Thermal desorption double-channel sample tube transfer system

A transfer system and sample tube technology, applied in the field of transfer of thermal desorption sample tubes, can solve problems such as shortened life, hard air, and damage to sample tube packing, and meet the requirements of reducing complex hardware, automation, intelligence, convenience, and analysis The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

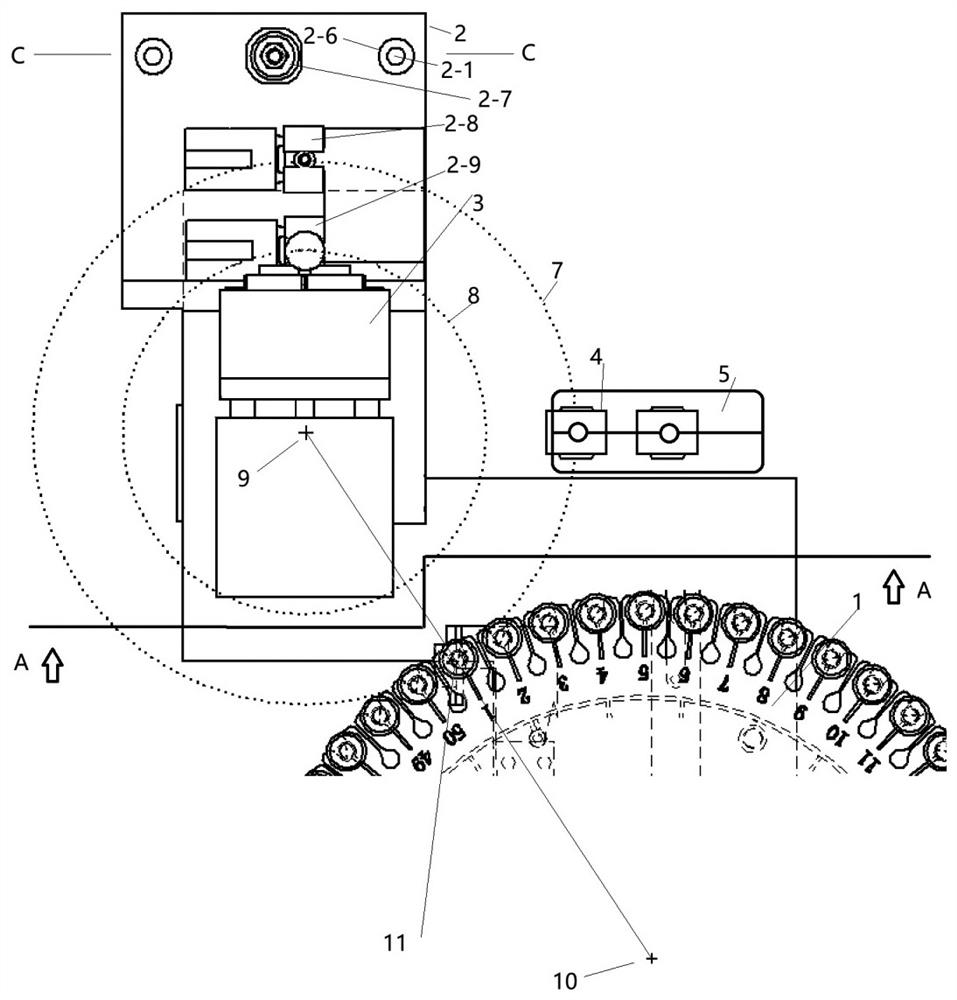

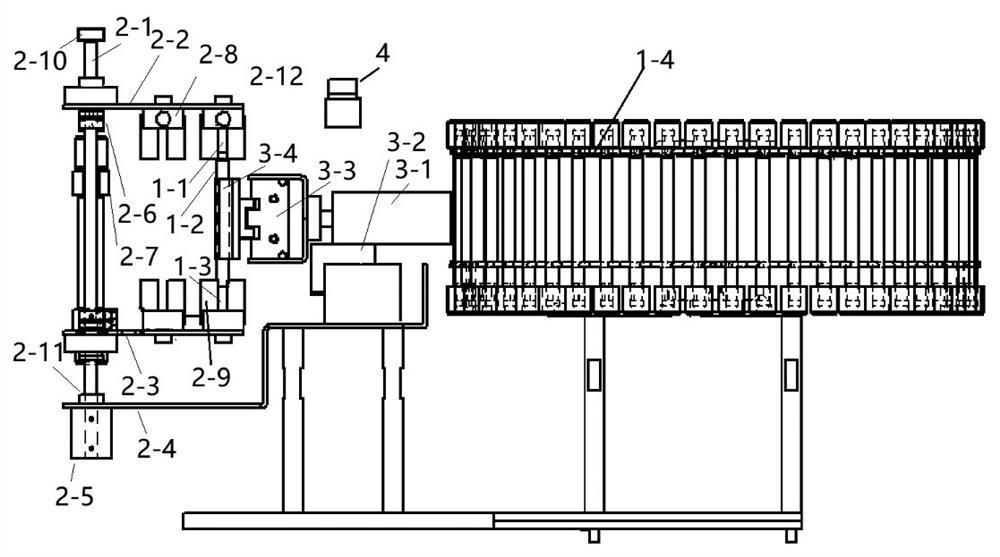

[0021] The sample plate is a disc with multiple clamps with clamping function, driven by a motor and controlled by a controller;

[0022] The manipulator is a device that is rotatable controlled by the controller, the manipulator arm is retractable, and a pipe clamp is installed at one end of the manipulator arm;

[0023] The hat-removing frame is mainly composed of two vertical slide rods, a driver and a limiter that can fix the cap-removing clamp up and down and move the cap-removing plate up and down

[0024] The lifting tube seat can move up and down and stay in the middle state, and can also move along the direction of the expansion and contraction of the mechanical arm at the interface position with the two connecting tube outlets;

[0025] For the structure of double sample tube heaters, see Patent No. ZL 2013 1 0023569.5, thermal desorption primary sample tube heater.

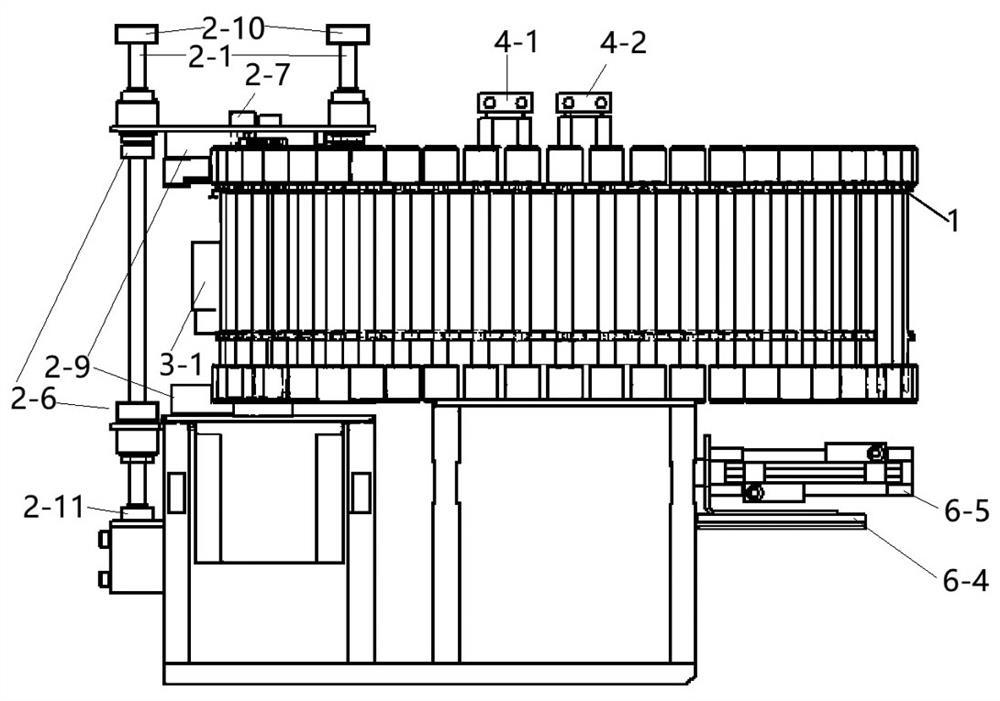

[0026] Thermal desorption dual-channel sample tube transfer system, one side of the sample tray 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com