How to Formulate Hypochlorous Acid for Household Cleaners?

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Formulation Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising solution for household cleaning applications due to its potent antimicrobial properties and environmental friendliness. The development of HOCl-based household cleaners represents a significant shift in the cleaning industry, addressing growing consumer demands for safer and more sustainable cleaning products.

The primary objective of formulating HOCl for household cleaners is to harness its powerful disinfectant capabilities while ensuring stability, efficacy, and user-friendliness. HOCl is known for its ability to kill a wide range of pathogens, including bacteria, viruses, and fungi, making it an ideal candidate for various cleaning applications.

Historically, the use of HOCl has been limited due to its instability and short shelf life. However, recent technological advancements have paved the way for more stable formulations, opening up new possibilities for its widespread use in household cleaning products.

The evolution of HOCl formulation techniques has been driven by several factors, including increased awareness of the harmful effects of traditional chemical cleaners, the rise of antibiotic-resistant bacteria, and the global emphasis on sustainable and eco-friendly solutions. These factors have created a favorable environment for the development and adoption of HOCl-based cleaning products.

One of the key challenges in formulating HOCl for household cleaners is maintaining its stability over time. HOCl is known to degrade rapidly when exposed to light, heat, and certain materials. Therefore, a primary goal of the formulation process is to develop methods that preserve the active ingredient's efficacy throughout the product's intended shelf life.

Another critical objective is to optimize the concentration of HOCl in the formulation. While higher concentrations may offer increased antimicrobial activity, they can also lead to potential irritation or corrosion. Striking the right balance between efficacy and safety is crucial for creating a product that is both effective and consumer-friendly.

Furthermore, the formulation process aims to address the challenge of compatibility with various surfaces commonly found in households. The ideal HOCl-based cleaner should be effective on multiple surfaces without causing damage or discoloration, expanding its versatility and appeal to consumers.

As the cleaning industry continues to evolve, the development of HOCl formulations for household cleaners represents a significant opportunity for innovation. The successful creation of stable, effective, and user-friendly HOCl-based products has the potential to revolutionize household cleaning practices, offering a safer and more sustainable alternative to traditional chemical cleaners.

The primary objective of formulating HOCl for household cleaners is to harness its powerful disinfectant capabilities while ensuring stability, efficacy, and user-friendliness. HOCl is known for its ability to kill a wide range of pathogens, including bacteria, viruses, and fungi, making it an ideal candidate for various cleaning applications.

Historically, the use of HOCl has been limited due to its instability and short shelf life. However, recent technological advancements have paved the way for more stable formulations, opening up new possibilities for its widespread use in household cleaning products.

The evolution of HOCl formulation techniques has been driven by several factors, including increased awareness of the harmful effects of traditional chemical cleaners, the rise of antibiotic-resistant bacteria, and the global emphasis on sustainable and eco-friendly solutions. These factors have created a favorable environment for the development and adoption of HOCl-based cleaning products.

One of the key challenges in formulating HOCl for household cleaners is maintaining its stability over time. HOCl is known to degrade rapidly when exposed to light, heat, and certain materials. Therefore, a primary goal of the formulation process is to develop methods that preserve the active ingredient's efficacy throughout the product's intended shelf life.

Another critical objective is to optimize the concentration of HOCl in the formulation. While higher concentrations may offer increased antimicrobial activity, they can also lead to potential irritation or corrosion. Striking the right balance between efficacy and safety is crucial for creating a product that is both effective and consumer-friendly.

Furthermore, the formulation process aims to address the challenge of compatibility with various surfaces commonly found in households. The ideal HOCl-based cleaner should be effective on multiple surfaces without causing damage or discoloration, expanding its versatility and appeal to consumers.

As the cleaning industry continues to evolve, the development of HOCl formulations for household cleaners represents a significant opportunity for innovation. The successful creation of stable, effective, and user-friendly HOCl-based products has the potential to revolutionize household cleaning practices, offering a safer and more sustainable alternative to traditional chemical cleaners.

Market Analysis for HOCl-based Cleaners

The market for hypochlorous acid (HOCl) based household cleaners has been experiencing significant growth in recent years, driven by increasing consumer awareness of the product's effectiveness and safety profile. HOCl-based cleaners are gaining traction due to their powerful disinfecting properties, coupled with their non-toxic and environmentally friendly nature.

The global household cleaning products market, valued at approximately $235 billion in 2021, is expected to reach $320 billion by 2028, with a compound annual growth rate (CAGR) of 4.5%. Within this broader market, the segment for eco-friendly and natural cleaning products, which includes HOCl-based cleaners, is growing at an even faster rate, with some estimates suggesting a CAGR of 6.8% through 2027.

Consumer demand for HOCl-based cleaners is primarily driven by health and environmental concerns. As awareness of the potential harmful effects of traditional chemical cleaners grows, consumers are increasingly seeking safer alternatives that do not compromise on efficacy. HOCl-based products meet this demand by offering a powerful cleaning solution that is non-toxic, non-irritating, and safe for use around children and pets.

The COVID-19 pandemic has further accelerated the adoption of HOCl-based cleaners. The increased focus on hygiene and disinfection has led consumers to seek out more effective cleaning solutions, with many turning to HOCl for its proven ability to kill a wide range of pathogens, including viruses.

Market segmentation reveals that HOCl-based cleaners are gaining popularity across various household applications, including kitchen and bathroom cleaning, surface disinfection, and air purification. The versatility of HOCl formulations allows manufacturers to develop a wide range of products tailored to specific cleaning needs, further expanding market opportunities.

Geographically, North America and Europe currently lead the market for HOCl-based cleaners, with the Asia-Pacific region showing the highest growth potential. This regional variation is largely attributed to differences in consumer awareness, regulatory environments, and the presence of key market players.

Despite the positive growth trends, the HOCl-based cleaner market faces some challenges. These include the need for consumer education about the benefits of HOCl, competition from established cleaning product brands, and the technical challenges associated with maintaining product stability and shelf life.

Looking ahead, the market for HOCl-based household cleaners is expected to continue its growth trajectory. Factors such as increasing health consciousness, stringent regulations on chemical cleaners, and ongoing product innovations are likely to drive further adoption. As manufacturers overcome technical challenges and expand their product offerings, HOCl-based cleaners are poised to capture a larger share of the household cleaning products market in the coming years.

The global household cleaning products market, valued at approximately $235 billion in 2021, is expected to reach $320 billion by 2028, with a compound annual growth rate (CAGR) of 4.5%. Within this broader market, the segment for eco-friendly and natural cleaning products, which includes HOCl-based cleaners, is growing at an even faster rate, with some estimates suggesting a CAGR of 6.8% through 2027.

Consumer demand for HOCl-based cleaners is primarily driven by health and environmental concerns. As awareness of the potential harmful effects of traditional chemical cleaners grows, consumers are increasingly seeking safer alternatives that do not compromise on efficacy. HOCl-based products meet this demand by offering a powerful cleaning solution that is non-toxic, non-irritating, and safe for use around children and pets.

The COVID-19 pandemic has further accelerated the adoption of HOCl-based cleaners. The increased focus on hygiene and disinfection has led consumers to seek out more effective cleaning solutions, with many turning to HOCl for its proven ability to kill a wide range of pathogens, including viruses.

Market segmentation reveals that HOCl-based cleaners are gaining popularity across various household applications, including kitchen and bathroom cleaning, surface disinfection, and air purification. The versatility of HOCl formulations allows manufacturers to develop a wide range of products tailored to specific cleaning needs, further expanding market opportunities.

Geographically, North America and Europe currently lead the market for HOCl-based cleaners, with the Asia-Pacific region showing the highest growth potential. This regional variation is largely attributed to differences in consumer awareness, regulatory environments, and the presence of key market players.

Despite the positive growth trends, the HOCl-based cleaner market faces some challenges. These include the need for consumer education about the benefits of HOCl, competition from established cleaning product brands, and the technical challenges associated with maintaining product stability and shelf life.

Looking ahead, the market for HOCl-based household cleaners is expected to continue its growth trajectory. Factors such as increasing health consciousness, stringent regulations on chemical cleaners, and ongoing product innovations are likely to drive further adoption. As manufacturers overcome technical challenges and expand their product offerings, HOCl-based cleaners are poised to capture a larger share of the household cleaning products market in the coming years.

HOCl Stability Challenges

Hypochlorous acid (HOCl) presents significant stability challenges when formulated for household cleaners. The primary issue lies in its tendency to decompose rapidly, particularly in aqueous solutions. This instability is primarily attributed to the molecule's reactive nature, which makes it an effective disinfectant but also leads to its short shelf life.

One of the main factors affecting HOCl stability is pH. The acid is most stable at a pH range of 3.5 to 5.5. Outside this range, it quickly decomposes into other chlorine species, such as hypochlorite ions or chlorine gas. This pH sensitivity necessitates careful formulation and packaging to maintain the desired acidity level throughout the product's shelf life.

Temperature also plays a crucial role in HOCl stability. Higher temperatures accelerate the decomposition process, while lower temperatures can help prolong the acid's effectiveness. This temperature dependence poses challenges for storage and transportation, especially in warmer climates or during summer months.

Light exposure is another significant factor impacting HOCl stability. Ultraviolet (UV) light can catalyze the breakdown of hypochlorous acid, leading to a loss of disinfecting power over time. This necessitates the use of opaque or UV-resistant packaging to protect the formulation from light-induced degradation.

The presence of organic matter and certain metal ions can also accelerate HOCl decomposition. When formulating household cleaners, it's crucial to consider the potential interaction between HOCl and other ingredients or contaminants that may be present in the cleaning environment.

Concentration is yet another factor affecting stability. Higher concentrations of HOCl tend to be less stable, as the molecules are more likely to interact and decompose. However, lower concentrations may not provide sufficient cleaning power, creating a delicate balance that formulators must navigate.

The choice of stabilizers and buffering agents is critical in addressing these stability challenges. Common stabilizers include sodium chloride, which can help maintain the desired chlorine species balance, and phosphate buffers, which assist in pH control. However, the use of these additives must be carefully balanced to maintain cleaning efficacy while enhancing stability.

Packaging innovations play a vital role in overcoming HOCl stability issues. Airless pump bottles, for instance, can help minimize exposure to oxygen, which contributes to decomposition. Multi-compartment packaging systems that separate HOCl precursors until the point of use are also being explored as potential solutions to extend shelf life.

One of the main factors affecting HOCl stability is pH. The acid is most stable at a pH range of 3.5 to 5.5. Outside this range, it quickly decomposes into other chlorine species, such as hypochlorite ions or chlorine gas. This pH sensitivity necessitates careful formulation and packaging to maintain the desired acidity level throughout the product's shelf life.

Temperature also plays a crucial role in HOCl stability. Higher temperatures accelerate the decomposition process, while lower temperatures can help prolong the acid's effectiveness. This temperature dependence poses challenges for storage and transportation, especially in warmer climates or during summer months.

Light exposure is another significant factor impacting HOCl stability. Ultraviolet (UV) light can catalyze the breakdown of hypochlorous acid, leading to a loss of disinfecting power over time. This necessitates the use of opaque or UV-resistant packaging to protect the formulation from light-induced degradation.

The presence of organic matter and certain metal ions can also accelerate HOCl decomposition. When formulating household cleaners, it's crucial to consider the potential interaction between HOCl and other ingredients or contaminants that may be present in the cleaning environment.

Concentration is yet another factor affecting stability. Higher concentrations of HOCl tend to be less stable, as the molecules are more likely to interact and decompose. However, lower concentrations may not provide sufficient cleaning power, creating a delicate balance that formulators must navigate.

The choice of stabilizers and buffering agents is critical in addressing these stability challenges. Common stabilizers include sodium chloride, which can help maintain the desired chlorine species balance, and phosphate buffers, which assist in pH control. However, the use of these additives must be carefully balanced to maintain cleaning efficacy while enhancing stability.

Packaging innovations play a vital role in overcoming HOCl stability issues. Airless pump bottles, for instance, can help minimize exposure to oxygen, which contributes to decomposition. Multi-compartment packaging systems that separate HOCl precursors until the point of use are also being explored as potential solutions to extend shelf life.

Current HOCl Formulation Techniques

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization and formulation of hypochlorous acid solutions: Techniques for stabilizing hypochlorous acid solutions to extend their shelf life and maintain efficacy are crucial. This includes pH adjustment, addition of stabilizing agents, and specialized packaging methods to prevent degradation and ensure consistent performance over time.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in wound care, dermatology, and respiratory treatments. Its ability to promote healing, reduce inflammation, and combat infections without harming healthy tissue makes it valuable in various medical contexts.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental remediation, wastewater treatment, and industrial cleaning processes. Its eco-friendly nature and effectiveness in breaking down contaminants make it suitable for large-scale applications in various industries.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its relatively low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization and formulation of hypochlorous acid solutions

Techniques for stabilizing hypochlorous acid solutions are crucial for maintaining their efficacy over time. This includes pH adjustment, addition of stabilizing agents, and specialized packaging to prevent degradation. Formulation strategies aim to enhance shelf life and preserve the active properties of hypochlorous acid.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid finds applications in various medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to promote healing while providing antimicrobial protection makes it valuable in clinical settings and for personal healthcare products.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Beyond healthcare, hypochlorous acid is utilized in environmental and industrial applications such as water treatment, agriculture, and surface disinfection. Its eco-friendly nature and effectiveness in removing contaminants make it a preferred choice in various sectors concerned with cleanliness and safety.Expand Specific Solutions

Key HOCl Cleaner Manufacturers

The market for hypochlorous acid formulation in household cleaners is in a growth phase, driven by increasing demand for safe and effective disinfectants. The global market size is expanding rapidly, estimated to reach several billion dollars in the coming years. Technologically, the field is advancing with innovations in production methods and stabilization techniques. Companies like Aquaox, Annihilare Medical Systems, and Enlighten Innovations are at the forefront, developing proprietary formulations and on-site generation systems. Established players such as Colgate-Palmolive are also entering the market, indicating its growing mainstream appeal. However, challenges remain in scaling production and educating consumers about this relatively new cleaning technology.

Dyson Technology Ltd.

Technical Solution: Dyson Technology has approached the formulation of hypochlorous acid for household cleaners from an engineering perspective, focusing on innovative delivery systems. Their method involves integrating HOCl generation into their household cleaning appliances, such as vacuum cleaners and air purifiers[10]. Dyson's approach uses electrolyzed water technology to produce HOCl on-demand within the device itself[11]. The system incorporates a miniaturized electrolysis cell that converts a salt solution into HOCl at the point of use, ensuring maximum potency and eliminating the need for stabilizers[12]. Dyson's formulation maintains a pH range of 6.0-7.0 and typically produces HOCl concentrations between 100-300 ppm, adjustable based on the cleaning task[13]. The company has also developed sensors to monitor and adjust the HOCl concentration in real-time, ensuring consistent cleaning performance[14].

Strengths: Integration with existing household appliances; on-demand HOCl generation; precise control over concentration. Weaknesses: Limited to specific Dyson products; potentially higher cost for consumers due to specialized technology.

Aquaox, Inc.

Technical Solution: Aquaox has developed a proprietary electrolysis process to produce stable hypochlorous acid (HOCl) solutions for household cleaners. Their method utilizes a specialized membrane electrolysis cell to generate HOCl with precise control over pH and free available chlorine (FAC) concentration[1]. The process involves passing a salt brine solution through the cell, where it undergoes electrolysis to produce HOCl at a near-neutral pH (typically 6.5-7.5)[2]. Aquaox's formulation includes stabilizers to maintain HOCl efficacy over extended periods, addressing the stability challenges often associated with HOCl solutions[3]. The company has also developed a patented dispensing system that allows for on-site generation of HOCl, ensuring freshness and potency at the point of use[4].

Strengths: Precise control over HOCl concentration and pH; extended stability of HOCl solutions; on-site generation capability. Weaknesses: Potentially higher production costs due to specialized equipment; reliance on electricity for production.

Innovative HOCl Stabilization Methods

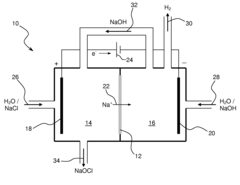

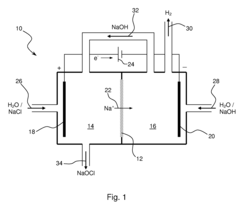

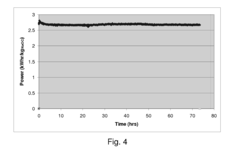

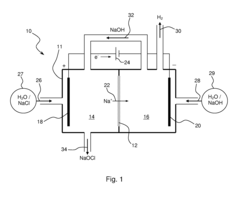

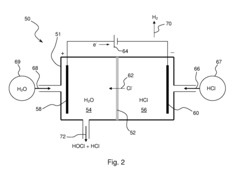

Electrolytic process to produce sodium hypochlorite using sodium ion conductive ceramic membranes

PatentInactiveUS20070138020A1

Innovation

- An electrochemical process using a sodium ion conductive ceramic membrane, specifically NaSICON-type membranes, separates anolyte and catholyte compartments in an electrolytic cell, allowing sodium ion transport while preventing water and calcium/magnesium ion diffusion, enabling continuous sodium hypochlorite production from various sodium chloride solutions, including seawater, and facilitating hydrogen gas recovery.

Cleansing Agent Generator and Dispenser

PatentInactiveUS20080264778A1

Innovation

- An electrochemical process using a sodium ion conductive ceramic membrane to generate sodium hypochlorite and an anionic conductive membrane to produce hypochlorous acid, utilizing common table salt and moderate electricity, allowing for on-demand production of these compounds at the point of use.

Safety and Regulatory Compliance

Safety and regulatory compliance are paramount considerations when formulating hypochlorous acid for household cleaners. The production and use of hypochlorous acid must adhere to strict guidelines set by regulatory bodies such as the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) in the United States, as well as similar agencies in other countries.

Hypochlorous acid is generally recognized as safe (GRAS) by the FDA when used as an antimicrobial agent in food processing. However, its use in household cleaners requires careful formulation to ensure safety for consumers and the environment. The concentration of hypochlorous acid in household cleaners typically ranges from 50 to 200 parts per million (ppm), which is considered safe for general use.

Manufacturers must comply with labeling requirements, including clear instructions for use, safety precautions, and proper storage guidelines. The pH level of the final product is crucial, as hypochlorous acid is most effective and stable at a pH range of 3.5 to 6.5. Formulations outside this range may compromise the product's efficacy or safety.

Environmental considerations are also significant. Hypochlorous acid breaks down into salt and water, making it environmentally friendly. However, manufacturers must ensure that the production process and packaging meet sustainability standards and minimize environmental impact.

Quality control measures are essential to maintain consistent product safety and efficacy. Regular testing of hypochlorous acid concentrations, pH levels, and microbial efficacy is necessary to comply with regulatory standards. Stability testing is also crucial to determine the product's shelf life and ensure its effectiveness throughout its intended use period.

Occupational safety is another critical aspect of regulatory compliance. Manufacturers must implement proper safety protocols for workers involved in the production and handling of hypochlorous acid. This includes providing appropriate personal protective equipment (PPE) and ensuring adequate ventilation in production facilities.

International regulations must be considered for products intended for global distribution. Different countries may have varying requirements for household cleaners containing hypochlorous acid. Manufacturers must navigate these regulatory landscapes to ensure compliance in all target markets.

Ongoing monitoring of regulatory changes is essential, as guidelines for household cleaners may evolve based on new scientific evidence or environmental concerns. Companies must be prepared to adapt their formulations and production processes to meet updated regulatory requirements promptly.

Hypochlorous acid is generally recognized as safe (GRAS) by the FDA when used as an antimicrobial agent in food processing. However, its use in household cleaners requires careful formulation to ensure safety for consumers and the environment. The concentration of hypochlorous acid in household cleaners typically ranges from 50 to 200 parts per million (ppm), which is considered safe for general use.

Manufacturers must comply with labeling requirements, including clear instructions for use, safety precautions, and proper storage guidelines. The pH level of the final product is crucial, as hypochlorous acid is most effective and stable at a pH range of 3.5 to 6.5. Formulations outside this range may compromise the product's efficacy or safety.

Environmental considerations are also significant. Hypochlorous acid breaks down into salt and water, making it environmentally friendly. However, manufacturers must ensure that the production process and packaging meet sustainability standards and minimize environmental impact.

Quality control measures are essential to maintain consistent product safety and efficacy. Regular testing of hypochlorous acid concentrations, pH levels, and microbial efficacy is necessary to comply with regulatory standards. Stability testing is also crucial to determine the product's shelf life and ensure its effectiveness throughout its intended use period.

Occupational safety is another critical aspect of regulatory compliance. Manufacturers must implement proper safety protocols for workers involved in the production and handling of hypochlorous acid. This includes providing appropriate personal protective equipment (PPE) and ensuring adequate ventilation in production facilities.

International regulations must be considered for products intended for global distribution. Different countries may have varying requirements for household cleaners containing hypochlorous acid. Manufacturers must navigate these regulatory landscapes to ensure compliance in all target markets.

Ongoing monitoring of regulatory changes is essential, as guidelines for household cleaners may evolve based on new scientific evidence or environmental concerns. Companies must be prepared to adapt their formulations and production processes to meet updated regulatory requirements promptly.

Environmental Impact Assessment

The formulation of hypochlorous acid for household cleaners necessitates a comprehensive environmental impact assessment to ensure sustainable and eco-friendly product development. Hypochlorous acid (HOCl) is known for its potent disinfecting properties and has gained popularity as an effective, yet potentially safer alternative to traditional cleaning agents. However, its widespread use in household products warrants a thorough examination of its environmental implications.

One of the primary environmental considerations is the fate of HOCl after use. When discharged into wastewater systems, hypochlorous acid typically decomposes rapidly into harmless byproducts, primarily salt and water. This quick degradation minimizes its persistence in aquatic environments, reducing the risk of long-term ecological impacts. However, the potential formation of disinfection byproducts (DBPs) during the breakdown process requires careful monitoring and assessment.

The production process of HOCl for household cleaners also merits scrutiny from an environmental perspective. The most common method involves the electrolysis of salt water, which is generally considered a low-impact process. Nevertheless, the energy consumption associated with electrolysis should be evaluated to minimize the carbon footprint of production. Implementing renewable energy sources in the manufacturing process could significantly reduce the overall environmental impact.

Packaging and distribution of HOCl-based cleaners present another area for environmental consideration. The stability of hypochlorous acid solutions can be affected by light and temperature, potentially necessitating specialized packaging. Manufacturers should prioritize recyclable or biodegradable packaging materials to reduce waste and align with circular economy principles. Additionally, optimizing distribution networks to minimize transportation-related emissions is crucial for reducing the product's overall carbon footprint.

The potential impact on indoor air quality is another important aspect of the environmental assessment. While HOCl is generally considered safer than many traditional cleaning chemicals, its use in enclosed spaces should be evaluated for any potential effects on air quality or human health. This includes assessing the formation of volatile organic compounds (VOCs) and other airborne byproducts during and after use.

Lastly, the environmental impact assessment should consider the broader lifecycle implications of HOCl-based cleaners. This includes evaluating the sourcing of raw materials, comparing the environmental footprint to alternative cleaning products, and assessing the potential for reducing overall chemical usage in household cleaning. By taking a holistic approach, manufacturers can ensure that the formulation and use of hypochlorous acid in household cleaners align with sustainable practices and environmental stewardship goals.

One of the primary environmental considerations is the fate of HOCl after use. When discharged into wastewater systems, hypochlorous acid typically decomposes rapidly into harmless byproducts, primarily salt and water. This quick degradation minimizes its persistence in aquatic environments, reducing the risk of long-term ecological impacts. However, the potential formation of disinfection byproducts (DBPs) during the breakdown process requires careful monitoring and assessment.

The production process of HOCl for household cleaners also merits scrutiny from an environmental perspective. The most common method involves the electrolysis of salt water, which is generally considered a low-impact process. Nevertheless, the energy consumption associated with electrolysis should be evaluated to minimize the carbon footprint of production. Implementing renewable energy sources in the manufacturing process could significantly reduce the overall environmental impact.

Packaging and distribution of HOCl-based cleaners present another area for environmental consideration. The stability of hypochlorous acid solutions can be affected by light and temperature, potentially necessitating specialized packaging. Manufacturers should prioritize recyclable or biodegradable packaging materials to reduce waste and align with circular economy principles. Additionally, optimizing distribution networks to minimize transportation-related emissions is crucial for reducing the product's overall carbon footprint.

The potential impact on indoor air quality is another important aspect of the environmental assessment. While HOCl is generally considered safer than many traditional cleaning chemicals, its use in enclosed spaces should be evaluated for any potential effects on air quality or human health. This includes assessing the formation of volatile organic compounds (VOCs) and other airborne byproducts during and after use.

Lastly, the environmental impact assessment should consider the broader lifecycle implications of HOCl-based cleaners. This includes evaluating the sourcing of raw materials, comparing the environmental footprint to alternative cleaning products, and assessing the potential for reducing overall chemical usage in household cleaning. By taking a holistic approach, manufacturers can ensure that the formulation and use of hypochlorous acid in household cleaners align with sustainable practices and environmental stewardship goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!