Colored porous ceramic atomizing core and preparation method thereof

A porous ceramic and atomizing core technology, applied in the field of ceramics, can solve the problem of single color of the ceramic atomizing core, and achieve the effect of reducing the added amount, optimizing the pore structure, and improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

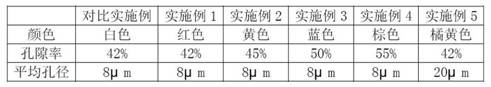

Examples

preparation example Construction

[0047] The preparation method of described colored sintering aid comprises the following steps:

[0048] (1) According to the sintering temperature and required color of the porous ceramic atomizing core, select the corresponding ceramic sintering agent and ceramic pigment powder as raw materials;

[0049] (2) Weigh the ceramic sintering agent and ceramic pigment powder according to the above weight percentage, put them in a ball mill, the weight ratio of the material to the ball is 1:2, use absolute ethanol as the wet medium, and after wet ball milling for 24 to 36 hours, at 80 Dry at ℃ and sieve to obtain a uniformly mixed colored sintering aid raw material mixed powder;

[0050] (3) Dry press the mixed powder of colored sintering aid raw materials obtained in step (2) under a pressure of 200 MPa, and heat-treat it in a high-temperature furnace for melting or semi-melting. , and then naturally cooled to obtain a sintering aid block; through briquetting and sintering, the ce...

Embodiment 1

[0070] (1) Select low-temperature glass powder with a melting temperature of 650°C as a ceramic sintering agent, such as red environmental protection inorganic non-metallic mineral pigments with a resistance of more than 700°C according to the weight ratio of 98% and 2%, as red ceramic sintering aids raw material;

[0071] (2) Put the red sintering aid raw material powder weighed above in a ball mill, the weight ratio of the material to the ball is 1:2, use absolute ethanol as the wet medium, and after wet ball milling for 25 hours, dry it at 80°C and dry it. Sieve to obtain evenly mixed red sintering aid raw material mixed powder;

[0072] (3) The above-mentioned red sintering aid raw material mixed powder was dry-pressed at a pressure of 200 MPa, kept in a heat treatment furnace at 650°C for 3 hours, and then naturally cooled to obtain a red sintering aid block;

[0073] (4) Crushing and grinding the red sintering aid block obtained from the above heat treatment to make a r...

Embodiment 2

[0078] (1) Select low-temperature glass powder with a melting temperature of 550°C as the ceramic sintering agent and a yellow environmental protection inorganic non-metallic mineral pigment resistant to 600°C and weigh them according to the weight ratio of 97% and 3%, and use them as yellow porous ceramic atomizing cores for sintering raw materials for additives;

[0079] (2) Put the yellow sintering aid raw material powder weighed above in a ball mill, the weight ratio of the material to the ball is 1:2, use absolute ethanol as the wet medium, and after wet ball milling for 25 hours, dry it at 80°C and dry it. Sieve to obtain uniformly mixed yellow sintering aid raw material mixed powder;

[0080] (3) The above-mentioned yellow sintering aid raw material mixed powder was dry-pressed at a pressure of 200 MPa, kept in a heat treatment furnace at 550°C for 3 hours, and then naturally cooled to obtain a yellow sintering aid block;

[0081] (4) Crushing and grinding the yellow s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com