Feed conveying mechanism for pulping and papermaking spectrum detection equipment

A technology of feeding conveying mechanism and spectral detection, which is applied to structural parts of electrical equipment, measurement of color/spectral characteristics, material analysis by optical means, etc. Improves the effect of the wind collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

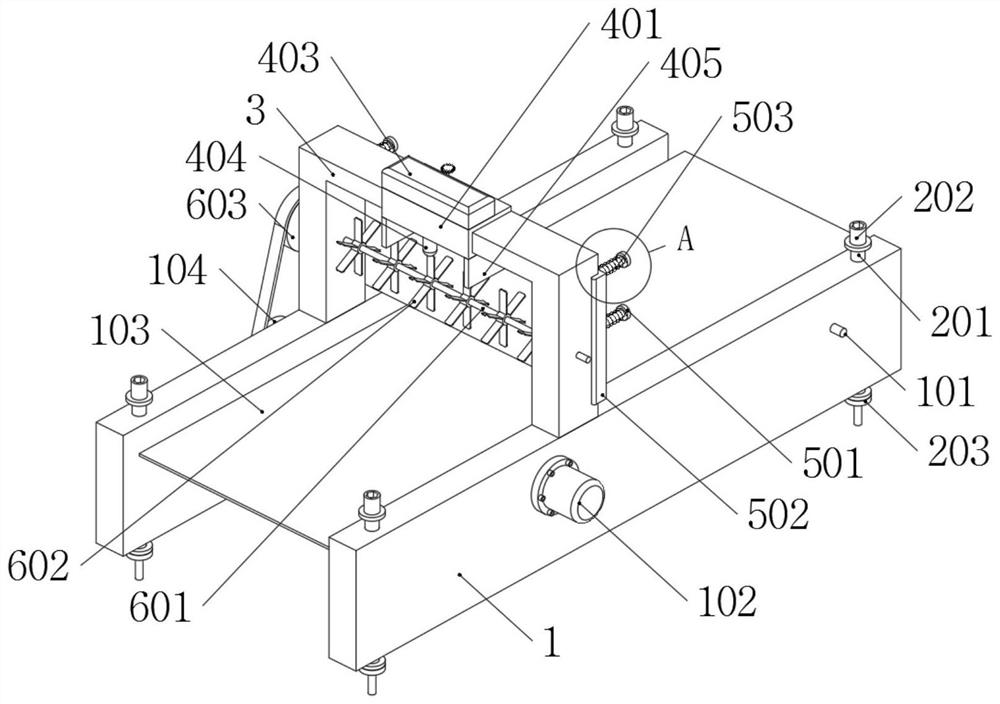

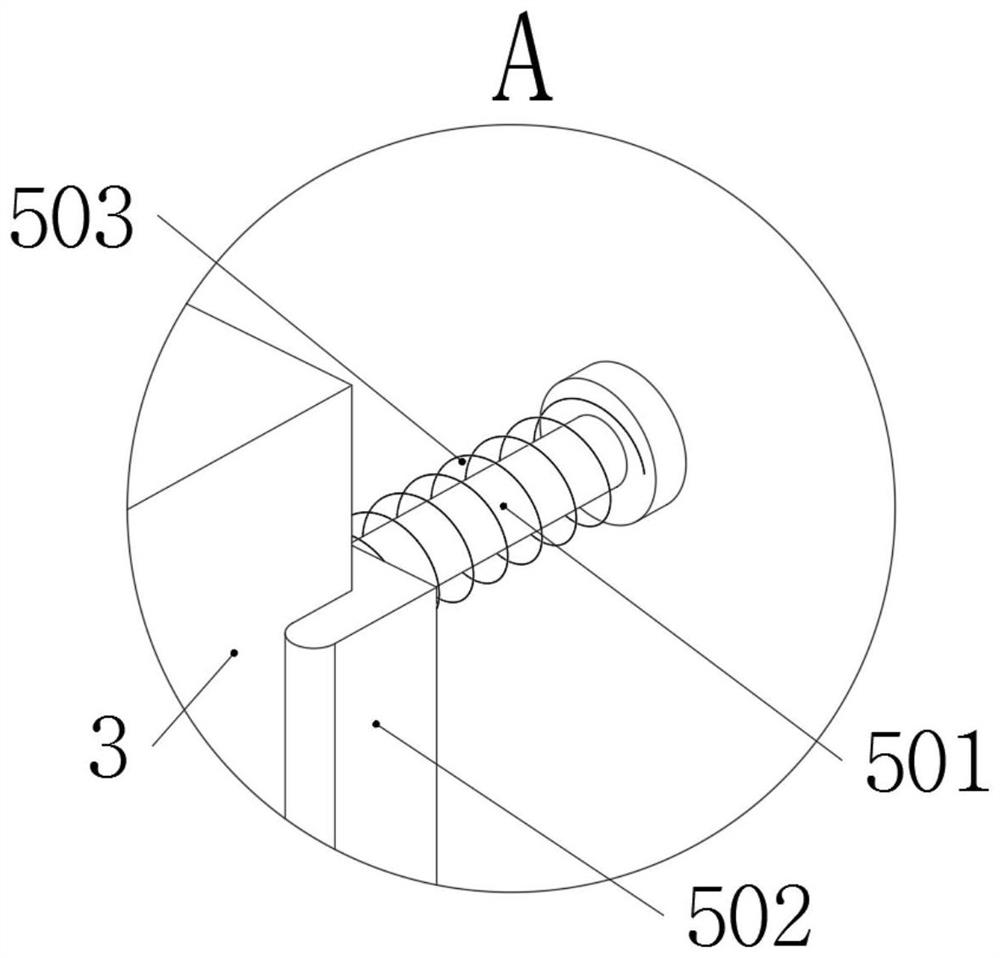

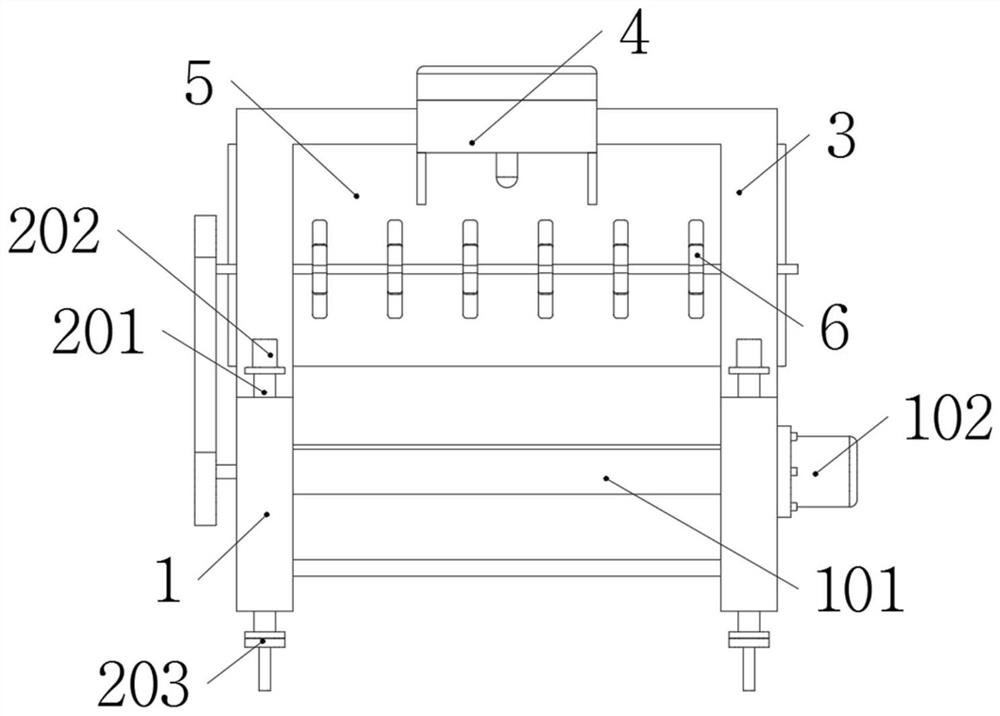

[0044] Example: Please refer to Figure 1 to Figure 8 :

[0045] The present invention proposes a feeding and conveying mechanism for pulping and papermaking spectrum detection equipment, including: an assembly line frame 1, a fixing part 2, a detection part 4, a second heat dissipation part 5 and a first heat dissipation part 6;

[0046] A roller shaft 101 is installed on the assembly line frame 1, and a pulley A104 is installed on the front roller shaft 101, and the frame body 3 is fixedly connected to the assembly line frame 1 by bolts; the drive motor is fixedly connected to the assembly line frame 1 by bolts 102, and the rotating shaft of drive motor 102 is connected with roller shaft 101;

[0047] The fixed part 2 is composed of a support seat 201, a fixing screw 202 and an auxiliary seat 203, and there are four support seats 201; the four support seats 201 are all threaded on the assembly line frame 1, and the four support seats 201 together form a The horizontal adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com