Large-area single-layer semiconductor two-dimensional WS2 film material and preparation method and application thereof

A thin-film material, large-area technology, applied in the field of materials, can solve problems such as unfavorable commercial applications, increase experimental costs, pollution, etc., and achieve excellent light response speed, low cost, and good controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

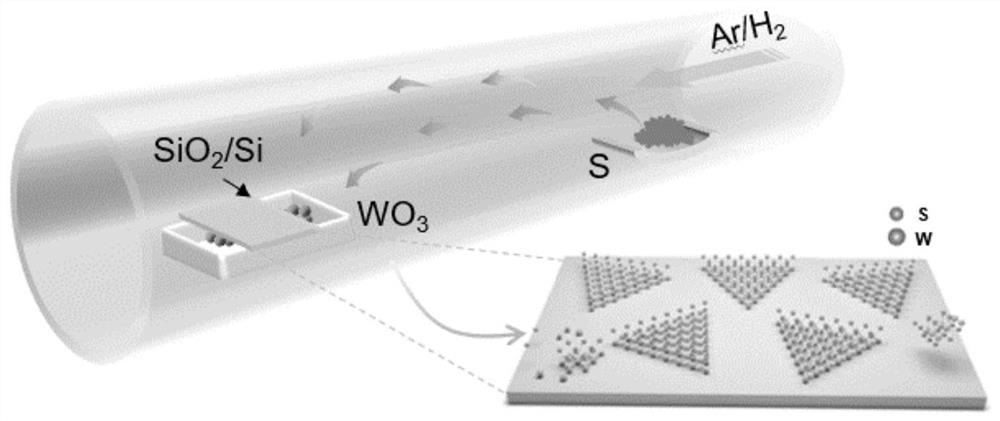

[0034] Preparation of large-area monolayer semiconductor two-dimensional WS 2 A method for thin film materials, comprising the steps of:

[0035] 1) Weigh 50mg WO 3 Placed in a ceramic boat in the center of a tube furnace in a quartz tube; place two silicon wafers with a thickness of 1*1cm and a silicon dioxide layer of 300nm upside down on the WO 3 On the ceramic boat; Take by weighing 100mg sulfur powder and place in the ceramic boat and be positioned at the position of 15cm away from the center of the upstream of the quartz tube;

[0036] 2) Pass into the argon gas of 300sccm in the tube furnace, the aeration time is 10min, to get rid of the air in the tube, after 10min, the argon flow rate is adjusted to 100sccm;

[0037] 3) Start heating, and after reaching the set growth temperature of 850°C, grow under this condition for 10 minutes; at this moment, the temperature corresponding to the sulfur powder is 200°C.

[0038] Stop heating, cool down to room temperature natura...

Embodiment 2

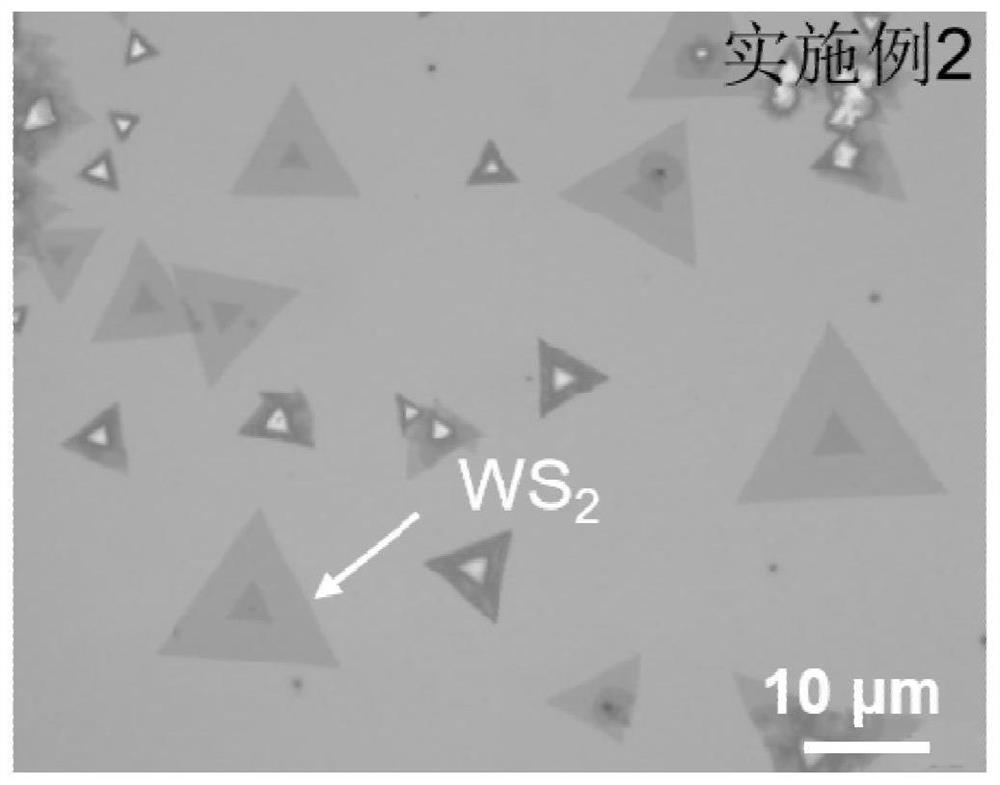

[0040] The difference from Example 1 is that step 3) is: first open the hydrogen valve, set the hydrogen flow rate to 20 sccm and start heating, and after reaching the set growth temperature of 850 ° C, grow under this condition for 10 min; at this moment, the sulfur powder corresponds to The temperature is 200° C., and other condition parameters are the same as in Example 1.

Embodiment 3

[0042] The difference from Example 1 is that step 3) is: start heating, and after reaching the set growth temperature of 850°C, open the hydrogen valve, set the hydrogen flow rate to 20 sccm, and grow for 10 minutes under this condition; at this moment, the temperature corresponding to the sulfur powder is 200°C, other condition parameters are the same as in Example 1.

[0043] For the large-area single-layer semiconductor two-dimensional WS prepared in the above examples 2 Morphological and structural characterization of thin film materials:

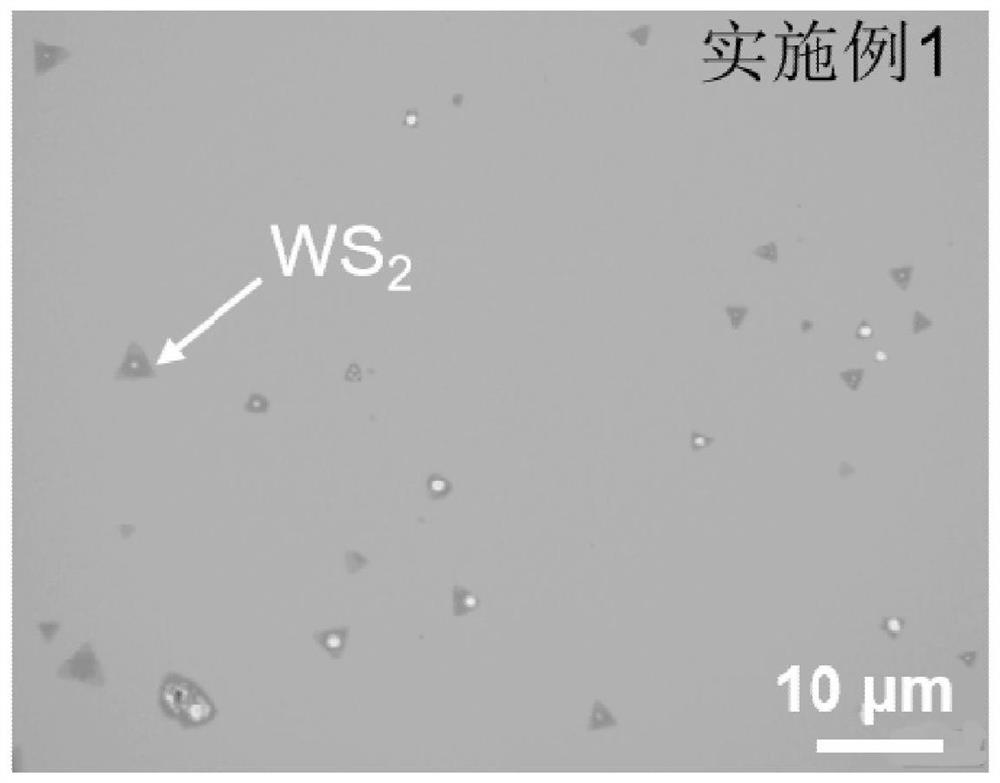

[0044] 1. Reference figure 2 , image 3 and Figure 4 Respectively, WS grown without feeding hydrogen, continuously feeding hydrogen and feeding hydrogen after reaching the preset temperature during the growth process 2 Comparison of the optical microscope photos, the microscope model is BX51 produced by Olympus Corporation. It can be seen from the figure that when no hydrogen is introduced, the samples are scattered on the silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com