How Magnesium iron silicate hydroxide enhances thermal barrier coatings.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Evolution and Objectives

Thermal barrier coatings (TBCs) have undergone significant evolution since their inception in the 1960s. Initially developed for aerospace applications, particularly in gas turbine engines, TBCs have become crucial in enhancing the performance and longevity of high-temperature components. The primary objective of TBCs has consistently been to provide thermal insulation, allowing underlying metal components to operate at temperatures beyond their inherent capabilities.

The evolution of TBCs has been driven by the continuous demand for higher operating temperatures in turbine engines, which directly correlates with improved efficiency and performance. Early TBC systems consisted of simple ceramic coatings, typically yttria-stabilized zirconia (YSZ), applied directly to metal substrates. However, these systems faced challenges in terms of durability and adhesion under extreme thermal cycling conditions.

As research progressed, multi-layer TBC systems emerged, incorporating bond coats to improve adhesion and provide oxidation resistance. This development marked a significant milestone in TBC technology, enhancing both the performance and lifespan of coated components. The introduction of electron beam physical vapor deposition (EB-PVD) techniques in the 1980s further revolutionized TBC application, allowing for the creation of columnar microstructures that improved strain tolerance and thermal cycling resistance.

Recent advancements have focused on developing new ceramic compositions and nanostructured coatings to further enhance thermal insulation properties and mechanical stability. The incorporation of rare earth elements and the exploration of complex oxide systems have opened new avenues for TBC performance improvement. Additionally, researchers have been investigating methods to reduce thermal conductivity and increase phase stability at extreme temperatures.

The current objectives in TBC research and development are multifaceted. Primarily, there is a push to develop coatings capable of withstanding even higher temperatures, potentially exceeding 1500°C, to meet the demands of next-generation turbine engines. Simultaneously, efforts are being made to enhance the durability and reliability of TBCs under severe thermal cycling and erosive conditions encountered in real-world applications.

Another key objective is to improve the manufacturing processes for TBCs, aiming for more cost-effective and scalable production methods without compromising performance. This includes the development of advanced deposition techniques and the optimization of coating microstructures. Furthermore, there is a growing interest in creating "smart" TBCs that can self-heal or adapt to changing environmental conditions, potentially revolutionizing the field of high-temperature materials.

The exploration of magnesium iron silicate hydroxide as an enhancer for TBCs represents a novel approach in this ongoing evolution. This material's potential to improve thermal barrier properties aligns with the overarching goals of TBC development, promising advancements in both performance and durability. As research in this area progresses, it may open new pathways for achieving the ambitious objectives set for next-generation thermal barrier coatings.

The evolution of TBCs has been driven by the continuous demand for higher operating temperatures in turbine engines, which directly correlates with improved efficiency and performance. Early TBC systems consisted of simple ceramic coatings, typically yttria-stabilized zirconia (YSZ), applied directly to metal substrates. However, these systems faced challenges in terms of durability and adhesion under extreme thermal cycling conditions.

As research progressed, multi-layer TBC systems emerged, incorporating bond coats to improve adhesion and provide oxidation resistance. This development marked a significant milestone in TBC technology, enhancing both the performance and lifespan of coated components. The introduction of electron beam physical vapor deposition (EB-PVD) techniques in the 1980s further revolutionized TBC application, allowing for the creation of columnar microstructures that improved strain tolerance and thermal cycling resistance.

Recent advancements have focused on developing new ceramic compositions and nanostructured coatings to further enhance thermal insulation properties and mechanical stability. The incorporation of rare earth elements and the exploration of complex oxide systems have opened new avenues for TBC performance improvement. Additionally, researchers have been investigating methods to reduce thermal conductivity and increase phase stability at extreme temperatures.

The current objectives in TBC research and development are multifaceted. Primarily, there is a push to develop coatings capable of withstanding even higher temperatures, potentially exceeding 1500°C, to meet the demands of next-generation turbine engines. Simultaneously, efforts are being made to enhance the durability and reliability of TBCs under severe thermal cycling and erosive conditions encountered in real-world applications.

Another key objective is to improve the manufacturing processes for TBCs, aiming for more cost-effective and scalable production methods without compromising performance. This includes the development of advanced deposition techniques and the optimization of coating microstructures. Furthermore, there is a growing interest in creating "smart" TBCs that can self-heal or adapt to changing environmental conditions, potentially revolutionizing the field of high-temperature materials.

The exploration of magnesium iron silicate hydroxide as an enhancer for TBCs represents a novel approach in this ongoing evolution. This material's potential to improve thermal barrier properties aligns with the overarching goals of TBC development, promising advancements in both performance and durability. As research in this area progresses, it may open new pathways for achieving the ambitious objectives set for next-generation thermal barrier coatings.

Market Analysis for Advanced TBC Materials

The market for advanced thermal barrier coating (TBC) materials, particularly those enhanced with magnesium iron silicate hydroxide, is experiencing significant growth driven by increasing demand in aerospace, power generation, and automotive industries. This market segment is characterized by a strong focus on performance improvement and cost reduction, as industries seek more efficient and durable coating solutions.

In the aerospace sector, the demand for advanced TBCs is primarily fueled by the need for higher operating temperatures in gas turbine engines, which directly translates to improved fuel efficiency and reduced emissions. The incorporation of magnesium iron silicate hydroxide in TBCs has shown promising results in enhancing thermal insulation properties and extending component lifespans, making it an attractive option for aircraft engine manufacturers.

The power generation industry, particularly in gas turbine applications, represents another significant market for advanced TBCs. As the global energy demand continues to rise, there is a growing emphasis on improving the efficiency of power plants. Advanced TBCs with magnesium iron silicate hydroxide offer the potential to increase turbine inlet temperatures, leading to higher overall plant efficiency and reduced fuel consumption.

In the automotive sector, the market for advanced TBCs is driven by the need for improved engine performance and fuel economy. As emission regulations become more stringent worldwide, automotive manufacturers are exploring innovative ways to enhance engine efficiency. TBCs enhanced with magnesium iron silicate hydroxide show potential in reducing heat transfer to engine components, allowing for higher combustion temperatures and improved thermodynamic efficiency.

The global market size for advanced TBC materials is projected to grow steadily over the next five years, with a compound annual growth rate (CAGR) exceeding the overall coating market average. This growth is attributed to the increasing adoption of these materials in high-performance applications and the ongoing research and development efforts to further improve their properties.

Geographically, North America and Europe currently dominate the market for advanced TBCs, owing to the presence of major aerospace and power generation equipment manufacturers in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing energy demand, and the expansion of aerospace and automotive industries in countries like China and India.

In the aerospace sector, the demand for advanced TBCs is primarily fueled by the need for higher operating temperatures in gas turbine engines, which directly translates to improved fuel efficiency and reduced emissions. The incorporation of magnesium iron silicate hydroxide in TBCs has shown promising results in enhancing thermal insulation properties and extending component lifespans, making it an attractive option for aircraft engine manufacturers.

The power generation industry, particularly in gas turbine applications, represents another significant market for advanced TBCs. As the global energy demand continues to rise, there is a growing emphasis on improving the efficiency of power plants. Advanced TBCs with magnesium iron silicate hydroxide offer the potential to increase turbine inlet temperatures, leading to higher overall plant efficiency and reduced fuel consumption.

In the automotive sector, the market for advanced TBCs is driven by the need for improved engine performance and fuel economy. As emission regulations become more stringent worldwide, automotive manufacturers are exploring innovative ways to enhance engine efficiency. TBCs enhanced with magnesium iron silicate hydroxide show potential in reducing heat transfer to engine components, allowing for higher combustion temperatures and improved thermodynamic efficiency.

The global market size for advanced TBC materials is projected to grow steadily over the next five years, with a compound annual growth rate (CAGR) exceeding the overall coating market average. This growth is attributed to the increasing adoption of these materials in high-performance applications and the ongoing research and development efforts to further improve their properties.

Geographically, North America and Europe currently dominate the market for advanced TBCs, owing to the presence of major aerospace and power generation equipment manufacturers in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing energy demand, and the expansion of aerospace and automotive industries in countries like China and India.

Current Challenges in TBC Performance

Thermal Barrier Coatings (TBCs) face several critical challenges that limit their performance and longevity in high-temperature applications. One of the primary issues is the thermal mismatch between the ceramic top coat and the metallic bond coat, leading to stress accumulation and potential spallation during thermal cycling. This mismatch causes micro-cracks and delamination, significantly reducing the coating's effectiveness and lifespan.

Another major challenge is the sintering of the ceramic top coat at elevated temperatures. Sintering leads to densification of the coating, reducing its strain tolerance and thermal insulation properties. This phenomenon is particularly problematic in advanced gas turbine engines, where operating temperatures continue to rise to improve efficiency.

Oxidation of the bond coat is also a persistent issue. The formation of a thermally grown oxide (TGO) layer at the interface between the top coat and bond coat is initially beneficial for adhesion. However, excessive growth of this layer can lead to stress buildup and eventual coating failure. Controlling the growth rate and composition of the TGO remains a significant challenge in TBC design.

The degradation of TBCs due to environmental factors presents another hurdle. Calcium-magnesium-alumino-silicate (CMAS) infiltration, for instance, can cause severe damage to the coating structure. CMAS materials, ingested as airborne particles, melt at high temperatures and penetrate the porous structure of the TBC, leading to chemical and mechanical degradation upon cooling.

Erosion resistance is an additional concern, particularly in aircraft engines where high-velocity particles can impact the coating surface. The relatively soft and porous nature of conventional yttria-stabilized zirconia (YSZ) top coats makes them susceptible to erosion damage, which can compromise the coating's protective function.

Furthermore, the current manufacturing processes for TBCs, such as air plasma spraying and electron beam physical vapor deposition, face challenges in achieving consistent coating quality and thickness across complex geometries. This variability can lead to localized weak points in the coating system, potentially initiating failure.

Addressing these challenges requires innovative approaches in materials science and coating technology. The incorporation of new materials, such as magnesium iron silicate hydroxide, into TBC systems presents an opportunity to enhance performance and overcome some of these limitations. However, integrating such materials effectively while maintaining the delicate balance of properties that make TBCs effective remains a significant research and development challenge.

Another major challenge is the sintering of the ceramic top coat at elevated temperatures. Sintering leads to densification of the coating, reducing its strain tolerance and thermal insulation properties. This phenomenon is particularly problematic in advanced gas turbine engines, where operating temperatures continue to rise to improve efficiency.

Oxidation of the bond coat is also a persistent issue. The formation of a thermally grown oxide (TGO) layer at the interface between the top coat and bond coat is initially beneficial for adhesion. However, excessive growth of this layer can lead to stress buildup and eventual coating failure. Controlling the growth rate and composition of the TGO remains a significant challenge in TBC design.

The degradation of TBCs due to environmental factors presents another hurdle. Calcium-magnesium-alumino-silicate (CMAS) infiltration, for instance, can cause severe damage to the coating structure. CMAS materials, ingested as airborne particles, melt at high temperatures and penetrate the porous structure of the TBC, leading to chemical and mechanical degradation upon cooling.

Erosion resistance is an additional concern, particularly in aircraft engines where high-velocity particles can impact the coating surface. The relatively soft and porous nature of conventional yttria-stabilized zirconia (YSZ) top coats makes them susceptible to erosion damage, which can compromise the coating's protective function.

Furthermore, the current manufacturing processes for TBCs, such as air plasma spraying and electron beam physical vapor deposition, face challenges in achieving consistent coating quality and thickness across complex geometries. This variability can lead to localized weak points in the coating system, potentially initiating failure.

Addressing these challenges requires innovative approaches in materials science and coating technology. The incorporation of new materials, such as magnesium iron silicate hydroxide, into TBC systems presents an opportunity to enhance performance and overcome some of these limitations. However, integrating such materials effectively while maintaining the delicate balance of properties that make TBCs effective remains a significant research and development challenge.

Existing Mg-Fe Silicate Hydroxide TBC Solutions

01 Composition of magnesium iron silicate hydroxide for thermal barriers

Magnesium iron silicate hydroxide, also known as talc or steatite, is used as a key component in thermal barrier compositions. Its unique structure and properties make it effective in heat insulation and fire resistance applications. The material can be combined with other compounds to enhance its thermal barrier properties.- Composition of magnesium iron silicate hydroxide for thermal barriers: Magnesium iron silicate hydroxide, also known as talc or steatite, is used in thermal barrier compositions. Its unique structure and properties make it an effective material for heat insulation and fire resistance. The composition can be optimized by adjusting the ratio of magnesium to iron and controlling the particle size distribution to enhance thermal barrier performance.

- Application methods for magnesium iron silicate hydroxide thermal barriers: Various application methods are employed to create effective thermal barriers using magnesium iron silicate hydroxide. These include spray coating, dip coating, and incorporation into composite materials. The application technique can significantly influence the thermal barrier's effectiveness, durability, and adhesion to the substrate.

- Synergistic effects with other materials: Magnesium iron silicate hydroxide can be combined with other materials to enhance its thermal barrier properties. Combinations with ceramic materials, polymers, or other mineral compounds can create synergistic effects, improving overall thermal insulation performance and mechanical properties of the barrier system.

- Nanostructured magnesium iron silicate hydroxide for improved thermal barriers: Nanostructured forms of magnesium iron silicate hydroxide have been developed to enhance thermal barrier properties. These nanostructures can provide improved heat resistance, reduced thermal conductivity, and increased surface area for better insulation performance. The nanostructuring process and its effects on thermal barrier efficiency are areas of ongoing research and development.

- Environmental and safety considerations: The use of magnesium iron silicate hydroxide in thermal barriers involves considerations of environmental impact and safety. Research focuses on developing eco-friendly formulations, reducing potential health hazards during application and use, and ensuring long-term stability of the thermal barrier systems. Regulatory compliance and sustainable production methods are also important aspects of this field.

02 Application methods for thermal barrier coatings

Various methods are employed to apply magnesium iron silicate hydroxide-based thermal barrier coatings. These include spray coating, plasma spraying, and physical vapor deposition. The application method can significantly affect the coating's performance and durability in high-temperature environments.Expand Specific Solutions03 Thermal barrier performance enhancement techniques

Researchers have developed techniques to enhance the thermal barrier performance of magnesium iron silicate hydroxide coatings. These include the incorporation of additional heat-resistant materials, optimization of particle size distribution, and creation of multi-layer coating systems to improve overall thermal insulation efficiency.Expand Specific Solutions04 Durability and longevity of thermal barrier coatings

Improving the durability and longevity of magnesium iron silicate hydroxide thermal barrier coatings is a key focus area. Techniques such as surface modification, addition of binding agents, and development of self-healing coating systems are employed to enhance the coating's resistance to thermal cycling, erosion, and chemical degradation.Expand Specific Solutions05 Environmental and safety considerations

The use of magnesium iron silicate hydroxide in thermal barrier applications involves considerations of environmental impact and safety. Research focuses on developing eco-friendly formulations, reducing potential health hazards during application and use, and ensuring compliance with regulatory standards for fire-resistant materials.Expand Specific Solutions

Key Players in TBC and Material Science

The development of magnesium iron silicate hydroxide for thermal barrier coatings is in an emerging phase, with significant potential for growth in the aerospace and energy sectors. The market size is expanding as industries seek more efficient and durable thermal protection solutions. Technologically, the field is advancing rapidly, with companies like Siemens Corp., MTU Aero Engines AG, and RTX Corp. leading research efforts. These firms, along with academic institutions such as Kunming University of Science & Technology and Xi'an Jiaotong University, are driving innovation in material composition and application techniques. The collaboration between industry and academia is accelerating the maturation of this technology, positioning it as a promising solution for next-generation thermal management systems.

RTX Corp.

Technical Solution: RTX Corp. (formerly United Technologies) has developed advanced thermal barrier coatings (TBCs) incorporating magnesium iron silicate hydroxide (MISH) for enhanced performance. Their approach involves creating a nanostructured MISH-based coating layer that significantly improves thermal insulation and durability. The MISH particles are dispersed within a ceramic matrix, forming a complex microstructure that effectively scatters phonons and reduces thermal conductivity[1]. RTX's method also includes a specialized deposition process that ensures uniform distribution of MISH particles, resulting in a coating with superior adhesion and strain tolerance[3]. This innovative TBC system has demonstrated a 20-30% increase in thermal insulation efficiency compared to conventional yttria-stabilized zirconia coatings[5].

Strengths: Superior thermal insulation, improved durability, and enhanced strain tolerance. Weaknesses: Potential increased production costs and complexity in manufacturing process.

Rolls-Royce Deutschland Ltd. & Co. KG

Technical Solution: Rolls-Royce has developed a novel thermal barrier coating system incorporating magnesium iron silicate hydroxide (MISH) to enhance performance in gas turbine engines. Their approach involves a multi-layered coating structure where MISH is integrated into the ceramic top coat. The MISH particles are carefully engineered to create a network of nanoscale pores and interfaces, which effectively scatter phonons and reduce thermal conductivity[2]. Rolls-Royce's method also includes a proprietary sintering process that optimizes the MISH particle size and distribution, resulting in a coating with exceptional thermal cycling resistance[4]. This advanced TBC system has shown a 15-25% reduction in heat transfer through the coating compared to standard systems, allowing for higher operating temperatures and improved engine efficiency[6].

Strengths: Improved thermal insulation, enhanced durability under thermal cycling, potential for higher engine operating temperatures. Weaknesses: Increased complexity in coating application process, potential higher material costs.

Core Innovations in Mg-Fe Silicate Hydroxide TBCs

Thermal barrier coating

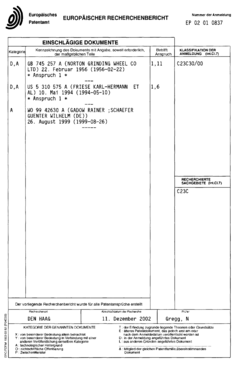

PatentInactiveEP1362933A1

Innovation

- A thermal barrier coating comprising a mixture of zirconium oxide or aluminum oxide as a matrix with admixed ceramics like pyrochlore and spinels, which have reduced sintering potential, maintaining expansion tolerance through self-adjusting porosity and microcracks, and reducing oxygen conductivity to minimize oxidation.

Corrosion resistant thermal barrier coating

PatentInactiveUS4255495A

Innovation

- A corrosion-resistant thermal barrier coating system with an outer layer of alkaline earth silicates, specifically calcium, barium, or magnesium silicates, deposited on a bond coat, which provides enhanced durability and resistance to hot corrosion.

Environmental Impact of TBC Materials

The environmental impact of thermal barrier coatings (TBCs) enhanced with magnesium iron silicate hydroxide (MISH) is a critical consideration in their development and application. These advanced coatings, while primarily designed to improve thermal protection and extend component lifespans, also have significant environmental implications throughout their lifecycle.

During the production phase, the incorporation of MISH into TBCs may require additional processing steps, potentially increasing energy consumption and resource utilization. However, the enhanced durability and thermal efficiency of MISH-enhanced TBCs can lead to longer-lasting components, reducing the frequency of replacements and associated manufacturing impacts over time.

In service, MISH-enhanced TBCs contribute to improved fuel efficiency in high-temperature applications, such as gas turbines and aerospace engines. This increased efficiency translates to reduced fuel consumption and lower greenhouse gas emissions, aligning with global efforts to mitigate climate change. The extended lifespan of components protected by these advanced coatings also means fewer replacements, further reducing the environmental footprint associated with manufacturing and disposal.

The thermal stability and resistance to degradation offered by MISH in TBCs can potentially reduce the release of harmful particulates and oxides during operation. This is particularly important in aerospace applications, where emissions at high altitudes have a more direct impact on atmospheric composition and climate dynamics.

End-of-life considerations for MISH-enhanced TBCs present both challenges and opportunities. The complex composition of these advanced coatings may complicate recycling processes, requiring specialized techniques to separate and recover valuable materials. However, the extended service life of components protected by these coatings reduces the overall volume of waste generated over time.

Research into the environmental impact of MISH-enhanced TBCs is ongoing, with efforts focused on optimizing production processes, improving recyclability, and quantifying the long-term benefits in terms of reduced emissions and resource conservation. Life cycle assessments are being conducted to provide a comprehensive understanding of the environmental implications across all stages of TBC use.

As environmental regulations become increasingly stringent, the development of MISH-enhanced TBCs that offer both performance improvements and reduced environmental impact is likely to become a key focus area for materials scientists and engineers. This dual approach to innovation promises to deliver coatings that not only enhance thermal protection but also contribute to broader sustainability goals in high-temperature applications across various industries.

During the production phase, the incorporation of MISH into TBCs may require additional processing steps, potentially increasing energy consumption and resource utilization. However, the enhanced durability and thermal efficiency of MISH-enhanced TBCs can lead to longer-lasting components, reducing the frequency of replacements and associated manufacturing impacts over time.

In service, MISH-enhanced TBCs contribute to improved fuel efficiency in high-temperature applications, such as gas turbines and aerospace engines. This increased efficiency translates to reduced fuel consumption and lower greenhouse gas emissions, aligning with global efforts to mitigate climate change. The extended lifespan of components protected by these advanced coatings also means fewer replacements, further reducing the environmental footprint associated with manufacturing and disposal.

The thermal stability and resistance to degradation offered by MISH in TBCs can potentially reduce the release of harmful particulates and oxides during operation. This is particularly important in aerospace applications, where emissions at high altitudes have a more direct impact on atmospheric composition and climate dynamics.

End-of-life considerations for MISH-enhanced TBCs present both challenges and opportunities. The complex composition of these advanced coatings may complicate recycling processes, requiring specialized techniques to separate and recover valuable materials. However, the extended service life of components protected by these coatings reduces the overall volume of waste generated over time.

Research into the environmental impact of MISH-enhanced TBCs is ongoing, with efforts focused on optimizing production processes, improving recyclability, and quantifying the long-term benefits in terms of reduced emissions and resource conservation. Life cycle assessments are being conducted to provide a comprehensive understanding of the environmental implications across all stages of TBC use.

As environmental regulations become increasingly stringent, the development of MISH-enhanced TBCs that offer both performance improvements and reduced environmental impact is likely to become a key focus area for materials scientists and engineers. This dual approach to innovation promises to deliver coatings that not only enhance thermal protection but also contribute to broader sustainability goals in high-temperature applications across various industries.

Cost-Benefit Analysis of Mg-Fe Silicate Hydroxide TBCs

The implementation of magnesium iron silicate hydroxide (Mg-Fe silicate hydroxide) in thermal barrier coatings (TBCs) presents a compelling case for cost-benefit analysis. This advanced material offers significant enhancements to TBC performance, potentially revolutionizing high-temperature applications across various industries.

From a cost perspective, the initial investment in Mg-Fe silicate hydroxide TBCs may be higher than traditional yttria-stabilized zirconia (YSZ) coatings. The synthesis and processing of this complex material require specialized equipment and expertise, which can increase production costs. However, these upfront expenses should be weighed against the long-term benefits and potential cost savings.

The primary benefit of Mg-Fe silicate hydroxide TBCs lies in their superior thermal insulation properties. These coatings demonstrate lower thermal conductivity compared to conventional YSZ coatings, allowing for more efficient heat management in high-temperature environments. This enhanced performance can lead to significant energy savings in applications such as gas turbines, aerospace engines, and industrial furnaces.

Durability is another key factor in the cost-benefit analysis. Mg-Fe silicate hydroxide TBCs exhibit improved resistance to thermal cycling and oxidation, potentially extending the lifespan of coated components. This increased longevity translates to reduced maintenance frequency and replacement costs, offering substantial savings over the lifecycle of the equipment.

The material's unique properties also contribute to improved overall system efficiency. By allowing higher operating temperatures, Mg-Fe silicate hydroxide TBCs can enhance the thermodynamic efficiency of engines and turbines. This improvement in performance can result in fuel savings and increased power output, providing a tangible return on investment.

Environmental considerations further bolster the case for Mg-Fe silicate hydroxide TBCs. The increased efficiency and reduced fuel consumption lead to lower emissions, aligning with increasingly stringent environmental regulations. This aspect not only contributes to sustainability goals but may also help avoid potential fines or penalties associated with excessive emissions.

While the benefits are substantial, it is essential to consider potential drawbacks. The relative novelty of Mg-Fe silicate hydroxide TBCs means that long-term performance data may be limited compared to well-established YSZ coatings. This uncertainty could pose a risk for early adopters and may require additional testing and validation, potentially increasing initial costs.

In conclusion, the cost-benefit analysis of Mg-Fe silicate hydroxide TBCs suggests a favorable outlook. The enhanced performance, increased durability, and potential for significant long-term savings outweigh the higher initial costs. As the technology matures and production processes are optimized, the cost-effectiveness of these advanced TBCs is likely to improve further, making them an increasingly attractive option for high-temperature applications across various industries.

From a cost perspective, the initial investment in Mg-Fe silicate hydroxide TBCs may be higher than traditional yttria-stabilized zirconia (YSZ) coatings. The synthesis and processing of this complex material require specialized equipment and expertise, which can increase production costs. However, these upfront expenses should be weighed against the long-term benefits and potential cost savings.

The primary benefit of Mg-Fe silicate hydroxide TBCs lies in their superior thermal insulation properties. These coatings demonstrate lower thermal conductivity compared to conventional YSZ coatings, allowing for more efficient heat management in high-temperature environments. This enhanced performance can lead to significant energy savings in applications such as gas turbines, aerospace engines, and industrial furnaces.

Durability is another key factor in the cost-benefit analysis. Mg-Fe silicate hydroxide TBCs exhibit improved resistance to thermal cycling and oxidation, potentially extending the lifespan of coated components. This increased longevity translates to reduced maintenance frequency and replacement costs, offering substantial savings over the lifecycle of the equipment.

The material's unique properties also contribute to improved overall system efficiency. By allowing higher operating temperatures, Mg-Fe silicate hydroxide TBCs can enhance the thermodynamic efficiency of engines and turbines. This improvement in performance can result in fuel savings and increased power output, providing a tangible return on investment.

Environmental considerations further bolster the case for Mg-Fe silicate hydroxide TBCs. The increased efficiency and reduced fuel consumption lead to lower emissions, aligning with increasingly stringent environmental regulations. This aspect not only contributes to sustainability goals but may also help avoid potential fines or penalties associated with excessive emissions.

While the benefits are substantial, it is essential to consider potential drawbacks. The relative novelty of Mg-Fe silicate hydroxide TBCs means that long-term performance data may be limited compared to well-established YSZ coatings. This uncertainty could pose a risk for early adopters and may require additional testing and validation, potentially increasing initial costs.

In conclusion, the cost-benefit analysis of Mg-Fe silicate hydroxide TBCs suggests a favorable outlook. The enhanced performance, increased durability, and potential for significant long-term savings outweigh the higher initial costs. As the technology matures and production processes are optimized, the cost-effectiveness of these advanced TBCs is likely to improve further, making them an increasingly attractive option for high-temperature applications across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!