Novel hub polishing and grinding device

A technology of polishing and grinding and wheel hubs, which is applied in the direction of grinding drive devices, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as high labor costs, low production efficiency, and harmful dust to human health, and achieve reasonable structural design , Improve production efficiency and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A new wheel hub polishing and grinding device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

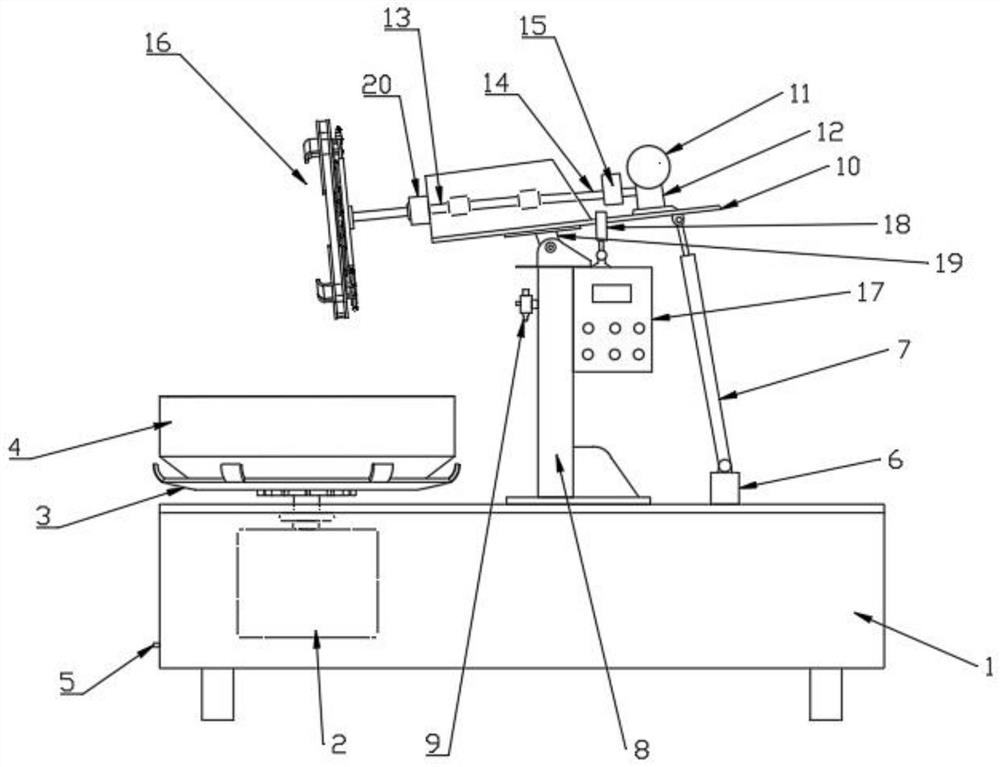

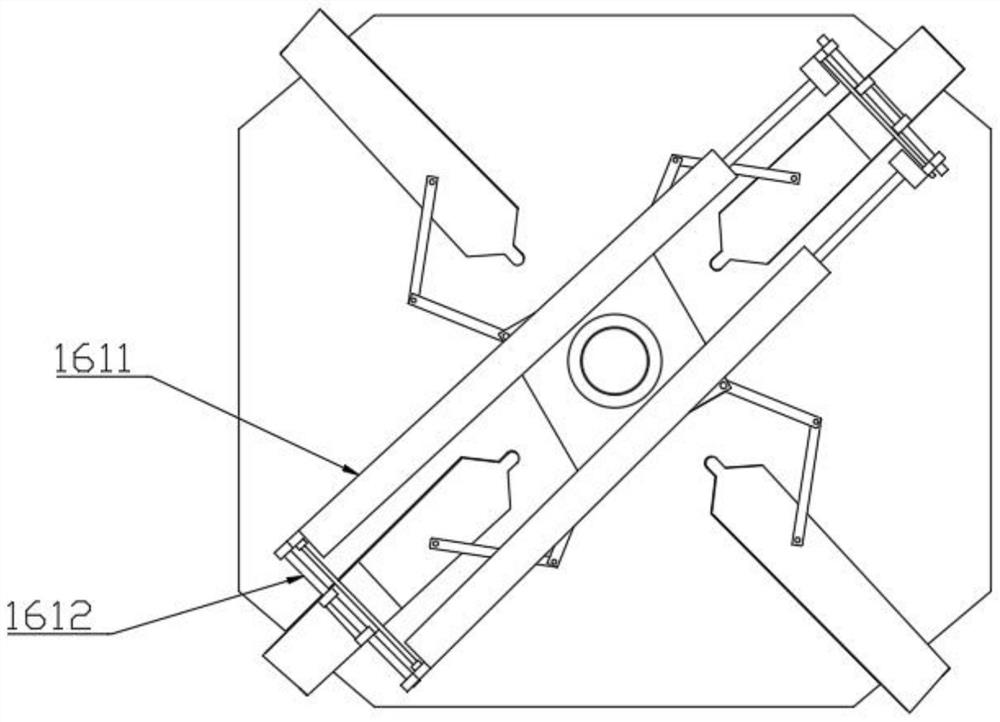

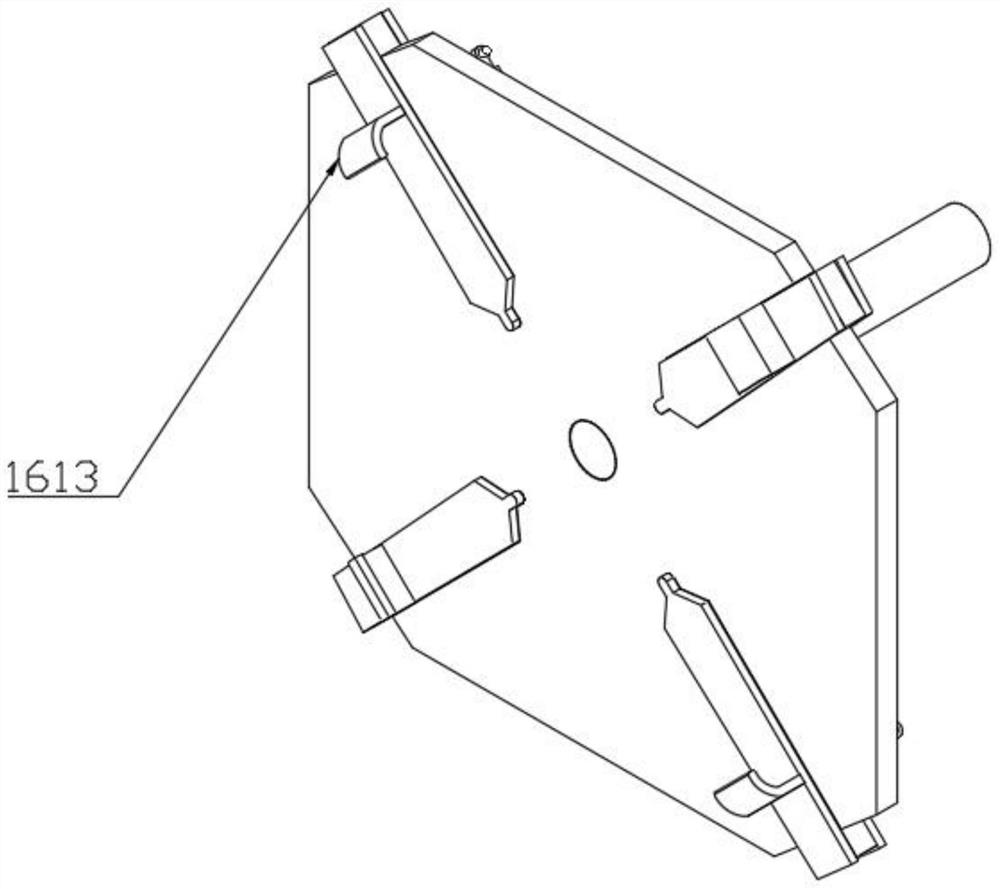

[0020] combined with figure 1 - attached Figure 5 , a new wheel hub polishing and grinding device, including a workbench 1, a silo motor 2, a silo support tray 3, a silo 4, a fixture control switch 5, an air support base 6, an air support 7, a gantry frame 8, and an air valve adjustment Device 9, mounting plate 10, motor 11, reducer 12, connecting rod 14, coupling 15, pneumatic four-claw clamping hub structure 16, control box 17 and warning light 18, the workbench 1 is equipped with a bin motor 2. The output shaft of the silo motor 2 is fixedly connected to the silo support tray 3, the silo support tray 3 is provided with a silo 4, and the workbench 1 is provided with an air support base 6 and a gantry 8. The gantry frame 8 is provided with an air valve regulator 9 and a control box 17, one end of the air st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com