Phase redundancy fault-tolerant control system and method for electronic fuel injection system of diesel engine

A system phase, redundant and fault-tolerant technology, applied in electrical control, engine control, electrical automatic control, etc., can solve the problem of low reliability of single-group diesel engine speed signals, underutilized sensor resources, and ECU reliability needs to be enhanced, etc. problems, to achieve the effect of improving maintainability and security, improving reliability, and strong fault isolation capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

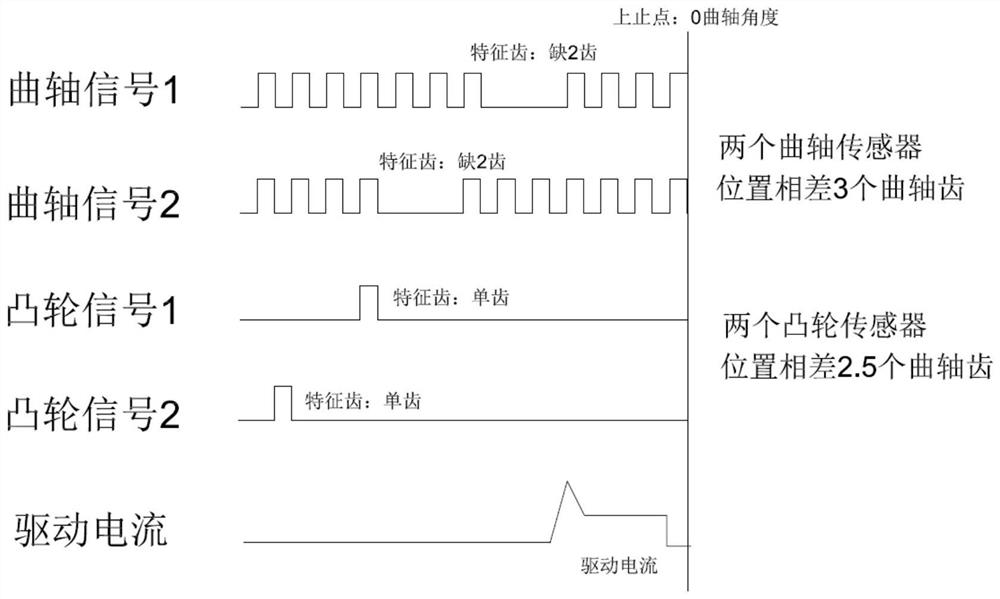

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific examples. In this embodiment, two channels of crankshaft Hall speed sensor signals and two channels of cam Hall speed sensor signals are used as examples for illustration, and the case of multiple speed signals is analogized. figure 1 Shown is the block diagram of the phase redundant fault-tolerant control system of the diesel engine EFI system of the present invention, including, 2-way crankshaft Hall speed sensor signal processing module, 2-way cam Hall speed sensor signal processing module, redundant power supply module, injection / ignition The drive module, the microcontroller system module, the crankshaft Hall speed signal processing module and the cam Hall speed signal processing module are respectively connected to the crankshaft signal gear plate and the cam signal gear plate through the sensor, and the crankshaft signal gear plate and the cam signal ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com