Method for removing antimony through electrolytic reduction of electrodeposited copper modified carbon fiber felt electrode

A carbon fiber felt and electrodeposition technology, which is applied in the field of electrolytic reduction and antimony removal of electrodeposited copper-modified carbon fiber felt electrodes, and can solve the problems of insufficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

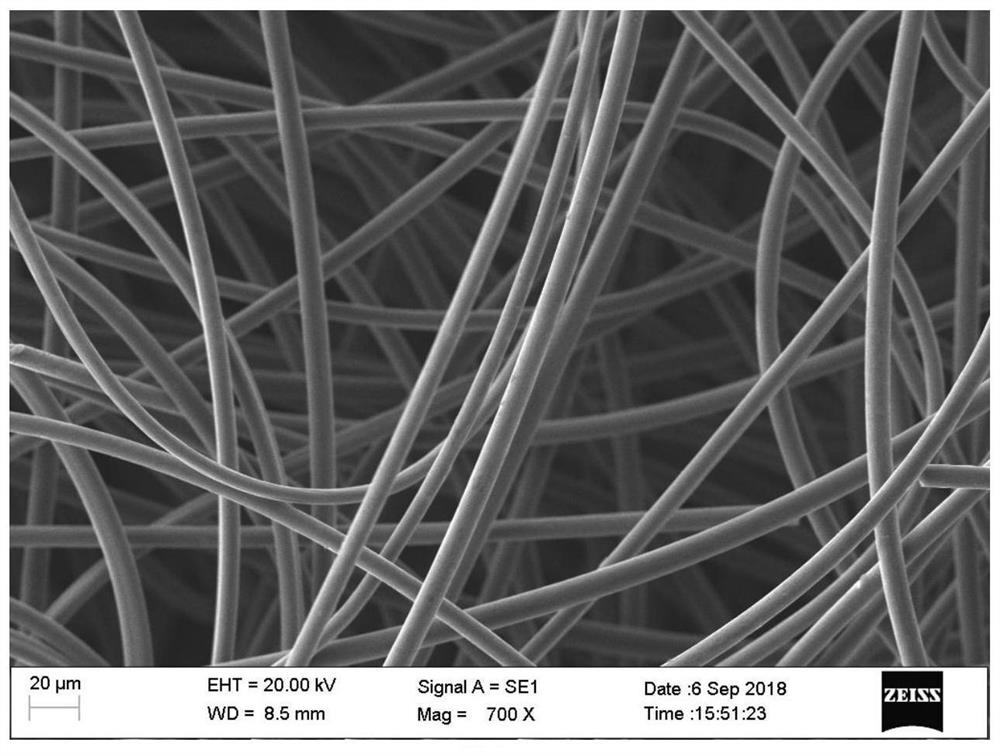

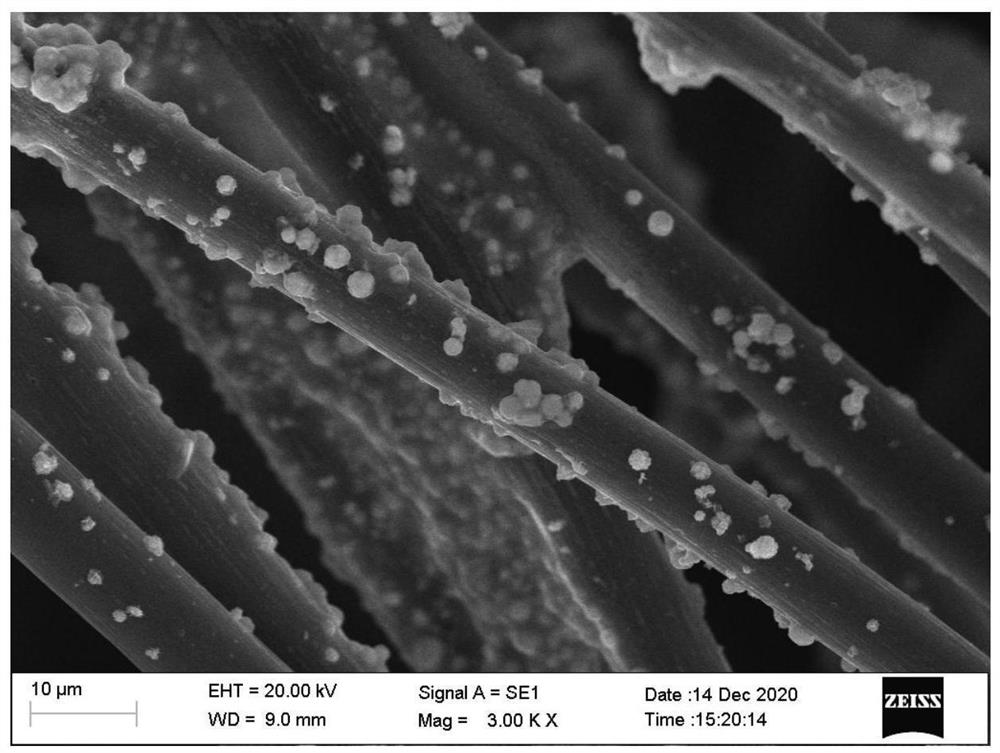

[0041] Preparation of Copper Modified Carbon Fiber Felt Electrode

[0042] 1.1 Instrument

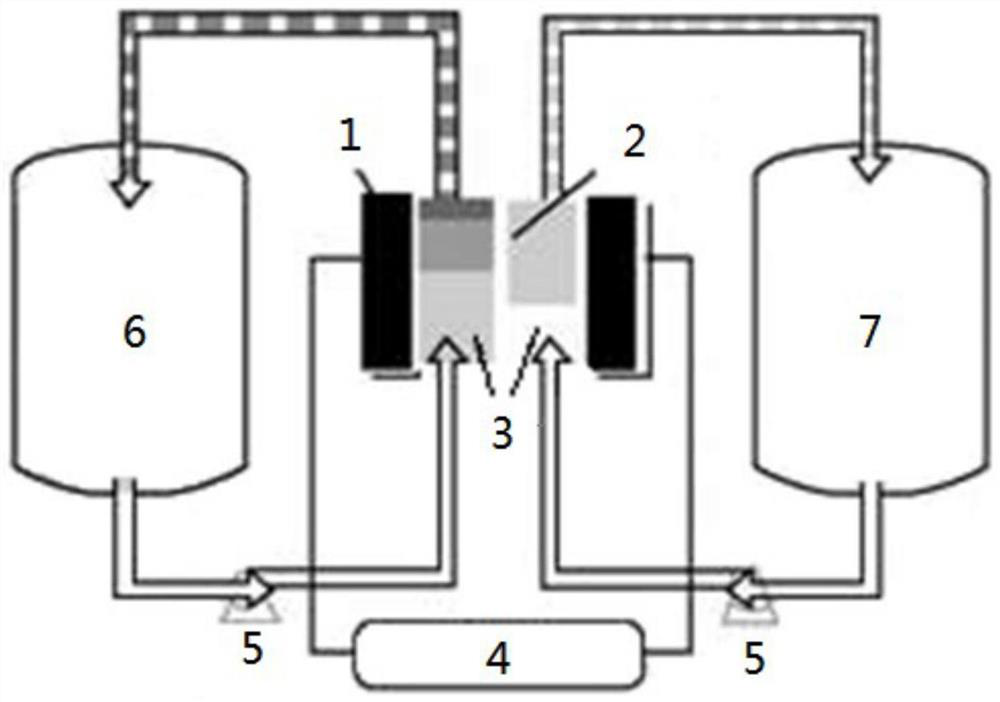

[0043] The electrolytic cell consists of figure 1 Shown: flow battery, the effective cross-section of the battery electrode is 48cm 2 Anode: iridium-plated titanium plate electrode; cathode: graphite plate is used as current collector 1, carbon fiber felt 2 is used as electrode; ion semi-permeable membrane 3.

[0044] DC power supply 4: PCS charge and discharge instrument

[0045] Water pump: magnetic circulation pump 5

[0046] 1.2 Electrolyte

[0047] Anolyte 6: ferrous ion solution, prepared by dissolving 10g iron filings in 500mL sulfuric acid solution (1+1), let stand for 10min, and take 100mL supernatant;

[0048] Catholyte 7: 12g / L copper sulfate solution, 100mL.

[0049] 1.3 Electrodeposition process

[0050]Turn on the cathode magnetic circulation pump and pump the cathode solution into the battery for circulation. After 20 minutes, stop the circulation of the negative e...

Embodiment 2

[0052] Antimony Removal by Electrochemical Reduction Using Copper Modified Carbon Fiber Felt Electrode—(1) Antimony Removal from Wastewater

[0053] 2.1 Pretreatment of antimony-containing aqueous solution

[0054] Pipette 200mL of antimony-containing aqueous solution, antimony content: 2.88mg / L. Add appropriate amount of solid sodium hydroxide to adjust the pH of the solution to 11. After heating to make the temperature of the solution reach 95°C, 0.4 g of solid sodium sulfide was added, and the reaction was stirred for 1 h.

[0055] 2.2 Electrolytic antimony removal using copper-modified carbon fiber felt electrodes:

[0056] Cathode electrode: the copper-modified carbon fiber felt electrode prepared in Example 1.

[0057] Anode electrode: iridium plated titanium plate.

[0058] Catholyte: Antimony-containing aqueous solution treated in step 2.1.

[0059] Anolyte: 1.0mol / L NaOH solution.

[0060] Power supply: PCS charge and discharge instrument.

[0061] Electrolytic...

Embodiment 3

[0066] Antimony Removal by Electrochemical Reduction Using Copper Modified Carbon Fiber Felt Electrode—(2) Antimony Removal by Hydrometallurgical Vanadium Extraction and Leach Solution

[0067] 3.1 Pretreatment of antimony vanadium leaching solution

[0068] Pipette 200mL vanadium leaching solution solution, antimony content: 3.18mg / L. Add appropriate amount of solid sodium hydroxide to adjust the pH of the solution to 12. After heating to make the temperature of the solution reach 91°C, 0.5 g of solid sodium sulfide was added, and the reaction was stirred for 1 h.

[0069] 3.2 Electrolytic antimony removal using copper-modified carbon fiber felt electrodes:

[0070] Cathode electrode: the copper-modified carbon fiber felt electrode prepared in Example 1.

[0071] Anode electrode: iridium plated titanium plate.

[0072] Catholyte: the antimony-containing aqueous solution disposed of in step 3.1.

[0073] Anolyte: 1.0mol / L NaOH solution.

[0074] Power supply: PCS charge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com