Winding equipment

A kind of equipment and reel technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of difficult product delivery, complex structure, low working efficiency of winding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

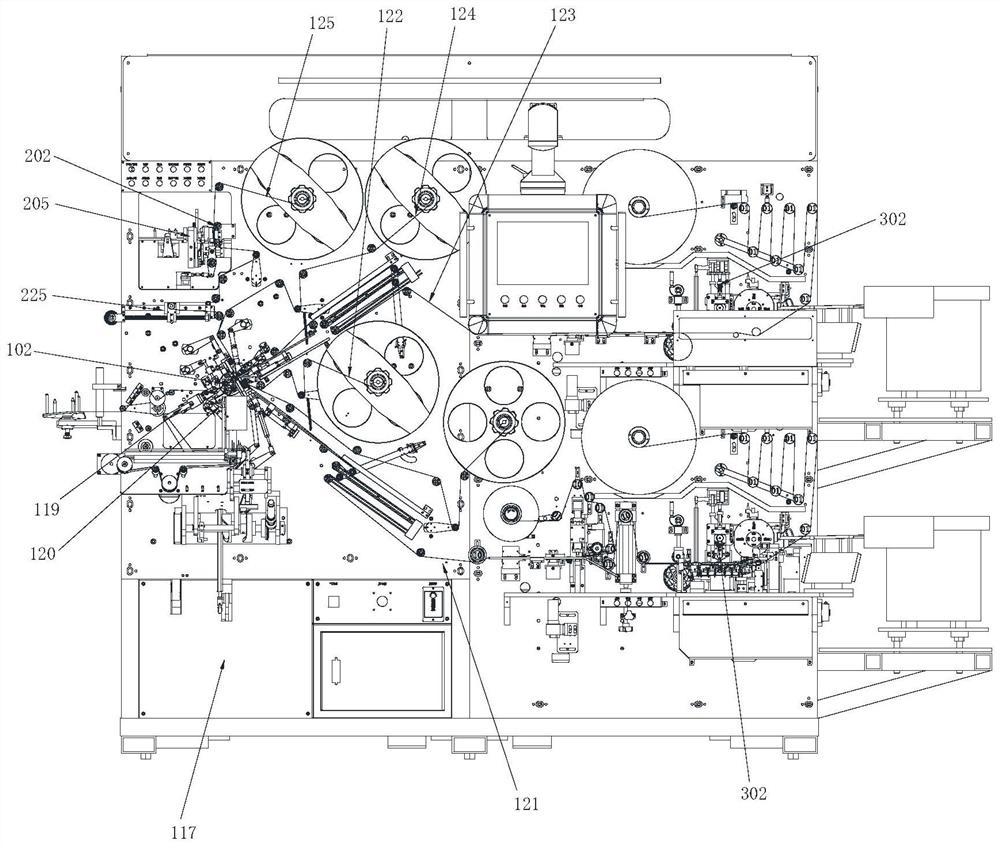

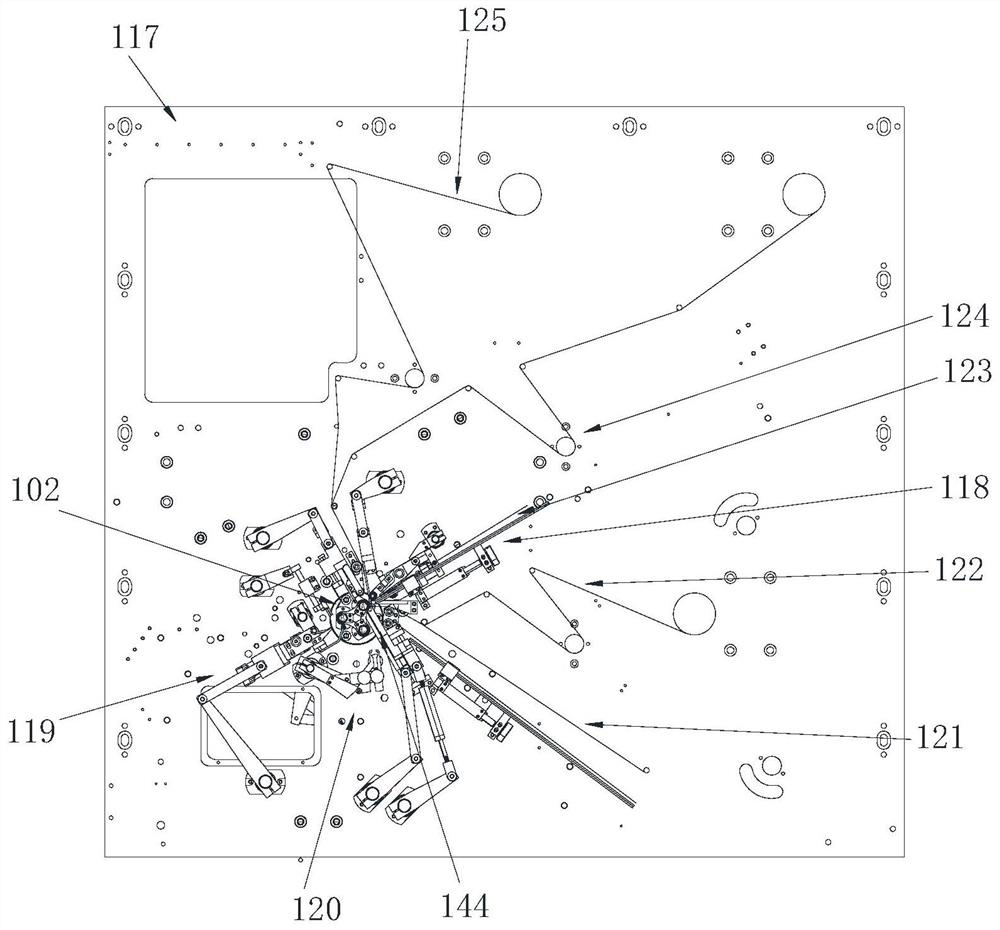

[0052] A winding device such as Figure 1 to Figure 18 As shown, it includes a frame 117 and a winding head installed on the frame 117, and the frame 117 is also equipped with a feeding mechanism 118, a material cutting mechanism 144, a gluing mechanism 119 and a discharging mechanism 120. The feeding mechanism 118, the material cutting mechanism 144, the gluing mechanism 119 and the discharging mechanism 120 are arranged around the outer periphery of the winding head; Component 121, the first paper tape feeding assembly 122, the positive electrode aluminum foil feeding assembly 123, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com