A kind of heavy metal polluted soil remediation agent and its preparation method and application

A technology for remediating chemicals and polluted soil, applied in the field of environmental materials, can solve the problems of difficult preparation of phosphate-loaded biochar, cumbersome preparation process of activated steel slag powder, cumbersome preparation process of adsorbent, etc., so as to improve the curing and repairing effect and increase the curing effect. Effects, Effects of Omitting Processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

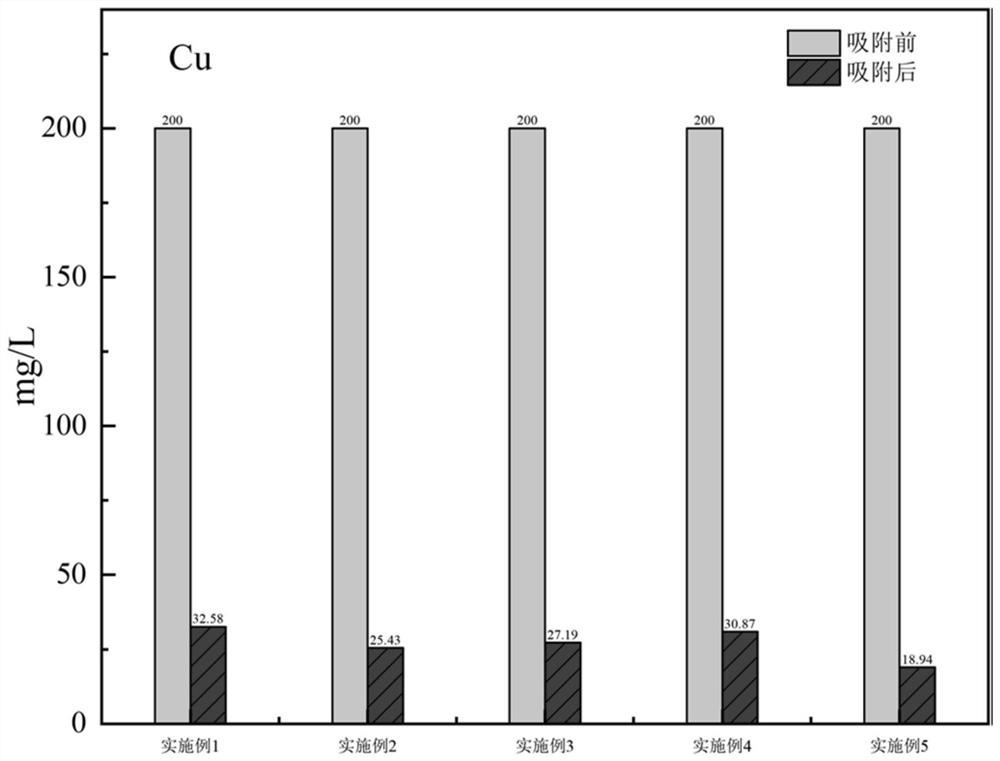

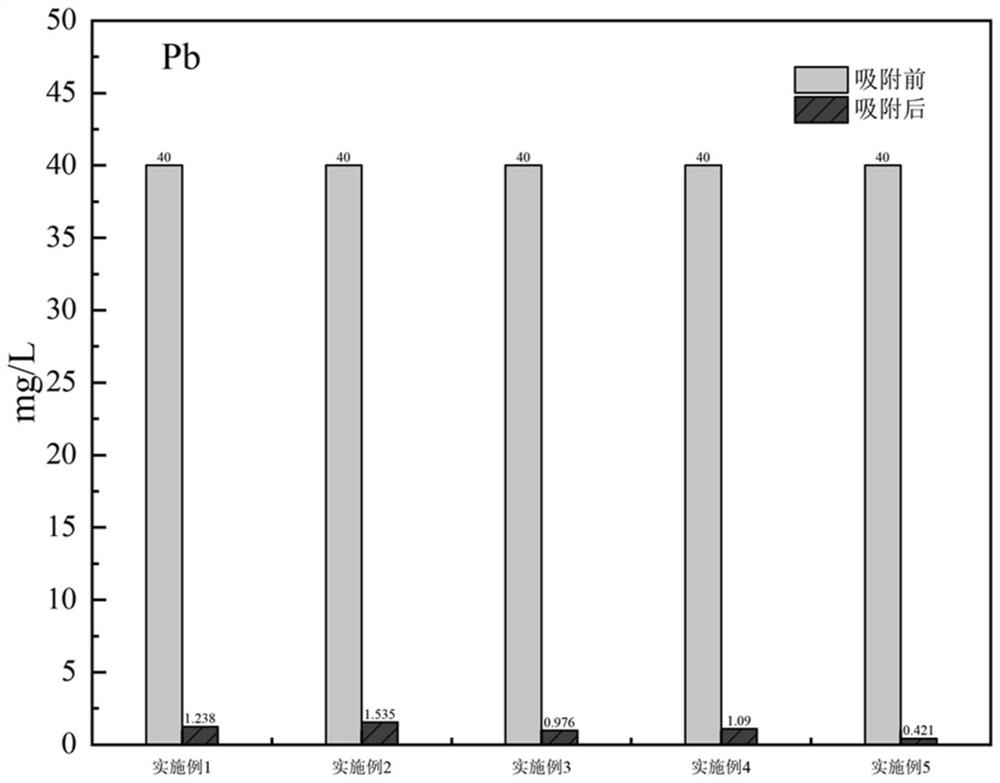

Examples

Embodiment 1

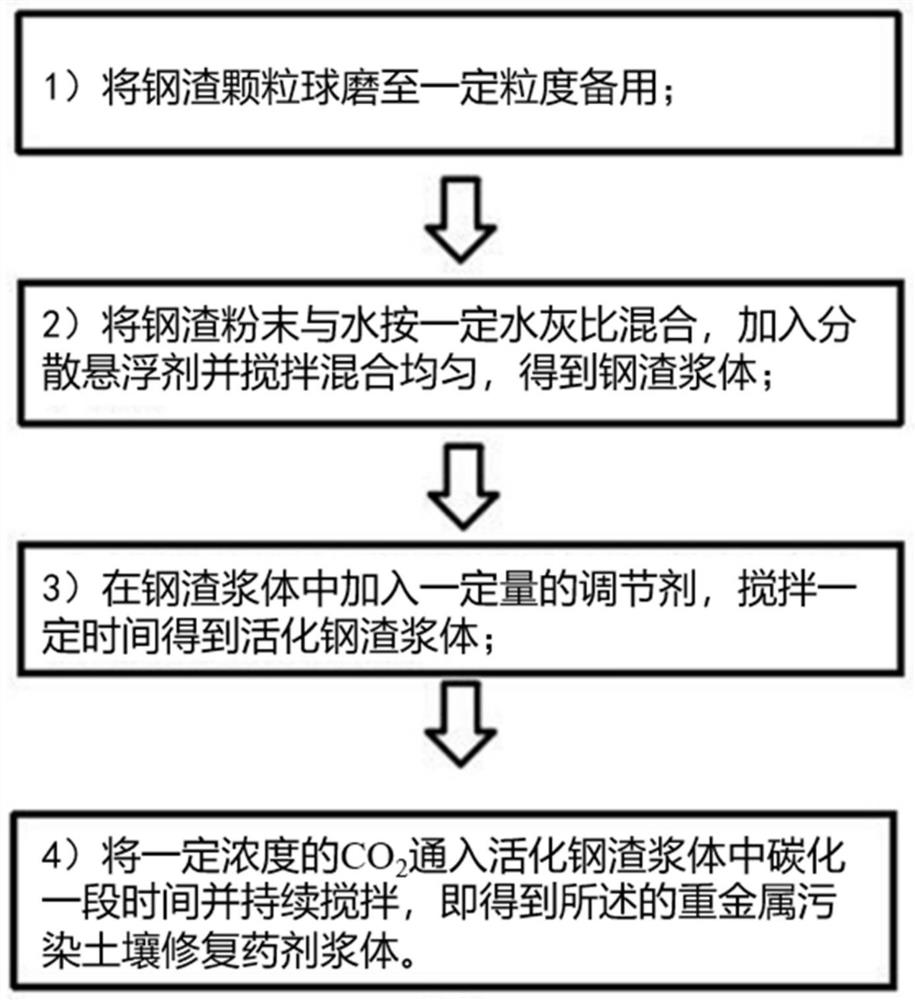

[0022] A preparation method of a repair agent for heavy metal polluted soil:

[0023] Pretreatment of steel slag: grind the steel slag particles with a small cement experimental mill to control the specific surface area at 200-250m 2 / kg;

[0024] Steel slag slurry preparation: by weight, take 80 parts of steel slag powder and distilled water according to the water-cement ratio of 3, add 5 parts of dispersing suspending agent (3 parts of oleic acid amide, 2 parts of monoglyceride), use a constant speed electric mixer Stir for 30 minutes at a rotational speed of 240 r / min; add 15 parts of regulator (potassium dihydrogen phosphate) and stir for 120 minutes at a rotational speed of 240 r / min to obtain steel slag slurry.

[0025] Carbonization treatment: CO with a concentration of 99% 2 Pour into the prepared steel slag slurry, and at the same time use a constant-speed electric stirrer to stir at a speed of 240r / min, and the operation lasts for 60 minutes to obtain the heavy met...

Embodiment 2

[0027] A preparation method of a repair agent for heavy metal polluted soil:

[0028] Pretreatment of steel slag: grind the steel slag particles with a small cement experimental mill to control the specific surface area at 400-450m 2 / kg;

[0029] Preparation of steel slag slurry: in parts by weight, take 90 parts of steel slag powder and distilled water and mix them with a water-cement ratio of 3, add 5 parts of dispersing suspending agent (3 parts of oleic acid amide, 2 parts of monoglyceride), and use a constant speed electric mixer Stir for 30 minutes at a speed of 240 r / min; then add 5 parts of regulator (potassium dihydrogen phosphate), and stir for 120 minutes at a speed of 240 r / min to obtain a steel slag slurry.

[0030] Carbonization treatment: CO with a concentration of 99% 2 Pour into the prepared steel slag slurry, and at the same time use a constant-speed electric stirrer to stir at a speed of 240r / min, and the operation lasts for 60 minutes to obtain the heavy...

Embodiment 3

[0032] A preparation method of a repair agent for heavy metal polluted soil:

[0033] Pretreatment of steel slag: grind the steel slag particles with a small cement experimental mill to control the specific surface area at 400-450m 2 / kg;

[0034] Steel slag slurry preparation: by weight, take 80 parts of steel slag powder and distilled water according to the water-cement ratio of 3, add 5 parts of dispersing suspending agent (3 parts of oleic acid amide, 2 parts of monoglyceride), use a constant speed electric mixer Stir for 30 minutes at a rotational speed of 240 r / min; add 15 parts of regulator (potassium dihydrogen phosphate) and stir for 120 minutes at a rotational speed of 240 r / min to obtain steel slag slurry.

[0035] Carbonization treatment: the concentration of 50% CO 2 Pour into the prepared steel slag slurry, and at the same time use a constant-speed electric stirrer to stir at a speed of 240r / min, and the operation lasts for 60 minutes to obtain the heavy metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com