Application of streptomyces and bacillus in promoting formation of aerobic granular sludge

An aerobic granular sludge and Bacillus technology, which is applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. Good, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

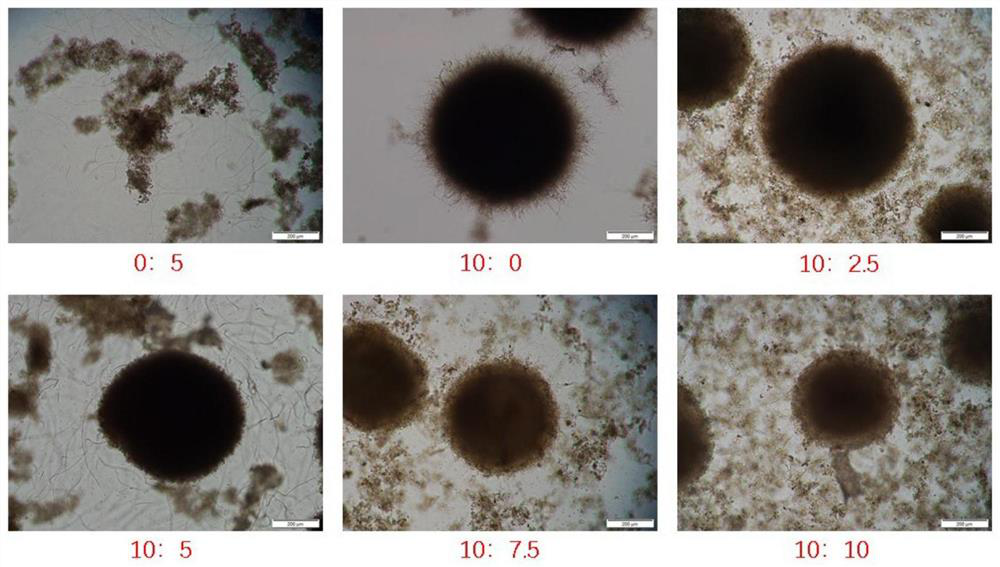

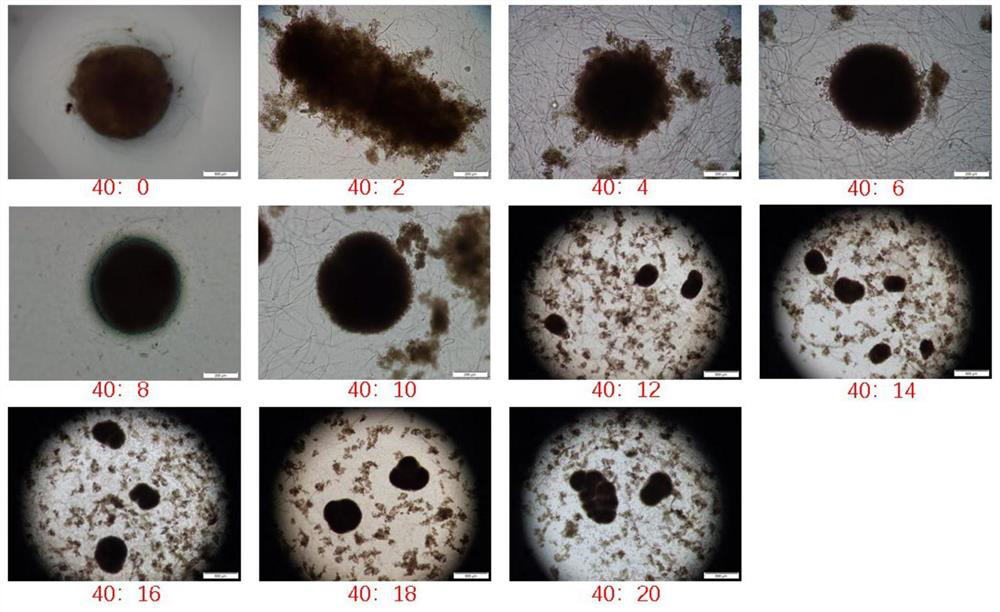

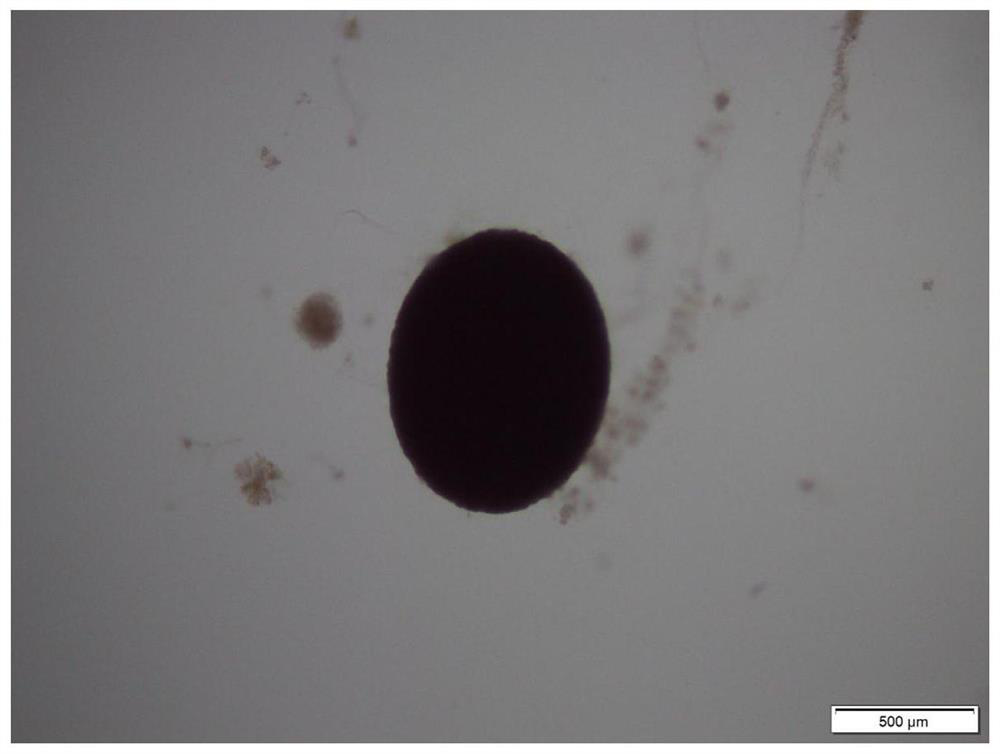

[0041] Example 1 Using Streptomyces-Bacillus functional bacterial agent to cultivate aerobic granular sludge in a shaker

[0042] In this example, aerobic granular sludge was cultivated in a shaker by using a triangular flask containing activated sludge, and the bacteria used were Streptomyces with the deposit number of CICC 11030 and Bacillus with the deposit number of CICC 10142.

[0043] S1. Cultivation of Streptomyces: Under sterile conditions, inoculate Streptomyces into Gao's No. 1 medium and place it in a shaker for 4 days under the conditions of 37°C and 250rpm for liquid expansion, and the concentration of colonies is 1×10 7 CFU / mL of Streptomyces granule bacterial solution;

[0044] Each 1 L of Gao's No. 1 medium contains 20 g of soluble starch, 1 g of potassium nitrate, 0.5 g of sodium chloride, 0.5 g of dipotassium hydrogen phosphate, 0.5 g of magnesium sulfate, and 0.01 g of ferrous sulfate, and the pH is 7.2 to 7.4.

[0045] S2. Cultivation of Bacillus: Under st...

Embodiment 2

[0049] Example 2 Using different Streptomyces-Bacillus functional bacterial agents to cultivate aerobic granular sludge in a shaker

[0050] The difference between this example and Example 1 is that the used Streptomyces and Bacillus are different. In this example, the same method as in Example 1 was adopted, and Streptomyces with the deposit number of CICC 11040 and Bacillus with the deposit number of CICC 21298, Streptomyces with the deposit number of CICC 11030 and Bacillus with the deposit number of CICC 21290, and Streptomyces with preservation number CICC 11056 and Bacillus with preservation number CICC 21290 were prepared as Streptomyces-Bacillus functional inoculants, and the prepared functional inoculants were added to the conical flask containing activated sludge , shaking culture to obtain aerobic granular sludge.

[0051] The results showed that adding functional inoculants made of Streptomyces with preservation number of CICC 11040 and Bacillus with preservation ...

Embodiment 3

[0052] Example 3 Using Streptomyces-Bacillus functional bacterial agent to cultivate aerobic granular sludge in a shaker

[0053] In this example, aerobic granular sludge was cultivated in a shaker by using a triangular flask containing activated sludge, and the bacteria used were Streptomyces with the deposit number of CICC 11030 and Bacillus with the deposit number of CICC 10142.

[0054] S1. Cultivation of Streptomyces: under sterile conditions, inoculate Streptomyces into Gao's No. 1 medium and place it in a shaker at 25 °C and 150 rpm for liquid expansion for 2 days, and obtain a colony concentration of 2 × 10 6 CFU / mL of Streptomyces granule bacterial solution;

[0055] S2. Cultivation of Bacillus: Under sterile conditions, inoculate Bacillus into LB liquid medium and place it in a shaker, and expand the liquid for 3 days at 25°C and 150 rpm to obtain a colony concentration of 4 × 10 9 Bacillus bacteria liquid of CFU / mL;

[0056] S3. Cultivation of aerobic granular slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com