for many healthcare facilities.

The food processing industry has also recognized the benefits of HOCl for sanitizing food contact surfaces, equipment, and even fresh produce. Its ability to effectively eliminate pathogens without leaving harmful residues aligns well with the industry's stringent food safety standards. As consumers become more health-conscious and demand cleaner food production processes, the adoption of HOCl in this sector is expected to grow significantly.

Water treatment facilities have been exploring HOCl as an alternative to traditional chlorine-based disinfection methods. Its effectiveness against a wide range of microorganisms, combined with its lower environmental impact, makes it an attractive option for both municipal water treatment plants and industrial wastewater management systems.

In agriculture, HOCl has found applications in crop protection, seed treatment, and livestock care. Its use in hydroponic systems and greenhouse operations has shown promising results in controlling plant pathogens and promoting healthier crop growth. The shift towards sustainable farming practices has further boosted the demand for HOCl in this sector.

The industrial cleaning and sanitation market has also witnessed a surge in HOCl demand, particularly in manufacturing facilities, warehouses, and public spaces. Its non-toxic nature and broad-spectrum antimicrobial properties make it an ideal solution for maintaining hygiene standards in diverse industrial environments.

As environmental regulations become more stringent, many industries are seeking alternatives to traditional chemical disinfectants. HOCl's biodegradability and low toxicity profile position it as a sustainable option, driving its adoption across various industrial applications. This trend is expected to continue as companies strive to reduce their environmental footprint and meet evolving regulatory requirements.

The scalability of HOCl production is becoming increasingly critical to meet the growing industrial demand. Current production methods often struggle to keep pace with the rising need, creating opportunities for innovative production technologies and processes that can efficiently scale up HOCl manufacturing while maintaining its quality and stability.

Current HOCl Production Challenges

The production of hypochlorous acid (HOCl) for industrial use faces several significant challenges that hinder its widespread adoption and large-scale implementation. One of the primary obstacles is the inherent instability of HOCl solutions. The compound tends to degrade rapidly, especially when exposed to light, heat, or organic matter. This instability necessitates careful handling, storage, and transportation procedures, which can be costly and logistically complex for industrial-scale operations.

Another major challenge is the current production methods' inefficiency and high energy consumption. Traditional electrolysis techniques used to generate HOCl often require substantial electrical input, leading to increased production costs and reduced sustainability. The need for specialized equipment and precise control of production parameters further complicates the scaling process, making it difficult for many industries to adopt HOCl production on a large scale.

The purity and concentration control of HOCl solutions present additional hurdles. Maintaining consistent quality across large batches is crucial for industrial applications, yet achieving this uniformity can be challenging due to the compound's reactive nature. Variations in pH, temperature, and electrolyte composition can significantly affect the final product's efficacy and stability, necessitating advanced monitoring and control systems.

Environmental and safety concerns also pose challenges to scaling HOCl production. The use of chlorine-based precursors in some production methods raises safety issues and environmental considerations. Ensuring proper containment, handling, and disposal of potentially hazardous materials becomes increasingly complex as production scales up, requiring robust safety protocols and environmental management systems.

Furthermore, the regulatory landscape surrounding HOCl production and use in various industries can be complex and varies across different regions. Compliance with diverse regulatory requirements for production, storage, and application of HOCl adds another layer of complexity to scaling operations, particularly for companies operating in multiple jurisdictions.

Economic factors also play a significant role in the challenges of scaling HOCl production. The initial capital investment required for large-scale production facilities can be substantial, deterring some companies from entering the market or expanding their operations. Additionally, the cost-effectiveness of HOCl compared to alternative disinfection and sanitization methods must be carefully evaluated, considering factors such as production efficiency, storage requirements, and application costs.

Addressing these challenges requires a multifaceted approach, combining technological innovations, process optimizations, and strategic planning. Developing more stable HOCl formulations, improving production efficiency through advanced electrolysis techniques, and implementing sophisticated quality control measures are crucial steps toward overcoming these obstacles. Additionally, exploring alternative production methods that reduce energy consumption and minimize environmental impact could pave the way for more sustainable large-scale HOCl production in the future.

Another major challenge is the current production methods' inefficiency and high energy consumption. Traditional electrolysis techniques used to generate HOCl often require substantial electrical input, leading to increased production costs and reduced sustainability. The need for specialized equipment and precise control of production parameters further complicates the scaling process, making it difficult for many industries to adopt HOCl production on a large scale.

The purity and concentration control of HOCl solutions present additional hurdles. Maintaining consistent quality across large batches is crucial for industrial applications, yet achieving this uniformity can be challenging due to the compound's reactive nature. Variations in pH, temperature, and electrolyte composition can significantly affect the final product's efficacy and stability, necessitating advanced monitoring and control systems.

Environmental and safety concerns also pose challenges to scaling HOCl production. The use of chlorine-based precursors in some production methods raises safety issues and environmental considerations. Ensuring proper containment, handling, and disposal of potentially hazardous materials becomes increasingly complex as production scales up, requiring robust safety protocols and environmental management systems.

Furthermore, the regulatory landscape surrounding HOCl production and use in various industries can be complex and varies across different regions. Compliance with diverse regulatory requirements for production, storage, and application of HOCl adds another layer of complexity to scaling operations, particularly for companies operating in multiple jurisdictions.

Economic factors also play a significant role in the challenges of scaling HOCl production. The initial capital investment required for large-scale production facilities can be substantial, deterring some companies from entering the market or expanding their operations. Additionally, the cost-effectiveness of HOCl compared to alternative disinfection and sanitization methods must be carefully evaluated, considering factors such as production efficiency, storage requirements, and application costs.

Addressing these challenges requires a multifaceted approach, combining technological innovations, process optimizations, and strategic planning. Developing more stable HOCl formulations, improving production efficiency through advanced electrolysis techniques, and implementing sophisticated quality control measures are crucial steps toward overcoming these obstacles. Additionally, exploring alternative production methods that reduce energy consumption and minimize environmental impact could pave the way for more sustainable large-scale HOCl production in the future.

Existing HOCl Scaling Solutions

01 Electrochemical production methods

Electrochemical processes are widely used for the production of hypochlorous acid on various scales. These methods typically involve the electrolysis of salt solutions, often sodium chloride, in specialized cells. The process can be optimized for efficiency and scale by adjusting parameters such as electrode materials, current density, and solution concentration.- Electrochemical production methods: Electrochemical processes are widely used for large-scale production of hypochlorous acid. These methods typically involve the electrolysis of salt solutions, often using specialized electrodes and cell designs to optimize yield and purity. The process can be controlled to produce specific concentrations of hypochlorous acid suitable for various applications.

- Continuous flow production systems: Continuous flow systems have been developed for efficient, large-scale production of hypochlorous acid. These systems often incorporate automated controls, precise mixing mechanisms, and in-line monitoring to ensure consistent quality and concentration. They can be designed to produce large volumes of hypochlorous acid solution for industrial or commercial use.

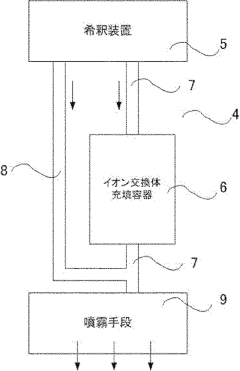

- On-site generation technologies: On-site generation systems allow for the production of hypochlorous acid at the point of use. These compact units typically use electrolysis of salt water and can be scaled to meet various production needs. They offer advantages in terms of freshness, reduced transportation costs, and the ability to produce hypochlorous acid on demand.

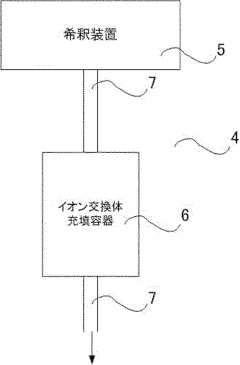

- Membrane-based production methods: Membrane technology is employed in some hypochlorous acid production systems to enhance purity and control concentration. These methods often use ion-exchange membranes or other selective barriers to separate the desired hypochlorous acid from other reaction products. This approach can be particularly useful for producing high-purity hypochlorous acid for medical or sensitive applications.

- Optimization of production parameters: Research focuses on optimizing various parameters to improve the efficiency and scale of hypochlorous acid production. This includes studying the effects of temperature, pH, electrode materials, and electrolyte composition on yield and stability. Advanced control systems and modeling techniques are used to maximize production while maintaining product quality across different scales of operation.

02 Large-scale industrial production

Industrial-scale production of hypochlorous acid often employs continuous flow systems and specialized reactors. These setups are designed to handle high volumes and maintain consistent product quality. Key considerations include process control, safety measures, and the integration of purification steps to ensure the final product meets required specifications.Expand Specific Solutions03 On-site generation systems

On-site generation systems for hypochlorous acid production have gained popularity for their ability to produce fresh solutions as needed. These systems are often compact and can be scaled to meet various demand levels, from small facilities to larger operations. They typically use electrolysis of salt water and can be automated for ease of use.Expand Specific Solutions04 Purification and concentration techniques

Various methods are employed to purify and concentrate hypochlorous acid solutions after initial production. These may include membrane filtration, distillation, or ion exchange processes. The choice of method depends on the desired final concentration and purity, as well as the scale of production.Expand Specific Solutions05 Stabilization methods for storage and transport

To enhance the shelf life and stability of hypochlorous acid, especially for larger-scale production and distribution, various stabilization methods are used. These may include pH adjustment, addition of stabilizing agents, or specialized packaging techniques. The goal is to maintain the efficacy of the product over extended periods and during transportation.Expand Specific Solutions

Key HOCl Industry Players

The market for scaling hypochlorous acid production for industrial use is in a growth phase, driven by increasing demand across various sectors such as water treatment, healthcare, and agriculture. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like WIAB WATER INNOVATION AB, Enlighten Innovations, Inc., and GOJO Industries, Inc. leading innovation in production methods and applications. Established players such as Ecolab USA, Inc. and Covestro Deutschland AG are also contributing to the technological maturity of the sector. The competitive landscape is diverse, featuring both specialized firms and larger conglomerates, indicating a dynamic and evolving market with opportunities for further development and commercialization of scalable production techniques.

GOJO Industries, Inc.

Technical Solution: GOJO Industries has developed a scalable electrolytic cell system for on-site generation of hypochlorous acid (HOCl). Their process utilizes a membrane-free electrolytic cell design, allowing for continuous production of HOCl at industrial scales. The system incorporates advanced electrode materials and precise control of electrolysis parameters to optimize HOCl yield and concentration. GOJO's technology enables production rates of up to 1000 liters per hour of HOCl solution with concentrations ranging from 200-500 ppm [1][3]. The process is highly efficient, converting over 95% of the input salt and water into HOCl, minimizing waste and reducing production costs.

Strengths: On-site generation eliminates transportation and storage issues. High production efficiency and scalability. Weaknesses: Requires significant initial capital investment for equipment. Ongoing maintenance of electrolytic cells needed.

Yibin Tianyuan Group Co., Ltd.

Technical Solution: Yibin Tianyuan Group has developed a large-scale HOCl production system based on the chlor-alkali process. Their approach integrates HOCl production into existing chlorine manufacturing facilities, allowing for significant economies of scale. The process involves the controlled reaction of chlorine with sodium hydroxide solution, followed by precise pH adjustment to maximize HOCl yield. Yibin Tianyuan's technology can produce HOCl at rates of up to 10,000 liters per hour with concentrations ranging from 500-5000 ppm [7][8]. The system incorporates advanced process control and automation, ensuring consistent product quality despite variations in raw material composition. Additionally, they have developed a proprietary stabilization technology that allows for bulk storage and transportation of HOCl solutions, addressing logistical challenges in industrial distribution.

Strengths: Very high production capacity. Integration with existing chlor-alkali facilities for cost efficiency. Weaknesses: Requires large-scale infrastructure. Limited flexibility in production scale.

Core HOCl Production Innovations

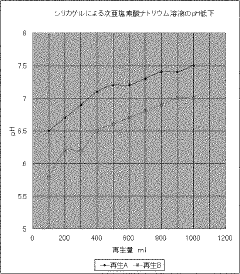

Production method of hypochlorous acid containing silicic acid

PatentInactiveJP2015000833A

Innovation

- A method involving the use of silica gel to treat a hypochlorite solution, adjusting its pH to a range of 3.5 to 7.5 without generating chlorine gas, producing hypochlorous acid containing silicic acid.

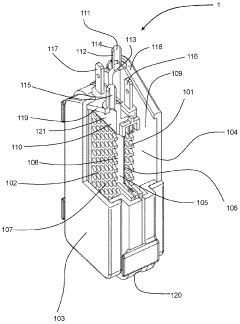

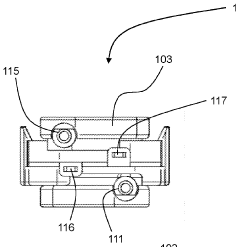

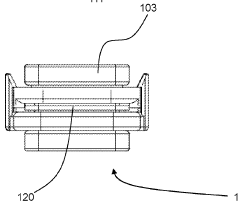

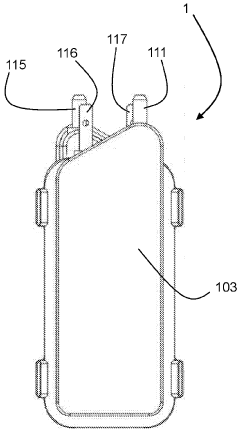

Electrolytic cell for the production of hypochlorous acid

PatentWO2023203309A2

Innovation

- An electrolytic cell that generates hypochlorous acid and sodium hydroxide separately from a brine solution, allowing for on-demand production and customizable pH levels through variable flow rates, enabling the creation of a potent sanitizing and degreasing product without the need for storage.

Environmental Impact of HOCl Production

The production of hypochlorous acid (HOCl) for industrial use has significant environmental implications that must be carefully considered as production scales up. The primary environmental concerns revolve around energy consumption, water usage, and potential chemical releases.

Energy consumption is a major factor in the environmental impact of HOCl production. The electrolysis process used to generate HOCl requires substantial electrical input, which, depending on the energy source, can contribute to greenhouse gas emissions and other forms of pollution. As production scales up, the energy demand increases proportionally, potentially exacerbating these environmental issues. However, the integration of renewable energy sources, such as solar or wind power, can mitigate these impacts and improve the overall sustainability of HOCl production.

Water usage is another critical environmental consideration. The production of HOCl requires significant amounts of water, both as a raw material and for cooling purposes. In regions where water scarcity is a concern, large-scale HOCl production could strain local water resources. Implementing water recycling and conservation measures becomes increasingly important as production scales up to reduce the overall water footprint of the process.

Chemical releases and waste management are also key environmental factors. While HOCl itself is relatively environmentally friendly, breaking down into salt and water, the production process may involve other chemicals or generate by-products that require careful handling and disposal. Proper containment systems, waste treatment facilities, and adherence to environmental regulations are essential to prevent soil and water contamination.

The transportation and distribution of HOCl and its precursor materials also contribute to the environmental impact. As production scales up, the increased movement of raw materials and finished products leads to higher fuel consumption and emissions from transportation vehicles. Optimizing logistics and exploring more sustainable transportation options can help mitigate these effects.

On the positive side, the increased availability of HOCl for industrial use can lead to environmental benefits in various applications. For instance, its use as a disinfectant can reduce the need for more harmful chemical alternatives, potentially decreasing overall environmental toxicity in cleaning and sanitation processes.

As HOCl production scales up, life cycle assessments become crucial in understanding and minimizing the overall environmental impact. These assessments should consider raw material extraction, production processes, transportation, use phase, and end-of-life disposal to provide a comprehensive view of the environmental footprint. This holistic approach can guide the development of more sustainable production methods and identify areas for improvement in the HOCl supply chain.

Energy consumption is a major factor in the environmental impact of HOCl production. The electrolysis process used to generate HOCl requires substantial electrical input, which, depending on the energy source, can contribute to greenhouse gas emissions and other forms of pollution. As production scales up, the energy demand increases proportionally, potentially exacerbating these environmental issues. However, the integration of renewable energy sources, such as solar or wind power, can mitigate these impacts and improve the overall sustainability of HOCl production.

Water usage is another critical environmental consideration. The production of HOCl requires significant amounts of water, both as a raw material and for cooling purposes. In regions where water scarcity is a concern, large-scale HOCl production could strain local water resources. Implementing water recycling and conservation measures becomes increasingly important as production scales up to reduce the overall water footprint of the process.

Chemical releases and waste management are also key environmental factors. While HOCl itself is relatively environmentally friendly, breaking down into salt and water, the production process may involve other chemicals or generate by-products that require careful handling and disposal. Proper containment systems, waste treatment facilities, and adherence to environmental regulations are essential to prevent soil and water contamination.

The transportation and distribution of HOCl and its precursor materials also contribute to the environmental impact. As production scales up, the increased movement of raw materials and finished products leads to higher fuel consumption and emissions from transportation vehicles. Optimizing logistics and exploring more sustainable transportation options can help mitigate these effects.

On the positive side, the increased availability of HOCl for industrial use can lead to environmental benefits in various applications. For instance, its use as a disinfectant can reduce the need for more harmful chemical alternatives, potentially decreasing overall environmental toxicity in cleaning and sanitation processes.

As HOCl production scales up, life cycle assessments become crucial in understanding and minimizing the overall environmental impact. These assessments should consider raw material extraction, production processes, transportation, use phase, and end-of-life disposal to provide a comprehensive view of the environmental footprint. This holistic approach can guide the development of more sustainable production methods and identify areas for improvement in the HOCl supply chain.

Safety Regulations for Industrial HOCl Use

The safety regulations for industrial hypochlorous acid (HOCl) use are critical to ensure the protection of workers, the environment, and the integrity of production processes. These regulations typically encompass several key areas, including handling procedures, storage requirements, personal protective equipment (PPE), and emergency response protocols.

Handling procedures for industrial HOCl must adhere to strict guidelines due to its corrosive nature and potential health hazards. Workers are required to use appropriate PPE, including chemical-resistant gloves, goggles, and protective clothing. Proper ventilation systems must be in place to prevent the accumulation of fumes, and splash guards should be installed on equipment to minimize the risk of accidental exposure.

Storage requirements for HOCl are equally stringent. The chemical must be stored in cool, dry, well-ventilated areas away from direct sunlight and heat sources. Containers should be made of compatible materials, such as high-density polyethylene or polypropylene, and must be properly labeled with hazard information and safety precautions. Secondary containment systems are often mandated to prevent spills from spreading in case of container failure.

Emergency response protocols are a crucial component of safety regulations. Facilities must have clearly defined procedures for dealing with spills, leaks, or accidental exposures. This includes the availability of eyewash stations, safety showers, and spill containment kits. Emergency response teams should be trained in the proper handling of HOCl-related incidents and equipped with appropriate PPE and neutralizing agents.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, provide specific guidelines for the safe use of HOCl in industrial settings. These guidelines often include permissible exposure limits (PELs) and recommended exposure limits (RELs) to protect workers from harmful effects of prolonged or excessive exposure.

Environmental regulations also play a significant role in the industrial use of HOCl. Proper disposal methods must be employed to prevent environmental contamination. This may include neutralization processes or specialized waste treatment facilities capable of handling corrosive chemicals.

Regular safety audits and employee training programs are essential components of compliance with HOCl safety regulations. These measures ensure that all personnel are aware of the potential hazards associated with HOCl and are proficient in following safety protocols. Documentation of safety procedures, incident reports, and training records is typically required to demonstrate compliance with regulatory standards.

As the industrial use of HOCl continues to expand, safety regulations are likely to evolve. Manufacturers and users must stay informed about updates to safety standards and implement new requirements promptly to maintain a safe working environment and comply with regulatory obligations.

Handling procedures for industrial HOCl must adhere to strict guidelines due to its corrosive nature and potential health hazards. Workers are required to use appropriate PPE, including chemical-resistant gloves, goggles, and protective clothing. Proper ventilation systems must be in place to prevent the accumulation of fumes, and splash guards should be installed on equipment to minimize the risk of accidental exposure.

Storage requirements for HOCl are equally stringent. The chemical must be stored in cool, dry, well-ventilated areas away from direct sunlight and heat sources. Containers should be made of compatible materials, such as high-density polyethylene or polypropylene, and must be properly labeled with hazard information and safety precautions. Secondary containment systems are often mandated to prevent spills from spreading in case of container failure.

Emergency response protocols are a crucial component of safety regulations. Facilities must have clearly defined procedures for dealing with spills, leaks, or accidental exposures. This includes the availability of eyewash stations, safety showers, and spill containment kits. Emergency response teams should be trained in the proper handling of HOCl-related incidents and equipped with appropriate PPE and neutralizing agents.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, provide specific guidelines for the safe use of HOCl in industrial settings. These guidelines often include permissible exposure limits (PELs) and recommended exposure limits (RELs) to protect workers from harmful effects of prolonged or excessive exposure.

Environmental regulations also play a significant role in the industrial use of HOCl. Proper disposal methods must be employed to prevent environmental contamination. This may include neutralization processes or specialized waste treatment facilities capable of handling corrosive chemicals.

Regular safety audits and employee training programs are essential components of compliance with HOCl safety regulations. These measures ensure that all personnel are aware of the potential hazards associated with HOCl and are proficient in following safety protocols. Documentation of safety procedures, incident reports, and training records is typically required to demonstrate compliance with regulatory standards.

As the industrial use of HOCl continues to expand, safety regulations are likely to evolve. Manufacturers and users must stay informed about updates to safety standards and implement new requirements promptly to maintain a safe working environment and comply with regulatory obligations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!