Box opening system with height rapid adjusting function and box opening method thereof

A height-adjusting and fast technology, applied in the manufacture of rigid/semi-rigid containers, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of high work intensity, long stroke, unstable movement, etc. Easy to grab, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

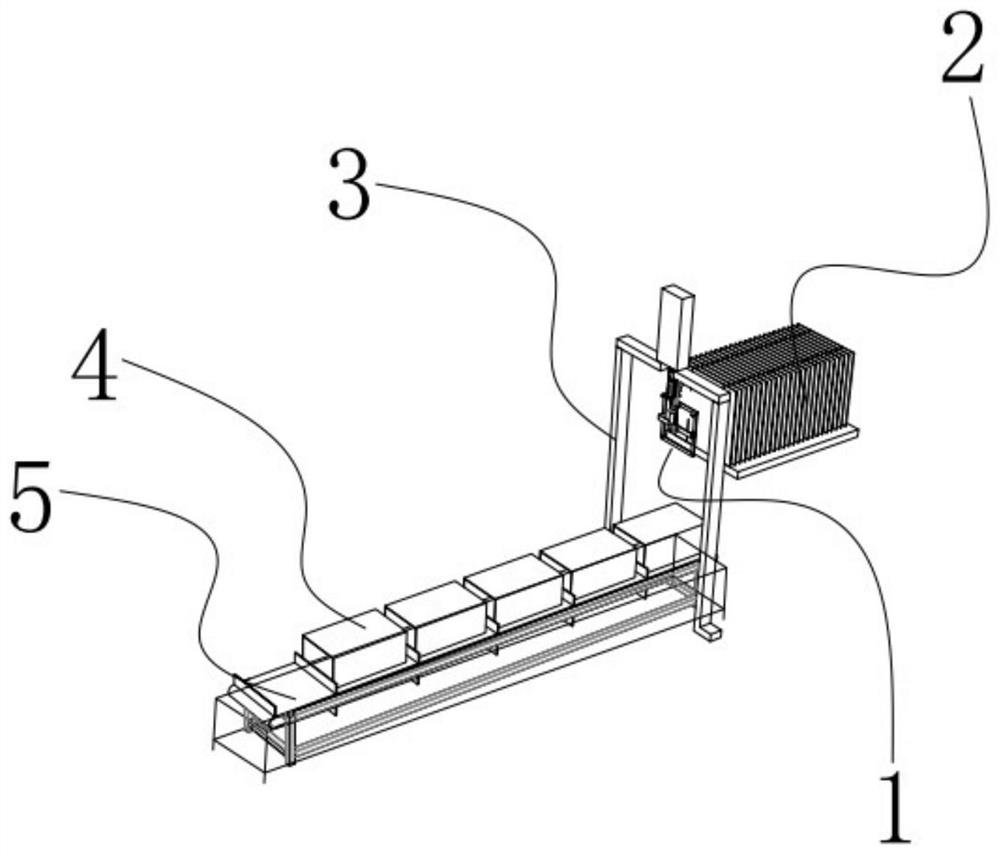

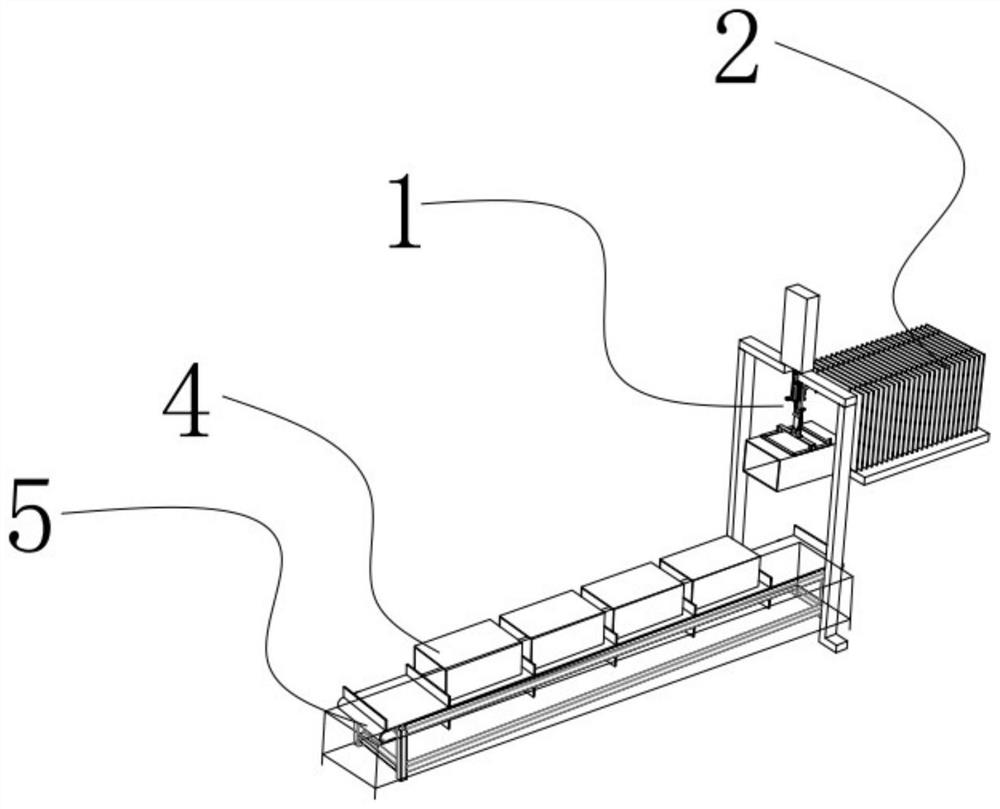

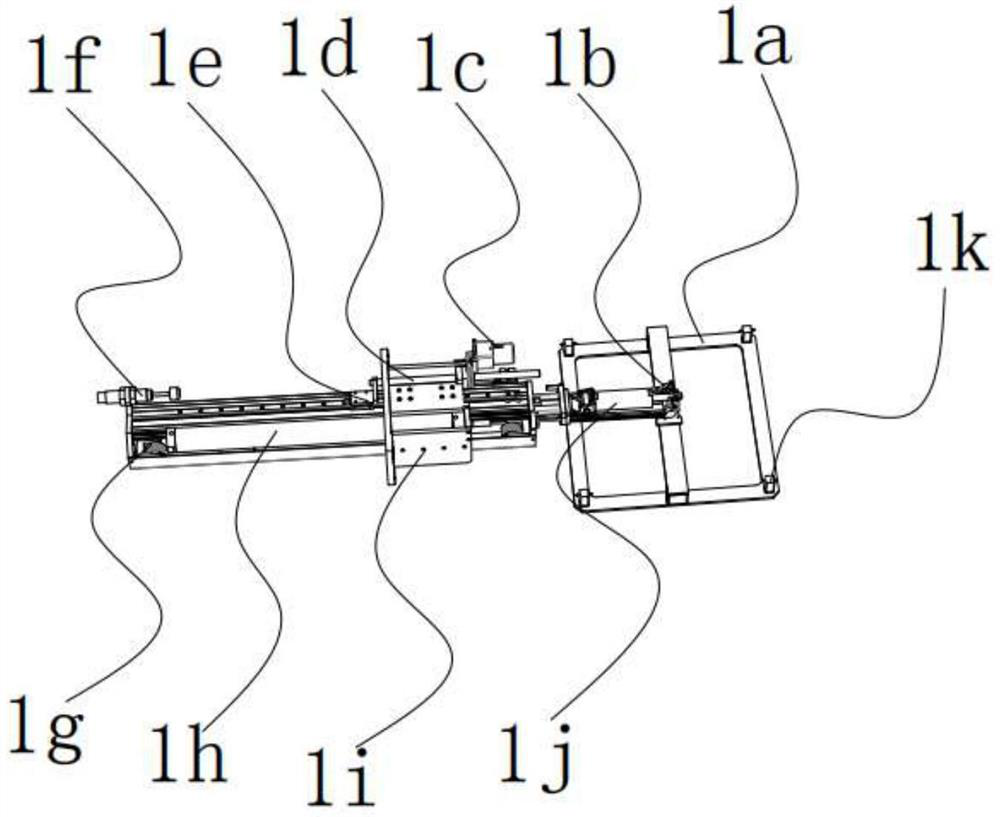

[0036] This embodiment provides a quick height adjustment unpacking system 1. In practical applications, as shown in the figure, the quick height adjustment unpacking system 1 includes a first power assembly, an adjustment assembly, a second power assembly and a turning components;

[0037] Wherein the first power assembly includes a first power module, a first moving plate 1n connected to the first power module, and a first guide component connected to the first moving plate 1n, wherein the first power assembly is a first cylinder 1h, The first guide component is the first linear guide rail 11, and the first power assembly is used to adjust the unpacking height; the adjustment assembly is arranged on one side of the first power assembly, includes a second power module, and is connected with the second power module The transmission part, and the limit block 1e connected with the transmission part, wherein the limit block 1e is arranged above the first guide part, wherein the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com