Solid tire and manufacturing process thereof

A technology of solid tires and manufacturing process, applied to tire parts, tires, non-pneumatic tires, etc., can solve problems that affect driving safety, safety hazards, easy to fall off the wheel hub, etc., and achieve the effect of ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object and technical solutions of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

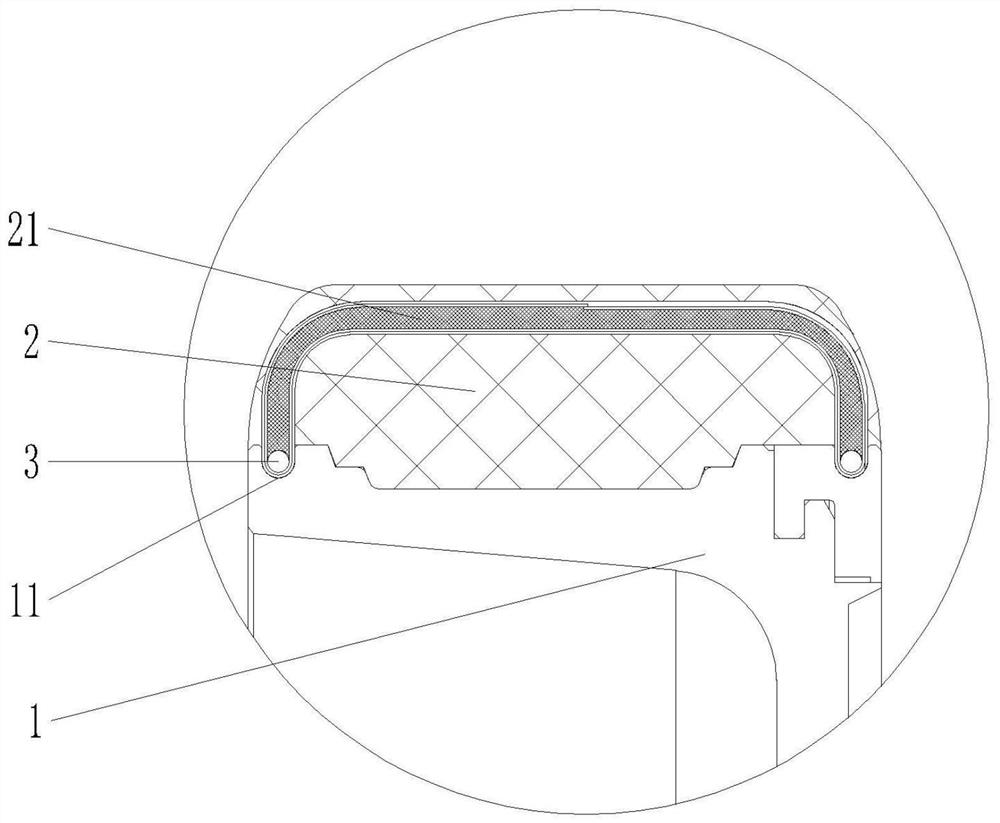

[0023] Such as figure 1 A solid tire shown as a solid tire comprises: a wheel hub 1 with fixing grooves 11 on both sides of the surface of the wheel hub 1; a solid tire carcass 2 installed and fixed on the wheel hub 1; the solid tire tire There is one or several layers of cord fabrics 21 inside the body 2; the steel ring 3 is arranged inside the solid tire carcass 2, presses one or several layers of the cord fabrics 21 and is tightly hooped in the fixing groove 11.

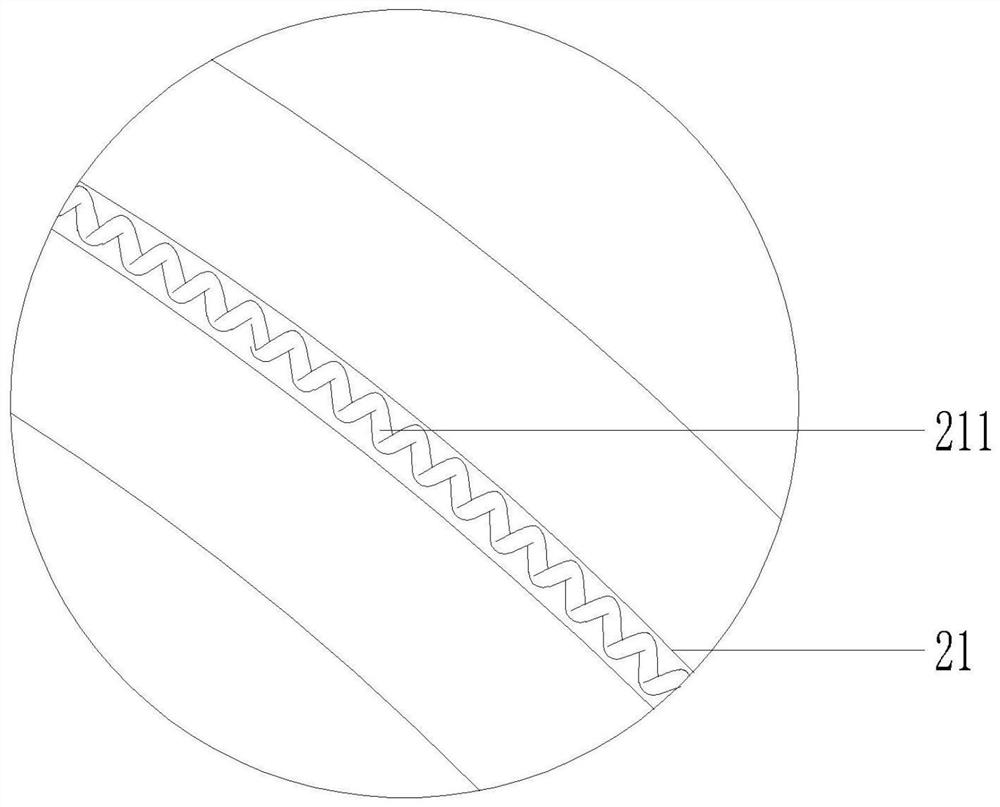

[0024] Preferably, the cords in the cord fabric 21 are arranged obliquely relative to the wheel axis (not shown in the figure), so that the cord fabric has certain elasticity.

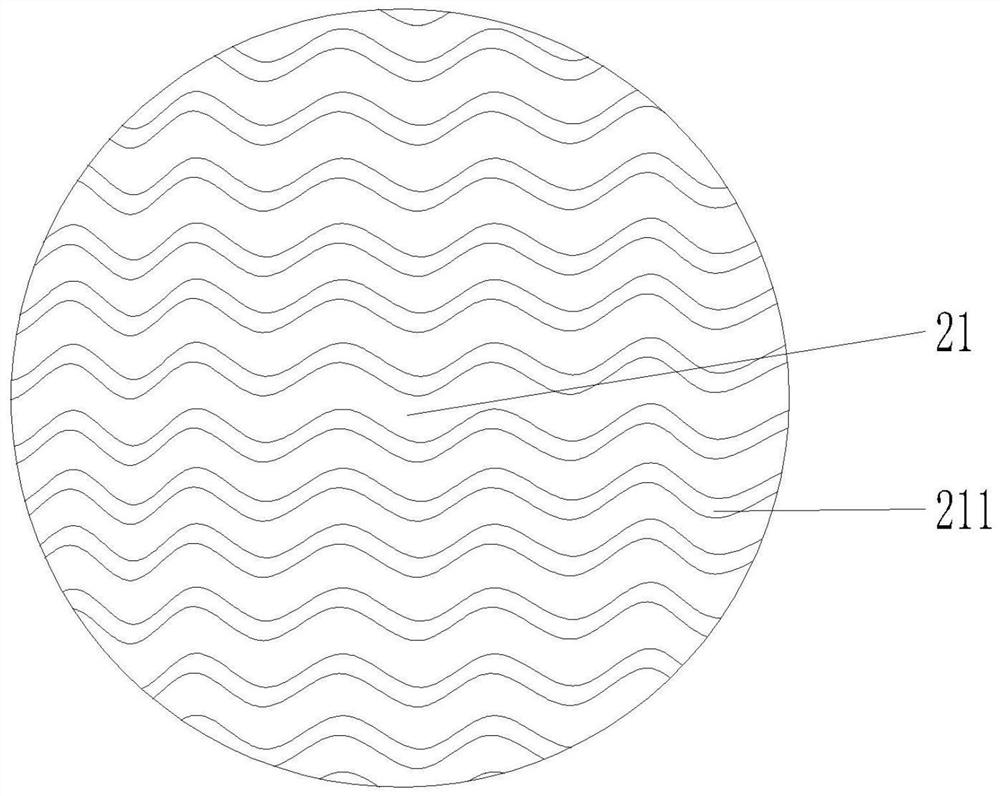

[0025] preferred, such as figure 2 As shown, the cords 211 in the cord fabric 21 are arranged in a wave shape, so that the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com