Powdered industrial no-TNT ammonium nitrate explosive

A technology of ladderless explosives and powdery emulsion explosives, which is applied to explosives and other fields, and can solve the problems of low volume power and low charge density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

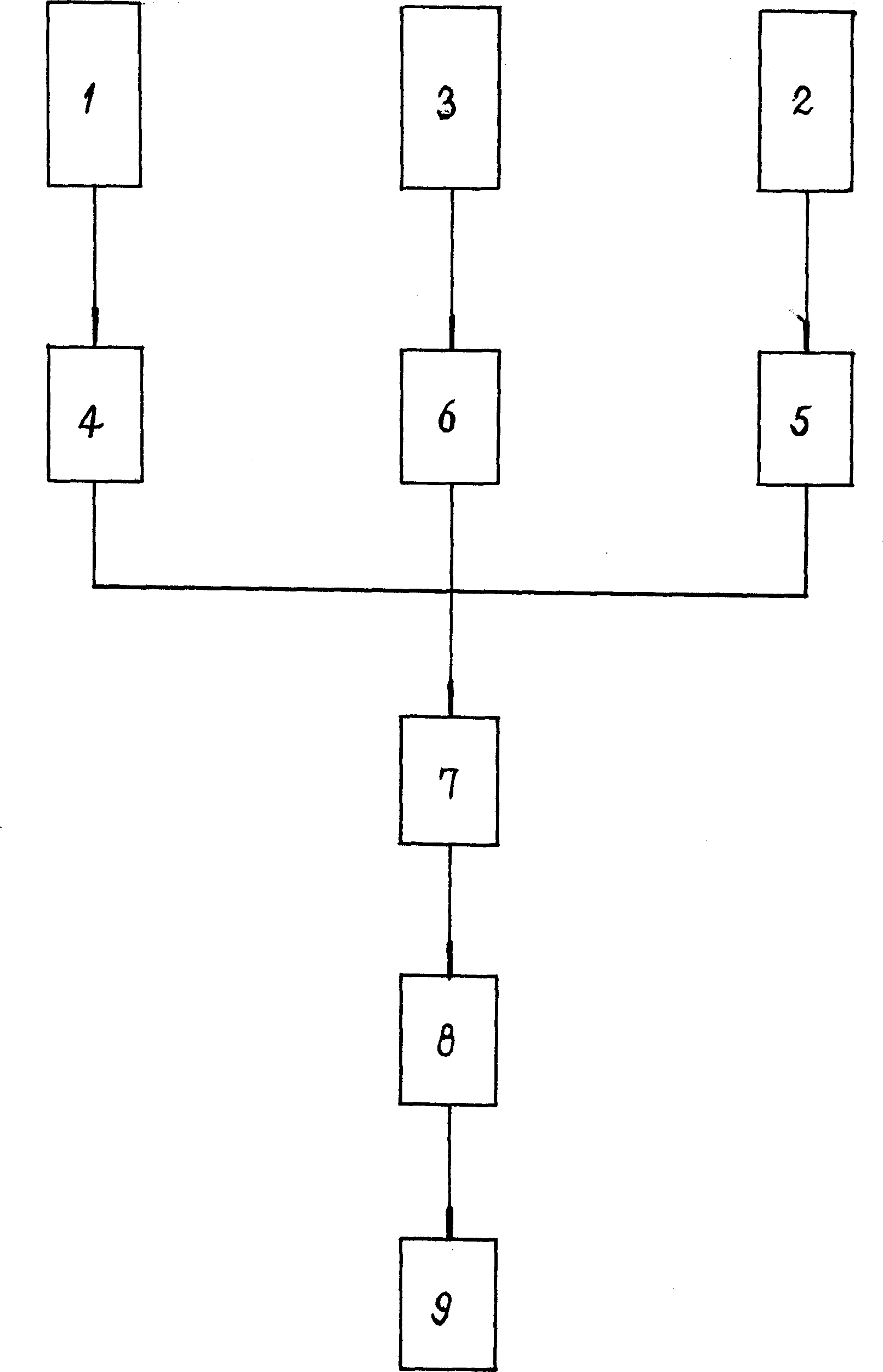

Image

Examples

Embodiment Construction

[0017] Brief description of the production process: The powdered ammonium nitrate passed through the ammonium nitrate pulverizer is 50%-80% through a 40-mesh sieve as a standard. At room temperature, a certain amount of powdered emulsion explosive (sensitizer) is added for mechanical mixing. A certain compound oil phase is added to the material, and the material can be discharged after mixing for 10-15 minutes. In order to solve the problem of low density of expanded ammonium nitrate explosives and powdered emulsion explosives, low blasthole filling density and volume power, in the production process, 50%-80% of crushed ammonium nitrate is controlled to pass through a 40-mesh sieve to effectively control the size of ammonium nitrate powder. The powdery emulsion explosive is filled into the gaps of the accumulated ammonium nitrate, thereby increasing the quality of the explosive per unit volume, fundamentally increasing the density of the explosive roll, and solving the problem of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com