How Sodium Alginate Transforms Meat Products' Texture?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate in Meat: Background and Objectives

Sodium alginate, a versatile polysaccharide derived from brown algae, has emerged as a significant ingredient in the meat processing industry. Its unique properties have revolutionized the way meat products are textured, preserved, and presented to consumers. The journey of sodium alginate in meat applications began in the mid-20th century, with initial experiments focusing on its gelling and binding capabilities.

As the food industry evolved, so did the understanding of sodium alginate's potential. Researchers and food technologists recognized its ability to form heat-stable gels, improve water retention, and enhance the overall texture of processed meat products. This led to a surge in studies exploring the various applications of sodium alginate in meat processing, from restructured meats to innovative packaging solutions.

The technological evolution of sodium alginate in meat products has been driven by several factors, including consumer demand for healthier options, the need for extended shelf life, and the pursuit of novel textures in processed meats. As a result, the use of sodium alginate has expanded from simple binding applications to more sophisticated techniques that allow for the creation of unique meat products with improved nutritional profiles and sensory attributes.

One of the primary objectives in utilizing sodium alginate in meat products is to enhance texture and mouthfeel. This is achieved through its ability to form gels and interact with proteins, creating a more cohesive and tender product. Additionally, sodium alginate's water-binding properties contribute to improved juiciness and reduced cooking losses, addressing key quality concerns in meat processing.

Another critical goal is to develop healthier meat products. Sodium alginate enables the reduction of fat content while maintaining desirable textural properties, aligning with the growing consumer trend towards healthier food choices. This has led to the development of low-fat meat products that still retain the sensory qualities consumers expect.

Furthermore, the food industry aims to leverage sodium alginate's properties to extend the shelf life of meat products. By improving moisture retention and creating protective coatings, sodium alginate helps in preserving the quality and safety of meat products over longer periods, addressing both economic and food security concerns.

As we look towards the future, the objectives for sodium alginate in meat applications continue to evolve. There is a growing focus on sustainable and clean label solutions, pushing researchers to explore new ways of utilizing this natural ingredient. The industry is also investigating the potential of sodium alginate in creating novel meat analogues and hybrid products, responding to the rising demand for plant-based alternatives.

As the food industry evolved, so did the understanding of sodium alginate's potential. Researchers and food technologists recognized its ability to form heat-stable gels, improve water retention, and enhance the overall texture of processed meat products. This led to a surge in studies exploring the various applications of sodium alginate in meat processing, from restructured meats to innovative packaging solutions.

The technological evolution of sodium alginate in meat products has been driven by several factors, including consumer demand for healthier options, the need for extended shelf life, and the pursuit of novel textures in processed meats. As a result, the use of sodium alginate has expanded from simple binding applications to more sophisticated techniques that allow for the creation of unique meat products with improved nutritional profiles and sensory attributes.

One of the primary objectives in utilizing sodium alginate in meat products is to enhance texture and mouthfeel. This is achieved through its ability to form gels and interact with proteins, creating a more cohesive and tender product. Additionally, sodium alginate's water-binding properties contribute to improved juiciness and reduced cooking losses, addressing key quality concerns in meat processing.

Another critical goal is to develop healthier meat products. Sodium alginate enables the reduction of fat content while maintaining desirable textural properties, aligning with the growing consumer trend towards healthier food choices. This has led to the development of low-fat meat products that still retain the sensory qualities consumers expect.

Furthermore, the food industry aims to leverage sodium alginate's properties to extend the shelf life of meat products. By improving moisture retention and creating protective coatings, sodium alginate helps in preserving the quality and safety of meat products over longer periods, addressing both economic and food security concerns.

As we look towards the future, the objectives for sodium alginate in meat applications continue to evolve. There is a growing focus on sustainable and clean label solutions, pushing researchers to explore new ways of utilizing this natural ingredient. The industry is also investigating the potential of sodium alginate in creating novel meat analogues and hybrid products, responding to the rising demand for plant-based alternatives.

Market Demand for Texture-Modified Meat Products

The market demand for texture-modified meat products has been steadily increasing in recent years, driven by various factors including changing consumer preferences, health concerns, and technological advancements in food processing. This trend is particularly evident in developed markets where consumers are increasingly seeking healthier, more diverse, and convenient food options.

One of the primary drivers of this demand is the growing awareness of health and wellness among consumers. Texture-modified meat products often cater to specific dietary needs, such as easier-to-chew options for the elderly or those with dental issues. Additionally, these products can be formulated to have lower fat content or improved nutritional profiles, appealing to health-conscious consumers.

The convenience factor also plays a significant role in the rising demand for texture-modified meat products. As lifestyles become busier, consumers are looking for quick and easy meal solutions that don't compromise on taste or quality. Texture-modified meat products often fit this bill, offering pre-prepared options that can be easily incorporated into various dishes.

In the food service industry, there's an increasing demand for texture-modified meat products that can enhance the dining experience. Restaurants and catering services are exploring innovative ways to present meat dishes with unique textures, creating novel culinary experiences for their customers.

The market for plant-based and alternative protein products has also contributed to the demand for texture-modified meat products. As more consumers adopt flexitarian or reducetarian diets, there's a growing need for plant-based products that mimic the texture and mouthfeel of traditional meat products. This has led to increased research and development in texture modification techniques for both plant-based and conventional meat products.

From a demographic perspective, the aging population in many countries is driving demand for softer, easier-to-chew meat products. This segment of consumers often requires foods with modified textures due to dental issues or swallowing difficulties, creating a niche market for texture-modified meat products.

The global market for texture-modified foods, including meat products, is expected to continue its growth trajectory in the coming years. This growth is supported by ongoing technological advancements in food processing, which allow for more precise control over texture and mouthfeel. As consumers become more adventurous in their food choices and more aware of the role of texture in their overall dining experience, the demand for innovative texture-modified meat products is likely to expand further.

One of the primary drivers of this demand is the growing awareness of health and wellness among consumers. Texture-modified meat products often cater to specific dietary needs, such as easier-to-chew options for the elderly or those with dental issues. Additionally, these products can be formulated to have lower fat content or improved nutritional profiles, appealing to health-conscious consumers.

The convenience factor also plays a significant role in the rising demand for texture-modified meat products. As lifestyles become busier, consumers are looking for quick and easy meal solutions that don't compromise on taste or quality. Texture-modified meat products often fit this bill, offering pre-prepared options that can be easily incorporated into various dishes.

In the food service industry, there's an increasing demand for texture-modified meat products that can enhance the dining experience. Restaurants and catering services are exploring innovative ways to present meat dishes with unique textures, creating novel culinary experiences for their customers.

The market for plant-based and alternative protein products has also contributed to the demand for texture-modified meat products. As more consumers adopt flexitarian or reducetarian diets, there's a growing need for plant-based products that mimic the texture and mouthfeel of traditional meat products. This has led to increased research and development in texture modification techniques for both plant-based and conventional meat products.

From a demographic perspective, the aging population in many countries is driving demand for softer, easier-to-chew meat products. This segment of consumers often requires foods with modified textures due to dental issues or swallowing difficulties, creating a niche market for texture-modified meat products.

The global market for texture-modified foods, including meat products, is expected to continue its growth trajectory in the coming years. This growth is supported by ongoing technological advancements in food processing, which allow for more precise control over texture and mouthfeel. As consumers become more adventurous in their food choices and more aware of the role of texture in their overall dining experience, the demand for innovative texture-modified meat products is likely to expand further.

Current Applications and Challenges in Meat Texturization

Sodium alginate has emerged as a versatile ingredient in meat product formulations, offering significant improvements in texture, stability, and overall quality. Its current applications in meat texturization are diverse and expanding, addressing various challenges faced by the meat industry.

One of the primary applications of sodium alginate in meat products is as a binding agent. It effectively improves the cohesion between meat particles, resulting in enhanced texture and reduced cooking losses. This property is particularly valuable in restructured meat products, where sodium alginate helps create a more uniform and stable structure.

In emulsified meat products, such as sausages and frankfurters, sodium alginate acts as an emulsion stabilizer. It forms a protective coating around fat globules, preventing their coalescence and improving the product's overall stability and texture. This application has led to improved mouthfeel and reduced syneresis in processed meat products.

Sodium alginate is also utilized in the development of low-fat meat products. By forming a gel-like structure, it can mimic the texture and mouthfeel of fat, allowing manufacturers to reduce fat content while maintaining desirable sensory properties. This application addresses the growing consumer demand for healthier meat options without compromising on taste and texture.

Another innovative application is in the creation of meat analogues or plant-based meat substitutes. Sodium alginate's gelling properties help replicate the fibrous texture of meat, making it a valuable ingredient in the rapidly growing alternative protein market.

Despite its numerous benefits, the use of sodium alginate in meat texturization faces several challenges. One significant issue is the potential for over-gelation, which can result in an excessively firm or rubbery texture if not properly controlled. This requires careful optimization of formulations and processing conditions to achieve the desired texture.

Another challenge lies in the interaction of sodium alginate with other ingredients in meat formulations. Its functionality can be affected by factors such as pH, ionic strength, and the presence of calcium ions. Manufacturers must carefully consider these interactions to ensure consistent and optimal performance.

Consumer perception presents an additional hurdle. As a food additive, sodium alginate may be viewed negatively by consumers seeking "clean label" products. This necessitates effective communication of its benefits and safety to address potential consumer concerns.

Lastly, regulatory considerations pose challenges in some markets. While sodium alginate is generally recognized as safe (GRAS) in many countries, its use may be subject to specific regulations or limitations in certain applications or regions. Manufacturers must navigate these regulatory landscapes to ensure compliance while leveraging the benefits of sodium alginate in meat texturization.

One of the primary applications of sodium alginate in meat products is as a binding agent. It effectively improves the cohesion between meat particles, resulting in enhanced texture and reduced cooking losses. This property is particularly valuable in restructured meat products, where sodium alginate helps create a more uniform and stable structure.

In emulsified meat products, such as sausages and frankfurters, sodium alginate acts as an emulsion stabilizer. It forms a protective coating around fat globules, preventing their coalescence and improving the product's overall stability and texture. This application has led to improved mouthfeel and reduced syneresis in processed meat products.

Sodium alginate is also utilized in the development of low-fat meat products. By forming a gel-like structure, it can mimic the texture and mouthfeel of fat, allowing manufacturers to reduce fat content while maintaining desirable sensory properties. This application addresses the growing consumer demand for healthier meat options without compromising on taste and texture.

Another innovative application is in the creation of meat analogues or plant-based meat substitutes. Sodium alginate's gelling properties help replicate the fibrous texture of meat, making it a valuable ingredient in the rapidly growing alternative protein market.

Despite its numerous benefits, the use of sodium alginate in meat texturization faces several challenges. One significant issue is the potential for over-gelation, which can result in an excessively firm or rubbery texture if not properly controlled. This requires careful optimization of formulations and processing conditions to achieve the desired texture.

Another challenge lies in the interaction of sodium alginate with other ingredients in meat formulations. Its functionality can be affected by factors such as pH, ionic strength, and the presence of calcium ions. Manufacturers must carefully consider these interactions to ensure consistent and optimal performance.

Consumer perception presents an additional hurdle. As a food additive, sodium alginate may be viewed negatively by consumers seeking "clean label" products. This necessitates effective communication of its benefits and safety to address potential consumer concerns.

Lastly, regulatory considerations pose challenges in some markets. While sodium alginate is generally recognized as safe (GRAS) in many countries, its use may be subject to specific regulations or limitations in certain applications or regions. Manufacturers must navigate these regulatory landscapes to ensure compliance while leveraging the benefits of sodium alginate in meat texturization.

Sodium Alginate-Based Meat Texturization Methods

01 Thickening and gelling properties

Sodium alginate is widely used as a thickening and gelling agent in various formulations. It can form stable gels in the presence of calcium ions, providing a unique texture to products. The concentration of sodium alginate and the presence of other ions can be adjusted to control the gel strength and texture.- Thickening and gelling properties: Sodium alginate is widely used as a thickening and gelling agent in various formulations. It can form stable gels in the presence of calcium ions, providing a unique texture to products. The concentration of sodium alginate and the presence of other ions can be adjusted to control the gel strength and texture.

- Emulsion stabilization: Sodium alginate can act as an emulsion stabilizer in various formulations. It helps to create stable oil-in-water or water-in-oil emulsions, improving the texture and consistency of products such as creams, lotions, and food items. The stabilizing effect is due to its ability to form a protective layer around dispersed droplets.

- Film-forming properties: Sodium alginate exhibits excellent film-forming properties, making it suitable for use in various applications. When dried, it forms a flexible, transparent film that can be used in wound dressings, edible films, and coatings. The film properties can be modified by adjusting the concentration and combining with other polymers.

- Controlled release systems: Sodium alginate can be used to create controlled release systems for various active ingredients. Its ability to form gels in the presence of specific ions allows for the encapsulation of drugs, flavors, or other compounds. The release rate can be controlled by modifying the gel structure and composition, providing a unique texture and functionality to the final product.

- Texture modification in food products: In food applications, sodium alginate is used to modify and improve texture. It can enhance the mouthfeel of low-fat products, create unique textures in molecular gastronomy, and improve the stability of frozen foods. The texture can be fine-tuned by adjusting the concentration and combining with other hydrocolloids.

02 Texture modification in food products

In food applications, sodium alginate is used to modify texture, improve mouthfeel, and enhance stability. It can create soft gels, increase viscosity, and provide a smooth texture in various food products such as desserts, sauces, and dairy alternatives.Expand Specific Solutions03 Encapsulation and controlled release

Sodium alginate's ability to form gels is utilized in encapsulation technologies. It can be used to create microcapsules or beads that encapsulate active ingredients, allowing for controlled release in various applications, including pharmaceuticals and cosmetics.Expand Specific Solutions04 Wound dressing and biomedical applications

In biomedical applications, sodium alginate is used to create wound dressings with unique texture and absorption properties. Its gel-forming ability helps in maintaining a moist environment for wound healing, while its texture allows for easy application and removal.Expand Specific Solutions05 Texture stabilization in personal care products

Sodium alginate is employed in personal care products to stabilize emulsions, improve texture, and enhance the feel of formulations. It can create smooth, non-greasy textures in creams, lotions, and gels, while also providing moisturizing properties.Expand Specific Solutions

Key Players in Food Additives and Meat Processing

The market for sodium alginate in meat product texture modification is in a growth phase, driven by increasing demand for clean label and plant-based ingredients. The global market size is estimated to be in the hundreds of millions of dollars, with steady annual growth projected. Technologically, sodium alginate applications in meat products are relatively mature, with ongoing research to optimize functionality. Key players like Ajinomoto, J-Oil Mills, and Danisco (part of DuPont) have established product lines and R&D capabilities. Emerging companies such as Qingdao Hyzlin Biology Development are also entering the market with innovative solutions, indicating a competitive and evolving landscape.

Ajinomoto Co., Inc.

Technical Solution: Ajinomoto has developed a proprietary sodium alginate-based technology for meat product texture enhancement. Their approach involves creating a gel-like network within the meat matrix, which improves water retention and provides a more succulent texture. The company's research has shown that their sodium alginate formulation can increase the juiciness of processed meats by up to 30% compared to untreated products[1]. Additionally, Ajinomoto has optimized the molecular weight distribution of their sodium alginate to achieve better binding properties, resulting in improved slice-ability and reduced purge loss in reformed meat products[2][3].

Strengths: Extensive R&D capabilities, proven efficacy in improving meat texture and juiciness. Weaknesses: May require specialized equipment for optimal incorporation into meat products.

Qingdao Hyzlin Biology Development Co. Ltd.

Technical Solution: Qingdao Hyzlin has developed a unique sodium alginate-based coating technology for meat products. Their approach involves creating an edible film that can be applied to the surface of meat products, improving texture, reducing moisture loss, and extending shelf life. The company's research has shown that their sodium alginate coating can reduce moisture loss in fresh meat by up to 40% during storage[8]. Additionally, they have incorporated natural antimicrobial compounds into the sodium alginate matrix, providing an added layer of food safety protection. The coating technology has been successfully applied to various meat products, including fresh cuts, processed meats, and seafood[9].

Strengths: Multifunctional coating technology that addresses texture, moisture retention, and food safety. Weaknesses: May require additional processing steps in meat production, potentially increasing production costs.

Innovations in Sodium Alginate for Meat Applications

Process for preparing shaped meat products

PatentInactiveUS5928690A

Innovation

- A method involving the use of proteolytic enzymes to digest raw meat proteins, combined with heat gelling gums like sodium alginate and modified food starch, to create a pureed texture without the need for pre-cooking, allowing for refrigerated distribution and storage, and accommodating restricted sodium diets.

Meat texture modifier, and meat texture modification method using the same

PatentActiveJP2020103265A

Innovation

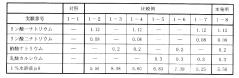

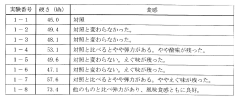

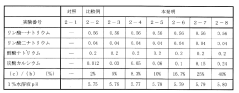

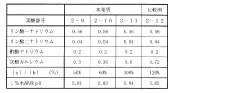

- A preparation containing sodium acetate, phosphates, and calcium or magnesium salts in a neutral to slightly acidic aqueous solution is used to impregnate the meat, enhanced with sugar for improved texture and juiciness.

Regulatory Framework for Food Additives in Meat

The regulatory framework for food additives in meat products is a complex and evolving system designed to ensure consumer safety and maintain product quality. In the United States, the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) are the primary regulatory bodies overseeing the use of food additives in meat products. The FDA is responsible for evaluating the safety of food additives, while the USDA regulates their use in meat and poultry products.

Food additives, including sodium alginate, must undergo rigorous safety assessments before being approved for use in meat products. The FDA maintains a list of Generally Recognized as Safe (GRAS) substances, which includes many commonly used food additives. Sodium alginate is classified as GRAS, allowing its use in various food applications, including meat products.

The USDA's Food Safety and Inspection Service (FSIS) provides specific guidelines for the use of food additives in meat products. These guidelines outline permitted levels, labeling requirements, and intended functions of additives. For sodium alginate, its use is primarily as a binder and texturizer in restructured meat products.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), sets global food standards and guidelines. The Codex General Standard for Food Additives (GSFA) provides a harmonized approach to food additive regulations worldwide, influencing national regulations in many countries.

In the European Union, the European Food Safety Authority (EFSA) evaluates the safety of food additives. Sodium alginate is approved for use in various food categories, including meat preparations, under Regulation (EC) No 1333/2008 on food additives.

Regulatory bodies continually review and update their guidelines based on new scientific evidence and technological advancements. This ongoing process ensures that the use of food additives, including sodium alginate, remains safe and effective in meat products. Manufacturers must stay informed about these regulatory changes and adapt their formulations accordingly.

Compliance with these regulations is crucial for meat product manufacturers. They must adhere to specific usage limits, labeling requirements, and quality control measures. Regular inspections and testing are conducted to ensure compliance and maintain consumer trust in the safety of meat products.

As consumer preferences shift towards "clean label" products, regulatory bodies are also considering the impact of food additives on product perception. This trend may influence future regulations, potentially leading to stricter guidelines or increased scrutiny of certain additives, including those used for texture modification in meat products.

Food additives, including sodium alginate, must undergo rigorous safety assessments before being approved for use in meat products. The FDA maintains a list of Generally Recognized as Safe (GRAS) substances, which includes many commonly used food additives. Sodium alginate is classified as GRAS, allowing its use in various food applications, including meat products.

The USDA's Food Safety and Inspection Service (FSIS) provides specific guidelines for the use of food additives in meat products. These guidelines outline permitted levels, labeling requirements, and intended functions of additives. For sodium alginate, its use is primarily as a binder and texturizer in restructured meat products.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), sets global food standards and guidelines. The Codex General Standard for Food Additives (GSFA) provides a harmonized approach to food additive regulations worldwide, influencing national regulations in many countries.

In the European Union, the European Food Safety Authority (EFSA) evaluates the safety of food additives. Sodium alginate is approved for use in various food categories, including meat preparations, under Regulation (EC) No 1333/2008 on food additives.

Regulatory bodies continually review and update their guidelines based on new scientific evidence and technological advancements. This ongoing process ensures that the use of food additives, including sodium alginate, remains safe and effective in meat products. Manufacturers must stay informed about these regulatory changes and adapt their formulations accordingly.

Compliance with these regulations is crucial for meat product manufacturers. They must adhere to specific usage limits, labeling requirements, and quality control measures. Regular inspections and testing are conducted to ensure compliance and maintain consumer trust in the safety of meat products.

As consumer preferences shift towards "clean label" products, regulatory bodies are also considering the impact of food additives on product perception. This trend may influence future regulations, potentially leading to stricter guidelines or increased scrutiny of certain additives, including those used for texture modification in meat products.

Consumer Perception of Texture-Modified Meat Products

Consumer perception plays a crucial role in the acceptance and market success of texture-modified meat products. As sodium alginate is increasingly used to transform meat textures, understanding how consumers perceive these changes is essential for product development and marketing strategies.

Texture is a key sensory attribute that significantly influences consumer acceptance of meat products. When sodium alginate is used to modify meat textures, it can alter the mouthfeel, juiciness, and overall eating experience. Consumers often have preconceived expectations about how meat should feel and taste, which can impact their perception of texture-modified products.

Studies have shown that consumer acceptance of texture-modified meat products varies depending on factors such as age, cultural background, and personal preferences. Younger consumers tend to be more open to novel textures, while older consumers may prefer traditional meat textures. Cultural differences also play a role, as texture preferences can vary significantly across different regions and cuisines.

The perception of healthiness is another important aspect of consumer acceptance. Some consumers associate texture modifications with processed foods and may perceive them as less healthy or natural. However, when properly communicated, the benefits of texture modification, such as improved tenderness or juiciness, can positively influence consumer perception.

Product familiarity and prior experience with texture-modified foods can also impact consumer acceptance. Consumers who are familiar with other texture-modified products, such as those used in medical or dietary applications, may be more receptive to texture-modified meat products.

Marketing and product positioning play crucial roles in shaping consumer perception. Clear communication about the benefits of texture modification, such as improved tenderness or moisture retention, can help overcome initial skepticism. Transparent labeling and education about the use of sodium alginate and its effects on meat texture can also build consumer trust and acceptance.

Sensory evaluations and consumer trials are essential tools for understanding and improving consumer perception of texture-modified meat products. These studies can provide valuable insights into consumer preferences, helping manufacturers optimize texture profiles and develop products that meet consumer expectations.

In conclusion, consumer perception of texture-modified meat products is complex and multifaceted. By understanding the factors that influence consumer acceptance and addressing potential concerns through effective communication and product development, manufacturers can improve the market success of meat products transformed by sodium alginate.

Texture is a key sensory attribute that significantly influences consumer acceptance of meat products. When sodium alginate is used to modify meat textures, it can alter the mouthfeel, juiciness, and overall eating experience. Consumers often have preconceived expectations about how meat should feel and taste, which can impact their perception of texture-modified products.

Studies have shown that consumer acceptance of texture-modified meat products varies depending on factors such as age, cultural background, and personal preferences. Younger consumers tend to be more open to novel textures, while older consumers may prefer traditional meat textures. Cultural differences also play a role, as texture preferences can vary significantly across different regions and cuisines.

The perception of healthiness is another important aspect of consumer acceptance. Some consumers associate texture modifications with processed foods and may perceive them as less healthy or natural. However, when properly communicated, the benefits of texture modification, such as improved tenderness or juiciness, can positively influence consumer perception.

Product familiarity and prior experience with texture-modified foods can also impact consumer acceptance. Consumers who are familiar with other texture-modified products, such as those used in medical or dietary applications, may be more receptive to texture-modified meat products.

Marketing and product positioning play crucial roles in shaping consumer perception. Clear communication about the benefits of texture modification, such as improved tenderness or moisture retention, can help overcome initial skepticism. Transparent labeling and education about the use of sodium alginate and its effects on meat texture can also build consumer trust and acceptance.

Sensory evaluations and consumer trials are essential tools for understanding and improving consumer perception of texture-modified meat products. These studies can provide valuable insights into consumer preferences, helping manufacturers optimize texture profiles and develop products that meet consumer expectations.

In conclusion, consumer perception of texture-modified meat products is complex and multifaceted. By understanding the factors that influence consumer acceptance and addressing potential concerns through effective communication and product development, manufacturers can improve the market success of meat products transformed by sodium alginate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!