Method and textile machine for automatically setting and maintaining a defined distance between a rotatably mounted cylinder and a further component

A textile machine, automatic adjustment technology, applied to the textile machine. It can solve problems such as collision, adjustment of inaccurate carding gap, and influence on yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

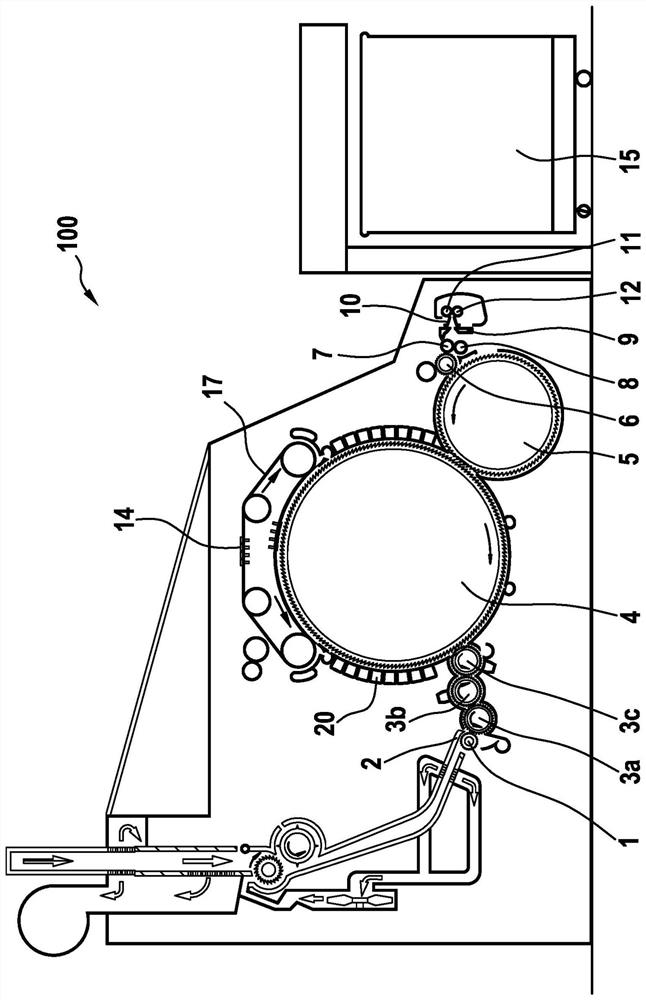

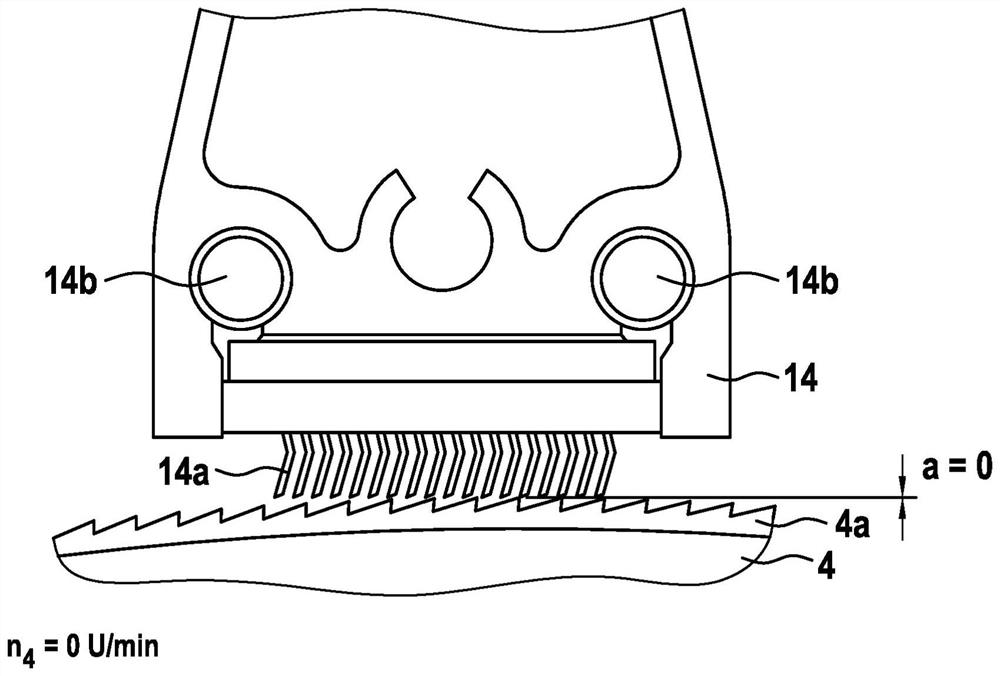

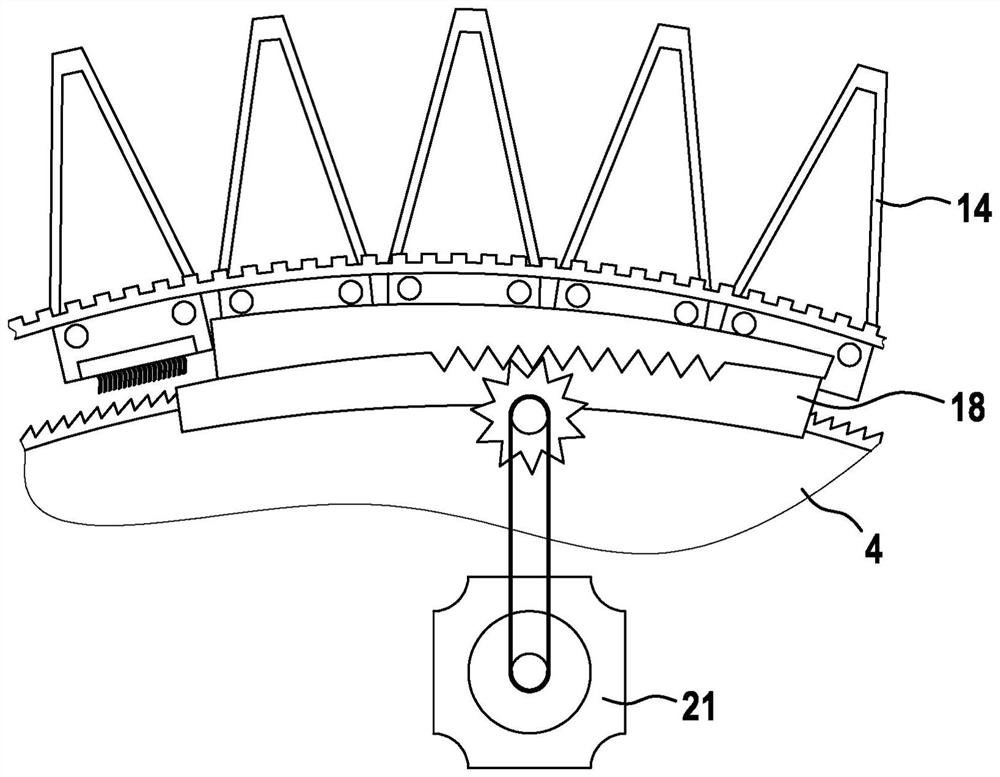

[0044] figure 1 Shows a card 100 according to the prior art in which loose fibers are guided via a shaft to a feed roller 1, a feed plate 2, via a plurality of licker-in rollers 3a, 3b, 3c to a cylinder 4 or drum . On the cylinder 4, by means of the fixed carding element 20, the suction hood and the chopping knife and by means of the surrounding carding element configured as a flat strip 14 arranged on the revolving flat system 17, the loose fiber The fibers are parallel and cleaned. The resulting fibrous web is then transported via a doffer 5, a stripping roller 6 and a plurality of squeeze rollers 7, 8 to a web guiding element 9 which deforms the fibrous web into fibers using a bell mouth 10 The slivers are transported by means of take-off rolls 11, 12 to downstream processors or cans 15. The adjustment of the flat strip 14 and the stationary carding elements 20 relative to the cylinder 4 (carding gap) takes place via a sliding strip ( 18 ) not shown here with wedge-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com