Air cooling internal combustion engine with oil temperature sensor

A technology of oil temperature sensor and internal combustion engine, which is applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problem of not being able to correspond with good accuracy, and achieve the effect of improving temperature detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

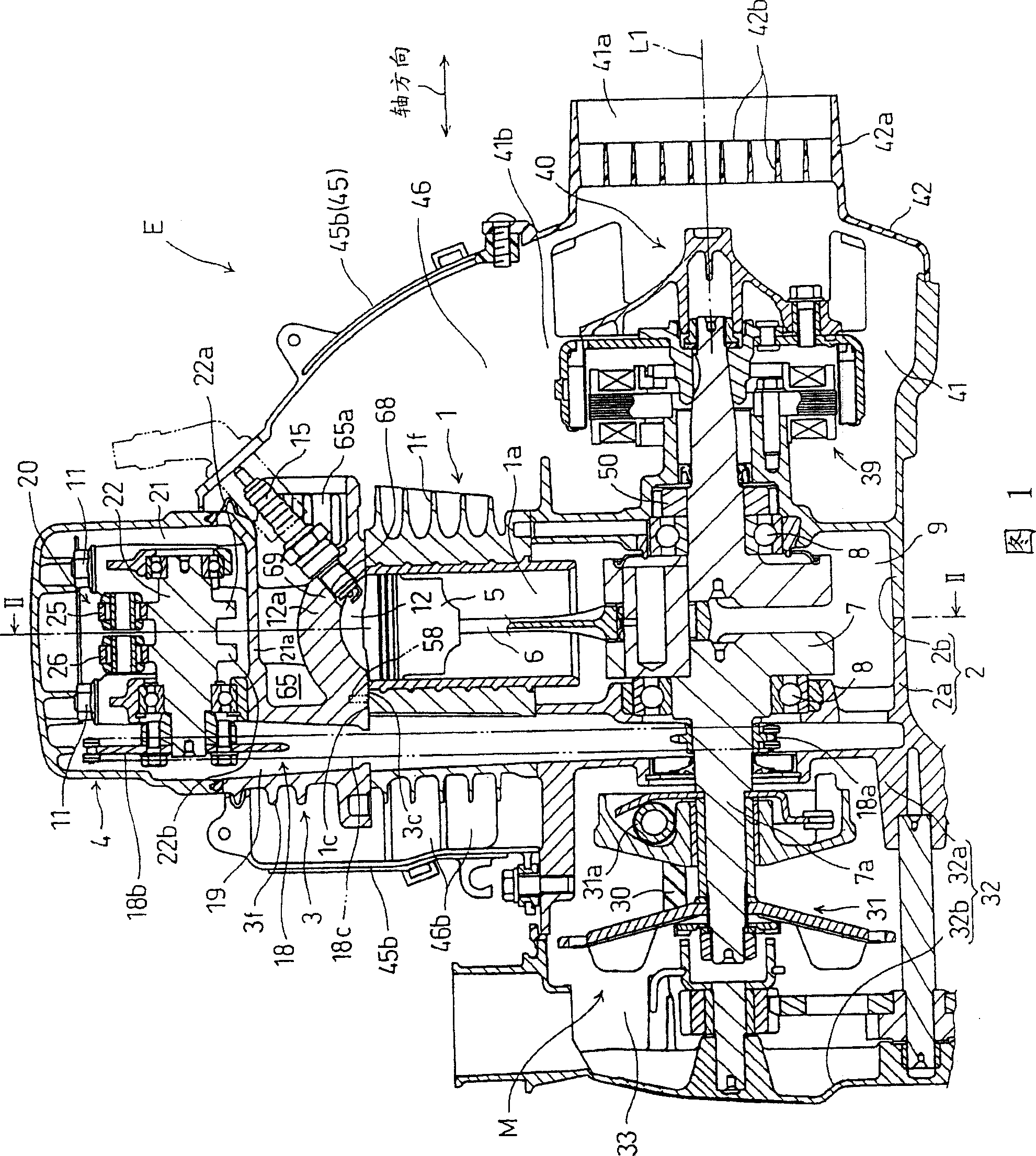

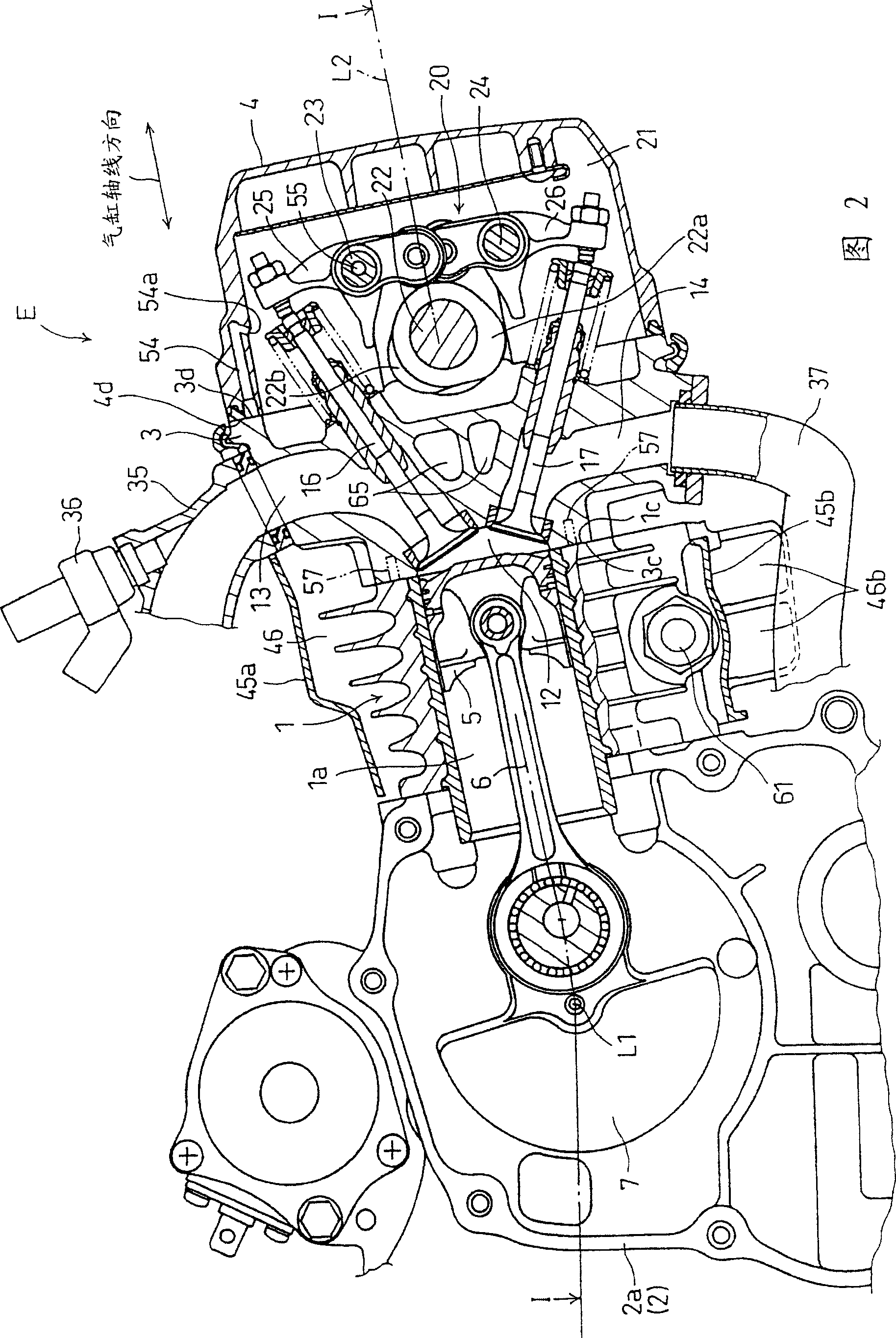

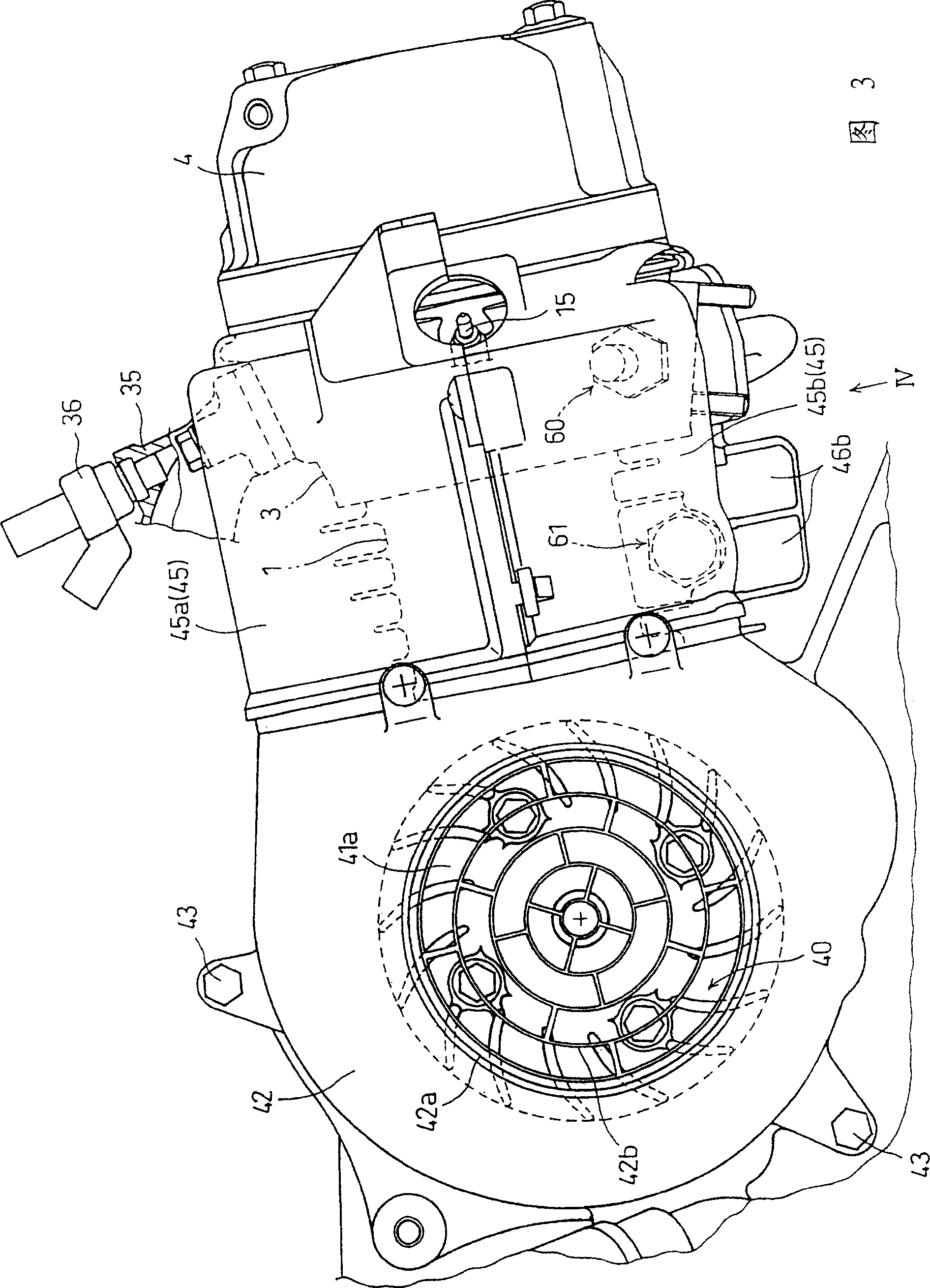

[0029] First, refer to figure 1 , 2 , The air-cooled internal combustion engine E used in the present invention is mounted on an automatic two-wheeled vehicle as a vehicle together with a power transmission device having a V-belt automatic transmission M.

[0030] The internal-combustion engine E supported by the vehicle body is a single-cylinder 4-stroke internal-combustion engine in a horizontal configuration with the rotation center line L1 of the crankshaft 7 pointing to the left and right directions, and has a cylinder 1 in the direction of the cylinder axis L2 (hereinafter referred to as (cylinder axis direction) ) The crankcase 2 combined with the crankshaft 7 side of the cylinder 1, the cylinder head 3 combined with the anti-crankshaft 7 side of the cylinder 1 in the cylinder axis direction, and the cylinder head cover 4 combined with the cylinder head 3 constitute the main body of the internal combustion engine. The cylinder 1, the crankcase 2, the cylinder head 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com