How to Achieve Maximum Disinfection with Hypochlorous Acid?

AUG 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Disinfection Background and Objectives

Hypochlorous acid (HOCl) has emerged as a powerful disinfectant with a rich history dating back to its discovery in the early 19th century. This naturally occurring molecule, produced by the human immune system to fight infections, has gained significant attention in recent years due to its remarkable efficacy and safety profile. The evolution of HOCl technology has been driven by the growing demand for effective, eco-friendly disinfection solutions across various industries.

The primary objective of maximizing disinfection with hypochlorous acid is to harness its full potential as a broad-spectrum antimicrobial agent. This goal encompasses optimizing HOCl production methods, stabilizing the solution for extended shelf life, and developing innovative application techniques to enhance its effectiveness against a wide range of pathogens. By achieving these objectives, industries can benefit from a highly efficient, non-toxic disinfection solution that addresses the limitations of traditional chemical disinfectants.

The technological trajectory of HOCl disinfection has been marked by significant advancements in production methods, from early electrolysis techniques to more sophisticated electrochemical activation processes. These developments have enabled the production of stable, high-concentration HOCl solutions, overcoming historical challenges related to the compound's instability. Concurrent research has focused on understanding the mechanisms of HOCl's antimicrobial action, revealing its ability to rapidly penetrate microbial cell walls and disrupt vital cellular processes.

As global health concerns and environmental awareness continue to grow, the demand for safe, effective disinfection solutions has intensified. This trend has propelled HOCl to the forefront of disinfection technology, with applications expanding beyond healthcare settings to include food processing, water treatment, and consumer products. The ongoing COVID-19 pandemic has further accelerated interest in HOCl, highlighting its potential as a versatile tool in infection control strategies.

Looking ahead, the future of HOCl disinfection technology is poised for continued innovation. Key areas of focus include enhancing production efficiency, improving solution stability, and developing novel delivery systems to maximize coverage and effectiveness. Additionally, there is growing interest in combining HOCl with other technologies, such as nanotechnology or UV light, to create synergistic disinfection systems capable of addressing complex contamination challenges.

The primary objective of maximizing disinfection with hypochlorous acid is to harness its full potential as a broad-spectrum antimicrobial agent. This goal encompasses optimizing HOCl production methods, stabilizing the solution for extended shelf life, and developing innovative application techniques to enhance its effectiveness against a wide range of pathogens. By achieving these objectives, industries can benefit from a highly efficient, non-toxic disinfection solution that addresses the limitations of traditional chemical disinfectants.

The technological trajectory of HOCl disinfection has been marked by significant advancements in production methods, from early electrolysis techniques to more sophisticated electrochemical activation processes. These developments have enabled the production of stable, high-concentration HOCl solutions, overcoming historical challenges related to the compound's instability. Concurrent research has focused on understanding the mechanisms of HOCl's antimicrobial action, revealing its ability to rapidly penetrate microbial cell walls and disrupt vital cellular processes.

As global health concerns and environmental awareness continue to grow, the demand for safe, effective disinfection solutions has intensified. This trend has propelled HOCl to the forefront of disinfection technology, with applications expanding beyond healthcare settings to include food processing, water treatment, and consumer products. The ongoing COVID-19 pandemic has further accelerated interest in HOCl, highlighting its potential as a versatile tool in infection control strategies.

Looking ahead, the future of HOCl disinfection technology is poised for continued innovation. Key areas of focus include enhancing production efficiency, improving solution stability, and developing novel delivery systems to maximize coverage and effectiveness. Additionally, there is growing interest in combining HOCl with other technologies, such as nanotechnology or UV light, to create synergistic disinfection systems capable of addressing complex contamination challenges.

Market Analysis for HOCl Disinfectants

The global market for hypochlorous acid (HOCl) disinfectants has experienced significant growth in recent years, driven by increasing awareness of its efficacy and safety profile. The COVID-19 pandemic has further accelerated market expansion, as businesses and consumers seek effective sanitization solutions. The HOCl disinfectant market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong through 2026.

Key factors contributing to market growth include HOCl's broad-spectrum antimicrobial properties, its non-toxic nature, and its environmentally friendly characteristics. These attributes have positioned HOCl as a preferred choice across various sectors, including healthcare, food and beverage, agriculture, and water treatment.

In the healthcare sector, HOCl disinfectants have gained traction due to their ability to effectively combat hospital-acquired infections without the harsh side effects associated with traditional chemical disinfectants. The food and beverage industry has also embraced HOCl for its ability to sanitize surfaces and equipment without leaving harmful residues.

The agriculture sector represents another significant market opportunity for HOCl disinfectants. Farmers are increasingly adopting HOCl solutions for crop protection and livestock management, as they offer an eco-friendly alternative to conventional pesticides and disinfectants.

Geographically, North America and Europe currently dominate the HOCl disinfectant market, owing to stringent regulations on chemical usage and a high level of health and safety awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare expenditure, and growing concerns about food safety.

Despite the positive outlook, the HOCl disinfectant market faces challenges such as limited shelf life and the need for specialized storage and handling. Manufacturers are actively addressing these issues through improved formulations and packaging innovations.

Consumer trends indicate a growing preference for natural and sustainable cleaning products, which aligns well with HOCl's eco-friendly profile. This shift in consumer behavior is likely to further boost market demand for HOCl-based disinfectants in the coming years.

As the market evolves, key players are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their competitive edge. The development of stabilized HOCl formulations with extended shelf life is a particular area of focus, as it could significantly expand the product's applications and market reach.

Key factors contributing to market growth include HOCl's broad-spectrum antimicrobial properties, its non-toxic nature, and its environmentally friendly characteristics. These attributes have positioned HOCl as a preferred choice across various sectors, including healthcare, food and beverage, agriculture, and water treatment.

In the healthcare sector, HOCl disinfectants have gained traction due to their ability to effectively combat hospital-acquired infections without the harsh side effects associated with traditional chemical disinfectants. The food and beverage industry has also embraced HOCl for its ability to sanitize surfaces and equipment without leaving harmful residues.

The agriculture sector represents another significant market opportunity for HOCl disinfectants. Farmers are increasingly adopting HOCl solutions for crop protection and livestock management, as they offer an eco-friendly alternative to conventional pesticides and disinfectants.

Geographically, North America and Europe currently dominate the HOCl disinfectant market, owing to stringent regulations on chemical usage and a high level of health and safety awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare expenditure, and growing concerns about food safety.

Despite the positive outlook, the HOCl disinfectant market faces challenges such as limited shelf life and the need for specialized storage and handling. Manufacturers are actively addressing these issues through improved formulations and packaging innovations.

Consumer trends indicate a growing preference for natural and sustainable cleaning products, which aligns well with HOCl's eco-friendly profile. This shift in consumer behavior is likely to further boost market demand for HOCl-based disinfectants in the coming years.

As the market evolves, key players are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their competitive edge. The development of stabilized HOCl formulations with extended shelf life is a particular area of focus, as it could significantly expand the product's applications and market reach.

Current HOCl Technology Challenges

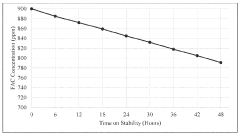

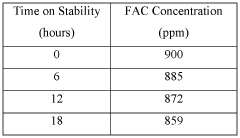

Despite the proven effectiveness of hypochlorous acid (HOCl) as a disinfectant, several challenges persist in maximizing its disinfection potential. One of the primary obstacles is the stability of HOCl solutions. The compound is known to degrade rapidly, especially when exposed to light, heat, or organic matter. This instability limits its shelf life and effectiveness over time, posing difficulties in storage and long-term use.

Another significant challenge lies in maintaining the optimal pH range for HOCl efficacy. The disinfectant is most effective at a pH between 3.5 and 6.5, with peak performance around pH 5. Maintaining this narrow pH range in various application environments can be problematic, as shifts in pH can dramatically reduce HOCl's disinfection power.

The concentration of HOCl in solution presents another hurdle. While higher concentrations generally lead to more effective disinfection, they also increase the risk of material compatibility issues and potential irritation to users. Striking the right balance between efficacy and safety remains a key challenge in HOCl technology.

Production methods for HOCl also face limitations. Current electrolysis techniques, while effective, can be energy-intensive and may produce varying concentrations of HOCl depending on the process parameters. Achieving consistent, high-quality HOCl production at scale remains an area of ongoing research and development.

The interaction of HOCl with organic matter in real-world applications poses additional challenges. When HOCl encounters high levels of organic contaminants, it can be rapidly consumed, reducing its overall disinfection efficacy. This necessitates careful consideration of application methods and dosing strategies in environments with significant organic loads.

Furthermore, the lack of standardized testing protocols for HOCl efficacy across different pathogens and environmental conditions hampers the ability to compare and optimize various HOCl-based disinfection solutions. This absence of uniform benchmarks makes it difficult for manufacturers to validate claims and for end-users to make informed decisions about product selection.

Lastly, regulatory hurdles and varying approval processes across different regions complicate the widespread adoption of HOCl technology. The classification of HOCl products and the requirements for their use in different sectors (healthcare, food industry, water treatment) vary significantly, creating barriers to market entry and global distribution.

Another significant challenge lies in maintaining the optimal pH range for HOCl efficacy. The disinfectant is most effective at a pH between 3.5 and 6.5, with peak performance around pH 5. Maintaining this narrow pH range in various application environments can be problematic, as shifts in pH can dramatically reduce HOCl's disinfection power.

The concentration of HOCl in solution presents another hurdle. While higher concentrations generally lead to more effective disinfection, they also increase the risk of material compatibility issues and potential irritation to users. Striking the right balance between efficacy and safety remains a key challenge in HOCl technology.

Production methods for HOCl also face limitations. Current electrolysis techniques, while effective, can be energy-intensive and may produce varying concentrations of HOCl depending on the process parameters. Achieving consistent, high-quality HOCl production at scale remains an area of ongoing research and development.

The interaction of HOCl with organic matter in real-world applications poses additional challenges. When HOCl encounters high levels of organic contaminants, it can be rapidly consumed, reducing its overall disinfection efficacy. This necessitates careful consideration of application methods and dosing strategies in environments with significant organic loads.

Furthermore, the lack of standardized testing protocols for HOCl efficacy across different pathogens and environmental conditions hampers the ability to compare and optimize various HOCl-based disinfection solutions. This absence of uniform benchmarks makes it difficult for manufacturers to validate claims and for end-users to make informed decisions about product selection.

Lastly, regulatory hurdles and varying approval processes across different regions complicate the widespread adoption of HOCl technology. The classification of HOCl products and the requirements for their use in different sectors (healthcare, food industry, water treatment) vary significantly, creating barriers to market entry and global distribution.

Existing HOCl Disinfection Methods

01 Hypochlorous acid generation and application methods

Various methods for generating and applying hypochlorous acid for disinfection purposes are described. These include electrolytic generation systems, spray devices, and misting systems. The focus is on efficient production and effective distribution of hypochlorous acid for maximum disinfection efficacy.- Hypochlorous acid generation systems: Various systems and devices are designed to generate hypochlorous acid for disinfection purposes. These systems often involve electrolysis of salt water or other chemical reactions to produce the disinfectant on-site. The generated hypochlorous acid can be used for a wide range of applications, including surface disinfection, water treatment, and air purification.

- Hypochlorous acid-based disinfection methods: Different methods of applying hypochlorous acid for disinfection are developed, including spraying, fogging, and direct application. These methods are tailored for specific environments such as hospitals, food processing facilities, and public spaces. The effectiveness of these methods depends on factors like concentration, contact time, and application technique.

- Stabilization and storage of hypochlorous acid: Techniques for stabilizing hypochlorous acid solutions to extend their shelf life and maintain efficacy are developed. These may include pH adjustment, addition of stabilizing agents, or specialized packaging. Proper storage conditions and handling procedures are crucial for maintaining the disinfectant's potency over time.

- Combination with other disinfectants or additives: Hypochlorous acid is often combined with other disinfectants or additives to enhance its effectiveness or broaden its spectrum of activity. This may include combining it with other oxidizing agents, surfactants, or pH modifiers. The synergistic effects of these combinations can lead to improved disinfection performance.

- Specialized applications of hypochlorous acid disinfection: Hypochlorous acid is utilized in specialized applications such as medical device sterilization, wound care, and agricultural disinfection. These applications often require specific formulations or delivery methods to ensure effectiveness while maintaining safety for the intended use. Research in this area focuses on optimizing hypochlorous acid solutions for these specialized purposes.

02 Hypochlorous acid-based disinfection devices

Specialized devices designed for hypochlorous acid disinfection are presented. These include portable units, integrated systems for buildings, and automated disinfection equipment. The devices aim to optimize the delivery and application of hypochlorous acid in various settings.Expand Specific Solutions03 Hypochlorous acid formulations and compositions

Specific formulations and compositions of hypochlorous acid for enhanced disinfection properties are discussed. These may include stabilized forms, pH-adjusted solutions, or combinations with other disinfecting agents to improve efficacy and shelf life.Expand Specific Solutions04 Applications of hypochlorous acid in specific industries

The use of hypochlorous acid for disinfection in particular industries or settings is explored. This includes applications in healthcare facilities, food processing plants, water treatment systems, and public spaces. The focus is on tailoring hypochlorous acid disinfection methods to meet industry-specific requirements.Expand Specific Solutions05 Monitoring and control systems for hypochlorous acid disinfection

Advanced systems for monitoring and controlling hypochlorous acid disinfection processes are presented. These include sensors for measuring concentration, automated dosing systems, and feedback mechanisms to ensure optimal disinfection performance while maintaining safety and efficiency.Expand Specific Solutions

Key HOCl Industry Players

The market for hypochlorous acid disinfection technology is in a growth phase, driven by increasing demand for effective and safe disinfection solutions. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Annihilare Medical Systems and Water Star Inc. leading innovation in on-site generation and electrochemical systems. Established players such as Nipro Corp. and Kureha Corp. are also contributing to market maturity through their diversified product portfolios. However, the presence of numerous smaller, specialized firms like PCT Ltd. and Eco Factory KK suggests that there is still room for technological differentiation and market expansion in this competitive landscape.

ANNIHILARE MEDICAL SYSTEMS, INC.

Technical Solution: ANNIHILARE MEDICAL SYSTEMS has developed an advanced hypochlorous acid (HOCl) generation system for maximum disinfection. Their technology utilizes electrolysis of salt water to produce a stable and highly effective HOCl solution. The system incorporates precise control of pH levels, maintaining the optimal range of 5.5-6.5 for maximum efficacy[1]. They have implemented a patented membrane technology that separates the electrodes, ensuring a consistent and pure HOCl output[3]. The company's system also features real-time monitoring and adjustment of free available chlorine (FAC) levels, typically maintaining 200-500 ppm for broad-spectrum antimicrobial activity[5].

Strengths: Highly stable HOCl production, precise pH control, and consistent FAC levels. Weaknesses: May require specialized maintenance and potentially higher initial investment compared to traditional disinfection methods.

WIAB WATER INNOVATION AB

Technical Solution: WIAB WATER INNOVATION AB has pioneered a novel approach to achieving maximum disinfection with hypochlorous acid through their patented electrochemical activation (ECA) technology. Their system employs a unique cell design that optimizes the production of HOCl by carefully controlling the electrolysis process. The technology ensures a consistent output of HOCl with a concentration of 500-700 ppm and a pH range of 6.0-6.5, which is ideal for maximum disinfection efficacy[2]. WIAB's innovation lies in their ability to produce HOCl on-site, eliminating the need for storage and transportation of hazardous chemicals. The system incorporates advanced sensors and automated control mechanisms to maintain optimal production parameters, ensuring a stable and effective HOCl solution[4].

Strengths: On-site production eliminates chemical storage risks, high consistency in HOCl output. Weaknesses: May require specialized training for operation and maintenance, potentially higher upfront costs.

HOCl Efficacy Research Insights

Stabilized hypochlorous acid

PatentInactiveUS20210238752A1

Innovation

- A method involving the electrolysis of a purified sodium chloride and water mixture, combined with carbon dioxide and sulfamic acid, to create a shelf-stable Hypochlorous acid solution with a pH between 6.0 and 7.0, enhancing its disinfecting power and stability.

Method for producing hypochlorous acid

PatentWO2023220374A1

Innovation

- A stable dry mix product kit containing premeasured calcium hypochlorite and cation exchange resins, allowing end-users to produce hypochlorous acid solutions on demand with adjustable concentration and pH, using a simple mixing process that does not require protective gear, and can be stored and diluted with tap water, reducing production and shipping costs.

HOCl Safety and Regulatory Compliance

Hypochlorous acid (HOCl) is a powerful disinfectant with broad-spectrum antimicrobial properties. However, its use in various applications requires careful consideration of safety measures and regulatory compliance. The safety profile of HOCl is generally favorable, as it is non-toxic to humans and animals when used at recommended concentrations. Unlike many other disinfectants, HOCl does not produce harmful byproducts and breaks down into simple salt and water.

Regulatory bodies worldwide have recognized the efficacy and safety of HOCl. In the United States, the Environmental Protection Agency (EPA) has approved HOCl for use as a disinfectant and sanitizer in various settings, including food processing facilities, healthcare environments, and water treatment systems. The Food and Drug Administration (FDA) has also cleared HOCl-based products for wound care and eye care applications.

To ensure maximum disinfection while maintaining safety, it is crucial to adhere to recommended concentration levels. Typically, effective HOCl solutions range from 50 to 500 parts per million (ppm), depending on the specific application. Higher concentrations may be used for more challenging disinfection tasks, but care must be taken to avoid potential irritation or corrosion of sensitive materials.

When implementing HOCl disinfection protocols, proper training of personnel is essential. This includes educating staff on the correct preparation, application, and storage of HOCl solutions. Personal protective equipment (PPE) requirements for handling HOCl are generally minimal compared to harsher disinfectants, but basic precautions such as gloves and eye protection should be observed, especially when working with higher concentrations.

Storage and handling of HOCl solutions require attention to maintain their efficacy. HOCl is light-sensitive and can degrade over time, so it should be stored in opaque containers away from direct sunlight. The pH of the solution is also critical, as HOCl is most effective at a slightly acidic pH range of 5.5 to 6.5. Regular monitoring and adjustment of pH levels may be necessary to ensure optimal disinfection performance.

In terms of environmental impact, HOCl is considered eco-friendly due to its rapid breakdown and lack of persistent residues. However, users should still follow local regulations regarding the disposal of disinfectant solutions. In most cases, HOCl can be safely discharged into regular drainage systems without special treatment.

To maintain regulatory compliance, it is important to keep accurate records of HOCl use, including concentration levels, application methods, and frequency of use. Regular testing of HOCl solutions for concentration and efficacy should be conducted to ensure consistent disinfection performance. Additionally, staying informed about updates to regulatory guidelines and industry best practices is crucial for maintaining a compliant and effective HOCl disinfection program.

Regulatory bodies worldwide have recognized the efficacy and safety of HOCl. In the United States, the Environmental Protection Agency (EPA) has approved HOCl for use as a disinfectant and sanitizer in various settings, including food processing facilities, healthcare environments, and water treatment systems. The Food and Drug Administration (FDA) has also cleared HOCl-based products for wound care and eye care applications.

To ensure maximum disinfection while maintaining safety, it is crucial to adhere to recommended concentration levels. Typically, effective HOCl solutions range from 50 to 500 parts per million (ppm), depending on the specific application. Higher concentrations may be used for more challenging disinfection tasks, but care must be taken to avoid potential irritation or corrosion of sensitive materials.

When implementing HOCl disinfection protocols, proper training of personnel is essential. This includes educating staff on the correct preparation, application, and storage of HOCl solutions. Personal protective equipment (PPE) requirements for handling HOCl are generally minimal compared to harsher disinfectants, but basic precautions such as gloves and eye protection should be observed, especially when working with higher concentrations.

Storage and handling of HOCl solutions require attention to maintain their efficacy. HOCl is light-sensitive and can degrade over time, so it should be stored in opaque containers away from direct sunlight. The pH of the solution is also critical, as HOCl is most effective at a slightly acidic pH range of 5.5 to 6.5. Regular monitoring and adjustment of pH levels may be necessary to ensure optimal disinfection performance.

In terms of environmental impact, HOCl is considered eco-friendly due to its rapid breakdown and lack of persistent residues. However, users should still follow local regulations regarding the disposal of disinfectant solutions. In most cases, HOCl can be safely discharged into regular drainage systems without special treatment.

To maintain regulatory compliance, it is important to keep accurate records of HOCl use, including concentration levels, application methods, and frequency of use. Regular testing of HOCl solutions for concentration and efficacy should be conducted to ensure consistent disinfection performance. Additionally, staying informed about updates to regulatory guidelines and industry best practices is crucial for maintaining a compliant and effective HOCl disinfection program.

Environmental Impact of HOCl Use

The use of hypochlorous acid (HOCl) for disinfection has gained significant attention due to its effectiveness and potential environmental benefits. When considering the environmental impact of HOCl use, several key factors come into play.

Firstly, HOCl is a naturally occurring compound that breaks down into harmless components, primarily water and salt. This decomposition process is rapid, typically occurring within hours of application, which significantly reduces the risk of long-term environmental accumulation. Unlike many traditional disinfectants, HOCl does not leave behind toxic residues or contribute to the formation of harmful byproducts in the environment.

The production of HOCl through electrolysis of salt water is generally considered an environmentally friendly process. It requires minimal raw materials and energy input, resulting in a lower carbon footprint compared to the manufacture of many conventional chemical disinfectants. Additionally, the on-site generation of HOCl can reduce transportation-related emissions associated with the distribution of pre-packaged disinfectants.

In aquatic ecosystems, the impact of HOCl is relatively benign. When properly diluted, it poses minimal risk to aquatic life due to its rapid breakdown. However, it is essential to note that excessive concentrations or improper disposal could potentially harm sensitive aquatic organisms. Therefore, adherence to recommended application rates and proper disposal practices is crucial to mitigate any potential negative effects.

The use of HOCl in agriculture and food processing presents both benefits and considerations. As a residue-free disinfectant, it can reduce the need for more persistent chemicals in crop protection and food safety applications. This can lead to decreased chemical runoff into soil and water systems. However, large-scale agricultural use should be monitored to ensure that soil microbial communities, which play a vital role in ecosystem health, are not adversely affected.

In indoor environments, HOCl use can contribute to improved air quality. Unlike many chemical disinfectants that release volatile organic compounds (VOCs), HOCl does not emit harmful fumes or leave lingering odors. This characteristic makes it particularly suitable for use in sensitive environments such as hospitals, schools, and households, where air quality is a significant concern.

From a waste management perspective, HOCl offers advantages over traditional disinfectants. Its biodegradability and non-toxic nature reduce the environmental burden associated with disposal. Furthermore, the ability to produce HOCl on-site can significantly decrease plastic waste from packaging, aligning with sustainability goals and circular economy principles.

Firstly, HOCl is a naturally occurring compound that breaks down into harmless components, primarily water and salt. This decomposition process is rapid, typically occurring within hours of application, which significantly reduces the risk of long-term environmental accumulation. Unlike many traditional disinfectants, HOCl does not leave behind toxic residues or contribute to the formation of harmful byproducts in the environment.

The production of HOCl through electrolysis of salt water is generally considered an environmentally friendly process. It requires minimal raw materials and energy input, resulting in a lower carbon footprint compared to the manufacture of many conventional chemical disinfectants. Additionally, the on-site generation of HOCl can reduce transportation-related emissions associated with the distribution of pre-packaged disinfectants.

In aquatic ecosystems, the impact of HOCl is relatively benign. When properly diluted, it poses minimal risk to aquatic life due to its rapid breakdown. However, it is essential to note that excessive concentrations or improper disposal could potentially harm sensitive aquatic organisms. Therefore, adherence to recommended application rates and proper disposal practices is crucial to mitigate any potential negative effects.

The use of HOCl in agriculture and food processing presents both benefits and considerations. As a residue-free disinfectant, it can reduce the need for more persistent chemicals in crop protection and food safety applications. This can lead to decreased chemical runoff into soil and water systems. However, large-scale agricultural use should be monitored to ensure that soil microbial communities, which play a vital role in ecosystem health, are not adversely affected.

In indoor environments, HOCl use can contribute to improved air quality. Unlike many chemical disinfectants that release volatile organic compounds (VOCs), HOCl does not emit harmful fumes or leave lingering odors. This characteristic makes it particularly suitable for use in sensitive environments such as hospitals, schools, and households, where air quality is a significant concern.

From a waste management perspective, HOCl offers advantages over traditional disinfectants. Its biodegradability and non-toxic nature reduce the environmental burden associated with disposal. Furthermore, the ability to produce HOCl on-site can significantly decrease plastic waste from packaging, aligning with sustainability goals and circular economy principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!