Shield construction system and shield construction method

A shield and component technology, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of not being able to perform at the same time and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

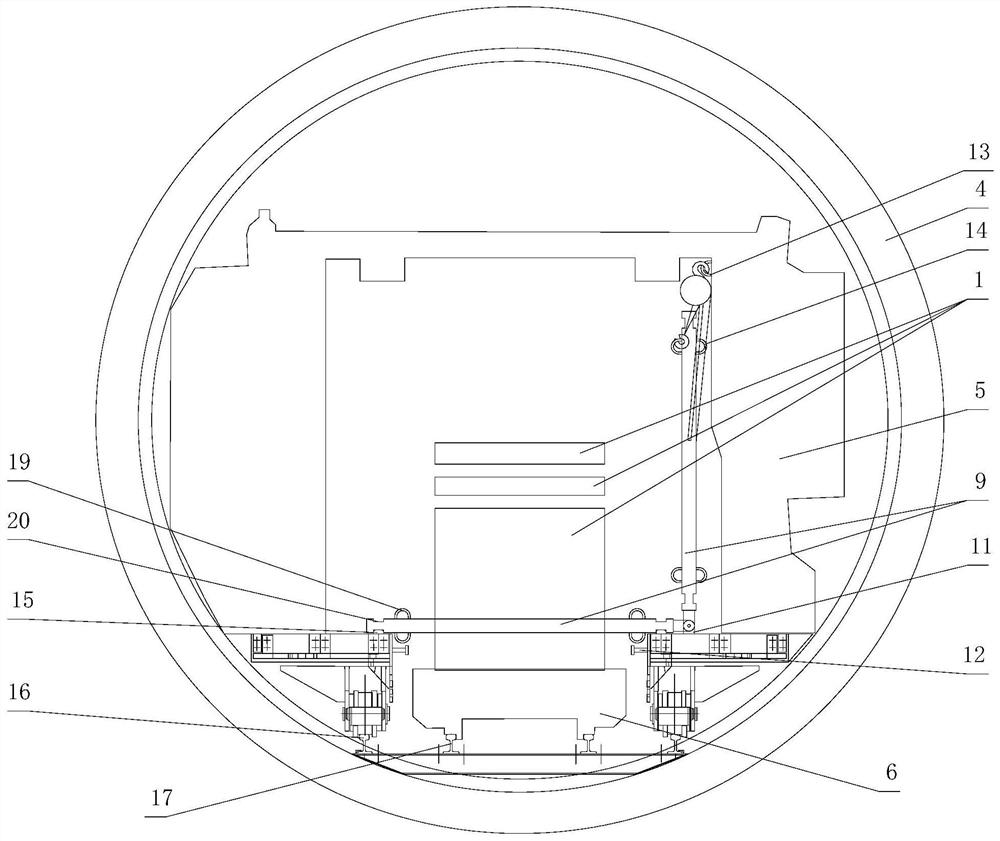

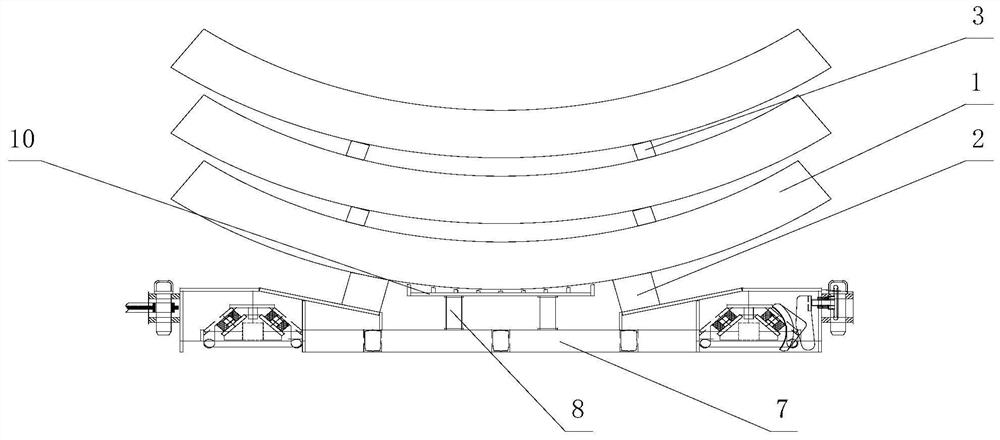

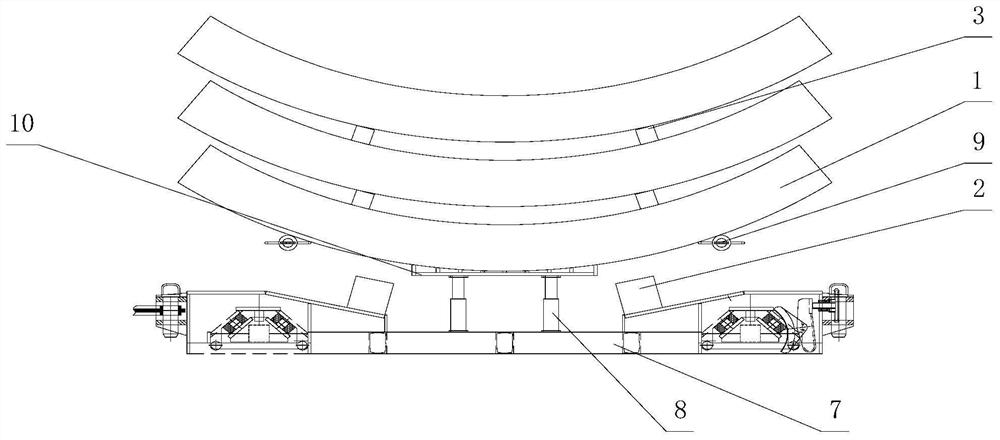

[0033] Such as Figure 1-Figure 5 As shown, a shield construction system is provided in this embodiment, including a trolley 5 and a tunnel battery car 6. Two trolley tracks 16 and a tunnel battery car track 17 are installed in the tunnel 4, and the tunnel battery car track 17 is located on two platforms. Between the trolley tracks 16, the trolley 5 is arranged on two trolley tracks 16, and the tunnel battery car 6 is arranged on the tunnel battery car track 16. The front part of the trolley 5 is open, and the front side of the bottom wall of the trolley 5 has an opening. Including the first square wood unit, the first component unit and the top support unit, the first square wood unit is arranged on the flat plate 7 of the tunnel battery car 6, the first square wood unit includes two first square wood 2, two first square wood units A square of wood 2 is distributed along the front and back directions and can support the segment group. The supporting unit is arranged on the fl...

Embodiment 2

[0052] This embodiment is further limited on the basis of Embodiment 1. In this embodiment, the segment group includes two or more segments 1, and the two or more segments 1 are distributed longitudinally. The adjacent two segments Slice 1, two second square timbers 3 are placed on the lower segment 1, and the two second square timbers 3 support the upper segment 1. Specifically, the number of segment 1 contained in the segment group is set according to the actual situation. For example, for a shield machine with an outer diameter of 6.28m, the outer diameter of segment 1 is 6m, the inner diameter is 5.4m, and the width is 1.2m. During use, on the tunnel battery car 6, a flat plate 7, a first square wooden unit, a first component unit, a supporting unit and a segment group are two, the flat plate 7, the first square wooden unit, the first component unit, the top The support unit corresponds to the segment group one by one, and each segment group contains three segments 1. In t...

Embodiment 3

[0054] This embodiment is further limited on the basis of Embodiment 1. A shield construction method is provided in this embodiment, using a shield construction system, including the following steps:

[0055] A. Place the segment group on the first square wooden unit;

[0056] B. Use the tunnel battery car 6 to transport the segment group from the tunnel entrance to the trolley 5;

[0057] C. Start the supporting unit to lift up the segment group so that the segment group is separated from the first square wood 2;

[0058] D. Use the first member unit to support the segment group;

[0059] E. The top supporting unit descends, and the tunnel battery car moves from below the trolley 5 to the excavation opening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com