Antimony selenide thin film with one-dimensional chain crystal structure and method for improving hole concentration of antimony selenide thin film

A technology of crystal structure and hole concentration, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of n-type doping and low hole carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

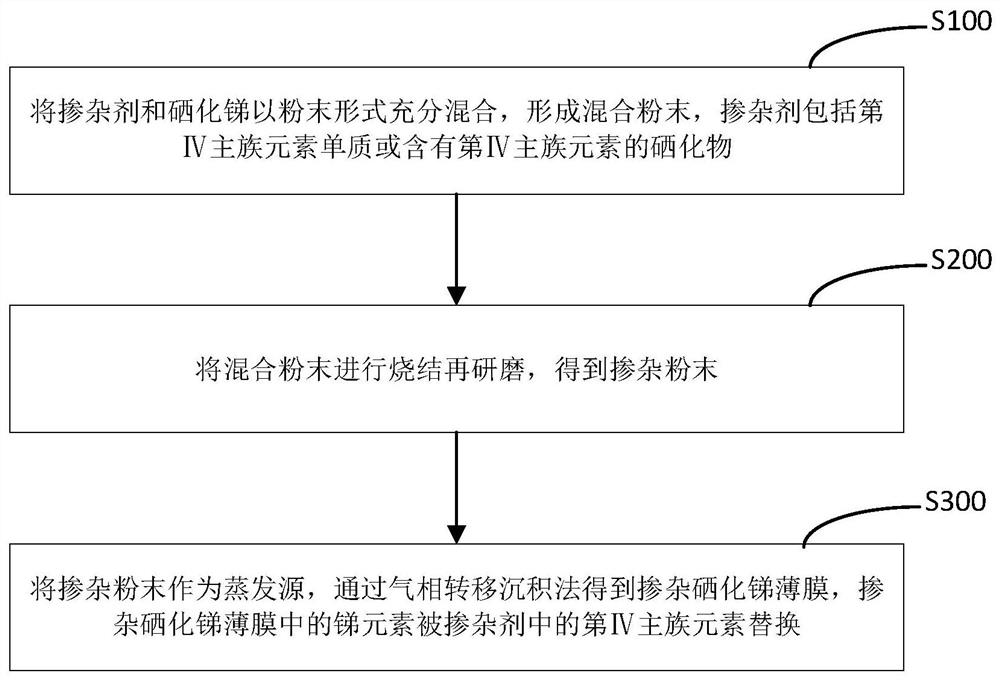

[0033] Such as figure 1 Shown is a flow chart of the steps of the method for improving the hole concentration of the antimony selenide film with a one-dimensional chain crystal structure, and the preparation method includes:

[0034] Step S100: Fully mix the dopant and antimony selenide in powder form to form a mixed powder, the dopant includes the element of the main group IV or the selenide containing the element of the main group IV.

[0035] In one embodiment, the dopant powder and the antimony selenide powder can be fully mixed in a certain molar ratio. Among them, the molar ratio of dopant powder and antimony selenide powder is not more than 1:100 to avoid the formation of alloy phase.

[0036] In an embodiment, the group IV element may include any one of carbon (C), silicon (Si), germanium (Ge), tin (Sn) and lead (Pb), preferably elemental Pb or compound PbSe.

[0037] Step S200: Sintering and grinding the mixed powder to obtain doped powder.

[0038] In one embodime...

Embodiment 1

[0054] In the first step, PbSe powder is mixed with Sb 2 Se 3 The powder is mixed evenly with a molar ratio of 1:100, put into a clean quartz tube, and a quartz column is filled at the sealing of the quartz tube, and the vacuum in the tube is lower than 10 -5 Pa, use a hydrogen-oxygen torch to vitrify the quartz tube by heating and stick to the inner quartz column to produce a sealed and isolated effect.

[0055] In the second step, put the sealed quartz tube into the muffle furnace, heat and fire it at 700°C for 10 hours, and take it out after it cools down naturally. Cut the quartz tube with a circular glass cutter, take out the sintered sample, put it into a clean mortar and grind it into powder.

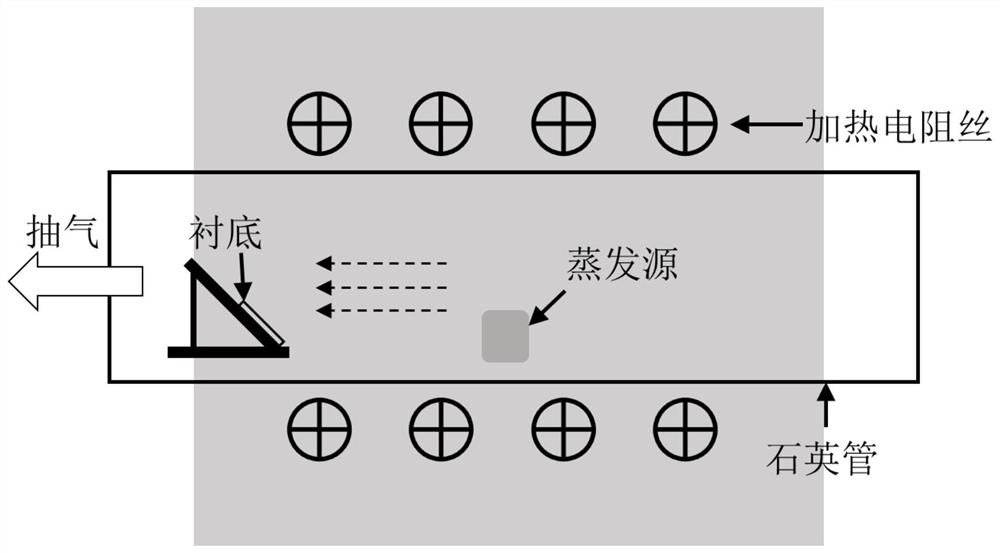

[0056] In the third step, take 0.25 g of ground powder, put it into a quartz crucible placed on a ceramic boat, and place the ceramic boat on figure 1 The center position (high temperature zone) of the single temperature zone tube furnace shown, place the graphite rack carryin...

Embodiment 2

[0060] Combine PbSe powder with Sb 2 Se 3 The molar ratio of powder is adjusted to be 1:1000, and other processing parameters are with embodiment 1, and the prepared doped antimony selenide film is carried out Hall test, and the results are shown in Table 2 and Figure 6 shown. in, Figure 6 is the current-voltage curve of antimony selenide thin film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com