Low-dielectric high-insulating-strength polyimide film and preparation method thereof

A polyimide film, high dielectric strength technology, applied in the field of polyimide materials, can solve problems such as dielectric performance improvement, and achieve the effect of narrowing the layer spacing and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

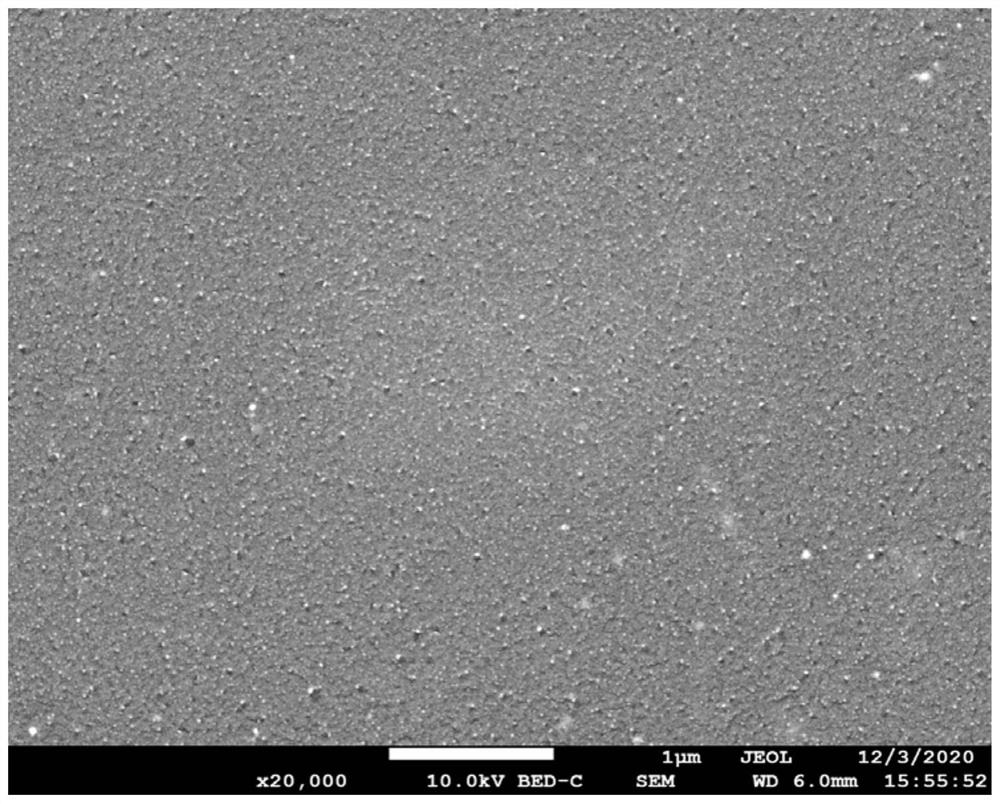

Embodiment 1

[0049] 1) In a nitrogen atmosphere, control the temperature of the synthesis system at 12°C, add 640.00kg N,N'-dimethylacetamide (DMAC) to the reactor, and then add 50.837kg 3,4'-diaminodiphenyl ether ( 3,4'-ODA), after stirring and dissolving, add dianhydride 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA, 29.878kg, added in 4 times), 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride (BPADA, 79.285kg, added in 8 times), stirred for 36h, Obtain a polyamic acid resin solution with a solid content of 20 wt% (solid content in the solution (abbreviated as M, the same below)=160.0kg);

[0050] 2) keep polyamic acid resin solution 15 ℃, add silver nitrate dispersion liquid (silver nitrate concentration is 12wt%), aluminum nitrate dispersion liquid (aluminum nitrate concentration is 8wt%) wherein, the add-on of described silver nitrate dispersion liquid is Control the add-on of silver nitrate to be 2.5wt% of polyamic acid resin solution solid content, the add-on of d...

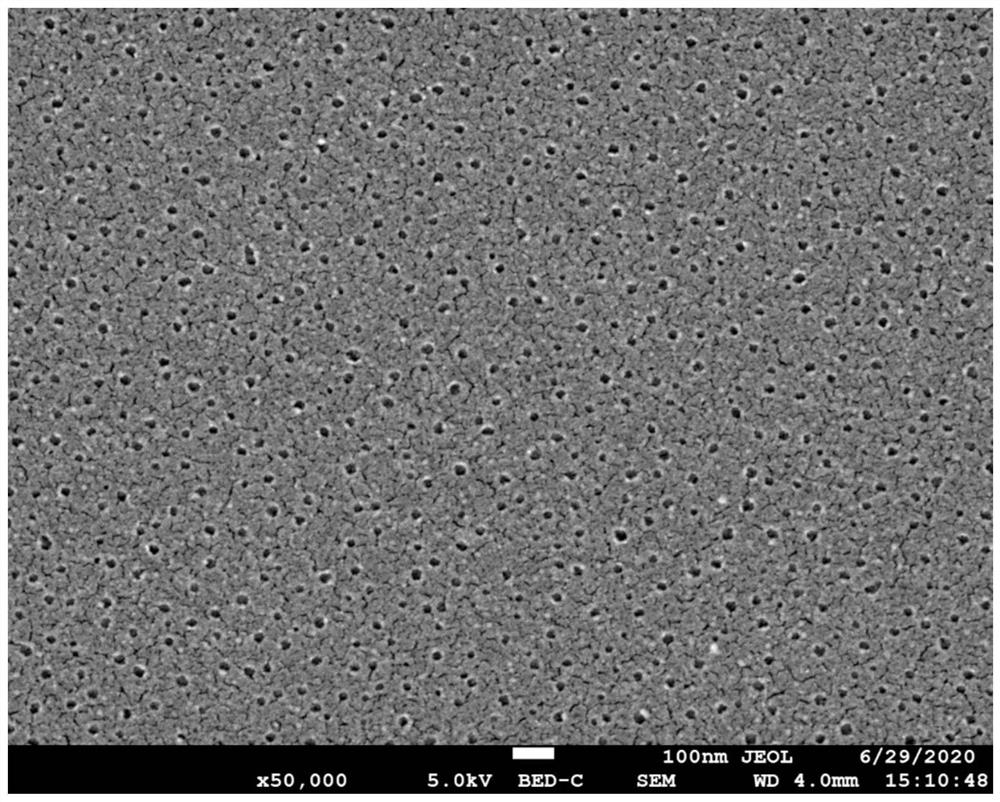

Embodiment 2

[0070] The difference between this embodiment and Example 1 is that in step 2), the addition of the silver nitrate dispersion is to control the addition of silver nitrate to be 10.0wt% of the solid content of the polyamic acid resin solution; The added amount is to control the added amount of aluminum nitrate to be 5.0wt% of the solid content of the polyamic acid resin solution. Bubbles are uniformly distributed inside the obtained film, and holes are formed on the surface of the film.

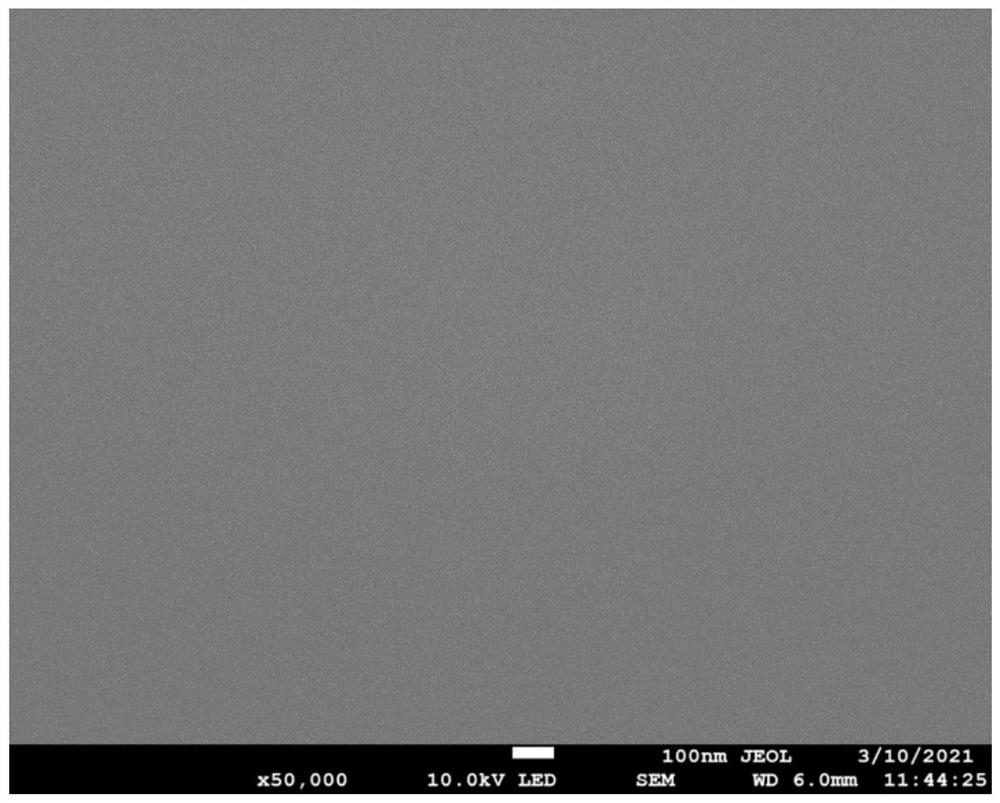

Embodiment 3

[0072] The difference between this embodiment and Example 1 is that in step 2), the addition of the silver nitrate dispersion is to control the addition of silver nitrate to be 0.1wt% of the solid content of the polyamic acid resin solution; The added amount is to control the added amount of aluminum nitrate to be 1.0 wt% of the solid content of the polyamic acid resin solution. Bubbles are uniformly distributed inside the obtained film, and holes are formed on the surface of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com