Environment-friendly anti-cracking dry-mixed plastering mortar

A plastering mortar and environmental protection technology is applied in the field of building materials to achieve the effects of superior water retention, good water retention and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

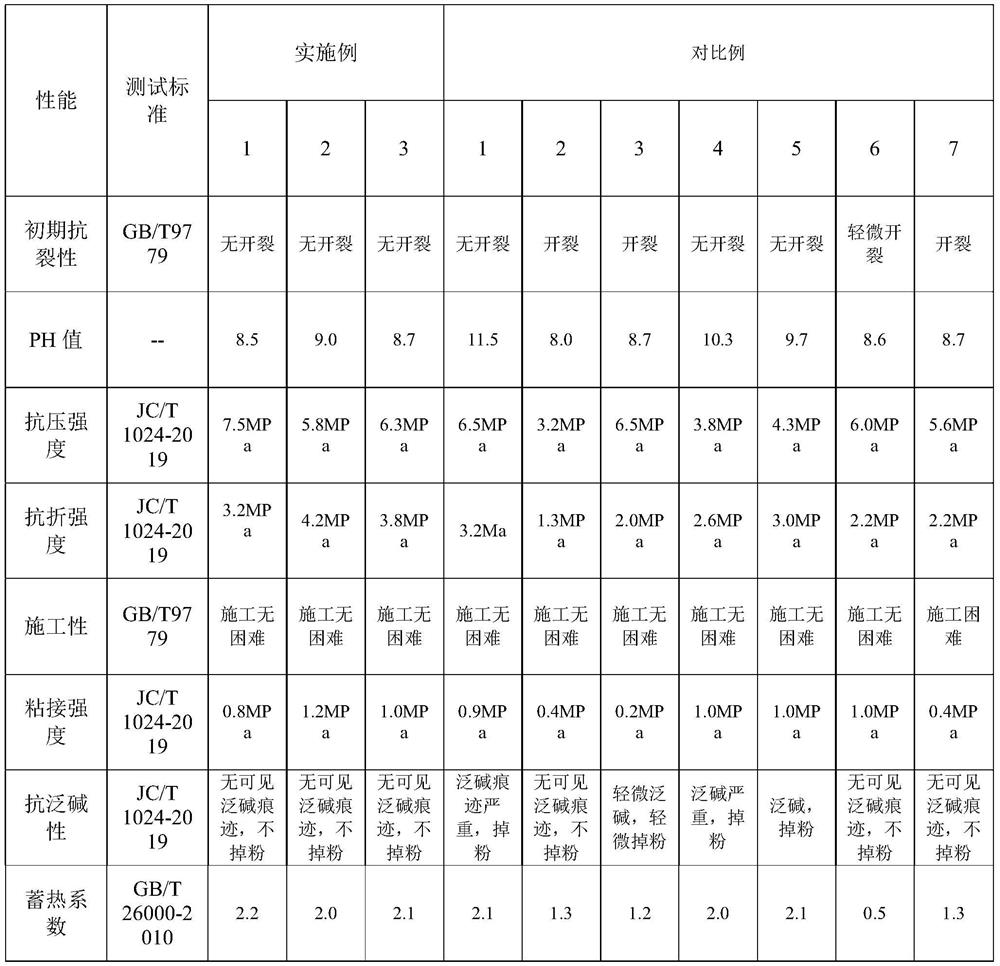

Examples

Embodiment 1

[0028] 70 parts of clinker-free ecological cementitious materials, 40 parts of slag powder, 50 parts of active fly ash, 5 parts of lithium silicate powder, 5 parts of anti-crack fiber, 50 parts of hollow microbeads, 700 parts of sand, 100,000 viscosity hydroxyl 0.2 part of propyl methylcellulose (HPMC), 0.2 part of thixotropic agent, 0.2 part of water reducing agent, and 5 parts of ethylene-vinyl acetate.

Embodiment 2

[0030] 40 parts of clinker-free ecological cementitious materials, 70 parts of slag powder, 90 parts of activated fly ash, 20 parts of lithium silicate powder, 15 parts of anti-crack fiber, 20 parts of hollow microbeads, 800 parts of sand, 100,000 viscosity hydroxyl 0.5 part of propyl methylcellulose (HPMC), 0.8 part of thixotropic agent, 0.8 part of water reducing agent, 20 parts of ethylene-vinyl acetate.

Embodiment 3

[0032] 60 parts of clinker-free ecological cementitious materials, 60 parts of slag powder, 80 parts of activated fly ash, 10 parts of lithium silicate powder, 10 parts of anti-crack fiber, 40 parts of hollow microbeads, 750 parts of sand, 100,000 viscosity hydroxyl 0.3 part of propyl methylcellulose (HPMC), 0.5 part of thixotropic agent, 0.5 part of water reducing agent, and 10 parts of ethylene-vinyl acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com