How to Integrate Kevlar into Smart Protective Clothing?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Smart Clothing Evolution and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized protective clothing. Its journey into smart protective gear represents a significant evolution in material science and wearable technology. The integration of Kevlar into smart protective clothing aims to enhance safety, comfort, and functionality for users in various high-risk professions.

The evolution of Kevlar in protective clothing began with its use in bulletproof vests and has since expanded to a wide range of applications. Initially, Kevlar was primarily valued for its exceptional strength-to-weight ratio and heat resistance. As technology advanced, researchers and manufacturers recognized the potential to combine Kevlar's protective properties with smart features, leading to the development of intelligent protective gear.

The objectives of integrating Kevlar into smart protective clothing are multifaceted. Primarily, it seeks to maintain or enhance the level of protection offered by traditional Kevlar garments while incorporating advanced functionalities. These may include real-time health monitoring, environmental sensing, communication capabilities, and adaptive protection mechanisms.

One key goal is to develop clothing that can dynamically respond to external threats or changes in the wearer's physiological state. For instance, smart Kevlar clothing could potentially stiffen upon impact or adjust its thermal properties based on environmental conditions. This adaptive protection aims to provide optimal safety in various scenarios, from law enforcement to industrial work environments.

Another objective is to improve the overall user experience by addressing comfort and ergonomic issues associated with traditional protective gear. Smart Kevlar clothing aims to be lighter, more flexible, and less cumbersome while maintaining its protective qualities. This includes developing breathable fabrics that incorporate Kevlar fibers and smart materials to regulate body temperature and moisture.

The integration of sensors and communication technologies into Kevlar-based smart clothing is another crucial objective. This allows for real-time monitoring of vital signs, detection of harmful substances in the environment, and immediate communication of potential dangers to the wearer and remote monitoring stations. Such features are particularly valuable in hazardous occupations like firefighting or chemical handling.

Sustainability and durability are also key considerations in the evolution of smart Kevlar clothing. Researchers are exploring ways to enhance the longevity of these garments, reduce their environmental impact, and potentially incorporate self-repairing mechanisms. This aligns with broader industry trends towards more sustainable and long-lasting protective equipment.

As the field progresses, the ultimate goal is to create a seamless integration of Kevlar's protective properties with cutting-edge smart technologies, resulting in clothing that not only protects but also enhances the wearer's capabilities and safety in complex, high-risk environments.

The evolution of Kevlar in protective clothing began with its use in bulletproof vests and has since expanded to a wide range of applications. Initially, Kevlar was primarily valued for its exceptional strength-to-weight ratio and heat resistance. As technology advanced, researchers and manufacturers recognized the potential to combine Kevlar's protective properties with smart features, leading to the development of intelligent protective gear.

The objectives of integrating Kevlar into smart protective clothing are multifaceted. Primarily, it seeks to maintain or enhance the level of protection offered by traditional Kevlar garments while incorporating advanced functionalities. These may include real-time health monitoring, environmental sensing, communication capabilities, and adaptive protection mechanisms.

One key goal is to develop clothing that can dynamically respond to external threats or changes in the wearer's physiological state. For instance, smart Kevlar clothing could potentially stiffen upon impact or adjust its thermal properties based on environmental conditions. This adaptive protection aims to provide optimal safety in various scenarios, from law enforcement to industrial work environments.

Another objective is to improve the overall user experience by addressing comfort and ergonomic issues associated with traditional protective gear. Smart Kevlar clothing aims to be lighter, more flexible, and less cumbersome while maintaining its protective qualities. This includes developing breathable fabrics that incorporate Kevlar fibers and smart materials to regulate body temperature and moisture.

The integration of sensors and communication technologies into Kevlar-based smart clothing is another crucial objective. This allows for real-time monitoring of vital signs, detection of harmful substances in the environment, and immediate communication of potential dangers to the wearer and remote monitoring stations. Such features are particularly valuable in hazardous occupations like firefighting or chemical handling.

Sustainability and durability are also key considerations in the evolution of smart Kevlar clothing. Researchers are exploring ways to enhance the longevity of these garments, reduce their environmental impact, and potentially incorporate self-repairing mechanisms. This aligns with broader industry trends towards more sustainable and long-lasting protective equipment.

As the field progresses, the ultimate goal is to create a seamless integration of Kevlar's protective properties with cutting-edge smart technologies, resulting in clothing that not only protects but also enhances the wearer's capabilities and safety in complex, high-risk environments.

Market Analysis for Smart Protective Apparel

The smart protective apparel market is experiencing significant growth, driven by increasing awareness of personal safety, technological advancements, and the rising demand for multifunctional clothing. This sector encompasses a wide range of products, including smart helmets, gloves, vests, and full-body suits, which integrate advanced materials like Kevlar with electronic components to enhance protection and functionality.

The global smart protective apparel market is projected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is fueled by various factors, including stringent workplace safety regulations, the need for improved soldier protection in defense applications, and the increasing adoption of wearable technology in sports and outdoor activities.

Key market segments for smart protective apparel include industrial safety, military and defense, sports and fitness, and healthcare. The industrial safety segment currently holds the largest market share, driven by the need for enhanced worker protection in hazardous environments such as construction, oil and gas, and manufacturing. The military and defense sector is expected to witness the fastest growth, as governments invest heavily in advanced protective gear for their personnel.

Geographically, North America dominates the smart protective apparel market, followed by Europe and Asia-Pacific. The United States, in particular, is a major contributor to market growth, owing to its strong focus on workplace safety and substantial defense spending. However, emerging economies in Asia-Pacific, such as China and India, are expected to present lucrative opportunities for market expansion in the coming years.

The integration of Kevlar into smart protective clothing represents a significant trend in the market. Kevlar, known for its exceptional strength-to-weight ratio and heat-resistant properties, is being combined with smart technologies to create highly protective and functional apparel. This integration addresses the growing demand for lightweight, comfortable, and technologically advanced protective gear across various industries.

Consumer preferences are shifting towards more ergonomic and user-friendly designs in smart protective apparel. There is an increasing demand for products that not only offer superior protection but also incorporate features such as biometric monitoring, environmental sensing, and communication capabilities. This trend is driving innovation in the sector, with manufacturers focusing on developing seamlessly integrated smart features without compromising the protective qualities of the apparel.

The market is also witnessing a surge in research and development activities aimed at improving the durability, flexibility, and smart functionalities of protective clothing. Collaborations between textile manufacturers, technology companies, and research institutions are becoming more common, leading to the development of novel materials and technologies that enhance the performance of smart protective apparel.

The global smart protective apparel market is projected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is fueled by various factors, including stringent workplace safety regulations, the need for improved soldier protection in defense applications, and the increasing adoption of wearable technology in sports and outdoor activities.

Key market segments for smart protective apparel include industrial safety, military and defense, sports and fitness, and healthcare. The industrial safety segment currently holds the largest market share, driven by the need for enhanced worker protection in hazardous environments such as construction, oil and gas, and manufacturing. The military and defense sector is expected to witness the fastest growth, as governments invest heavily in advanced protective gear for their personnel.

Geographically, North America dominates the smart protective apparel market, followed by Europe and Asia-Pacific. The United States, in particular, is a major contributor to market growth, owing to its strong focus on workplace safety and substantial defense spending. However, emerging economies in Asia-Pacific, such as China and India, are expected to present lucrative opportunities for market expansion in the coming years.

The integration of Kevlar into smart protective clothing represents a significant trend in the market. Kevlar, known for its exceptional strength-to-weight ratio and heat-resistant properties, is being combined with smart technologies to create highly protective and functional apparel. This integration addresses the growing demand for lightweight, comfortable, and technologically advanced protective gear across various industries.

Consumer preferences are shifting towards more ergonomic and user-friendly designs in smart protective apparel. There is an increasing demand for products that not only offer superior protection but also incorporate features such as biometric monitoring, environmental sensing, and communication capabilities. This trend is driving innovation in the sector, with manufacturers focusing on developing seamlessly integrated smart features without compromising the protective qualities of the apparel.

The market is also witnessing a surge in research and development activities aimed at improving the durability, flexibility, and smart functionalities of protective clothing. Collaborations between textile manufacturers, technology companies, and research institutions are becoming more common, leading to the development of novel materials and technologies that enhance the performance of smart protective apparel.

Kevlar Integration Challenges in Smart Textiles

The integration of Kevlar into smart protective clothing presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is maintaining the inherent strength and protective properties of Kevlar while incorporating electronic components and sensors. Kevlar's dense fiber structure, which provides its exceptional strength-to-weight ratio, can interfere with the flexibility and conductivity required for smart textiles.

Another major challenge lies in the development of suitable interfaces between Kevlar fibers and electronic elements. Creating reliable connections that can withstand the stress and strain of regular use, as well as potential impact scenarios, is crucial. These interfaces must be durable enough to maintain functionality under various environmental conditions, including exposure to moisture, heat, and chemicals.

The integration process also faces difficulties in terms of scalability and manufacturing. Current methods for incorporating electronic components into Kevlar fabrics are often labor-intensive and not easily adaptable to large-scale production. Developing automated processes that can efficiently weave or embed smart components into Kevlar materials without compromising their protective qualities is a significant hurdle.

Moreover, the addition of electronic components to Kevlar-based protective clothing raises concerns about power supply and management. Integrating lightweight, long-lasting power sources that do not compromise the garment's protective capabilities or add significant bulk is a complex engineering challenge. This includes developing efficient energy harvesting and storage solutions that can operate reliably in diverse environments.

Durability and maintenance of smart Kevlar garments pose additional challenges. The electronic components must be able to withstand the same harsh conditions as the Kevlar fabric itself, including high-impact forces, extreme temperatures, and chemical exposure. Furthermore, designing these garments to be easily maintainable and repairable without compromising their protective or smart functionalities is essential for their practical application.

Lastly, ensuring the compatibility of Kevlar-integrated smart clothing with existing protective gear standards and regulations presents a regulatory challenge. New testing and certification processes may need to be developed to assess the performance and safety of these hybrid protective systems, considering both their physical protective properties and their electronic functionalities.

Another major challenge lies in the development of suitable interfaces between Kevlar fibers and electronic elements. Creating reliable connections that can withstand the stress and strain of regular use, as well as potential impact scenarios, is crucial. These interfaces must be durable enough to maintain functionality under various environmental conditions, including exposure to moisture, heat, and chemicals.

The integration process also faces difficulties in terms of scalability and manufacturing. Current methods for incorporating electronic components into Kevlar fabrics are often labor-intensive and not easily adaptable to large-scale production. Developing automated processes that can efficiently weave or embed smart components into Kevlar materials without compromising their protective qualities is a significant hurdle.

Moreover, the addition of electronic components to Kevlar-based protective clothing raises concerns about power supply and management. Integrating lightweight, long-lasting power sources that do not compromise the garment's protective capabilities or add significant bulk is a complex engineering challenge. This includes developing efficient energy harvesting and storage solutions that can operate reliably in diverse environments.

Durability and maintenance of smart Kevlar garments pose additional challenges. The electronic components must be able to withstand the same harsh conditions as the Kevlar fabric itself, including high-impact forces, extreme temperatures, and chemical exposure. Furthermore, designing these garments to be easily maintainable and repairable without compromising their protective or smart functionalities is essential for their practical application.

Lastly, ensuring the compatibility of Kevlar-integrated smart clothing with existing protective gear standards and regulations presents a regulatory challenge. New testing and certification processes may need to be developed to assess the performance and safety of these hybrid protective systems, considering both their physical protective properties and their electronic functionalities.

Current Kevlar Smart Clothing Integration Methods

01 Kevlar-reinforced composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar fibers significantly improves the mechanical properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is extensively used in the production of personal protective equipment, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight nature make it ideal for creating protective gear that offers superior safety without compromising mobility.

- Kevlar in automotive applications: The automotive industry utilizes Kevlar in various components to reduce weight while maintaining strength. It is used in tire reinforcement, brake pads, and body panels. Kevlar's heat-resistant properties also make it suitable for high-temperature applications in vehicles.

- Kevlar-enhanced textiles and fabrics: Kevlar fibers are incorporated into textiles and fabrics to create durable, cut-resistant, and flame-retardant materials. These enhanced fabrics are used in industrial workwear, military uniforms, and high-performance sportswear, offering improved protection and longevity.

- Kevlar in aerospace and marine applications: The aerospace and marine industries utilize Kevlar in various applications due to its high strength-to-weight ratio and resistance to corrosion. It is used in aircraft components, spacecraft heat shields, and boat hulls. Kevlar's ability to withstand extreme conditions makes it valuable in these demanding environments.

02 Kevlar in protective gear and clothing

Kevlar is utilized in the manufacture of protective gear and clothing, such as bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.Expand Specific Solutions03 Kevlar-based fire-resistant materials

Kevlar is incorporated into fire-resistant materials and fabrics, providing enhanced thermal protection and flame retardancy. These materials are used in firefighting equipment, industrial safety gear, and high-temperature applications.Expand Specific Solutions04 Kevlar in automotive applications

Kevlar is used in various automotive components to reduce weight while maintaining strength and durability. Applications include tire reinforcement, brake pads, and body panels, contributing to improved fuel efficiency and safety.Expand Specific Solutions05 Kevlar in aerospace and marine industries

Kevlar finds applications in aerospace and marine industries for its high strength-to-weight ratio and resistance to corrosion. It is used in aircraft components, spacecraft heat shields, and boat hulls, enhancing performance and durability.Expand Specific Solutions

Key Players in Smart Kevlar Apparel Industry

The integration of Kevlar into smart protective clothing represents an emerging field at the intersection of advanced materials and wearable technology. The market is in its early growth stage, with increasing demand driven by military, law enforcement, and industrial safety sectors. While the global smart protective clothing market is expanding, the specific Kevlar-integrated segment remains niche. Technologically, the field is evolving rapidly, with companies like DuPont de Nemours, Inc., RMA Armament, Inc., and academic institutions such as MIT and IIT Delhi leading research efforts. The challenge lies in balancing Kevlar's protective properties with smart functionalities, requiring interdisciplinary collaboration between material scientists, electronics engineers, and textile experts.

DuPont de Nemours, Inc.

Technical Solution: DuPont, the inventor of Kevlar, has developed advanced smart protective clothing solutions integrating Kevlar fibers with electronic components. Their approach involves embedding conductive materials within Kevlar fabrics to create flexible circuits[1]. These smart textiles can monitor vital signs, detect impacts, and even provide localized heating. DuPont has also developed a proprietary coating technology that allows for the integration of sensors directly onto Kevlar fibers without compromising their strength[2]. This enables the creation of seamless, comfortable smart protective garments that maintain Kevlar's renowned ballistic and cut-resistant properties while adding intelligent functionalities.

Strengths: Unparalleled expertise in Kevlar technology, extensive R&D capabilities, and established market presence. Weaknesses: Potentially higher production costs and complexity in manufacturing integrated smart garments.

RMA Armament, Inc.

Technical Solution: RMA Armament has developed a novel approach to integrating Kevlar into smart protective clothing by focusing on modular, customizable designs. Their system utilizes Kevlar-based panels that can be easily inserted or removed from specially designed garments[3]. These panels are equipped with embedded sensors and communication modules, allowing for real-time monitoring of the wearer's vital signs and environmental conditions. RMA's innovative "plug-and-play" approach enables users to upgrade or replace smart components without replacing the entire garment, enhancing longevity and adaptability. The company has also developed a proprietary software platform that analyzes data from the smart clothing to provide actionable insights for wearers and command centers[4].

Strengths: Modular design allows for easy customization and upgrades, potentially lower long-term costs for users. Weaknesses: May sacrifice some integration compared to fully embedded solutions, potential for increased bulk in certain designs.

Innovative Kevlar-Electronics Interface Solutions

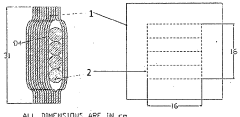

New body armour concept using semi-solid state shear thickening fluids

PatentInactiveIN6115CHE2015A

Innovation

- The use of semi-solid shear thickening fluids impregnated in KEVLAR layers, which exhibit high viscosity under impact to spread the force over a wider area, providing flexibility and reduced stress without the weight and rigidity issues of traditional solid reinforcements.

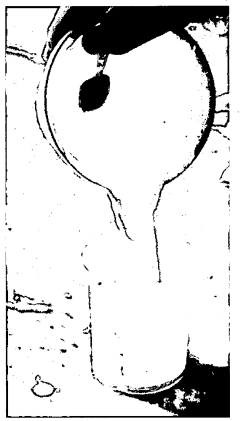

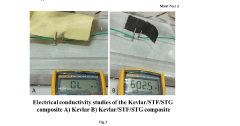

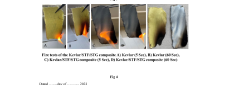

An improved process for fabricating kevlar fabric composite for multifunctional soft body armor

PatentPendingIN202321039845A

Innovation

- A composite material process involving Kevlar fabric impregnated with shear thickening fluid (STF) and shear-stiffening gel (STG), utilizing metal phosphate and carbon nanotubes, to enhance impact resistance, electrical conductivity, and flame retardancy, while allowing for temperature regulation.

Safety Standards for Smart Protective Clothing

Safety standards for smart protective clothing incorporating Kevlar are crucial to ensure the effectiveness and reliability of these advanced garments. The integration of Kevlar into smart protective clothing requires adherence to stringent safety regulations that encompass both traditional protective gear standards and emerging guidelines for wearable technology.

Existing safety standards for protective clothing, such as those set by the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA), provide a foundation for Kevlar-based smart protective clothing. These standards typically focus on factors like flame resistance, cut resistance, and durability. However, the incorporation of smart technologies necessitates additional considerations.

The International Electrotechnical Commission (IEC) has developed standards specifically for wearable electronic devices, which are applicable to smart protective clothing. These standards address issues such as electromagnetic compatibility, electrical safety, and battery performance. As Kevlar is integrated with electronic components, compliance with these standards becomes essential to ensure user safety and device functionality.

Thermal management is a critical aspect of safety standards for Kevlar-based smart protective clothing. The combination of Kevlar's inherent heat resistance with electronic components requires careful consideration of heat dissipation and thermal comfort. Standards must address the potential for overheating and ensure that the clothing maintains its protective properties under various environmental conditions.

Data privacy and security standards are increasingly important for smart protective clothing. As these garments may collect and transmit sensitive information about the wearer's health and location, compliance with data protection regulations such as GDPR in Europe or CCPA in California is necessary. Standards should outline protocols for secure data transmission, storage, and user consent.

Ergonomic standards play a vital role in ensuring that the integration of Kevlar and smart technologies does not compromise the wearer's mobility or comfort. Guidelines should address factors such as weight distribution, flexibility, and the placement of electronic components to maintain the garment's protective function while allowing for natural movement.

Durability and maintenance standards for smart protective clothing must account for both the Kevlar fabric and the embedded electronics. These standards should outline testing procedures for wash cycles, wear resistance, and the longevity of smart features under typical usage conditions. Additionally, guidelines for proper care and maintenance of the garments should be established to ensure ongoing safety and functionality.

As the field of smart protective clothing evolves, standards organizations must collaborate with industry leaders, researchers, and end-users to develop and refine safety guidelines. Regular updates to these standards will be necessary to keep pace with technological advancements and emerging safety concerns in the integration of Kevlar and smart technologies in protective clothing.

Existing safety standards for protective clothing, such as those set by the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA), provide a foundation for Kevlar-based smart protective clothing. These standards typically focus on factors like flame resistance, cut resistance, and durability. However, the incorporation of smart technologies necessitates additional considerations.

The International Electrotechnical Commission (IEC) has developed standards specifically for wearable electronic devices, which are applicable to smart protective clothing. These standards address issues such as electromagnetic compatibility, electrical safety, and battery performance. As Kevlar is integrated with electronic components, compliance with these standards becomes essential to ensure user safety and device functionality.

Thermal management is a critical aspect of safety standards for Kevlar-based smart protective clothing. The combination of Kevlar's inherent heat resistance with electronic components requires careful consideration of heat dissipation and thermal comfort. Standards must address the potential for overheating and ensure that the clothing maintains its protective properties under various environmental conditions.

Data privacy and security standards are increasingly important for smart protective clothing. As these garments may collect and transmit sensitive information about the wearer's health and location, compliance with data protection regulations such as GDPR in Europe or CCPA in California is necessary. Standards should outline protocols for secure data transmission, storage, and user consent.

Ergonomic standards play a vital role in ensuring that the integration of Kevlar and smart technologies does not compromise the wearer's mobility or comfort. Guidelines should address factors such as weight distribution, flexibility, and the placement of electronic components to maintain the garment's protective function while allowing for natural movement.

Durability and maintenance standards for smart protective clothing must account for both the Kevlar fabric and the embedded electronics. These standards should outline testing procedures for wash cycles, wear resistance, and the longevity of smart features under typical usage conditions. Additionally, guidelines for proper care and maintenance of the garments should be established to ensure ongoing safety and functionality.

As the field of smart protective clothing evolves, standards organizations must collaborate with industry leaders, researchers, and end-users to develop and refine safety guidelines. Regular updates to these standards will be necessary to keep pace with technological advancements and emerging safety concerns in the integration of Kevlar and smart technologies in protective clothing.

Durability and Maintenance of Smart Kevlar Garments

The integration of Kevlar into smart protective clothing presents unique challenges in terms of durability and maintenance. Kevlar, known for its exceptional strength-to-weight ratio, must be carefully incorporated to maintain its protective properties while accommodating the electronic components of smart garments. The durability of these hybrid garments is paramount, as they are often designed for high-stress environments such as military operations, law enforcement, or extreme sports.

One of the primary concerns in maintaining smart Kevlar garments is the potential degradation of the Kevlar fibers due to exposure to environmental factors. UV radiation, moisture, and chemical exposure can all impact the long-term performance of Kevlar. To address this, manufacturers are developing specialized coatings that can protect the Kevlar fibers without compromising their flexibility or breathability. These coatings must also be compatible with the electronic components embedded in the smart clothing.

The integration of electronic components into Kevlar fabric introduces new maintenance challenges. Traditional cleaning methods may not be suitable for smart garments, as water and detergents can damage sensitive electronics. Manufacturers are exploring innovative cleaning solutions, such as the use of antimicrobial treatments that reduce the need for frequent washing, and the development of modular designs that allow for the easy removal of electronic components before cleaning.

Wear and tear is another significant factor in the durability of smart Kevlar garments. The constant flexing and movement of the fabric can lead to stress on both the Kevlar fibers and the integrated electronics. To combat this, researchers are investigating self-healing materials that can repair minor damage autonomously, potentially extending the lifespan of these high-tech garments.

The maintenance of power sources in smart Kevlar clothing is also a critical consideration. Rechargeable batteries must be easily accessible for charging or replacement while remaining protected from impact and environmental factors. Some manufacturers are exploring the use of wireless charging technologies or energy harvesting systems that can extend the operational life of the smart components without compromising the protective qualities of the Kevlar.

Lastly, the repair and replacement of damaged components in smart Kevlar garments require specialized techniques. Manufacturers are developing modular designs that allow for the easy replacement of individual components, reducing the need for complete garment replacement and extending the overall lifespan of the product. Training programs for technicians specializing in the maintenance of smart protective clothing are becoming increasingly important to ensure proper care and longevity of these advanced garments.

One of the primary concerns in maintaining smart Kevlar garments is the potential degradation of the Kevlar fibers due to exposure to environmental factors. UV radiation, moisture, and chemical exposure can all impact the long-term performance of Kevlar. To address this, manufacturers are developing specialized coatings that can protect the Kevlar fibers without compromising their flexibility or breathability. These coatings must also be compatible with the electronic components embedded in the smart clothing.

The integration of electronic components into Kevlar fabric introduces new maintenance challenges. Traditional cleaning methods may not be suitable for smart garments, as water and detergents can damage sensitive electronics. Manufacturers are exploring innovative cleaning solutions, such as the use of antimicrobial treatments that reduce the need for frequent washing, and the development of modular designs that allow for the easy removal of electronic components before cleaning.

Wear and tear is another significant factor in the durability of smart Kevlar garments. The constant flexing and movement of the fabric can lead to stress on both the Kevlar fibers and the integrated electronics. To combat this, researchers are investigating self-healing materials that can repair minor damage autonomously, potentially extending the lifespan of these high-tech garments.

The maintenance of power sources in smart Kevlar clothing is also a critical consideration. Rechargeable batteries must be easily accessible for charging or replacement while remaining protected from impact and environmental factors. Some manufacturers are exploring the use of wireless charging technologies or energy harvesting systems that can extend the operational life of the smart components without compromising the protective qualities of the Kevlar.

Lastly, the repair and replacement of damaged components in smart Kevlar garments require specialized techniques. Manufacturers are developing modular designs that allow for the easy replacement of individual components, reducing the need for complete garment replacement and extending the overall lifespan of the product. Training programs for technicians specializing in the maintenance of smart protective clothing are becoming increasingly important to ensure proper care and longevity of these advanced garments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!