Welding flux, preparation method and application thereof, welding method and ceramic component

A welding method and solder technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of poor processing performance, low impact toughness, limiting the production and application of ceramic components and complex components, etc. Achieving good wetting effect and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

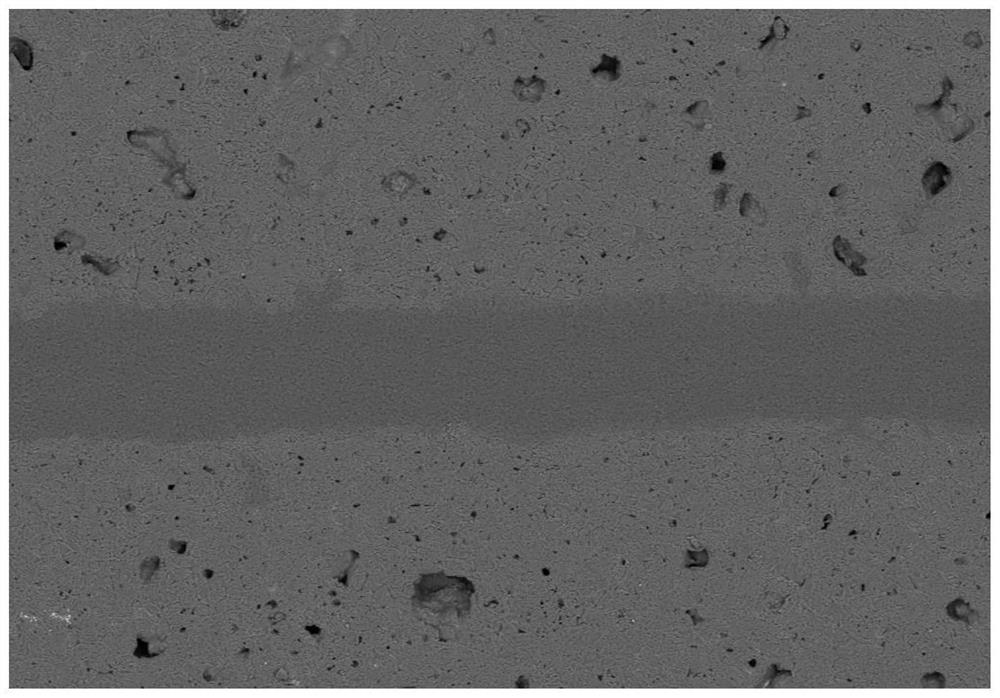

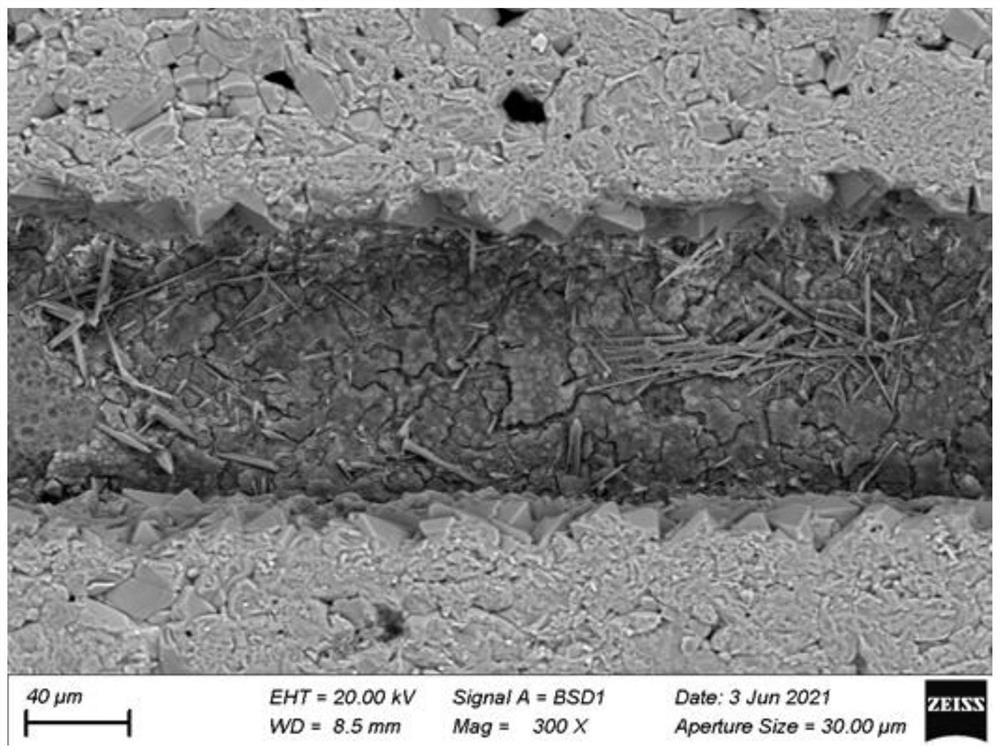

Image

Examples

preparation example Construction

[0060] Correspondingly, the present application also provides a preparation method of the above-mentioned solder, which includes the following steps: mixing the main components according to the proportion to obtain powdered solder.

[0061] Preferably, a three-dimensional mixer is used to mix the above main components. For reference, the mixing time may be 1.5-3h, such as 1.5h, 2h, 2.5h or 3h, etc., preferably 2h.

[0062] It is worth noting that the three-dimensional mixer used in this application is based on the targeted setting of the main components used. Among the main components used in this application, some components have a light specific gravity, and some components have a heavy specific gravity. When mixing, there will be heavy sinking and light The phenomenon of floating, the use of ordinary stirring methods (even if it is accompanied by stirring during the mixing process) will lead to uneven mixing of materials and stratification; and the three-dimensional mixer u...

Embodiment 1

[0097] This embodiment provides a method for Al 2 o 3 Solder for ceramic connections, the composition of which is: 10wt% SiO 2 Powder, 45wt% B 2 o 3 powder, 20wt% Al 2 o 3 powder and 25wt% MgO powder.

[0098] Among them, SiO 2 The purity of the powder is analytically pure, and its properties are colorless fine crystalline particles or white powder; B 2 o 3 Powder purity is analytically pure; Al 2 o 3 The purity of the powder is analytically pure, and its properties are white powder; the purity of MgO powder is analytically pure, and its properties are white fine powder.

[0099] The preparation method of above-mentioned solder and utilize above-mentioned solder to realize Al 2 o 3 The method of ceramic joining includes the following steps:

[0100] 1) Weigh SiO by mass percentage 2 Powder, B 2 o 3 Powder, Al 2 o 3 Powder and MgO powder were mixed for 2 hours using a three-dimensional mixer to prepare powdered solder;

[0101] 2) Mix powder solder with deion...

Embodiment 2

[0108] This embodiment is roughly the same as Embodiment 1, except that the temperature is raised to 1175° C. in step 6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weld width | aaaaa | aaaaa |

| Weld width | aaaaa | aaaaa |

| Weld width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com