Dry processing method for ceramic brick and a dry edging and bevelling machine

A processing method and technology of ceramic tiles, applied in the direction of stone processing tools, metal processing equipment, stone processing equipment, etc., can solve the problems of high operator quality requirements, high waterproof and anti-corrosion requirements, and high water and electricity consumption. , to achieve the effect of simple and reliable operation, saving labor and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

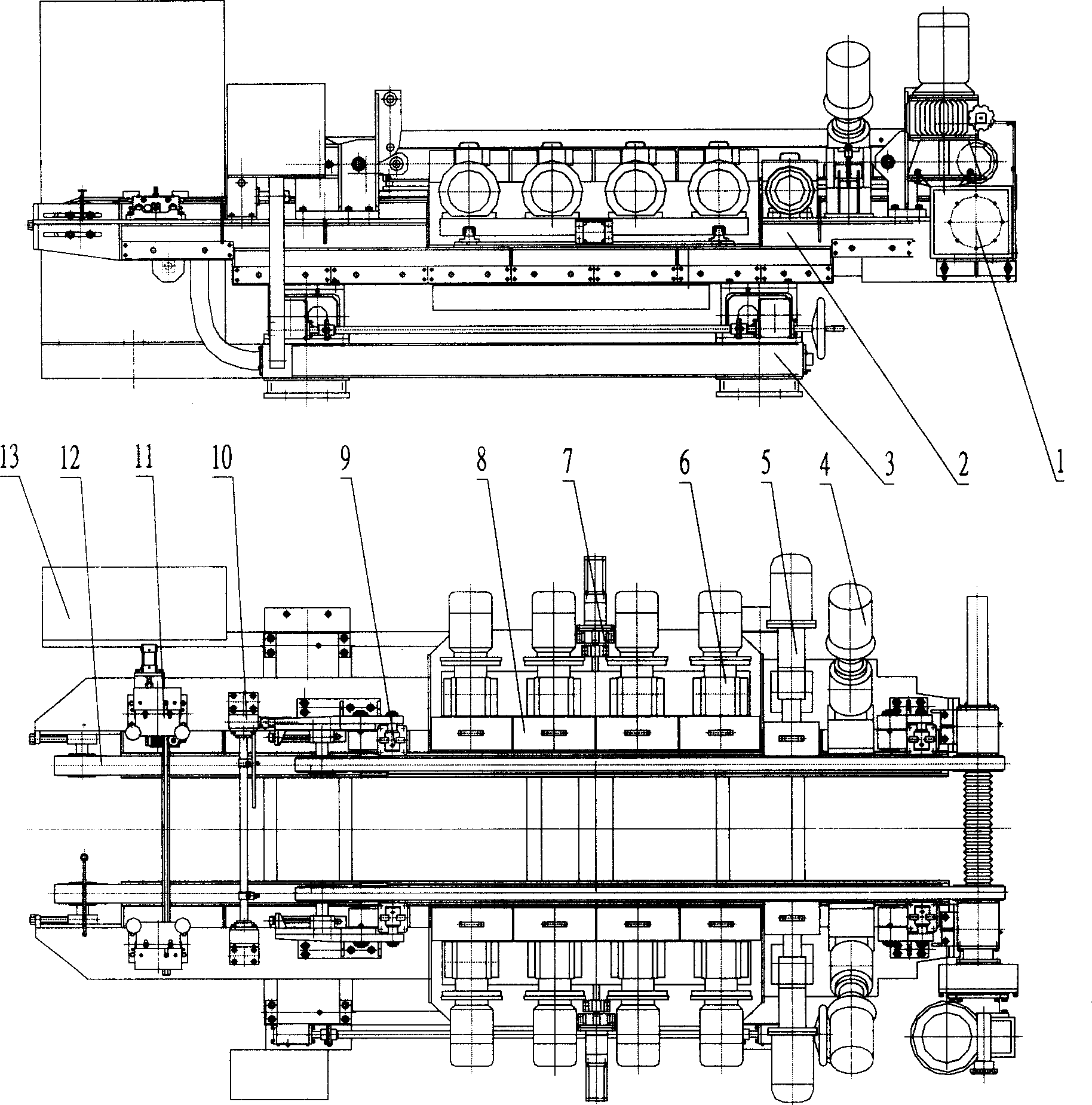

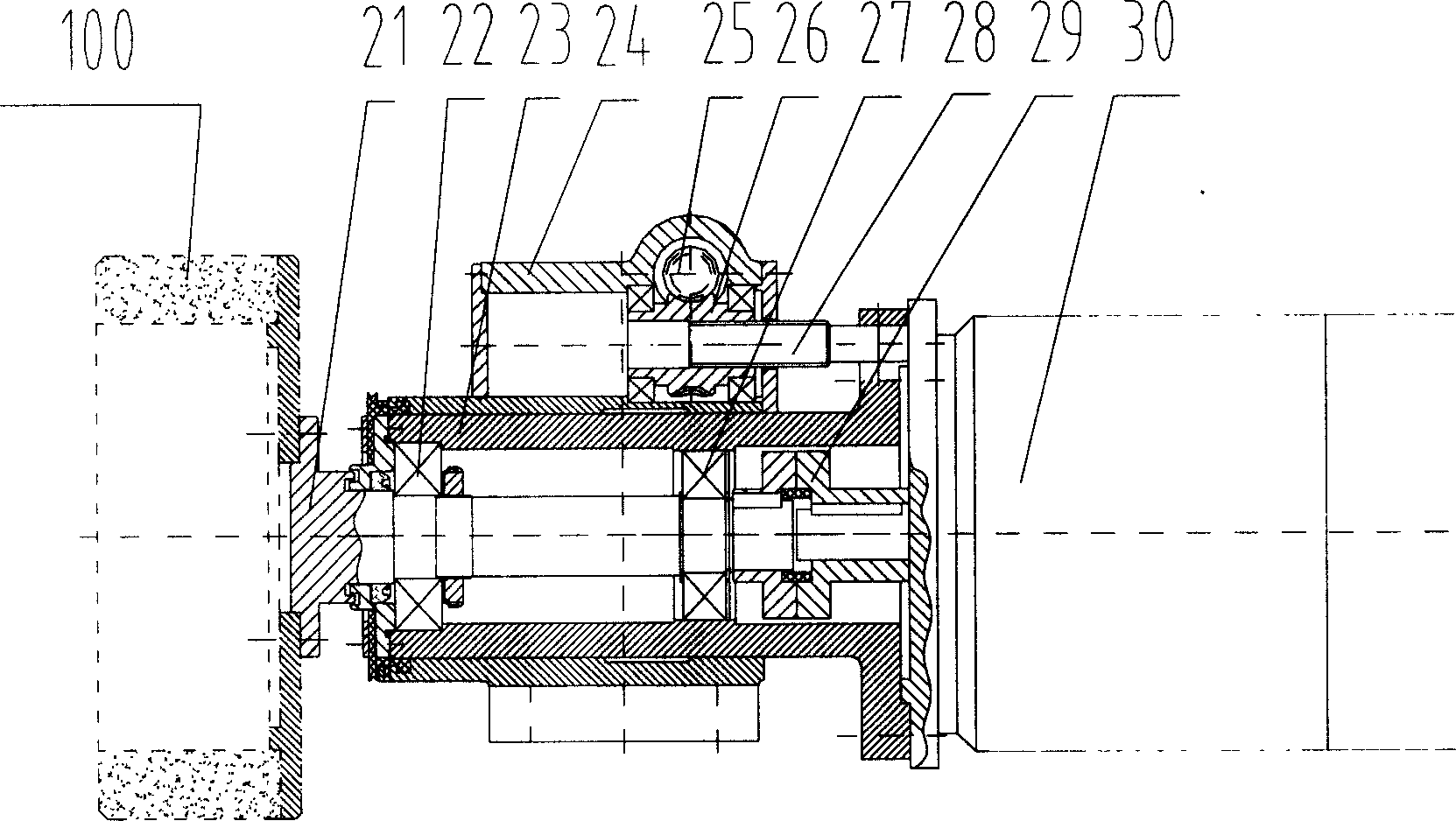

[0039] Ceramic brick dry type edge grinding and chamfering machine of the present invention (see figure 1 ) consists of frame 3, beam 2, driving device 1, transmission device 12, belt pressing device 9, centering mechanism 10, positioning device 11, edging grinding head 6, finishing grinding head 5, chamfering grinding head 4, automatic The feed compensation device 7, the electrical control cabinet 13 and the dustproof assembly 8 are composed of 13 parts. Frame 3 is a frame-type steel structure, which is used to support two large beams, and makes the two large beams slide forward and backward on its guide shafts, so as to adjust the opening width of the large beams according to different tile sizes. The girder 2 is a steel girder structure, which is used to fix all parts except the electrical control cabinet. Drive device 1 is made up of motor, speed reducer, base, drives the main transmission shaft of transmission device 12 to rotate through the speed reducer output. The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com