Modified epoxy resin, epoxy-based pressure plate and manufacturing method of epoxy-based pressure plate

A technology of epoxy resin and production method, which is applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of low cost, epoxy-based laminates cannot have heat resistance, etc., and achieve reduction Cost, improvement of poor temperature resistance, effect of heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

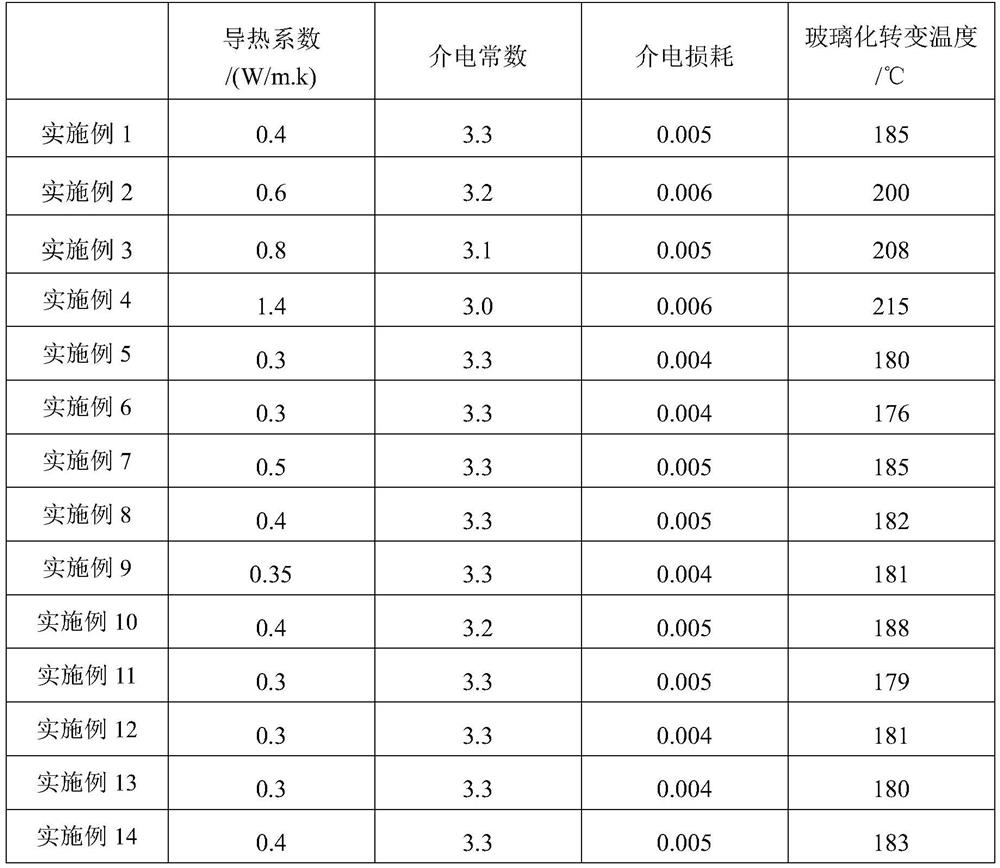

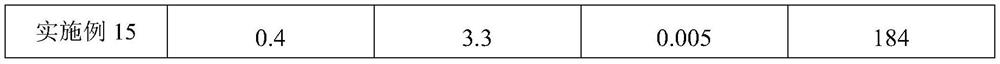

Examples

preparation example Construction

[0027] In a preferred embodiment, the above-mentioned hydroxyl-terminated hyperbranched polyphenylene ether-modified boron nitride nanosheets are prepared by the following method: the first solution in which the boron nitride nanosheets are dispersed is mixed with hydroxyl-terminated hyperbranched polyphenylene ether. Mixing, so that the hydroxyl-terminated hyperbranched polyphenylene ether is modified on the surface of the boron nitride nanosheets to obtain a first mixed solution; the first mixed solution is solid-liquid separated to obtain the hydroxyl-terminated hyperbranched polyphenylene ether modified boron nitride nanometer sheet piece.

[0028] In the above preferred embodiment, the solvent for dispersing the boron nitride nanosheets can be N-methylpyrrolidone solution (NMP solution). In order to improve the dispersibility of the boron nitride nanosheets in the solvent, the boron nitride nanosheets can be Ultrasonic treatment in solvent.

[0029] Before the step of di...

Embodiment 1

[0041] The present embodiment provides a manufacturing method of an epoxy-based laminate, comprising the following steps:

[0042] Step 1: Preparation of Surface-Modified Boron Nitride Nanosheets

[0043] Weigh 5g of boron nitride powder in 100ml of NMP solution, stir and ultrasonicate for 8h, centrifuge the treated mixed solution in a centrifuge at 8000 rpm, remove the unstripped boron nitride powder in the lower layer, collect the upper layer of mixed solution, and put the hyperbranched solution. The hydroxyl-terminated polyphenylene ether is dispersed into the supernatant liquid, fully mixed, and dried to obtain the final powder after suction filtration.

[0044] Step 2: Preparation of Epoxy Laminate

[0045] Weigh an appropriate amount of cyanate monomer (Yangzhou Tianqi New Materials, bisphenol A cyanate monomer, C01MO), heat and melt at 100 ° C, and heat and melt the hydroxyl-terminated hyperbranched polyphenylene ether modified boron nitride in step 1. The powder is a...

Embodiment 2

[0049] The difference between the manufacturing method of the epoxy-based laminate provided in this embodiment and Embodiment 1 is:

[0050] The weight ratio of surface-modified boron nitride powder, cyanate ester monomer and epoxy resin is 1:1:18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com