A kind of cohesion beam to buckle equipment

A technology of equipment and mounting plate, applied in the field of clasping beam pairing equipment, can solve the problems of large manual labor, low production efficiency, increased labor intensity, etc., and achieve the effects of good production efficiency, improved production efficiency, and reduced labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

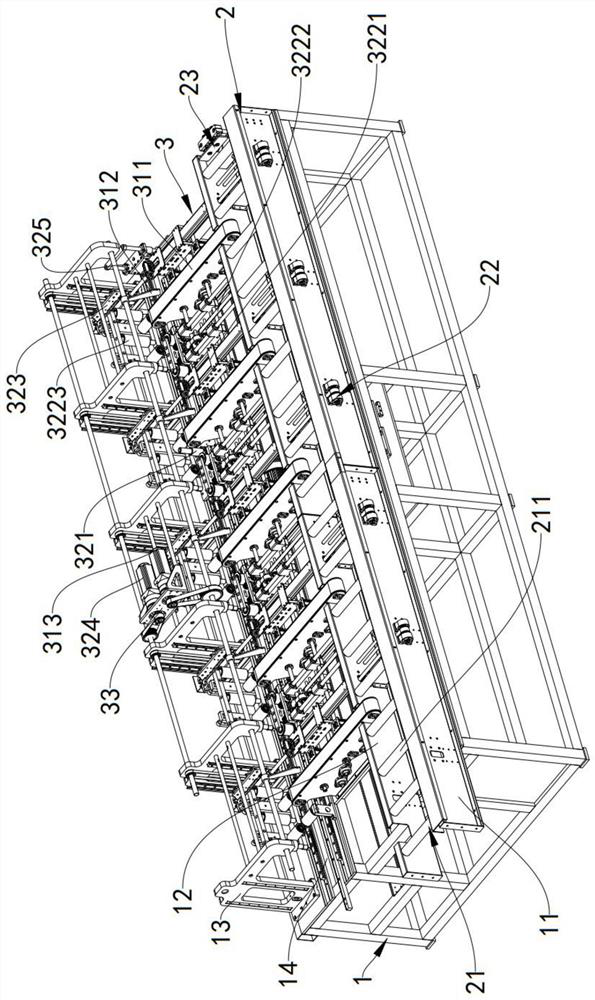

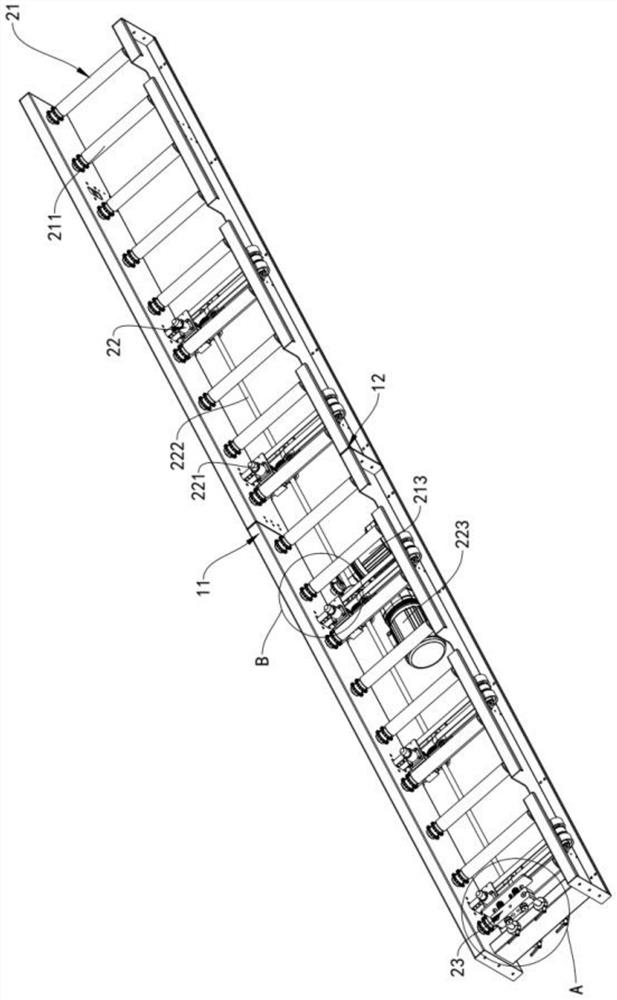

[0045] like Figures 1 to 14 As shown, an embracing beam buckling device includes a frame 1, a feeding device 2 fixed on the frame 1, and a buckle device 3 fixed on the frame 1; There are a first mounting plate 11 and a second mounting plate 12 that are parallel to each other; the feeding device 2 is embedded in the first mounting plate 11 and the second mounting plate 12; the rack 1 is also provided with a plurality of A third mounting plate 13 is fixed on the rack 1 at equal distances, and the rack 1 is provided with a discharge slot 14 on the inner side of the third mounting plate 13; the feeding device 2 includes a feeding mechanism 21 and push-out mechanism 22; the buckling device 3 includes a buckling mechanism 31 and an alignment mechanism 32;

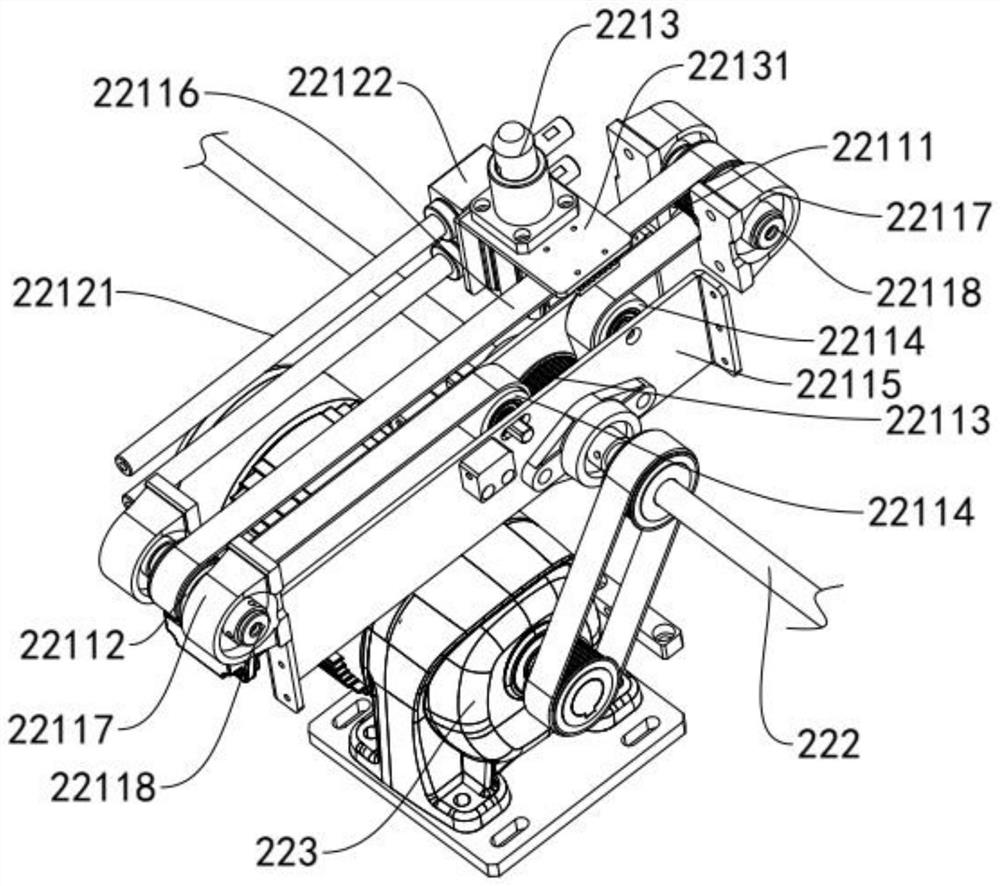

[0046] The feeding mechanism 21 includes a plurality of feeding conveying rollers 211 equidistantly arranged between the first mounting plate 11 and the second mounting plate 12; a push-out assembly 221 between the mounting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com