External pressure type expansion joint with leakage monitoring function

An expansion joint and leakage detection technology, applied in the field of expansion joints, can solve problems such as early warning function of leakage, achieve the effect of improving service safety and reliability, and avoiding emergency shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

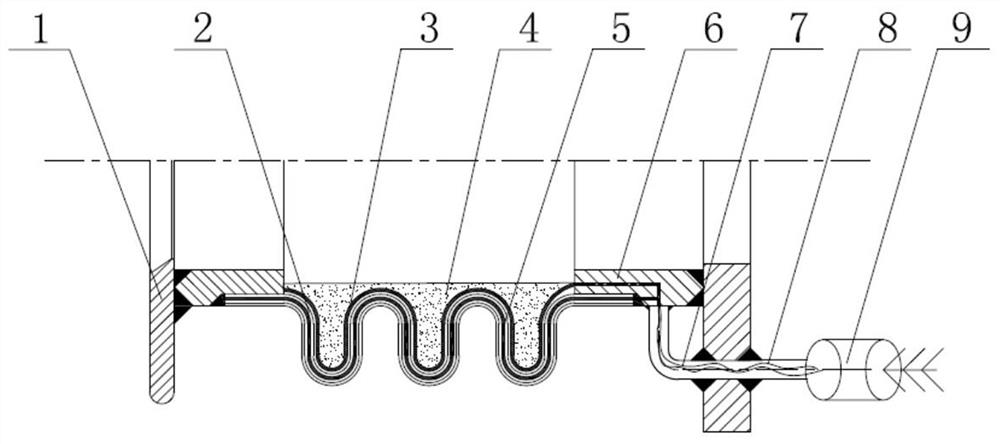

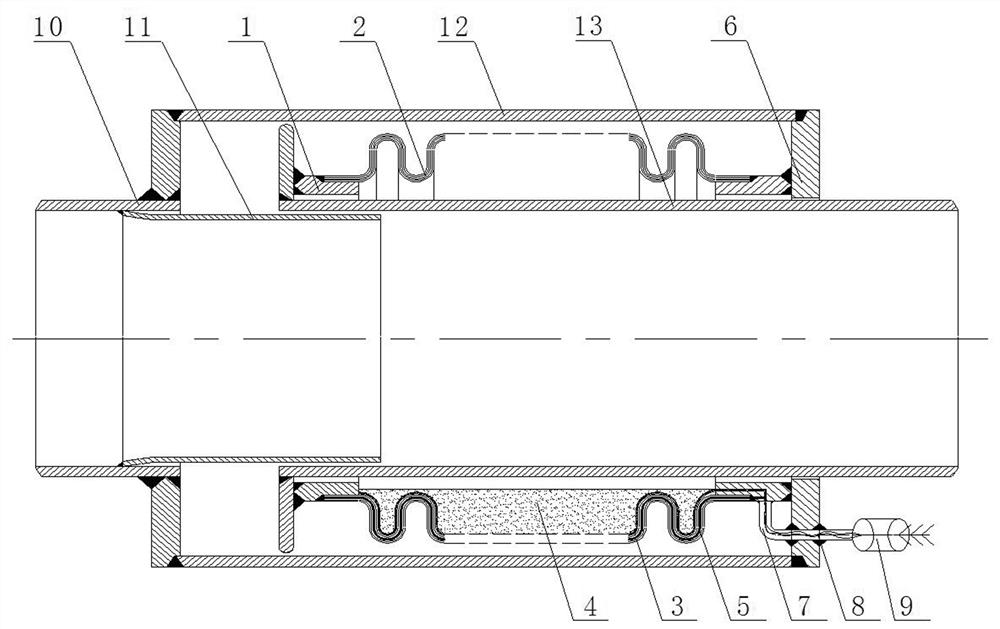

[0017] like figure 1 . As shown in 2, an external pressure expansion joint with leakage monitoring function includes an external pressure expansion joint and a leakage monitoring device. The external pressure expansion joint includes an inlet pipe 10, a guide tube 11, a bellows 2, Outer pipe 12 , outlet pipe 13 , outlet end ring 14 , end connection pipe 6 and limit ring 1 .

[0018] The leakage monitoring device is set at the lowest part of the innermost tube blank of the external pressure expansion joint bellows. The leakage monitoring device includes the outer leakage detection component and the middle detection component; this leakage monitoring device is also suitable for two or three sets of bellows connected in series. Happening.

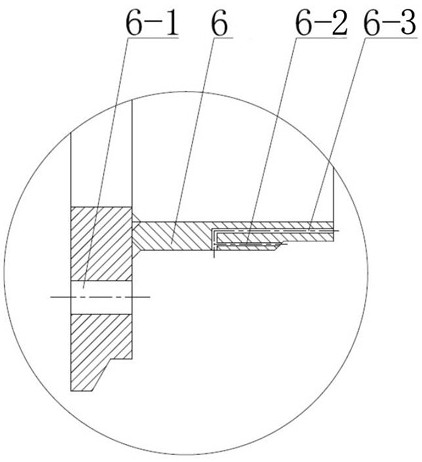

[0019] The outer leakage detection component is composed of a liquid detector 1 attached to the innermost inner wall of the bellows of the external pressure expansion joint and a sensor 1 arranged outside the external pressure expansion joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com