Ring traveler and method for production the same

A production method and traveler technology, applied in the direction of textiles and papermaking, can solve the problems of high cost and impact, and achieve the effects of low cost, pollution avoidance and good sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

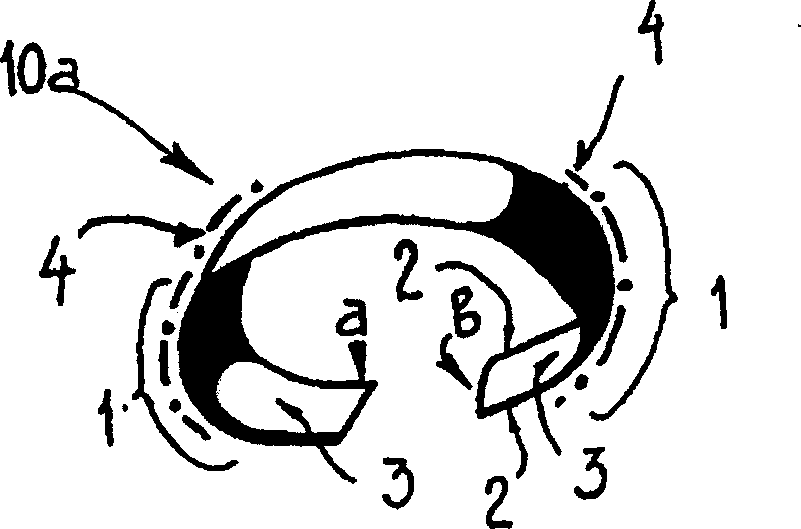

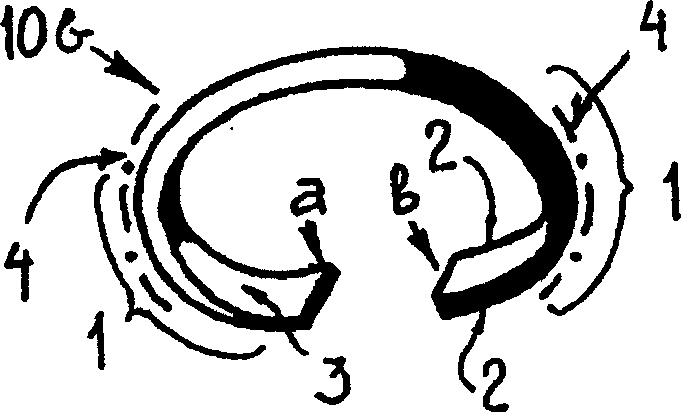

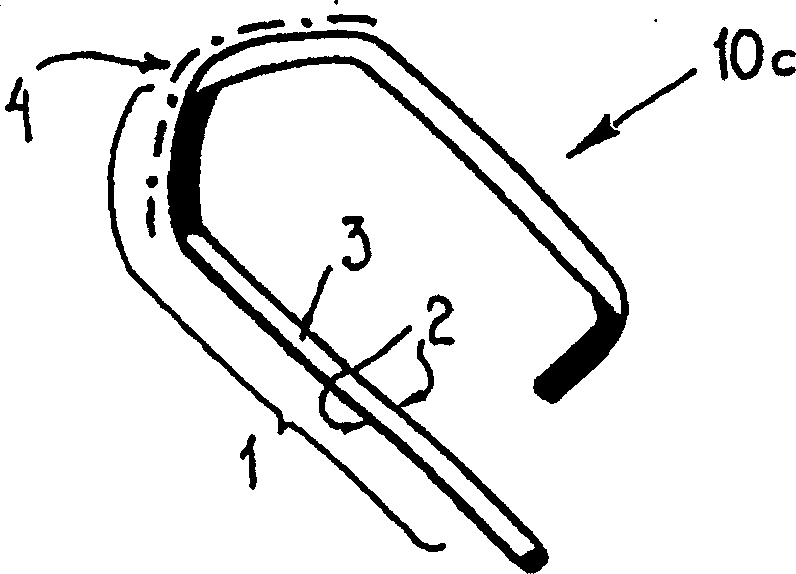

[0025] Figures 1a to 1f Shown are the travelers 10a to 10f in the various embodiments already described in International Patent WO 99 / 49113. Figure 1a and 1b C-shaped travelers 10a, 10b are shown, such as those normally used on the rings of the T-flanges of ring spinning machines or ring twisting machines. on the contrary, Figures 1c to 1f Ear and hook travelers 10c to 10f are shown. Travelers 10c and 10d are used on inclined flange rings, traveler 10e is used on conically running flange rings and traveler 10f is used on vertically running flange rings.

[0026] Those regions in which the travellers 10a to 10f slide in operation to form running surfaces on the flange rings are indicated with 1 in each case. In the case of C-shaped travelers 10a, 10b, both sides a, b are used as running surfaces due to their symmetrical construction. In the case of ear or hook travelers 10c to 10f, the running surface area 1 is clearly determined by the shape.

[0027] The traveler 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com