A kind of anticorrosion coating containing hatn@ graphene and preparation method thereof

A graphene and coating technology, applied in the field of anti-corrosion coating containing HATN@graphene and its preparation, can solve the problems such as the decrease of electrochemical protection ability of anti-corrosion coating, the reduction of graphene's electrical conductivity, and the inability to protect, and the The barrier range is continuous, the dispersion is improved, and the effect of electrochemical protection is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

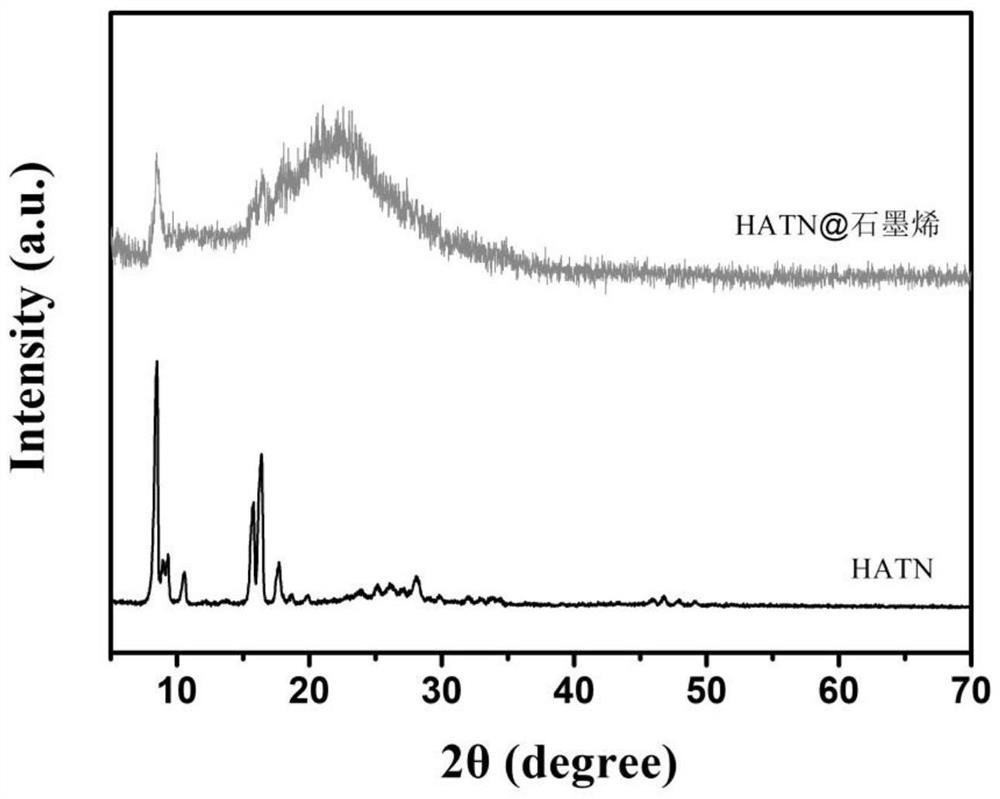

Image

Examples

Embodiment 1

[0039] Example 1: A HATN@graphene-containing anti-corrosion coating and its preparation method

[0040] The preparation method of the anti-corrosion coating containing HANT@graphene provided in this embodiment specifically includes the following steps:

[0041] Step 1, preparation of graphene oxide: at 0°C, slowly dissolve 2g of graphite and 1g of sodium nitrate in 46mL of concentrated sulfuric acid, slowly add 6g of potassium permanganate, and stir for 2 hours; Stir at 35°C for 2 hours, then raise the temperature to 95°C, slowly add 124mL of warm water and 30mL of 30% hydrogen peroxide to obtain a yellow solution without bubbles; use 5% hydrochloric acid and deionized water Repeated centrifugation and washing until the pH of the solution was neutral; finally dissolved in 100 mL of water, ultrasonicated for 3 hours, and freeze-dried to obtain graphene oxide powder.

[0042] Step 2. Preparation of HATN@graphene composite material: Take 200mg of graphene oxide powder and dissol...

Embodiment 2

[0045] Embodiment 2: A kind of anticorrosion coating containing HATN@graphene and its preparation method

[0046] The preparation method of the anti-corrosion coating containing HANT@graphene provided in this embodiment specifically includes the following steps:

[0047] The preparation method of the present invention comprises the steps:

[0048] Step 1, preparation of graphene oxide: at 0°C, slowly dissolve 2g of graphite and 1g of sodium nitrate in 46mL of concentrated sulfuric acid, slowly add 6g of potassium permanganate, and stir for 2 hours; Stir at 35°C for 2 hours, then raise the temperature to 95°C, slowly add 124mL of warm water and 30mL of 30% hydrogen peroxide to obtain a yellow solution without bubbles; use 5% hydrochloric acid and deionized water Repeated centrifugation and washing until the pH of the solution was neutral; finally dissolved in 100 mL of water, ultrasonicated for 3 hours, and freeze-dried to obtain graphene oxide powder.

[0049] Step 2. Prepar...

Embodiment 3

[0051] Embodiment 3: A kind of anticorrosion coating containing HATN@graphene and its preparation method

[0052] The preparation method of the anti-corrosion coating containing HANT@graphene provided in this embodiment specifically includes the following steps:

[0053] The preparation method of the present invention comprises the steps:

[0054] Step 1, preparation of graphene oxide: at 0°C, slowly dissolve 2g of graphite and 1g of sodium nitrate in 46mL of concentrated sulfuric acid, slowly add 6g of potassium permanganate, and stir for 2 hours; Stir at 35°C for 2 hours, then raise the temperature to 95°C, slowly add 124mL of warm water and 30mL of 30% hydrogen peroxide to obtain a yellow solution without bubbles; use 5% hydrochloric acid and deionized water Repeated centrifugation and washing until the pH of the solution was neutral; finally dissolved in 100 mL of water, ultrasonicated for 3 hours, and freeze-dried to obtain graphene oxide powder.

[0055] Step 2. Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com