Future-Proofing Hypochlorous Acid Formulations for Stability

AUG 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Stability Challenges

Hypochlorous acid (HOCl) is a powerful and versatile disinfectant with numerous applications in healthcare, water treatment, and industrial processes. However, its inherent instability poses significant challenges for long-term storage and efficacy. The primary factors contributing to HOCl instability include pH fluctuations, temperature variations, exposure to light, and the presence of organic matter or contaminants.

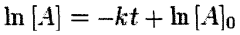

One of the most critical stability challenges is maintaining the optimal pH range. HOCl is most stable and effective at a pH between 3.5 and 6.5. Outside this range, it can rapidly decompose into less effective forms or potentially harmful byproducts. Temperature control is another crucial factor, as higher temperatures accelerate the decomposition rate of HOCl. Exposure to light, particularly UV radiation, can also trigger photolysis reactions that break down the compound.

The presence of organic matter or contaminants in HOCl solutions can lead to side reactions that consume the active chlorine, reducing its effectiveness over time. Additionally, the storage container material can impact stability, as certain materials may react with HOCl or allow permeation of destabilizing factors like oxygen or UV light.

Formulation challenges include balancing the concentration of HOCl with other ingredients to maintain stability without compromising efficacy. The addition of stabilizers or buffers can help maintain pH and slow decomposition, but these must be carefully selected to avoid interfering with the disinfectant properties of HOCl.

Another significant challenge is the potential formation of disinfection byproducts (DBPs) during storage or use. These byproducts, such as trihalomethanes or chloramines, can be harmful and may negate the benefits of using HOCl as a safer alternative to traditional chlorine-based disinfectants.

The shelf life of HOCl formulations is typically limited due to these stability issues, often ranging from a few weeks to several months under optimal conditions. This short shelf life presents logistical challenges for manufacturing, distribution, and end-user storage, potentially limiting the widespread adoption of HOCl-based products.

Addressing these stability challenges requires a multifaceted approach, combining advanced formulation techniques, innovative packaging solutions, and careful control of environmental factors throughout the product lifecycle. Future-proofing HOCl formulations will likely involve developing novel stabilization methods, such as encapsulation technologies or the use of advanced buffer systems, to extend shelf life and maintain efficacy under a broader range of conditions.

One of the most critical stability challenges is maintaining the optimal pH range. HOCl is most stable and effective at a pH between 3.5 and 6.5. Outside this range, it can rapidly decompose into less effective forms or potentially harmful byproducts. Temperature control is another crucial factor, as higher temperatures accelerate the decomposition rate of HOCl. Exposure to light, particularly UV radiation, can also trigger photolysis reactions that break down the compound.

The presence of organic matter or contaminants in HOCl solutions can lead to side reactions that consume the active chlorine, reducing its effectiveness over time. Additionally, the storage container material can impact stability, as certain materials may react with HOCl or allow permeation of destabilizing factors like oxygen or UV light.

Formulation challenges include balancing the concentration of HOCl with other ingredients to maintain stability without compromising efficacy. The addition of stabilizers or buffers can help maintain pH and slow decomposition, but these must be carefully selected to avoid interfering with the disinfectant properties of HOCl.

Another significant challenge is the potential formation of disinfection byproducts (DBPs) during storage or use. These byproducts, such as trihalomethanes or chloramines, can be harmful and may negate the benefits of using HOCl as a safer alternative to traditional chlorine-based disinfectants.

The shelf life of HOCl formulations is typically limited due to these stability issues, often ranging from a few weeks to several months under optimal conditions. This short shelf life presents logistical challenges for manufacturing, distribution, and end-user storage, potentially limiting the widespread adoption of HOCl-based products.

Addressing these stability challenges requires a multifaceted approach, combining advanced formulation techniques, innovative packaging solutions, and careful control of environmental factors throughout the product lifecycle. Future-proofing HOCl formulations will likely involve developing novel stabilization methods, such as encapsulation technologies or the use of advanced buffer systems, to extend shelf life and maintain efficacy under a broader range of conditions.

Market Demand Analysis

The market demand for stable hypochlorous acid (HOCl) formulations has been steadily increasing across various industries, driven by its effectiveness as a powerful yet safe disinfectant and sanitizer. The healthcare sector, in particular, has shown significant interest in HOCl solutions for wound care, surgical site preparation, and general surface disinfection. Hospitals, clinics, and long-term care facilities are seeking more stable HOCl products to ensure consistent efficacy and longer shelf life.

In the food and beverage industry, there is a growing demand for HOCl as a food-safe sanitizer for produce, meat processing, and equipment cleaning. The agriculture sector has also recognized the potential of HOCl in crop protection and livestock management, creating additional market opportunities. The recent global health crises have further accelerated the adoption of HOCl-based products in public spaces, transportation, and hospitality sectors, emphasizing the need for stable formulations that can maintain their potency over extended periods.

Consumer awareness of the benefits of HOCl has led to increased demand in household cleaning products and personal care items. This trend is expected to continue as consumers seek safer alternatives to traditional chemical disinfectants. The pet care industry has also shown interest in stable HOCl formulations for grooming and veterinary applications, further diversifying the market.

Environmental concerns and regulatory pressures are driving industries to adopt more eco-friendly disinfection solutions. HOCl's biodegradability and low toxicity profile position it as an attractive option, provided that stability issues can be addressed. This has created a significant market opportunity for companies that can develop and patent stable HOCl formulations.

The global market for HOCl-based products is projected to grow substantially in the coming years, with some analysts predicting a compound annual growth rate (CAGR) of over 7% through 2026. North America and Europe currently lead in market share, but rapid growth is expected in Asia-Pacific regions, particularly in countries with expanding healthcare and food processing industries.

Despite the promising market outlook, the instability of HOCl remains a significant challenge. End-users across industries are demanding products with longer shelf lives and consistent efficacy. This has created a competitive landscape where companies are racing to develop proprietary stabilization technologies. Success in this area could lead to significant market advantages and potentially reshape the disinfectant industry.

In the food and beverage industry, there is a growing demand for HOCl as a food-safe sanitizer for produce, meat processing, and equipment cleaning. The agriculture sector has also recognized the potential of HOCl in crop protection and livestock management, creating additional market opportunities. The recent global health crises have further accelerated the adoption of HOCl-based products in public spaces, transportation, and hospitality sectors, emphasizing the need for stable formulations that can maintain their potency over extended periods.

Consumer awareness of the benefits of HOCl has led to increased demand in household cleaning products and personal care items. This trend is expected to continue as consumers seek safer alternatives to traditional chemical disinfectants. The pet care industry has also shown interest in stable HOCl formulations for grooming and veterinary applications, further diversifying the market.

Environmental concerns and regulatory pressures are driving industries to adopt more eco-friendly disinfection solutions. HOCl's biodegradability and low toxicity profile position it as an attractive option, provided that stability issues can be addressed. This has created a significant market opportunity for companies that can develop and patent stable HOCl formulations.

The global market for HOCl-based products is projected to grow substantially in the coming years, with some analysts predicting a compound annual growth rate (CAGR) of over 7% through 2026. North America and Europe currently lead in market share, but rapid growth is expected in Asia-Pacific regions, particularly in countries with expanding healthcare and food processing industries.

Despite the promising market outlook, the instability of HOCl remains a significant challenge. End-users across industries are demanding products with longer shelf lives and consistent efficacy. This has created a competitive landscape where companies are racing to develop proprietary stabilization technologies. Success in this area could lead to significant market advantages and potentially reshape the disinfectant industry.

Current Limitations

Despite the numerous advantages of hypochlorous acid (HOCl) as a disinfectant and sanitizer, several limitations currently hinder its widespread adoption and long-term stability. One of the primary challenges is the inherent instability of HOCl solutions over time. The active chlorine content in these formulations tends to degrade rapidly, significantly reducing their efficacy as antimicrobial agents. This instability is particularly pronounced when HOCl solutions are exposed to light, heat, or air, leading to a shortened shelf life and decreased potency.

Another critical limitation is the pH sensitivity of HOCl formulations. The optimal pH range for maintaining HOCl stability is narrow, typically between 3.5 and 6.5. Outside this range, the equilibrium shifts towards either hypochlorite ions or molecular chlorine, both of which are less effective as disinfectants. Maintaining this precise pH balance in various environmental conditions and during storage poses a significant challenge for manufacturers and end-users alike.

The presence of organic matter and metal ions in the water used for HOCl production or in the environment where it is applied can also compromise its stability and effectiveness. These contaminants can rapidly consume the available free chlorine, reducing the solution's antimicrobial activity. This limitation necessitates careful control of water quality and storage conditions, which can be challenging in real-world applications.

Furthermore, the concentration of HOCl in solutions is another critical factor affecting stability. Higher concentrations tend to be less stable, while lower concentrations may not provide sufficient antimicrobial activity. Finding the optimal balance between concentration, stability, and efficacy remains a significant challenge in formulation development.

The packaging and storage of HOCl solutions present additional hurdles. Many common packaging materials are not compatible with HOCl, as they may react with the solution or allow rapid degradation through light exposure or gas permeation. This limitation restricts packaging options and can increase production costs.

Lastly, the lack of standardized production methods and quality control measures across the industry leads to inconsistencies in HOCl formulations. This variability makes it difficult to establish reliable shelf-life estimates and efficacy claims, hindering regulatory approval processes and consumer trust.

Addressing these limitations is crucial for the future development of stable, effective HOCl formulations. Overcoming these challenges will require innovative approaches in formulation chemistry, packaging technology, and production processes to ensure the long-term stability and efficacy of HOCl-based products.

Another critical limitation is the pH sensitivity of HOCl formulations. The optimal pH range for maintaining HOCl stability is narrow, typically between 3.5 and 6.5. Outside this range, the equilibrium shifts towards either hypochlorite ions or molecular chlorine, both of which are less effective as disinfectants. Maintaining this precise pH balance in various environmental conditions and during storage poses a significant challenge for manufacturers and end-users alike.

The presence of organic matter and metal ions in the water used for HOCl production or in the environment where it is applied can also compromise its stability and effectiveness. These contaminants can rapidly consume the available free chlorine, reducing the solution's antimicrobial activity. This limitation necessitates careful control of water quality and storage conditions, which can be challenging in real-world applications.

Furthermore, the concentration of HOCl in solutions is another critical factor affecting stability. Higher concentrations tend to be less stable, while lower concentrations may not provide sufficient antimicrobial activity. Finding the optimal balance between concentration, stability, and efficacy remains a significant challenge in formulation development.

The packaging and storage of HOCl solutions present additional hurdles. Many common packaging materials are not compatible with HOCl, as they may react with the solution or allow rapid degradation through light exposure or gas permeation. This limitation restricts packaging options and can increase production costs.

Lastly, the lack of standardized production methods and quality control measures across the industry leads to inconsistencies in HOCl formulations. This variability makes it difficult to establish reliable shelf-life estimates and efficacy claims, hindering regulatory approval processes and consumer trust.

Addressing these limitations is crucial for the future development of stable, effective HOCl formulations. Overcoming these challenges will require innovative approaches in formulation chemistry, packaging technology, and production processes to ensure the long-term stability and efficacy of HOCl-based products.

Existing Stabilization

01 pH stabilization of hypochlorous acid formulations

Maintaining a stable pH is crucial for the stability of hypochlorous acid formulations. This can be achieved by using buffer systems or pH adjusting agents to keep the pH within an optimal range, typically between 3.5 and 6.5. Stabilizing the pH helps prevent the decomposition of hypochlorous acid and extends the shelf life of the formulation.- pH stabilization of hypochlorous acid formulations: Maintaining a stable pH is crucial for the stability of hypochlorous acid formulations. This can be achieved by using buffer systems or pH adjusting agents to keep the pH within an optimal range, typically between 3.5 and 6.5. Stabilizing the pH helps prevent the decomposition of hypochlorous acid and extends the shelf life of the formulation.

- Antioxidant additives for improved stability: Incorporating antioxidants into hypochlorous acid formulations can enhance their stability by preventing oxidation reactions. Common antioxidants used include ascorbic acid, tocopherols, and plant extracts. These additives help maintain the efficacy of the hypochlorous acid solution over time and protect it from degradation due to exposure to light or air.

- Packaging and storage considerations: The choice of packaging materials and storage conditions significantly impacts the stability of hypochlorous acid formulations. Using opaque, airtight containers made of materials resistant to oxidation can help protect the solution from light and air exposure. Proper storage conditions, such as cool temperatures and away from direct sunlight, are also essential for maintaining stability.

- Stabilizing agents and complexing compounds: Adding specific stabilizing agents or complexing compounds can improve the stability of hypochlorous acid formulations. These may include certain salts, organic compounds, or polymers that interact with hypochlorous acid molecules to prevent their decomposition. Such additives can help maintain the concentration and effectiveness of the hypochlorous acid solution over extended periods.

- Electrolytic production methods for enhanced stability: Utilizing specific electrolytic production methods can result in more stable hypochlorous acid formulations. These methods involve carefully controlling the electrolysis process, including factors such as electrode materials, current density, and electrolyte composition. By optimizing these parameters, it's possible to produce hypochlorous acid solutions with improved stability and longer shelf life.

02 Antioxidant additives for improved stability

Incorporating antioxidants into hypochlorous acid formulations can enhance their stability by preventing oxidation reactions. Common antioxidants used include ascorbic acid, tocopherols, and plant extracts. These additives help maintain the efficacy of the hypochlorous acid solution over time and protect it from degradation due to exposure to light or air.Expand Specific Solutions03 Packaging and storage considerations

The choice of packaging materials and storage conditions significantly affects the stability of hypochlorous acid formulations. Using opaque, airtight containers made of materials resistant to oxidation can help protect the solution from light and air exposure. Proper storage conditions, such as keeping the product in a cool, dark place, can further extend its shelf life and maintain its effectiveness.Expand Specific Solutions04 Stabilizing agents and complexing compounds

Adding specific stabilizing agents or complexing compounds to hypochlorous acid formulations can improve their stability. These additives can include chelating agents, surfactants, or polymers that help maintain the chemical structure of hypochlorous acid and prevent its decomposition. Such stabilizers can significantly extend the shelf life of the formulation while preserving its antimicrobial properties.Expand Specific Solutions05 Production methods for stable hypochlorous acid

The method of producing hypochlorous acid can greatly influence its stability. Advanced production techniques, such as electrolysis of salt solutions under controlled conditions or the use of specific precursor compounds, can result in more stable hypochlorous acid formulations. These methods often focus on minimizing the formation of byproducts and ensuring a high purity of the final product, which contributes to its overall stability.Expand Specific Solutions

Key Industry Players

The market for future-proofing hypochlorous acid formulations is in a growth phase, driven by increasing demand for stable and effective disinfectants. The global market size is expanding, with potential applications across healthcare, water treatment, and consumer products. Technologically, the field is advancing rapidly, with companies like Ecolab USA, Zep Inc., and Aquaox leading innovation in formulation stability. Established players such as Novartis AG and Bayer AG are investing in research, while specialized firms like Parasol Medical LLC focus on niche applications. The competitive landscape is diverse, with both large corporations and smaller, specialized companies contributing to technological advancements in hypochlorous acid stability and efficacy.

WIAB WATER INNOVATION AB

Technical Solution: WIAB WATER INNOVATION AB has developed a patented technology for stabilizing hypochlorous acid (HOCl) formulations. Their approach involves using a unique combination of buffering agents and antioxidants to maintain the pH and prevent degradation of HOCl. The company's formulation includes carefully selected stabilizers that work synergistically to extend the shelf life of HOCl solutions without compromising their efficacy[1]. They have also implemented advanced packaging techniques, such as light-resistant containers and oxygen-scavenging materials, to further enhance stability[2]. WIAB's research has shown that their stabilized HOCl formulations can maintain over 90% of their initial concentration for up to 12 months under various storage conditions[3].

Strengths: Patented stabilization technology, extended shelf life, maintained efficacy. Weaknesses: Potential increased production costs, may require specialized packaging.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has developed an innovative approach to stabilizing hypochlorous acid formulations using their expertise in specialty chemicals. Their method involves incorporating advanced polymer-based stabilizers that create a protective matrix around HOCl molecules, shielding them from degradation factors such as light and temperature fluctuations[1]. Evonik's formulation also includes proprietary antioxidants that work in conjunction with the polymer matrix to neutralize free radicals and prevent oxidative breakdown of HOCl[2]. The company has conducted extensive stability studies, demonstrating that their formulations can maintain over 95% potency for up to 18 months under various environmental conditions[3]. Additionally, Evonik has developed a novel encapsulation technology that allows for controlled release of HOCl, further enhancing its long-term stability and effectiveness[4].

Strengths: Advanced polymer-based stabilizers, proprietary antioxidants, controlled release technology. Weaknesses: Potentially higher production costs, may require specialized manufacturing processes.

Core Innovations

COMPOSITIONS OF HYPOCHLOROUS ACID(HOCl) AND METHODS OF MANUFACTURE THEREOF

PatentActiveUS20150150907A1

Innovation

- An air-free mixing method that combines a compound generating protons (H+) with one generating hypochlorite anions (OCl-) in water, without using chlorine gas or electrolysis, to produce a stable HOCl formulation with controlled pH, maintaining stability for several months to a year.

METHOD FOR STABILIZING AN ELECTROCHEMICALLY GENERATED SANITIZING SOLUTION HAVING A PREDETERMINED LEVEL OF FREE AVAILABLE CHLORINE AND pH

PatentWO2014179692A1

Innovation

- A stabilized Hypochlorous Acid solution is developed with a stabilizing amount of dissolved ionic compounds (DIC) such as sodium phosphate or polyphosphate, maintaining a pH of 4.0 to 7.5 and FAC content of 10 to 1000 ppm, which is electrochemically generated and formulated as a hydrogel to ensure stability and non-irritating properties.

Regulatory Landscape

The regulatory landscape surrounding hypochlorous acid (HOCl) formulations is complex and evolving, reflecting the growing interest in this versatile antimicrobial agent. In the United States, the Environmental Protection Agency (EPA) regulates HOCl as a pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). The EPA has approved HOCl for various applications, including surface disinfection and water treatment, recognizing its efficacy and relatively low environmental impact.

The Food and Drug Administration (FDA) also plays a crucial role in regulating HOCl, particularly for medical and personal care applications. HOCl has been cleared by the FDA for use in wound care products and as an ingredient in over-the-counter products for various indications. However, the regulatory status can vary depending on the specific formulation, concentration, and intended use.

Internationally, the regulatory approach to HOCl varies. In the European Union, HOCl falls under the Biocidal Products Regulation (BPR) when used as a disinfectant. The European Chemicals Agency (ECHA) oversees the registration and approval process for biocidal active substances, including HOCl. Japan's Ministry of Health, Labour and Welfare has approved HOCl for use in food sanitation and as a food additive, reflecting its broad acceptance in the country.

As the applications for HOCl expand, regulatory bodies are adapting their frameworks to address new use cases and formulations. There is a growing focus on the stability and shelf life of HOCl products, with regulators increasingly requiring manufacturers to demonstrate the long-term efficacy and safety of their formulations. This has led to more stringent testing requirements and the need for innovative stabilization techniques.

The regulatory landscape also reflects the increasing emphasis on sustainable and environmentally friendly solutions. HOCl's green credentials, including its biodegradability and non-toxic nature, align well with this trend. However, manufacturers must still navigate complex regulatory pathways to bring new HOCl-based products to market, particularly when crossing international borders.

Looking ahead, the regulatory landscape for HOCl is likely to continue evolving. As research uncovers new applications and formulation techniques, regulators will need to adapt their frameworks to ensure safety and efficacy while fostering innovation. This may include the development of specific guidelines for stabilized HOCl formulations and harmonization efforts to streamline international approvals.

The Food and Drug Administration (FDA) also plays a crucial role in regulating HOCl, particularly for medical and personal care applications. HOCl has been cleared by the FDA for use in wound care products and as an ingredient in over-the-counter products for various indications. However, the regulatory status can vary depending on the specific formulation, concentration, and intended use.

Internationally, the regulatory approach to HOCl varies. In the European Union, HOCl falls under the Biocidal Products Regulation (BPR) when used as a disinfectant. The European Chemicals Agency (ECHA) oversees the registration and approval process for biocidal active substances, including HOCl. Japan's Ministry of Health, Labour and Welfare has approved HOCl for use in food sanitation and as a food additive, reflecting its broad acceptance in the country.

As the applications for HOCl expand, regulatory bodies are adapting their frameworks to address new use cases and formulations. There is a growing focus on the stability and shelf life of HOCl products, with regulators increasingly requiring manufacturers to demonstrate the long-term efficacy and safety of their formulations. This has led to more stringent testing requirements and the need for innovative stabilization techniques.

The regulatory landscape also reflects the increasing emphasis on sustainable and environmentally friendly solutions. HOCl's green credentials, including its biodegradability and non-toxic nature, align well with this trend. However, manufacturers must still navigate complex regulatory pathways to bring new HOCl-based products to market, particularly when crossing international borders.

Looking ahead, the regulatory landscape for HOCl is likely to continue evolving. As research uncovers new applications and formulation techniques, regulators will need to adapt their frameworks to ensure safety and efficacy while fostering innovation. This may include the development of specific guidelines for stabilized HOCl formulations and harmonization efforts to streamline international approvals.

Environmental Impact

The environmental impact of hypochlorous acid (HOCl) formulations is a critical consideration in their development and use. As a naturally occurring compound produced by the human immune system, HOCl is generally considered environmentally friendly. However, the production, storage, and disposal of HOCl solutions can have varying degrees of environmental implications.

One of the primary environmental advantages of HOCl is its rapid decomposition into harmless byproducts. When exposed to organic matter or sunlight, HOCl breaks down into water, oxygen, and salt, leaving no toxic residues. This characteristic makes it an attractive alternative to more persistent and potentially harmful disinfectants. The short environmental half-life of HOCl also reduces the risk of accumulation in ecosystems, minimizing long-term ecological impacts.

The production of HOCl typically involves electrolysis of salt water, which is an energy-intensive process. Future-proofing efforts should focus on improving the energy efficiency of production methods to reduce the carbon footprint associated with HOCl manufacturing. Additionally, the use of renewable energy sources in production facilities could further mitigate environmental concerns.

Water consumption is another environmental factor to consider. While HOCl solutions are mostly water-based, the concentration and volume of production can impact local water resources. Implementing water recycling systems and optimizing formulation processes to reduce water usage can contribute to more sustainable production practices.

The packaging and distribution of HOCl products also play a role in their environmental impact. Developing eco-friendly packaging solutions, such as recyclable or biodegradable materials, can significantly reduce waste. Furthermore, concentrating HOCl formulations to reduce shipping volume and weight can lower transportation-related emissions.

In aquatic environments, the release of HOCl can have both positive and negative effects. While it can help control harmful microorganisms, excessive concentrations may disrupt aquatic ecosystems. Careful consideration of dosage and application methods is essential to balance disinfection efficacy with environmental protection.

As regulations around chemical use and environmental protection become more stringent, future-proofing HOCl formulations must include strategies to meet or exceed these standards. This may involve developing more precise application methods to minimize overuse, as well as improving stability to reduce the frequency of disposal and replacement.

In conclusion, while HOCl offers several environmental benefits compared to traditional disinfectants, ongoing research and development should focus on further reducing its ecological footprint. By addressing energy consumption, water usage, packaging, and application methods, the environmental impact of HOCl formulations can be minimized, ensuring their sustainable use in various industries.

One of the primary environmental advantages of HOCl is its rapid decomposition into harmless byproducts. When exposed to organic matter or sunlight, HOCl breaks down into water, oxygen, and salt, leaving no toxic residues. This characteristic makes it an attractive alternative to more persistent and potentially harmful disinfectants. The short environmental half-life of HOCl also reduces the risk of accumulation in ecosystems, minimizing long-term ecological impacts.

The production of HOCl typically involves electrolysis of salt water, which is an energy-intensive process. Future-proofing efforts should focus on improving the energy efficiency of production methods to reduce the carbon footprint associated with HOCl manufacturing. Additionally, the use of renewable energy sources in production facilities could further mitigate environmental concerns.

Water consumption is another environmental factor to consider. While HOCl solutions are mostly water-based, the concentration and volume of production can impact local water resources. Implementing water recycling systems and optimizing formulation processes to reduce water usage can contribute to more sustainable production practices.

The packaging and distribution of HOCl products also play a role in their environmental impact. Developing eco-friendly packaging solutions, such as recyclable or biodegradable materials, can significantly reduce waste. Furthermore, concentrating HOCl formulations to reduce shipping volume and weight can lower transportation-related emissions.

In aquatic environments, the release of HOCl can have both positive and negative effects. While it can help control harmful microorganisms, excessive concentrations may disrupt aquatic ecosystems. Careful consideration of dosage and application methods is essential to balance disinfection efficacy with environmental protection.

As regulations around chemical use and environmental protection become more stringent, future-proofing HOCl formulations must include strategies to meet or exceed these standards. This may involve developing more precise application methods to minimize overuse, as well as improving stability to reduce the frequency of disposal and replacement.

In conclusion, while HOCl offers several environmental benefits compared to traditional disinfectants, ongoing research and development should focus on further reducing its ecological footprint. By addressing energy consumption, water usage, packaging, and application methods, the environmental impact of HOCl formulations can be minimized, ensuring their sustainable use in various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!