Epoxy resin composition for diffusion plate, prepreg and preparation method and application thereof

A technology of epoxy resin and prepreg, which is applied in sustainable biological treatment, instruments, diffusing elements, etc., can solve the problems of poor mechanical properties of plates, high production costs, complex processes, etc. Loss, the effect of expanding the luminous surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

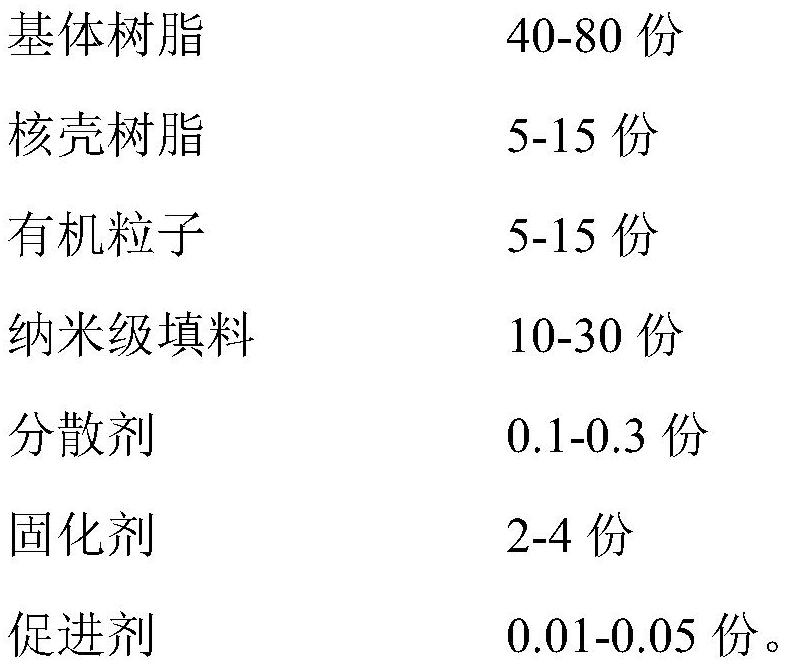

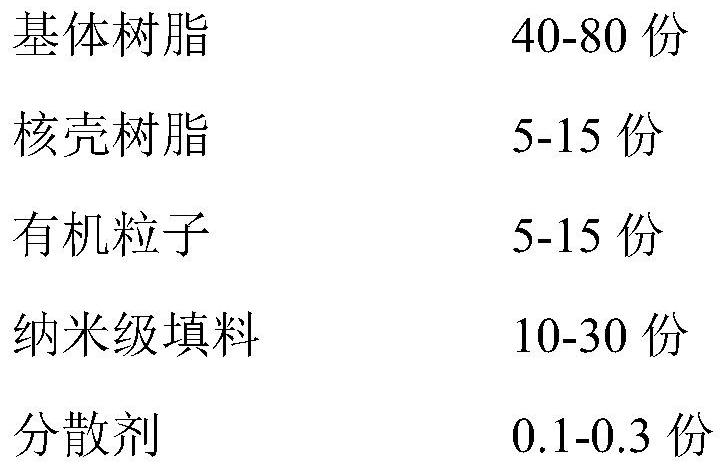

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of prepreg

[0046] Add 3 parts of dicyandiamide and 30 parts of N,N-dimethylformamide into the batching bottle ① and fully stir to dissolve, then add 5 parts of polyethylene powder and 0.1 part of sodium pyrophosphate in turn, and disperse at high speed for 0.5h; 40 parts of Add bisphenol A epoxy resin into batching bottle ②, add 5 parts of core-shell resin under stirring conditions, and after high-speed dispersion for 2 hours, add all the composition in batching bottle ② into batching bottle ①, and add in sequence under stirring conditions 0.03 part of 2-methylimidazole and 10 parts of nano-silicon dioxide were stirred evenly to prepare an epoxy resin composition for diffusion plate. Impregnated 1080 glass fiber cloth (basic weight 48g / m) with the epoxy resin composition for diffuser plate 2 ), and baked in a hot air circulating oven at 180° C. for 5 min to obtain a prepreg with a resin content of 71%.

[0047] (2) Preparation of diffuser plate

[0...

Embodiment 2

[0050] (1) Preparation of prepreg

[0051] Add 3 parts of dicyandiamide and 30 parts of N,N-dimethylformamide into the batching bottle ① and fully stir to dissolve, then add 5 parts of polyethylene powder and 0.1 part of sodium pyrophosphate in turn, and disperse at high speed for 0.5h; 50 parts of Add bisphenol A epoxy resin into batching bottle ②, add 5 parts of core-shell resin under stirring conditions, and disperse at high speed for 2 hours, add all the composition in batching bottle ② into batching bottle ①, and add in sequence under stirring conditions 0.03 part of 2-methylimidazole and 10 parts of nano-silicon dioxide were stirred evenly to prepare an epoxy resin composition for diffusion plate. Impregnated 1080 glass fiber cloth (basic weight 48g / m) with the epoxy resin composition for diffuser plate 2 ), and baked in a hot air circulating oven at 180° C. for 5 min to obtain a prepreg with a resin content of 71%.

[0052] (2) Preparation of diffuser plate

[0053] ...

Embodiment 3

[0055] (1) Preparation of prepreg

[0056] Add 3 parts of dicyandiamide and 30 parts of N,N-dimethylformamide into the batching bottle ① and stir to dissolve, then add 5 parts of polyethylene powder and 0.1 part of sodium pyrophosphate in sequence, and disperse at high speed for 0.5h; 60 parts of Add bisphenol A epoxy resin into batching bottle ②, add 5 parts of core-shell resin under stirring conditions, and after high-speed dispersion for 2 hours, add all the composition in batching bottle ② into batching bottle ①, and add in sequence under stirring conditions 0.03 part of 2-methylimidazole and 10 parts of nano-silicon dioxide were stirred evenly to prepare an epoxy resin composition for diffusion plate. Impregnated 1080 glass fiber cloth (basic weight 48g / m) with the epoxy resin composition for diffuser plate 2 ), and baked in a hot air circulating oven at 180° C. for 5 min to obtain a prepreg with a resin content of 70%.

[0057] (2) Preparation of diffuser plate

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com