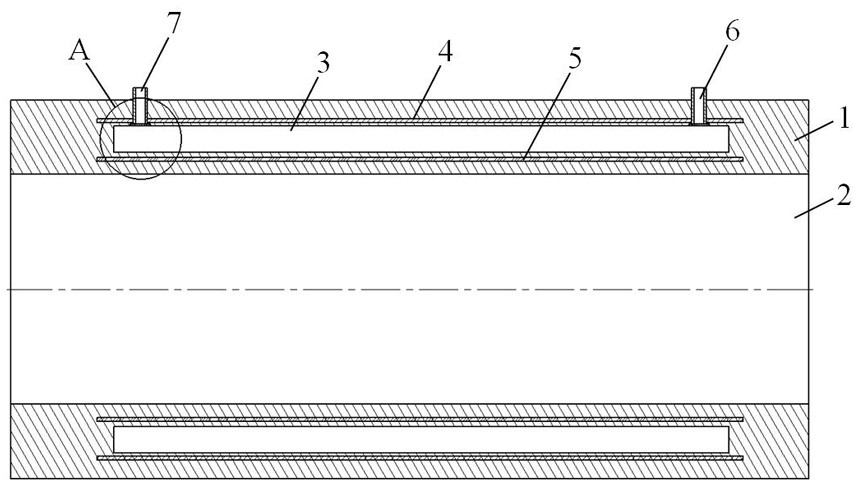

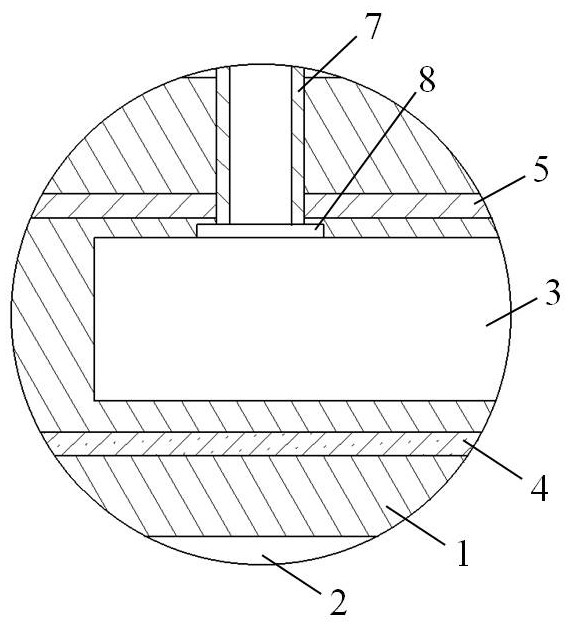

Cylinder external pressure resistance testing device

A test device and performance technology, which is applied in the field of cylinder external pressure resistance performance test device, can solve the problems of test failure, easy expansion, small deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the rubber is nitrile rubber, the elongation at break is 420%, and the Shore A hardness is 55. The thickness of the wall of the main body 1 is 5 times of the thickness of the wall between the inner cavity 3 and the test cavity 2 . The outer lining 4 is a mixed combination of metal mesh and synthetic fiber mesh.

[0042] During the external pressure resistance test of the cylinder, the cylindrical test piece is placed in the test chamber, the outer diameter of the test piece is 40mm smaller than the inner diameter of the test chamber, and the liquid loading medium is injected into the inner cavity through the liquid inlet. The liquid port overflows, and at the same time, the air bubbles in the inner cavity are discharged to ensure that the inner cavity is filled with a uniform medium. Seal the liquid outlet, and continue to inject the liquid loading medium from the liquid inlet until the inner wall of the body expands inwards and squeezes the outer w...

Embodiment 2

[0044] In this embodiment, the rubber is natural rubber, the elongation at break is 500%, and the Shore A hardness is 70. The thickness of the wall of the body 1 is 20 times the thickness of the wall between the inner chamber 3 and the test chamber 2 . The outer lining 4 is a mixed combination of metal shell and synthetic fiber cloth. The inner lining 5 is a synthetic fiber cloth.

[0045] During the external pressure resistance test of the cylinder, the cylindrical test piece is placed in the test chamber, the outer diameter of the test piece is 10mm smaller than the inner diameter, and the liquid loading medium is injected into the inner cavity through the liquid inlet. Overflow, and at the same time discharge the air bubbles in the inner cavity to ensure that the inner cavity is filled with a uniform medium. Seal the liquid outlet, and continue to inject the liquid loading medium from the liquid inlet until the inner wall expands inwards and squeezes the outer wall of a c...

Embodiment 3

[0047] In this embodiment, the rubber is a combination of nitrile rubber and ethylene-propylene rubber, the elongation at break is 450%, and the Shore A hardness is 60. The thickness of the wall of the main body 1 is 10 times of the thickness of the wall between the inner chamber 3 and the test chamber 2 . The outer lining 4 is a mixed combination of metal shell and synthetic fiber cloth. The inner lining 5 is a synthetic fiber cloth.

[0048] When testing the external pressure resistance of the cylinder, place the cylindrical test piece in the test chamber of the rubber bag, the outer diameter of the test piece is 10mm smaller than the inner diameter of the rubber bag, and inject the liquid loading medium into the inner cavity through the liquid inlet. It overflows from the liquid outlet, and at the same time discharges the air bubbles in the inner cavity to ensure that the inner cavity is filled with a uniform medium. Seal the liquid outlet, and continue to inject the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com