Scraping tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

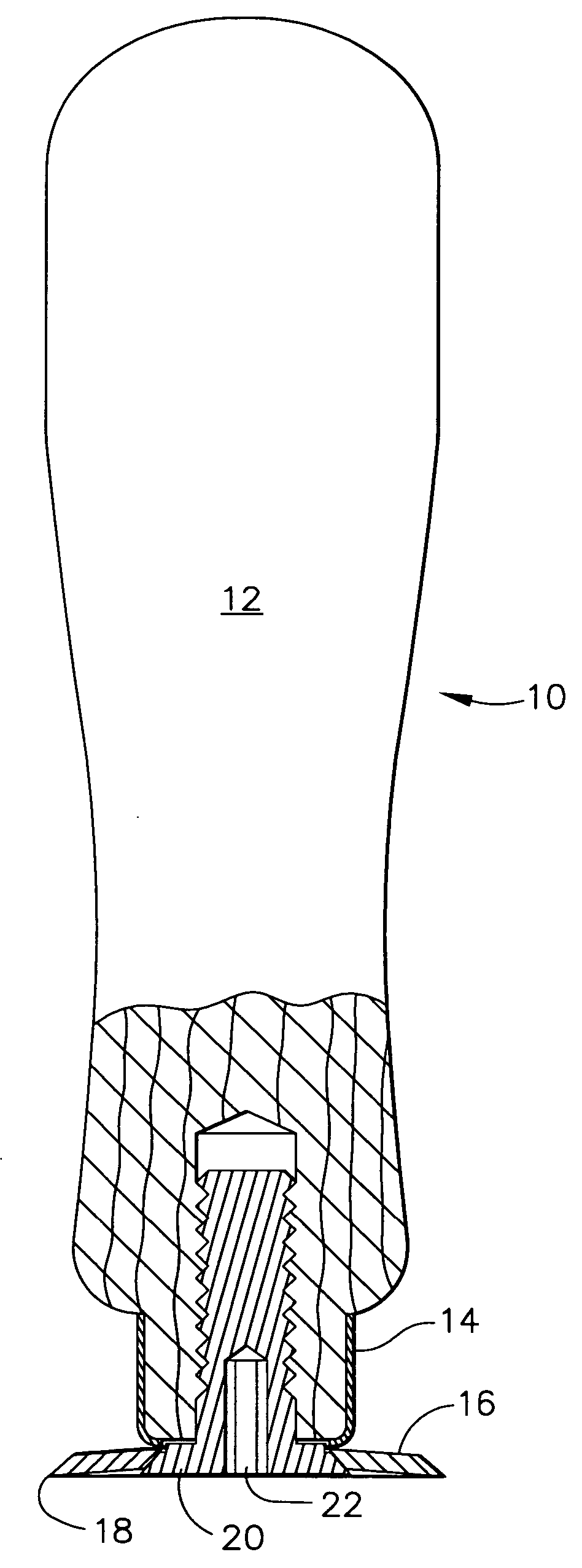

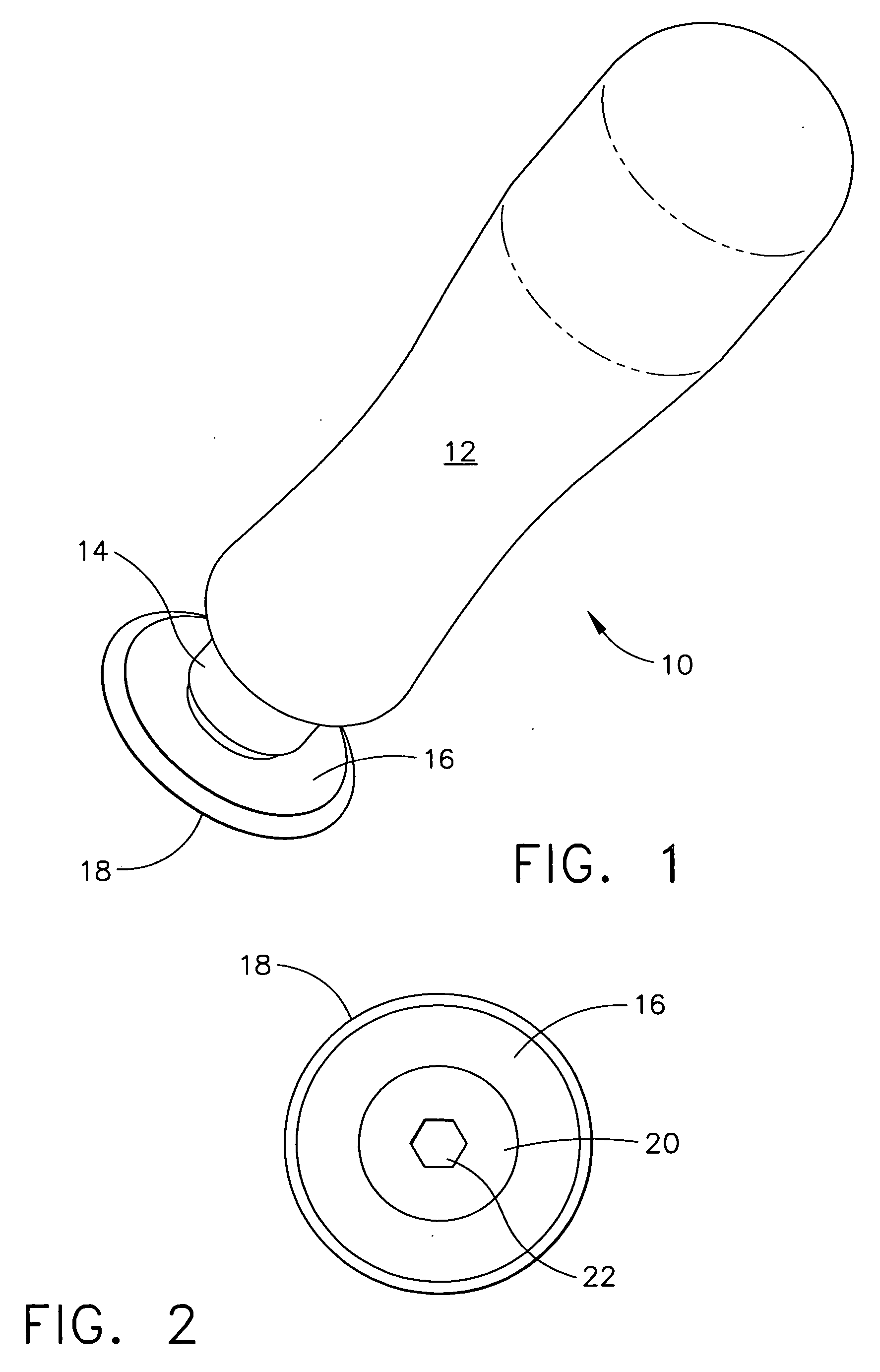

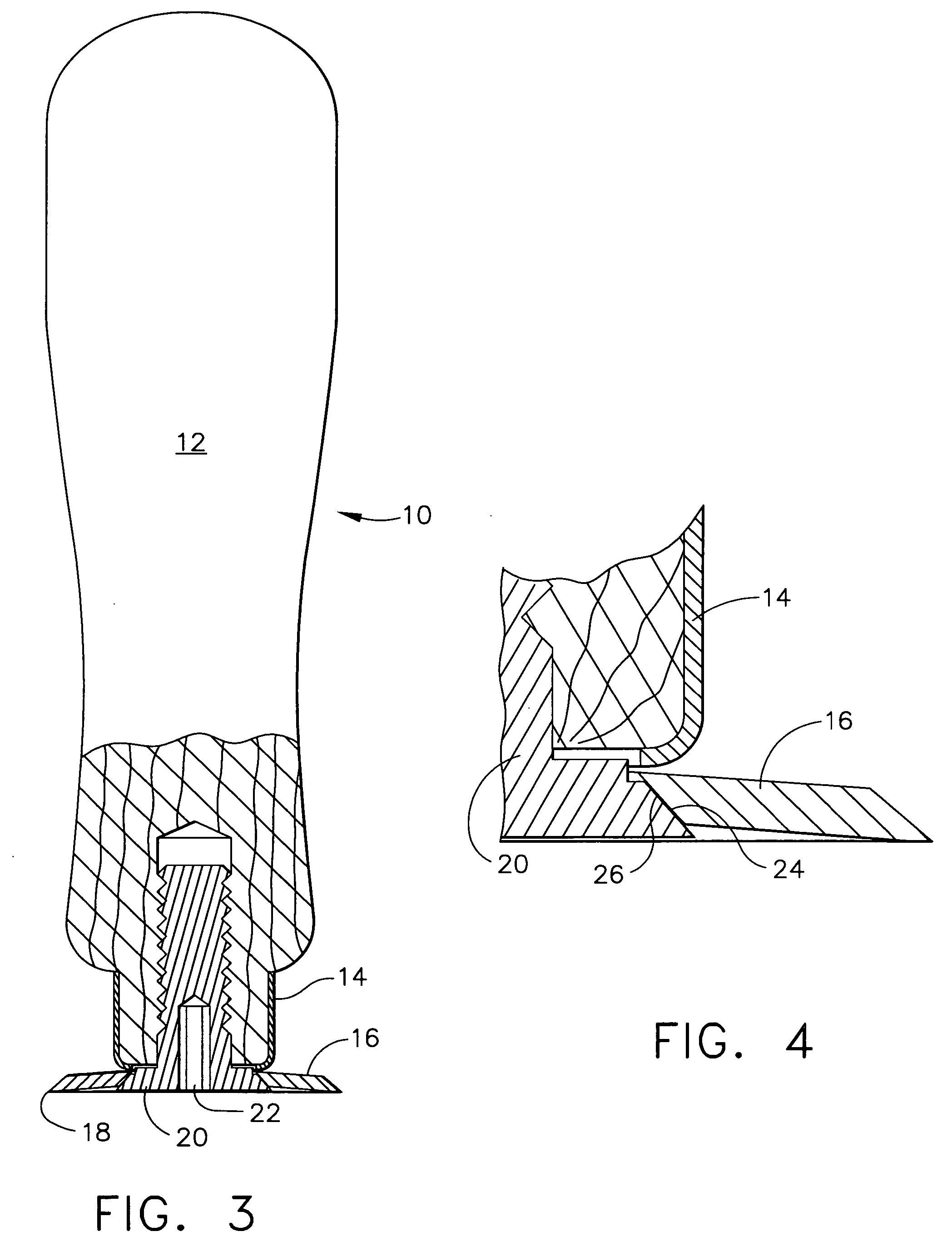

[0014] With reference to the Figures and as best shown in FIGS. 1, 2, and 3, the scraping tool 10 of the present invention generally includes a handle 12, a blade retaining component 20, and a rotatable blade 16. As will be described in greater detail, the blade retaining component is adapted to rotatably retain the blade 16 on the handle 12.

[0015] As shown in FIGS. 1-5, the handle 12 is preferably attached substantially perpendicularly to and substantially at the center of the blade 16. As shown in the figures, the handle 12 may include an ergonomically shaped gripping portion. The handle 12 may be comprised of wood, plastic, metal, and combinations of these or any other suitable conventional materials known in the art.

[0016] The scraping tool 10 may include a reinforcing handle cover 14 that adds additional strength and rigidity to the scraping tool 10. As shown in FIGS. 1 and 3, the optional reinforcing cover may cover a length of the handle 12 and may be comprised of any suita...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap