Lithium ion battery

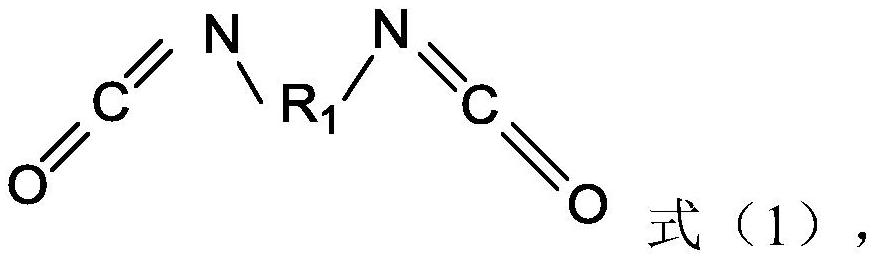

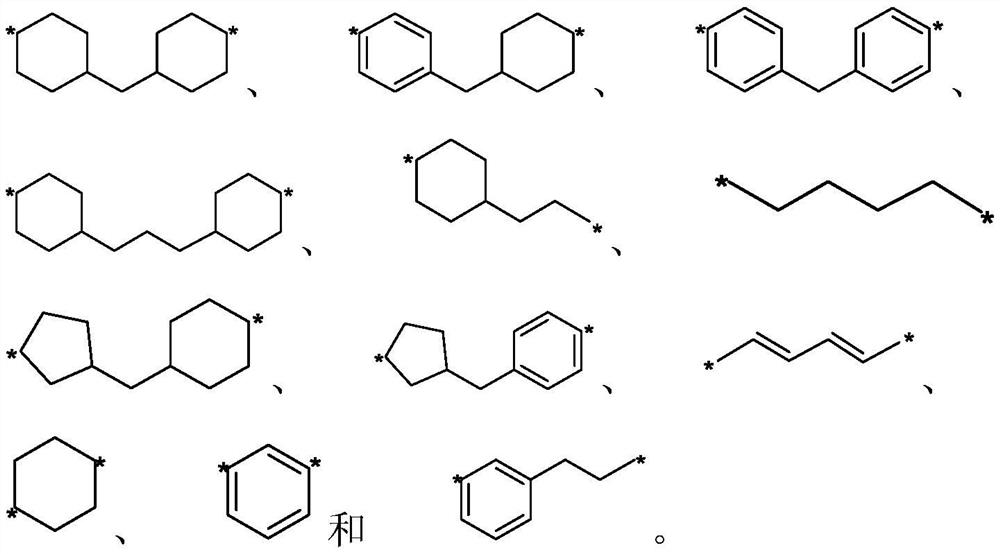

A technology of lithium-ion batteries and lithium salts, which is applied in the manufacture of battery electrodes, secondary batteries, and electrolyte batteries, etc., and can solve problems such as internal resistance growth, serious lithium analysis, and poor long-term cycle performance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

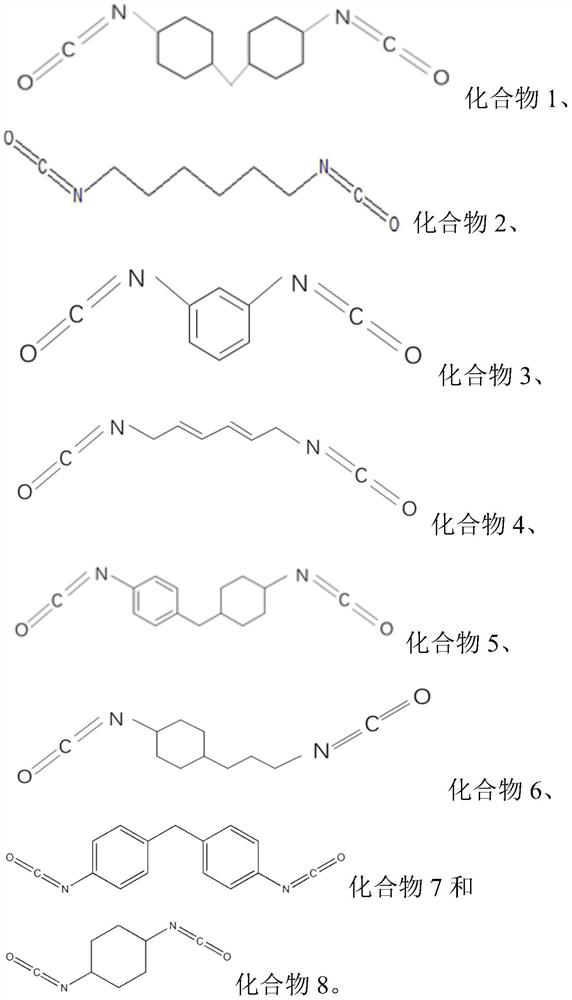

[0095] 1) Preparation of electrolyte

[0096] Ethylene carbonate (EC), diethyl carbonate (DEC), and ethyl methyl carbonate (EMC) were mixed in a mass ratio of EC:DEC:EMC=1:1:1, and then lithium hexafluorophosphate (LiPF) was added to the resulting mixture. 6 ) to a molar concentration of 1 mol / L, and then add compound 1 of 0.2% by weight of the total electrolyte mass (note: compound 1 here is compound 1 in the specification, the same below);

[0097] 2) Preparation of positive electrode sheet

[0098] The cathode active material LiCoO 2 (The surface has a metal oxide coating layer, LiCoO in the positive electrode active material 2 100%), conductive agent conductive carbon black Super-P and binder polyvinylidene fluoride (PVDF) were uniformly mixed in a weight ratio of 93:4:3, and then dispersed in N-methyl-2 - In pyrrolidone (NMP), the positive electrode slurry is obtained; the positive electrode slurry is uniformly coated on both sides of the aluminum foil, dried, rolled (...

Embodiment 2-22 and comparative example 1-5

[0107] Carry out according to the method of Example 1, the difference is that the positive electrode active material (with or without metal oxide coating layer) of the lithium ion battery, the compaction density of the positive and negative electrode materials, and the formula (1) added in the electrolyte The types and contents of the compounds, the types and contents of other additives, and the charge cut-off voltage are different, and the specific contents are shown in Table 1.

[0108] Table 1

[0109]

[0110] The relevant properties of the lithium ion batteries prepared in Examples 1-22 and Comparative Examples 1-5 are shown in Table 2.

[0111] Table 2

[0112]

[0113] From the results of Examples 1-3 and Comparative Examples 1-3, it can be seen that within the charge cut-off voltage range defined in the present invention, with the increase of the compaction density of the positive and negative electrodes, by adding the compound represented by the formula 1, it c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com